Mobile Crusher

Applied Materials:nConstruction waste, river pebbles, quartz sand, granite, basalt, iron ore, limestone, quartz stone, etc.- Feed Size:≤800mm

- Capacity: 85-650TPH

Introducing the Mobile Crusher

Mobile crushers can be classified into two main types

The Classification of Mobile Crusher

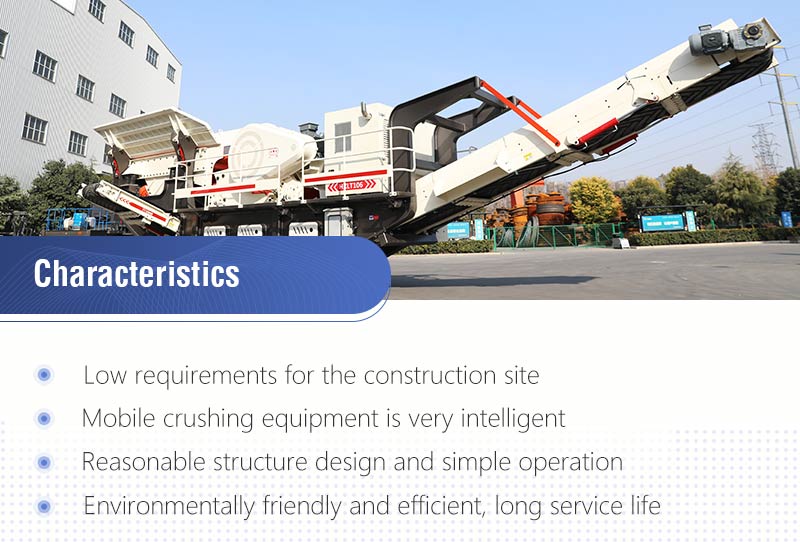

Performance Characteristics of Mobile Crusher

Customer Case

The Manufacturer of Mobile Crusher

General Specification

| Model | ZDM938F1210 | ZDM938FW1214 | ZDM1149F1315 | ZDM1349HD1110 | ZDM1349HD1315 |

| Transportation Length(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Transportation Width(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Transportation Height(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Maximum Length(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 | 62 | 62 |

| Crusher Model | PF-1210 | PF-1214 | PF-1315 | HD1110 | HD1315 |

| The Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

| Production Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3.2M | B500×3.2M | B650×4M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 320 | 320 | 400 | 320 | 440 |

| Iron Separator (Optional)(kw) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

Mobile Jaw Crusher Technical Parameters

| Model | ZDM938HD80 | ZDM1149HD98 | ZDM1349HD110 | ZDM1349HD125 |

| Transportation Length(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Length(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dual-axial | Dual-axial | Dual-axial | Dual-axial |

| Jaw Crusher | HD80 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge Opening Size(mm) | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Model | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5M | B1000×9.5M | B1000×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3M | B650×3.5M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 200 | 250 | 270 | 400 |

| Iron Separator (Optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

Related Products

Tracked Cone Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

Mobile Crushing and Screening Plant

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

Tracked Impact Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

Tracked Jaw Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message Applications of Tracked Jaw Crusher Performance Advantages of Tracked Jaw Crusher: …

Tracked Mobile Screening Plant

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

Mobile Cone Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

Mobile Impact Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

Mobile Jaw Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine