Search the whole station Crushing Equipment

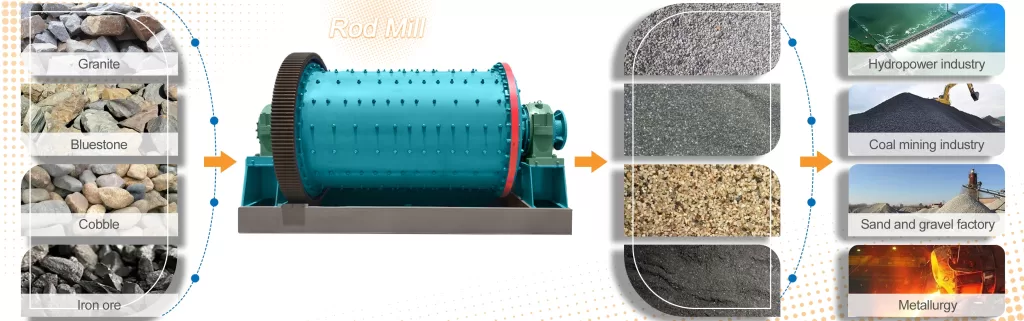

Our Rod Mill are available in different styles and numerous model sizes in each style to adapt to various grinding requirements.

The rod mill is a grinding equipment that uses steel rods as the grinding media, widely used in metal and non-metal mines, water conservancy, building materials, chemicals, refractories, metallurgy, glass, and other industries. This equipment adopts advanced controllable feeding and discharging technology, combined with actual grinding materials, and is equipped with suitable grinding bodies to change the traditional surface contact to line contact, resulting in more uniform discharge particle size and higher production capacity. Rod mills are available in both dry and wet forms for users to choose according to their actual situations.

A rod mill is a type of grinding mill that uses steel rods as the grinding media. These rods, spanning the length of the mill, grind material through rolling and impact as the mill rotates. This makes it suitable for coarse grinding, producing a product with a relatively uniform particle size.

Rod mills are primarily used for coarse grinding, often as a primary grinding stage before finer grinding processes. They are commonly used in the mining industry to prepare ore for further processing. They are also used in aggregate production to create materials for construction.

A rod mill works by rotating a cylindrical drum partially filled with steel rods and the material to be ground. As the drum rotates, the rods tumble and grind the material through a combination of impact, attrition, and crushing.

As the mill rotates, the rods lift and then fall back down onto the material. This constant impact and rolling action breaks down the material. The size of the final product is controlled by factors like the speed of rotation, the size and number of rods, and the feed rate of the material.

The working principle of the rod mill is to drive the rotation of the cylinder through the motor and the surrounding large gear reduction transmission. The interior of the cylinder is equipped with appropriate grinding media – steel rods. The grinding media is lifted to a certain height under the action of centrifugal force and friction and falls in a throwing or leaking state. The material to be ground continuously enters the interior of the cylinder through the feed port and is crushed by the moving grinding media. The product is discharged outside the machine through the force of overflow and continuous feeding for the next process operation.

Rod mills offer several advantages, including efficient coarse grinding, minimal over-grinding, and a relatively narrow particle size distribution. These features make them ideal for applications where a consistent, coarse product is desired.

Consider the problem of over-grinding, where valuable material is reduced to dust. Rod mills minimize this issue, making them efficient for processing materials where a specific coarse size is needed. Their ability to produce a narrow particle size distribution also helps in downstream processes.

Rod mills find applications in various industries, including mining, aggregate processing, and coal preparation. They are used to process ores, produce construction aggregates, and prepare coal for power generation.

In mining, rod mills are used to grind ores like gold, copper, and iron ore. In aggregate production, they create materials for road construction and concrete production. and In coal preparation, they reduce the size of coal to improve its combustion efficiency.

Rod mills can process a wide variety of materials, including ores, aggregates, and coal. They are effective on both hard and abrasive materials, making them versatile for different applications.Think of the diverse materials that need processing. Whether it’s the hard rock of a gold mine, the abrasive gravel for road construction, or the relatively soft coal for power plants, a rod mill can handle it. This versatility makes it a valuable asset in many operations.

The main difference between a rod mill and a ball mill lies in the grinding media used. Rod mills use steel rods, while ball mills use steel balls. This difference affects the grinding action and the resulting particle size distribution.

Rod mills are better suited for producing a coarser product with fewer fines, while ball mills are more effective for finer grinding. The linear contact of the rods in a rod mill promotes crushing, while the point contact of the balls in a ball mill favors attrition.

A rod mill consists of a cylindrical shell, steel rods, and liners. The shell is the outer body of the mill, the rods are the grinding media, and the liners protect the shell from wear and tear.

The shell is typically made of steel and is supported by bearings that allow it to rotate. The rods are made of high-carbon steel and come in various diameters. The liners are made of wear-resistant materials like rubber or steel and are bolted to the inside of the shell.

Rod mills can be classified based on their discharge method: central discharge and peripheral discharge. Central discharge mills discharge the ground material through an opening in the center of the mill, while peripheral discharge mills discharge through openings around the mill’s periphery.

Central discharge mills are typically used for wet grinding, while peripheral discharge mills can be used for both wet and dry grinding. The choice of discharge method depends on the specific application and the desired product characteristics.

Selecting the right rod mill involves considering factors like the material to be processed, the desired product size, the required capacity, and the operating conditions. It’s important to evaluate your specific needs and choose a mill that meets those requirements.

Start by analyzing your material’s hardness and abrasiveness. Then, determine the desired particle size distribution of the final product. Finally, consider the volume of material you need to process. By carefully evaluating these factors, you can select a rod mill that optimizes your operation.

Understanding the price of a rod mill is a critical first step when planning your mineral processing or industrial grinding operation. The final cost is not a one-size-fits-all figure; it is customized based on the specific demands of your project. The most significant factor influencing the price is the mill’s size and capacity, typically defined by its diameter, length, and the required throughput in tons per hour.

Beyond capacity, several other specifications determine the final rod mill cost. This includes the type of mill—such as an overflow or end peripheral discharge model—which is selected based on your grinding circuit needs. The choice of liner material, like high-manganese steel or specialized rubber for wear resistance, and the power of the motor and drive system are also major cost components. Whether your application requires fine particle size reduction through wet or dry grinding, these details ensure the mill is perfectly engineered for performance and longevity.

Wet grinding and dry grinding in a rod mill each offer unique benefits. and Wet grinding can increase throughput and reduce dust, while dry grinding avoids the need for dewatering and drying the product.

Wet grinding can help to cool the material and reduce dust emissions. Dry grinding is often preferred when the final product needs to be dry, as it eliminates the need for additional drying steps. The choice between wet and dry grinding depends on the specific application and the desired product characteristics.

Several factors can affect rod mill performance, including feed rate, material hardness, rod charge, and mill speed. Optimizing these factors is crucial for achieving efficient grinding and the desired product size.

A higher feed rate can increase throughput but may also lead to coarser products. Harder materials require more energy to grind. Maintaining the correct rod charge (the amount and size distribution of rods) is crucial for optimal performance. Rods wear down and break, altering the grinding action. Regularly inspect the rod charge, remove broken rods, and add new rods of the appropriate size to maintain the ideal charge volume and distribution. A “lazy” mill – one that doesn’t sound as active – often indicates an issue with the rod charge. Log rod additions and removals meticulously.

Controlling particle size distribution in a rod mill involves techniques like grading and separation. Classification equipment, such as screens and cyclones, can be used to separate the ground material into different size fractions.

By adjusting the mill’s operating parameters and using classification equipment, you can achieve the desired particle size distribution. This is particularly important in applications where a specific particle size range is required for downstream processes.

Common problems in rod mills include rod breakage, liner wear, and bearing failure. Troubleshooting these issues involves identifying the root cause and implementing corrective actions.

Rod breakage can be caused by excessive material hardness, improper rod size, or mill overloading. Liner wear can be minimized by using wear-resistant materials and avoiding abrasive feed materials. Bearing failure can be prevented by proper lubrication and regular maintenance.

Regular maintenance for a rod mill includes liner replacement, rod management, and lubrication. Proper maintenance is essential for ensuring the mill’s reliability and longevity.

Liners need to be replaced periodically as they wear down. Rod management involves adding new rods to maintain the correct rod charge and removing broken rods. Lubrication is essential for preventing bearing failure and reducing wear on moving parts.

Rod mills can be energy-intensive, so it’s important to consider energy consumption and implement power optimization strategies. This includes optimizing the mill’s operating parameters, using high-efficiency motors, and implementing variable speed drives.

By optimizing the mill’s operating parameters and using energy-efficient components, you can minimize energy consumption and reduce operating costs.

Recent advancements in rod mill technology include automation and control systems. These systems can help to optimize mill performance, reduce downtime, and improve safety.

Automation and control systems can monitor and adjust the mill’s operating parameters in real-time. This helps to maintain consistent product quality and minimize energy consumption. These systems can also detect potential problems early on, allowing for timely maintenance and preventing costly breakdowns.

ZONEDING rod mills are known for their durability, performance, and reliability. They are designed to withstand the harsh conditions of mining and aggregate processing.

ZONEDING rod mills feature robust construction, high-quality components, and advanced control systems. This ensures efficient grinding, minimal downtime, and long service life. With over 30 years of experience, ZONEDING is committed to providing you with top-tier mining equipment solutions tailored to your specific needs.

If you are interested in this, please contact us as soon as possible! We will provide you with more than 2 solutions for you to choose from.

We provide comprehensive pre-sales, in-sales, and after-sales service support, including technical consultation, scheme design, equipment installation and debugging, operation training, and maintenance. Our goal is to provide customers with the best quality products and services to ensure smooth production.

Professional gold leaching agitation tanks for CIL and CIP processes. Durable, wear-resistant impellers for reliable mineral processing. Request a custom layout!

Your reliable source for high-capacity, heavy-duty ball mills engineered for mining, cement, and fine powder processing.

the best Ceramic Ball Mill manufacturers and their competitive prices. Our selection offers top-quality mills for various applications at affordable costs.

Efficient flotation machine for mineral processing at competitive prices. Maximum recovery and optimal grade for your mining operations.

A magnetic separator is a device that separates magnetic minerals from nonmagnetic minerals by applying a magnetic field.

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

“Optimize mineral processing with our high-efficiency Jigging Separator Machine! Ideal for gold, tin, coltan separation.

Gold Mine Wet pan mill applys in the gold mining industry and is one of the indispensable equipment in the modern gold mining industry. In addition, it can also apply for mining and processing other non-ferrous metals and precious metal ore…

loading…

已经是到最后一篇内容了!