Search the whole station Crushing Equipment

A mineral powder briquetting machine is a type of roller press designed for high-pressure compaction. Its only job is to take dry or semi-dry mineral powders and squeeze them between two counter-rotating rollers. These rollers have pockets, or molds, on their surfaces. The extreme pressure forces the powder particles to bind together, forming solid, dense briquettes. This process is essential for making fine materials easy to handle, transport, and use in industrial processes like smelting.

Turning your fines into briquettes offers huge financial and operational benefits. It is not just about waste management; it is about value creation.

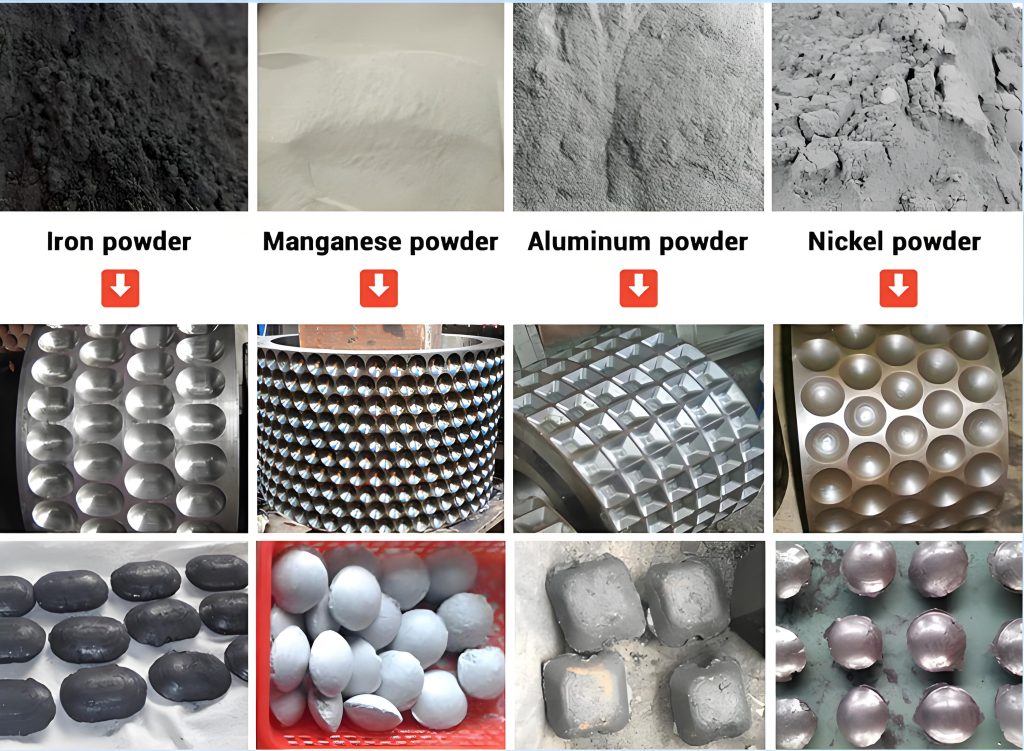

Our powder briquetting plant solutions can handle a wide range of materials. Some of the most common applications we see include:

Briquetting mineral powders is much more demanding than briquetting softer materials like charcoal or sawdust. This is a critical point that many buyers miss. The machine has to be engineered for a tougher battle.

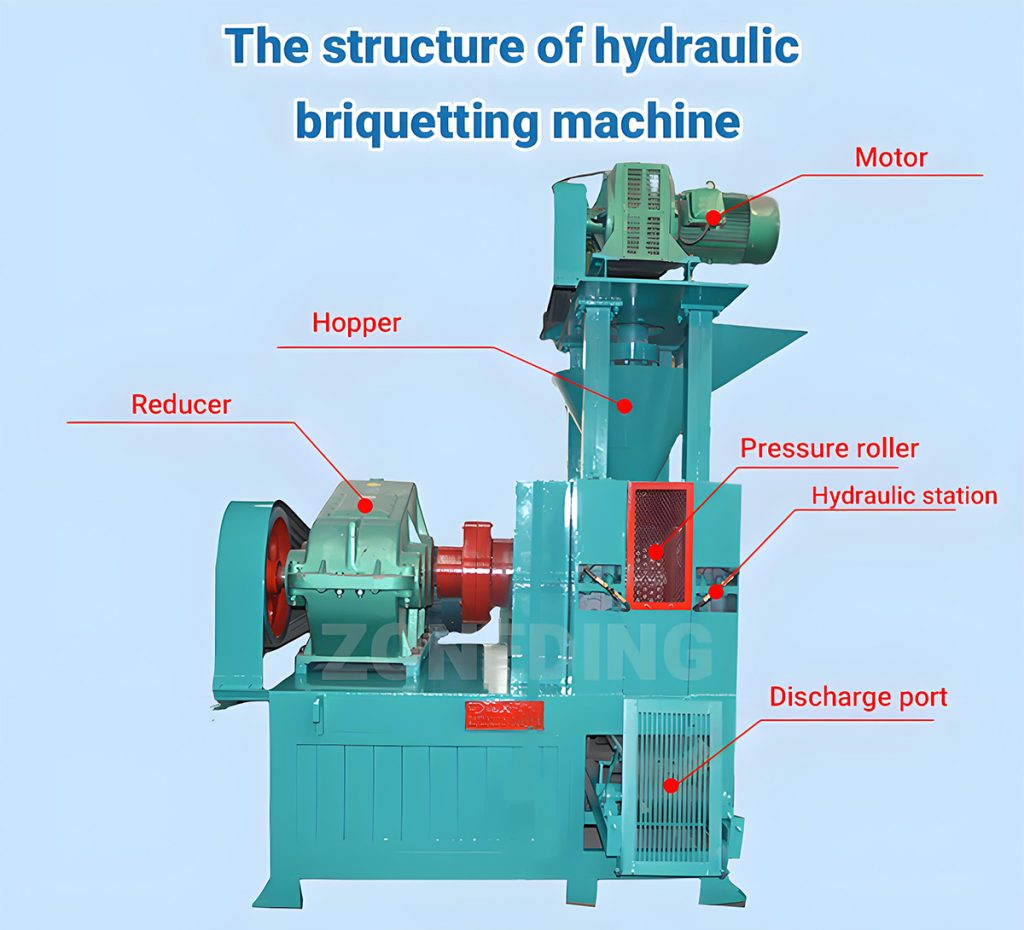

The main difference is abrasion. Many people look at Mohs hardness and think they understand the material. But the real enemy is attrition. You are forcing millions of tiny, sharp, hard mineral grains through the rollers under extreme pressure. It acts like a high-pressure grinding paste. Standard steel rollers, even hardened ones, will be destroyed in months. For mineral fines briquetting, you must use rollers made from high-chromium forged steel. These materials are not just hard; they are built to resist the intense grinding wear. This costs more initially but saves you a fortune in downtime and replacements.

After years of industrial use and improvement, mineral powder briquetting machine has the following advantages compared with other similar products

Our mineral powder briquetting machine is proud of that the finished briquettes come with high intensity, great convenience for transportation and various shapes. Custom-made equipment is also available. Mineral powder, metal powder, coal powder, gypsum, carbon powder, kaolin, activated carbon, coke powder, iron, ore, iron oxide, slag, refractory materials and other materials can also be pressed. Application scope is broad, and mineral powder briquetting machine is suitable for the use of refractory material, power plants, metallurgy, energy, transportation, heating and other industries, which also can effectively improve the efficiency of the use of materials, improve the utilization of waste, and bring good economic benefits to the public. There is a certain environmental effect, and the improvement of the people’s living environment has a certain effect.

Additionally, the briquettes made by this nonferrous metal powder forming equipment can be used in the blast furnace process and metal smelting as chemical and smelting auxiliary material. Since that, this mineral powder briquette machine has found wide application in the coal industry, metallurgy industry, chemical industry, etc. To be specific, the steel plants can supply mill scale briquettes made using this briquette equipment to chemical plants for manufacturing ferrosilicon. Aluminum briquettes can be put into smelting furnace for extracting aluminum. Fluorite briquettes can be used as cosolvent for making steel.

A professional briquette press machine is more than just two rollers in a frame. Every part is critical for performance and longevity.

The process is straightforward but requires precision.

The price of a mineral powder briquetting machine can range from $30,000 for a small, simple unit to over $500,000 for a large-scale, high-pressure hydraulic system. The price depends on several key factors:

We can customize the roller molds to produce briquettes in many shapes and sizes. The choice is not just for looks; it affects the briquette’s properties.

The size typically ranges from 20mm to 80mm. The ideal size depends on your material and how the final briquette will be used in the furnace.

This is the most important step. Buying the wrong machine is a costly mistake. The professional approach is based on data, not just machine specs.

The rookie buys a machine based on tons per hour. The professional buys a machine based on a lab report.

Before you even ask for a price, you must test your material. We strongly advise sending a 50kg sample of your mineral powder to our lab. We will perform a comprehensive analysis to determine:

Buying a machine without this data is like ordering a custom suit without taking measurements. It will never fit your needs properly. This testing process is the first step in our ZONEDING partnership with you.

At ZONEDING, we build our machines based on 30 years of experience battling the toughest materials. We focus on what keeps you profitable: reliability and performance.

Proper maintenance is simple and ensures your machine runs for decades.

What is a binder in briquetting?

A binder is like a glue that helps the mineral particles stick together. Common binders include molasses, starch, or sodium silicate. It is often necessary for brittle materials like fluorite.

Can I make briquettes without a binder?

Yes, this is called binderless briquetting. It is possible for some materials, like certain types of iron ore fines. However, it requires a machine capable of delivering extremely high pressures, which increases the initial investment.

What are the hidden costs of using a cheap binder?

Using a cheap binder like sodium silicate can cost you more in the long run. First, you have to pay for the binder. Second, you have to pay huge energy costs to dry the water out of the briquettes. Third, the impurities from the binder can result in penalties from the steel mill, as they have to use more energy and flux to remove them.

How important is the feeder system?

It is more important than the gearbox. If you cannot get a consistent, dense flow of powder into the rollers, you will never make a good briquette. For fine mineral powders, a forced screw feeder is not an option; it is a requirement.

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd…

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq…

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly …

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. …

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin…

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach…

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin…

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z…

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. …

Applied Materials:nCoal powder, iron powder, coke coal, aluminum powder, iron scrap, iron oxide sheet, charcoal powder, carbon powder, slag, sludge,etc. Charcoal briquette machine or charcoal briquetting mac…

loading…

已经是到最后一篇内容了!