Search the whole station Crushing Equipment

The vibrating feeder (vibratory feeder) is suitable for bulk and granular materials such as limestone, calcite, dolomite, barite, talc, gypsum. And also quartz stone, river pebble, granite, basalt, construction waste, iron ore, coal, slag, etc.

The vibrating feeder can evenly feed materials for the crushing equipment in the sand production line, and screen materials roughly. And also it can serve materials for belt conveyors, bucket elevator, screening equipment, crushing equipment and grinding machines.

A Vibrating Feeder, sometimes called a vibratory feeder, is industrial equipment to convey bulk materials over a short distance at a controlling rate. Think of it as a short, sturdy vibration conveyor with a motor that makes it shake. This controlled shaking action moves the material forward. This machine is a critical part of any feeder system, taking a large pile of material from a vibrating hopper and turning it into a consistent, predictable stream that other machines, like crushers, can handle efficiently.

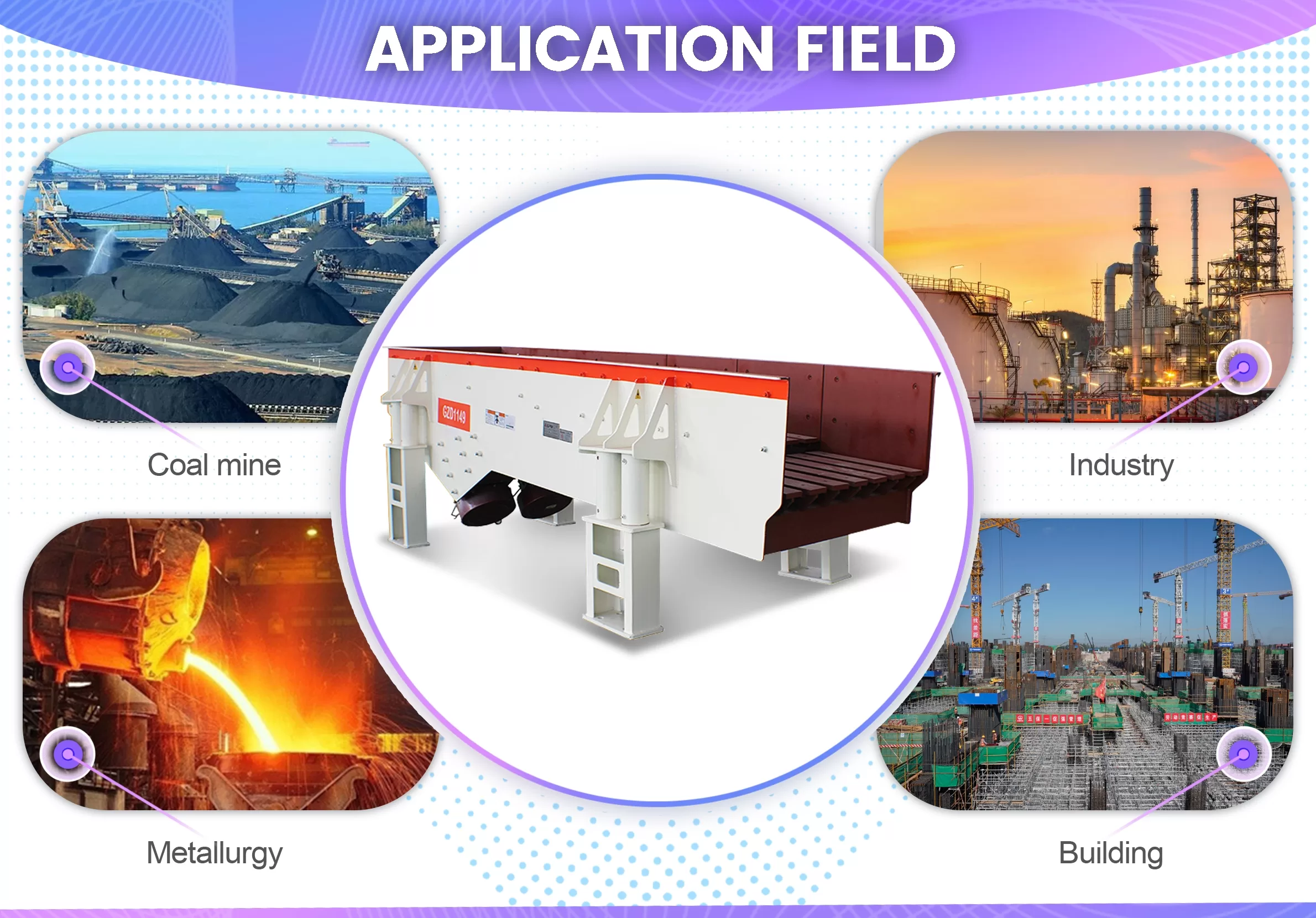

Mining vibrating feeder has a very wide range of use. This equipment applys in mining, metallurgy, coal, building materials, chemical industry, electric power and other industries. The following is the specific scope of use:

The working principle of the vibrating feeder is mainly to use the eccentric block in the vibrator to rotate to produce centrifugal force, so that the movable parts of the screen compartment and vibrator make a forced and continuous circular or nearly circular motion. This movement is transmitted to the conveying trough connected to the vibrating motor, so that the material is subjected to vibration force in the trough, thus generating sliding and dislodging, and realizing the uniform and continuous conveying of materials.

The machine consists of a trough or pan, which holds the material, mounted on flexible springs. A vibrator unit, which is either an electric motor with eccentric weights or an electromagnetic feeder drive, is attached to the pan. When you turn it on, it creates powerful, rapid vibrations. This motion moves the pan in a quick, repeated forward-and-up, backward-and-down cycle. Each tiny “throw” lifts the material and moves it forward, creating a smooth, continuous flow.

In addition, the mining vibrating feeder can also be adjusted by adjusting the phase and weight of the eccentric block to change the size and direction of the excitation force, so as to adapt to the changes in different materials and process requirements. This kind of adjustment is flexible and convenient, and can realize precise feeding control.

Using a vibration feeder provides several major benefits for your production line. The most important advantage is flow control. You can precisely adjust the feed rate, ensuring downstream equipment runs at peak efficiency and protecting expensive machines from damage. They are also very reliable with low maintenance needs because they have few moving parts. A key advantage of the vibrating grizzly feeder is its ability to act as a pre-screener. It has parallel bars that allow smaller particles to fall through, removing fines before they even reach the crusher, which boosts the efficiency of the entire circuit.

A Vibrating Feeder is built to handle a very wide range of bulk materials, especially in tough environments. They are designed to move heavy, abrasive, and large-sized materials with ease. As a dedicated aggregate feeder or ore feeder, it handles:

The robust construction of this vibratory equipment ensures it can withstand the constant impact and wear from these tough materials.

A vibratory feeder has a simple and strong structure with three main parts. First is the feeder pan or trough. This is the heavy-duty steel body that holds and conveys the material. It is often lined with replaceable wear plates. Second is the vibrator. This is the “engine” of the feeder. It can be a mechanical unit with a motor and eccentric weights or a quieter electromagnetic drive. Third is the suspension system. This usually consists of heavy-duty coil springs that allow the pan to vibrate freely while supporting its weight and isolating the vibratory force from the support structure.

There are two main types of vibrating feeders, categorized by their drive mechanism. The choice depends on your application’s needs for power and control.

Choosing the right feeder machine is critical for your plant’s performance. You must consider several key factors to make the correct decision.

The price of a vibrating feeder can range from a few thousand dollars to over $50,000 for a large, heavy-duty model. The cost depends on size, capacity, and drive type. However, beware of assuming all feeders are created equal. Cheaper models often have undersized vibrators and weak frames, leading to inconsistent feed rates and frequent breakdowns. It’s better to consider the total cost of ownership. Investing in a robust machine from a reputable feeder manufacturer like ZONEDING might cost more upfront but will save you money from lower energy use, less downtime, and a much longer service life.

| Model | Max.Feeding Size(mm) | Processing Capacity(t/h) | MotorPower(kw) | Obliquityof materialtrough(°) | Troughsize(mm) | Dimensions(mm) |

| GZD-650×2300 | 300 | 80-100 | 1.2×2 | 10-20 | 650×2300 | 2300×1360×780 |

| GZD-750×2500 | 350 | 100-130 | 1.5×2 | 10-20 | 750×2500 | 2500×1460×780 |

| GZD-850×3000 | 400 | 120-150 | 3×2 | 10-20 | 850×3000 | 3110×1800×1600 |

| GZD-1000×3600 | 500 | 150-200 | 3.7×2 | 10-20 | 1000×3600 | 3850×1950×1630 |

| GZD-1100×3600 | 580 | 240-300 | 3.7×2 | 10-20 | 1100×3600 | 3600×2050×1660 |

| GZD-1300×3600 | 650 | 450-600 | 7.5×2 | 10-20 | 1300×3600 | 3900×2350×1750 |

| GZD-1500×3600 | 1050 | 450-1000 | 7.5×2 | 10-20 | 1500×3600 | 3900×2000×1750 |

| GZD-2000×3600 | 1200 | 550-1000 | 10×2 | 10-20 | 2000×3600 | 3600×2000×1750 |

| GZD-2500×5000 | 1500 | 650-1500 | 18×2 | 10-20 | 2500×5000 | 5000×2500×1800 |

| ZSW-380×95 | 500 | 100-180 | 11 | 0-10 | 3800×960 | 3920×1640×1320 |

| ZSW-490×110 | 630 | 150-400 | 15 | 0-10 | 4900×1100 | 4980×1830×1320 |

| ZSW-490×130 | 750 | 400-700 | 22 | 0-10 | 4900×1300 | 4980×2580×2083 |

| ZSW-600×130 | 750 | 400-700 | 22 | 0-10 | 6000×1300 | 6082×2580×2083 |

| ZSW-600×150 | 800 | 500-900 | 30 | 0-10 | 6000×1300 | 6086×2662×1912 |

| ZSW-600×180 | 900 | 700-1300 | 45 | 0-10 | 6000×1500 | 6310×3262×2230 |

| ZSW-600×200 | 1200 | 800-1500 | 55 | 0-10 | 6000×2000 | 6310×3462×2230 |

To get the most out of your vibratory feeder, proper installation is critical for long-term performance. The feeder must be mounted on a solid, level foundation to work correctly. Ensure it is properly isolated from the surrounding structure to prevent damaging vibrations from being transmitted to other equipment. Also, ensure a consistent head load of material in the vibrating hopper feeder above; this prevents the feeder from running empty or being suddenly flooded. Regular inspections and preventative maintenance are the best way to keep your feeder system running efficiently for years.

Several factors impact how well your material feeder works. The most critical is the material’s characteristics, such as moisture and stickiness. The feeder’s setup is also key. A crucial technical detail is the vibrator’s stroke angle—the direction of the vibration. A steeper stroke angle creates a more aggressive action, which is better for heavy or sticky materials. A shallower angle is gentler, suitable for fragile materials. Experimenting to find the optimal angle for your material is important for top performance.

Vibrating feeders are known for their low maintenance needs, but they aren’t maintenance-free. A simple, regular inspection schedule will prevent most problems. On a weekly basis, you should check that all mounting bolts are tight, as vibration can loosen them. Visually inspect the feeder pan for any cracks, especially around welds, as metal fatigue can occur over time. For mechanical feeders, follow the manufacturer’s schedule for lubricating the vibrator bearings. Checking and replacing wear liners is also crucial to protect the main structure.

When you choose a vibrating feeder from ZONEDING, you are investing in reliability and performance. With experience dating back to 1990, we build our machines to withstand the toughest conditions. We are a factory-direct vibratory feeder manufacturer, which means you get a superior product at a more competitive price. Our feeders use high-efficiency motors and robust designs to minimize your operating costs. We avoid the common pitfalls of cheaper models, which often have undersized vibrators and weak frames. A ZONEDING feeder is engineered for a long service life and consistent performance.

We stand behind the quality of our equipment. Every ZONEDING vibrating feeder comes with a standard one-year warranty. This warranty covers any defects in materials and workmanship. Our commitment to you does not end with the sale. We provide comprehensive after-sales support, including access to our team of engineers for technical advice and a full inventory of spare parts to minimize any potential downtime. We also offer extended warranty options to give you even greater peace of mind.

Proper operation will extend the life of your feeder machine and keep it running safely. Always start the feeder before loading material onto it, and try to make sure the pan is empty before you shut it down. This prevents a heavy “dead load” from sitting on the pan, which can strain the springs and motor on startup. Listen to your feeder. Any new or unusual noises, like rattling or banging, can indicate a loose bolt or a cracked component. Address these sounds immediately to prevent a small issue from becoming a major failure.

A Vibrating Feeder is a fundamental component for any successful bulk material handling system. It provides the controlled, consistent flow necessary to protect your equipment and maximize your plant’s overall efficiency. By understanding how this vibratory equipment works, the different types available, and how to choose the right one, you can make a smart investment that will pay off for years. Proper operation and a simple maintenance routine are all that is needed to ensure a long and productive service life.

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Reliable Jaw Crushers for efficient primary crushing in mining, quarrying & aggregate production. Heavy-duty design, high throughput.

Cone Crusher For Sale: Highly efficient, stable and durable, ideal for all ore crushing needs. It can improve production efficiency and reduce operating costs.

High-efficiency VSI sand making machines for producing premium artificial sand from rock & gravel. Excellent particle shape, low wear cost.

PF Series Impact Crusher for secondary crushing of limestone, rock, and efficient recycling of concrete & asphalt. High throughput, excellent shape. Get Specs!

Sand Washing Machines (Wheel & Spiral types) to remove impurities & improve sand quality for construction & industry. High cleanliness, reliable performance. Get Your Quote!

The YK series circular vibrating screens are high-performance and suitable for heavy-duty quarrying and aggregate screening operations. Multi-layer screen options are available for precise grading.

Smooth Roll Crushers for finer sizing or Toothed Roll Crushers for better grip on materials like coal & shale. Reliable, low maintenance crushers for various industries.

Looking for a high-efficiency fine crusher? Explore our industrial fine crushing machines for sale. Factory-direct pricing and large capacity.

Compound Crushers (Vertical Shaft) for efficient fine crushing of medium-hard materials like limestone & clinker. Simple structure, high ratio, ideal for sand making & aggregate. Get Quote!

Looking for a high-performance Hammer Crusher? Our heavy-duty machines offer large crushing ratios and stable operation. Get your factory-direct quote today!

loading…

已经是到最后一篇内容了!