Search the whole station Crushing Equipment

Our Flotation Machine are available in different styles and numerous model sizes in each style to adapt to various mineral separation requirements.

A flotation machine is a crucial piece of equipment used to separate valuable minerals from ore. Flotation is a process that uses differences in the surface chemistry of materials to separate them. This is widely used in the mining and mineral processing industries. The flotation machine creates an environment where air bubbles attach to specific minerals, causing them to float to the surface for collection, leaving behind unwanted materials.

This makes flotation machines essential for efficiently extracting minerals from complex ores. These machines come in various designs. Each design is suited for different types of ores and processing requirements. These can significantly improve mineral recovery and reduce waste in mining operations. ZONEDING offers a variety of flotation machines designed for efficiency and reliability, helping you optimize your mineral processing.

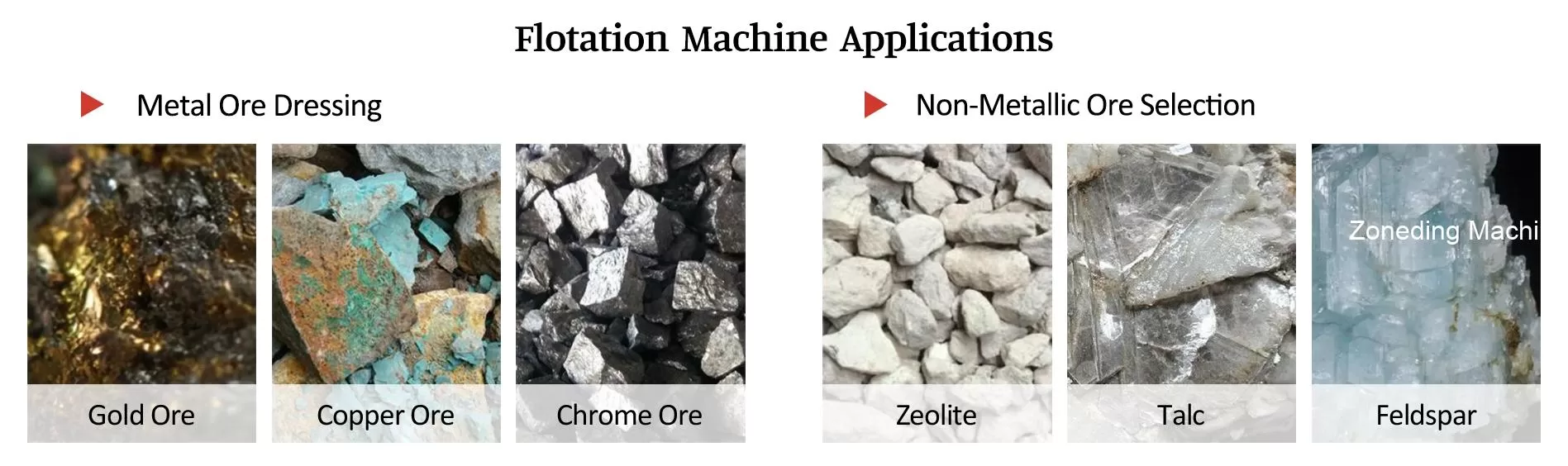

Flotation machine is mainly used for separating gold, silver, copper, iron, lead, zinc, molybdenum, nickel, aluminum and other metal minerals. It can also be used for the separation of ferrous metals and non-metals.

An air float machine uses air bubbles to separate materials, and has several advantages:

A float machine separates minerals based on their surface properties. The working principle of flotation machine involves these steps:

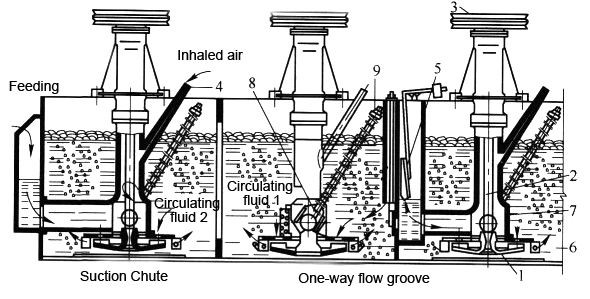

In the flotation machine, after adding the pharmaceutical treatment of the slurry, through the agitation of the inflatable, so that some of the mineral particles selectively fixed on top of the air bubbles; floated to the surface of the slurry is scraped to form a foam product, and the rest of the slurry is retained in the slurry, in order to achieve the purpose of separating the minerals. There are many structural forms of flotation machine, the more commonly used is the mechanical agitation flotation machine.

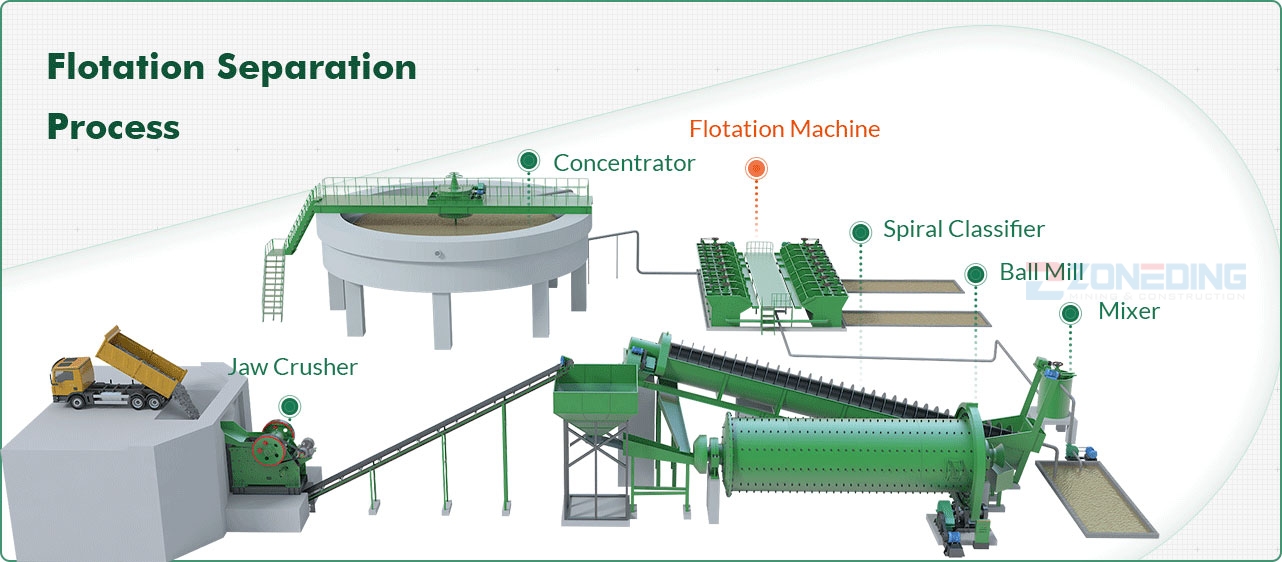

The work process when using a flotation machine in float mining includes:

Flotation process refers to the method used in the flotation process of a mineral. Flotation is the same as other mineral processing methods, to do a good job of material preparation before selection, that is, the ore should be milled and graded to achieve the concentration of fineness suitable for flotation. In addition, flotation has the following basic operations: slurry adjustment and add flotation chemicals, change the mineral wettability so that mineral particles attached to the bubble. Mineralization of bubbles. Selective attachment of mineral particles to air bubbles is the basic behavior of the flotation process. Flotation is a beneficiation method based on the different wettability of minerals by water. Generally, the nature of minerals easy to float and difficult to float is called the floatability of minerals. Flotation is the use of the difference in the floatability of minerals to separate minerals.

Floating machine technology is used across multiple industries:

The flotation method can separate a range of materials:

It’s important to note that different ore types may exhibit varying flotation properties during the process, such as density, specific gravity, surface characteristics, and reagent reactions. Therefore, flotation machines require parameter adjustments based on the ore’s unique characteristics and beneficiation requirements to achieve optimal separation results.

Additionally, with a wide range of flotation machine models and types available, selecting the most suitable one depends on factors like ore properties, processing capacity, and beneficiation needs.

flotation machines play a crucial role in the effective extraction and utilization of mineral resources, finding widespread applications in the flotation of various metallic, non-metallic, and non-ferrous ores.

Different types of flotation machine exist, each with its characteristics:

The key components/structure of a flotation machine include:

Flotation machine is mainly composed of impeller, cover plate, vertical shaft, inlet pipe, bearings, belts and other accessories, the wear parts of the equipment are selected from international new wear-resistant and pressure-resistant raw materials, which reduces the wear and tear and prolongs the service life of the equipment.

Specific Application Scenario: Recovering fine gold from tailings using enhanced gravity concentration followed by flotation. In this scenario, the flotation circuit is targeting extremely fine particles that are difficult to recover. Use a specialized flotation machine with a high-intensity impeller and a short residence time. Add a strong collector and a powerful frother to maximize gold recovery. Closely monitor the froth characteristics to prevent gold losses in the overflow.

Froth flotation reagents are essential for efficient mineral separation:

Several factors influence flotation efficiency:

Choosing a flotation machine requires:

| Category | Specification Model | Effective cubage (m) | Processing capacity (m/min) | Main shaft loam board | Dimensions (m) | Single trough Weight (t) | |||

| Power (kw) | Rotate Speed (r/min) | Rotate Speed(r/min) | Power (kw) | ||||||

| XJK type flotation machine | XJK-0.35 | 0.35 | 0.18-0.4 | 1.5 | 483 | 25 | 1.1 | 0.7x0.7x0.7 | 0.5 |

| XJK-0.62 | 0.62 | 0.3-0.9 | 3.0 | 400 | 25 | 1.1 | 0.90x0.82x0.85 | 1.0 | |

| XJK-1.1 | 1.1 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1x1.1x1 | 1.4 | |

| XJK-2.8 | 2.8 | 1.5-3.5 | 11 | 280 | 25 | 1.1 | 1.75x1.6x1.1 | 2.5 | |

| XJK-5.8 | 5.8 | 5-7 | 22 | 240 | 25 | 1.5 | 2.2x2.2x1.2 | 3.6 | |

| SF type flotation machine | SF-0.37 | 0.37 | 0.2-0.4 | 1.5 | 386 | 25 | 1.1 | 0.7x0.7x0.75 | 0.5 |

| SF-0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | 0.9x0.82x0.95 | 1.0 | |

| SF-1.2 | 1.2 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1x1.1x1.1 | 1.9 | |

| SF-2.8 | 2.8 | 1.5-3.5 | 11 | 268 | 25 | 1.1 | 1.75x1.6x1.15 | 2.6 | |

| SF-4 | 4 | 2-4 | 15 | 220 | 25 | 1.5 | 1.85x2.05x1.2 | 2.9 | |

| SF-8 | 8 | 4-8 | 30 | 191 | 25 | 1.5 | 2.2x2.9x1.4 | 4.2 | |

| SF-10 | 10 | 5-10 | 30 | 191 | 25 | 1.5 | 2.2x2.9x1.7 | 4.5 | |

| SF-20 | 20 | 5-20 | 30×2 | 191 | 25 | 1.5 | 2.85x3.8x2 | 9.9 | |

| JJF type flotation machine | JJF-2 | 2 | 1-3 | 7.5 | 443 | 25 | 1.5 | 1.4x1.4x1.1 | 1.7 |

| JJF-4 | 4 | 2-4 | 11 | 305 | 25 | 1.5 | 1.6x2.15x1.25 | 2.4 | |

| JJF-8 | 8 | 4-8 | 22 | 233 | 25 | 1.5 | 2.2x2.9x1.4 | 4.5 | |

| JJF-10 | 10 | 5-10 | 22 | 233 | 25 | 1.5 | 2.2x2.9x1.7 | 4.9 | |

| JJF-16 | 16 | 5-16 | 30 | 180 | 25 | 1.5 | 2.85x3.8x1.7 | 8.0 | |

| JJF-20 | 20 | 5-20 | 37 | 180 | 25 | 1.5 | 2.9x3.8x2.0 | 10.5 | |

ZONEDING‘s Flotation Machine is known for

ZONEDING has more than 30 years of experience in manufacturing flotation machine, and excels in this field by developing high-end flotation machine integrating cutting-edge technology and precision engineering.

Innovations in flotation technology include:

Environmental considerations for flotation operations include:

The flotation machine price depends on:

Maintenance requirements for a flotation machine include:

Choosing ZONEDING ensures:

ZONEDING is dedicated to providing solutions for mineral processing. Contact us to enhance operations with equipment.

Q1: What is the typical recovery rate of a flotation machine?

Recovery rates vary, but machines can achieve 90% or higher with proper optimization. Fine-tuning your reagent system and closely monitoring froth characteristics are key. Consider pilot testing with ZONEDING equipment to determine achievable recovery rates for your specific ore.

Q2: How often should I replace the impeller in my flotation cell?

Impeller wear depends on the abrasiveness of the slurry. Inspect impellers every 3-6 months. Replace them when significant wear is evident to maintain performance and ensure efficient flotation services. ZONEDING offers durable, wear-resistant impellers designed for long-term use.

Q3: Can flotation be used to recover multiple minerals from the same ore?

Yes, by using selective reagents and adjusting the process parameters in stages. This is known as sequential flotation. Each stage targets a specific mineral, maximizing overall recovery.

Q4: What are the main advantages of column flotation over mechanical flotation?

Column flotation generally provides superior separation of fine particles, lower reagent consumption, and higher concentrate grades compared to mechanical cells. However, they can be more sensitive to feed variations.

Q5: Is flotation suitable for small-scale mining operations?

Yes, smaller, modular flotation systems are available that are cost-effective for small-scale mining. These systems can be easily transported and set up, making them ideal for remote locations.

Q6: How do I choose the right frother for my flotation process?

The choice of frother depends on the specific ore and the desired froth characteristics. Factors to consider include bubble size, froth stability, and selectivity. Consulting with a reagent supplier and conducting laboratory tests can help you select the appropriate frother.

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy