Search the whole station Crushing Equipment

Cone crusher is usually used as secondary or tertiary crushing stage. It is characterized by robust structure, excellent productivity and simple operation.

Cone crusher is ideal for crushing different stone and rock in quarry, mining, road construction, etc. It can also provide aggregate for concrete batching plant. Zoneding mainly provides the following four types of cone crushers to meet your different needs in aggregate size.

A cone crusher is a type of compression crusher used to break rock by squeezing it between a moving and a stationary piece of steel. The moving piece is an inverted cone, called the mantle, which gyrates inside a fixed, cone-shaped bowl, called the concave or bowl liner. As rock falls into the chamber, it is repeatedly squeezed and broken into smaller and smaller pieces until it is small enough to fall out the bottom. It is a powerful and efficient machine for producing fine to medium-sized aggregate.

You will find cone crushers working hard in the middle and final stages of a crushing and screening plant. Their primary job is not to handle massive, quarry-run boulders. Instead, they take the smaller rock that has already been broken down by a primary crusher, like a jaw crusher. Their main purpose is to reduce this material further, down to sizes like 10mm, 20mm, or 40mm gravel, and to create a superior, cubical shape. This cubical shape is very important for making strong concrete and asphalt.

A cone crusher is the key to quality and efficiency. A primary jaw crusher gives you size reduction, but the product can be flaky and inconsistent. The cone crusher refines this material. It’s the perfect machine to prepare feed for a VSI (Vertical Shaft Impactor) if you are making sand. A cone crusher can take 40-100mm material and turn it into a consistent 5-20mm product. This high-quality feed allows the VSI to work at its best, focusing on shaping rather than just breaking. A plant with a well-run cone crusher will produce a superior product and dominate the market.

Cone crushers have evolved over the years, but they mainly fall into a few categories.

At ZONEDING, we focus on these modern hydraulic systems for their superior performance and ease of use.

You will find cone crushers in any industry that needs to produce high-quality, consistently sized aggregate.

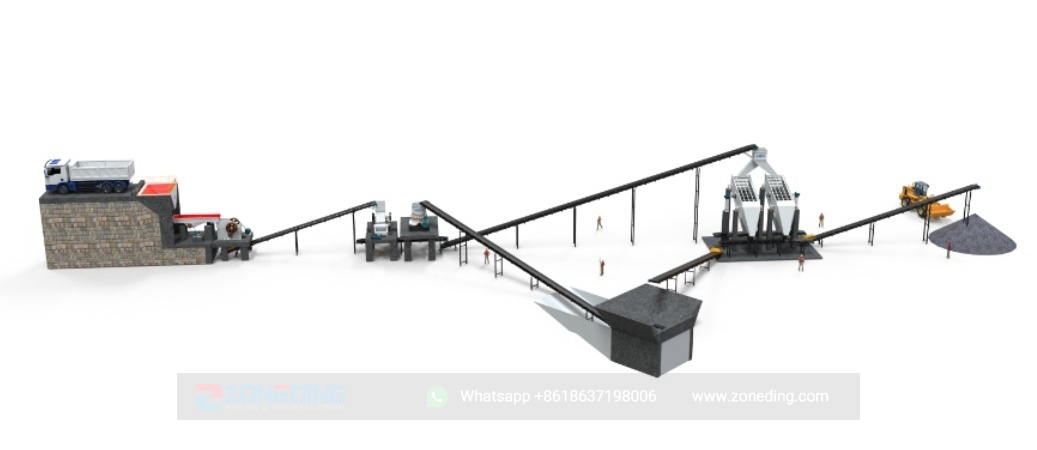

Zoneding provides comprehensive cone crushing and screening solutions. Whether you are establishing a new venture and require plant construction, or aiming to enhance your existing crushing plant, Zoneding can cater to all your requirements. Dig deeper into various crushing solutions by exploring the subsequent sections.

Capacity:100-450TPH

Output Size:5-38mm

Configuration: wheel-mounted chassis, vibrating feeder, cone crusher, vibrating screen, etc.

Features: strong mobility, low transportation costs.

Advantages: High capacity; Various output size.

Capacity:100-450TPH

Output Size:5-38mm

Configuration: wheel-mounted chassis, vibrating feeder, cone crusher, vibrating screen, etc.

Features: strong mobility, low transportation costs.

Advantages: High capacity; Various output size.

Capacity:100-450TPH

Output Size:5-38mm

Configuration: wheel-mounted chassis, vibrating feeder, cone crusher, vibrating screen, etc.

Features: strong mobility, low transportation costs.

Advantages: High capacity; Various output size.

A cone crusher is built for toughness. It excels at crushing medium-hard to extremely hard and abrasive materials. If a rock is tough, a cone crusher is usually the right choice for the secondary and tertiary stages.

The cone crusher working principle is based on gyration. The main shaft, which holds the mantle, does not spin; it gyrates. This means it moves in a circular, oscillating path. This motion continuously changes the gap between the mantle and the stationary bowl liner. Rock enters at the top, gets squeezed and broken, falls lower, and gets squeezed again in the narrower gap. This happens multiple times as it travels down through the chamber. The key to efficient operation is “choke feeding.” This means you must keep the crushing chamber completely full of rock. This forces the rocks to crush against each other, not just against the steel liners. This is more efficient, creates a better product shape, and protects the liners from damage. A happy cone is a full cone.

A cone crusher is a complex machine with many precision parts working together. The main components include:

At ZONEDING, we build our cone crushers to be productive and reliable. We understand you need a machine that runs all day, every day. Our features focus on performance and low operating costs.

The main wear parts of a cone crusher are the mantle and bowl liner (concave). These are made from high-manganese steel and are designed to be replaced. These parts are not generic. They come in different profiles like Fine, Medium, and Coarse. You must match the liner profile to the size of the rock you are feeding it. Using the wrong liner is the most common mistake we see. It leads to poor performance, low production, and high energy use. When you replace these liners, you use a special epoxy called “backing compound.” This is not glue. Its job is to absorb and distribute the crushing forces. Never skimp on the backing compound; it protects the entire machine.

People often ask about the difference between a Jaw Crusher and a Cone Crusher. They are both compression crushers, but they have very different jobs.

| Feature | Jaw Crusher | Cone Crusher |

|---|---|---|

| Crushing Stage | Primary Stage | Secondary, Tertiary, or Quaternary Stage |

| Feed Size | Large (up to 1.5 meters) | Medium to small (typically under 250mm) |

| Crushing Action | Squeezing between two plates (one fixed, one moving) | Grinding and squeezing via gyration |

| Product Shape | Can be somewhat flaky or elongated | Typically very cubical and well-shaped |

| Main Use | Initial breaking of large quarry rock | Refining and producing final product sizes |

You control the output size by adjusting the Closed Side Setting (CSS). The CSS is the narrowest gap between the mantle and the bowl liner at the bottom of the crushing chamber. On a modern hydraulic cone crusher, you can change this setting from the control panel in just a few minutes. However, a cone crusher is not a truly variable machine. It has a “sweet spot” where it runs most efficiently. Trying to make big changes to your product size just by changing the CSS is a bad idea. A cone crusher is like a rifle, not a shotgun. It is designed to do one job very well.

The price of a cone crusher can vary widely based on several factors. A smaller, older-style spring cone crusher might cost around $50,000. A large, modern, high-capacity hydraulic cone crusher from a premium brand can cost over $500,000.The main factors influencing the price are:

At ZONEDING, as a direct manufacturer, we offer a significant price advantage for high-quality, modern hydraulic cone crushers.

Choosing the right cone crusher is a critical decision. Here is a simple checklist to guide you:

Daily maintenance is the key to long life and reliable performance. Your lubrication oil is like a blood report for the machine’s health.

When you buy a cone crusher from ZONEDING, our relationship is just beginning. We provide comprehensive after-sales service to ensure your investment is profitable for years to come.

What is the main difference between a standard and short head cone crusher?

The main difference is the shape of the crushing chamber. A standard head cone crusher has a steeper chamber and a larger feed opening, making it suitable for secondary crushing. A short head cone has a flatter, wider chamber, designed for tertiary or quaternary crushing to produce finer products.

How often do I need to replace the mantle and bowl liner?

This depends entirely on how abrasive your rock is and your operating hours. For very hard, abrasive rock like granite, you might get 400-600 hours. For softer limestone, you could get over 1500 hours. Regular inspection is key.

Can a cone crusher make sand?

While a cone crusher can produce some fine material, it is not a dedicated sand-making machine. It is designed to make cubical aggregates. For high-quality manufactured sand, a VSI (Vertical Shaft Impact) crusher is a much better and more efficient choice.

Reliable Jaw Crushers for efficient primary crushing in mining, quarrying & aggregate production. Heavy-duty design, high throughput.

High-efficiency VSI sand making machines for producing premium artificial sand from rock & gravel. Excellent particle shape, low wear cost.

PF Series Impact Crusher for secondary crushing of limestone, rock, and efficient recycling of concrete & asphalt. High throughput, excellent shape. Get Specs!

Looking for a high-performance Vibrating Feeder? Explore our durable industrial feeding machines for mining & aggregate plants.

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy