Search the whole station Crushing Equipment

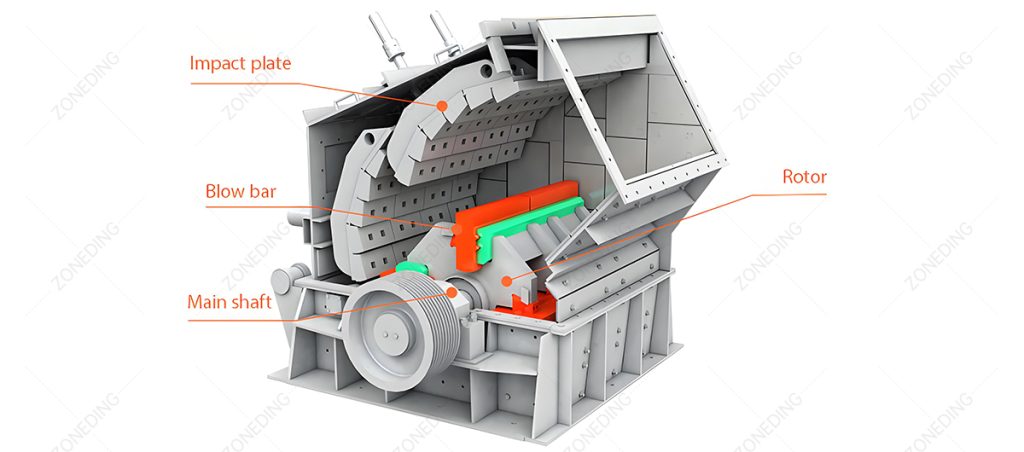

A mobile impact crusher uses a high-speed spinning rotor with “blow bars” (hammers) to strike feed material, breaking it along natural fissure lines. This differs significantly from mobile jaw crushers (compression between plates) and mobile cone crushers (compression within a cavity).

The core difference lies in how the rock is broken. Mobile impact crushers, often called Mobile Horizontal Shaft Impactors (HSIs), work on the principle of rapid impact and collision.

Understanding this difference in mechanism is key to selecting the right mobile crusher for your material and product requirements.

The mobility of an impact crusher offers major advantages in quick setup, easy movement between sites or work areas, and avoiding costly foundation work. This convenience is especially valuable for contractors, recycling operations, and quarries with changing work faces.

Just like mobile jaw crushers, the “mobile” aspect of impact crushers delivers significant operational flexibility compared to traditional stationary plants. This convenience translates directly into time and cost savings in many scenarios.

While high-volume, permanent operations might still favor large fixed plants for maximum efficiency, the convenience and flexibility offered by mobile impact crushers are undeniable advantages for a vast range of modern aggregate production and recycling tasks. ZONEDING provides both wheeled and tracked options to maximize this convenience depending on your primary mode of operation.

A mobile impact crusher is often the better choice when producing highly cubical aggregates is the primary goal, when processing soft to medium-hard, less abrasive materials (like limestone), or when working with recycling applications (concrete, asphalt).

While versatile, mobile impact crushers truly excel in specific scenarios where their unique characteristics offer distinct advantages over jaw or cone crushers.

However, impact crushers are generally not the first choice for highly abrasive materials (like high-silica gravel or granite) due to high wear part consumption, or for primary crushing of very large, hard rock where a jaw crusher excels.

Mobile impact crushers are widely considered “experts” for processing limestone and recycling construction & demolition (C&D) waste and Reclaimed Asphalt Pavement (RAP). Their crushing action is ideal for these materials, producing valuable, well-shaped end products.

Mobile impact crushers have carved out a strong niche in these specific applications due to how well their operating principle aligns with the material characteristics and desired outcomes.

While expert machines for these tasks, success, especially in recycling, depends on proper feed preparation (removing contaminants like excessive dirt, wood, plastic, and especially large metal pieces) and choosing a robust machine designed for the demands of recycling, like those offered by ZONEDING.

blow bars (hammers) and impact plates are the primary wear parts in an impact crusher, and they wear faster than components in jaw or cone crushers, especially with abrasive materials. The cost and downtime associated with replacing these parts are absolutely critical factors in the purchasing decision and overall operating economics.

The high-speed impact nature of this crusher type means wear parts take a beating. Understanding and managing this wear cost is paramount for anyone considering a mobile impact crusher.

Calculate the estimated wear cost per tonne for different machines in your specific application. At ZONEDING, we aim to provide durable wear parts and designs that facilitate easier maintenance to help manage these crucial costs.

Tracked mobile impact crushers offer superior on-site mobility on rough or soft ground and faster setup. Wheeled versions are typically easier and faster to transport between sites using roads but need more prepared ground for operation.

Similar to mobile jaw crushers, the choice between a tracked or wheeled chassis for your mobile impact crusher depends heavily on your primary operating environment and how often you need to move the machine between different locations.

| Feature | Tracked Mobile Impact Crusher (Example) | Wheeled Mobile Impact Crusher (Example) | Key Considerations |

|---|---|---|---|

| On-Site Mobility | Excellent. Navigates uneven, soft, muddy terrain easily. Can reposition close to work face. | Limited. Needs firm, reasonably level ground. May require towing assistance on site. | If you move often within the quarry/site or work on unprepared ground, tracks are far superior. |

| Site Setup Time | Very Fast. Often features hydraulic self-leveling. Minimal ground prep needed. | Slower. Requires positioning, lowering stabilizing jacks/legs. Needs stable ground. | Tracked units get working faster after arriving or repositioning. |

| Between-Site Transport | Slower/More Complex. Needs a low-bed trailer. May require permits due to size/weight. | Faster/Simpler. Usually towed by a truck tractor. Less likely to need special permits. | If road transport between distant sites is frequent, wheels offer logistical ease and potentially lower cost. |

| Initial Cost | Generally Higher. Complex tracked undercarriage adds cost. | Generally Lower initial purchase price. | Weigh the initial cost against operational flexibility and lifetime transport expenses. |

| Operating Footprint | Can operate effectively in tighter spaces due to zero-turn capability. | Requires more space for maneuvering the tow vehicle and setting up. | Consider the space constraints of your typical work zones. |

| Structural Stress | Tracks can impose less point loading stress on the chassis during operation on uneven ground. | Stabilizing legs concentrate load, requires firm pad. | Robust chassis design is critical fo |

For most quarrying, demolition, and recycling applications where on-site flexibility and handling varied ground conditions are key, tracked mobile impact crushers are usually the preferred choice. For contractors primarily moving between established sites with good road access and prepared operating pads, wheeled units can offer transport advantages. ZONEDING offers both types to ensure the best fit for your operational profile.

| Model | ZDM938F1210 | ZDM938FW1214 | ZDM1149F1315 | ZDM1349HD1110 | ZDM1349HD1315 |

| Transportation Length(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Transportation Width(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Transportation Height(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Maximum Length(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 | 62 | 62 |

| Crusher Model | PF-1210 | PF-1214 | PF-1315 | HD1110 | HD1315 |

| The Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

| Production Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3.2M | B500×3.2M | B650×4M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 320 | 320 | 400 | 320 | 440 |

| Iron Separator (Optional)(kw) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

Q1. What exactly is a mobile crushing station used for? How is it better than a stationary production line?

A1: The biggest advantage of a mobile crushing station is its flexibility and convenience. It doesn’t require foundation work and can be quickly relocated or moved closer to the working face. For you, this means significant savings in civil engineering costs and time, enabling faster production startup. It also reduces the internal material transport distance on site, lowering transportation costs and dust. It’s particularly suitable for projects with tight schedules, scattered sites, or those requiring phased progression.

Q2. Crawler-type vs. tire-type mobile crushing station, which is more suitable for me?

A2: It mainly depends on your mobility needs and site conditions. Crawler-type is like a tank, suitable for moving within mines or rugged construction sites, offering flexible relocation but troublesome for long-distance transport; tire-type is like a trailer, suitable for projects with better road conditions that require frequent long-distance transfers across regions. Simply put, choose crawler for on-site flexibility, choose tire for long-distance transfers.

Q3. Mobile crushing stations have several main machine types (jaw crusher/impact crusher/cone crusher). How should I choose?

A3: Choose based on your material and output requirements. Mobile jaw crushers are suitable for primary crushing, handling large, hard materials; mobile impact crushers are suitable for processing medium-soft materials (like limestone, construction waste) and produce good particle shapes; mobile cone crushers are suitable for medium-fine crushing of hard rocks (like granite, river pebbles). Not sure? Tell us your raw materials and finished product needs, and we’ll help you configure the setup.

Q4. What capacity mobile crushing station do I need? How can I estimate reliably?

A4: The capacity stated by manufacturers is usually the “maximum capacity” under ideal conditions; actual output will be lower. You need to consider: What material needs processing (hardness)? What’s the feed size? How much soil/clay content? How fine does the output need to be? Provide this information to the supplier, and let them use their experience to help you choose a model with sufficient margin. Don’t just rely on paper figures.

Q5: Is maintaining a mobile crushing station troublesome? Is the fuel/power consumption high?

A5: Routine maintenance (lubrication, tightening, cleaning) isn’t complex, but hydraulic and electrical systems require some professional knowledge. Mobile stations have compact structures, so maintenance in some areas might be less convenient than stationary plants. Fuel/power consumption is a major operating cost, highly related to equipment power, load, and power system (diesel/electric/hybrid). Choosing a diesel-electric hybrid might save more money in the long run.

Q6: What if one mobile crushing station isn’t enough? Can they be combined into a production line?

A6:Absolutely! Mobile crushing stations are very suitable for combined use, forming a complete mobile crushing and screening production line. For example, use a mobile jaw crusher for primary coarse crushing, followed by a mobile impact crusher or mobile cone crusher for medium-fine crushing, and then add a mobile screening plant for sizing. This combination can meet complex production needs with extreme flexibility.

Q7: When selecting a mobile crushing station, what key points should I focus on besides price?

A7: Price is important, but definitely not the only criterion! Pay more attention to: 1. Quality of core components (main crusher, engine/motor, hydraulic system); 2. Match between actual output and working conditions; 3. Durability of structural parts (chassis, frame); 4. Cost-effectiveness and supply of wear parts; 5. Ease and safety of operation and maintenance; 6. Manufacturer’s after-sales service and technical support capabilities.

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy