Search the whole station Crushing Equipment

Due to the increasing cost of common fuels like coal and gas and the recently appearing need for new resources, more and more attention are in biomass fuels industry. Briquetting plant is the key part in the biomass fuel production line and other powdery materials storage and transportation.

Briquetting plant is also name with briquette plant or briquette production line. It mainly contains the key machine briquetting machine and other equipment like dryer, batcher, biaxial mixer, compound crusher, etc. Compared with the single briquetting machine, the briquetting plant is prior in production capacity, automatization, briquetting efficiency and other fields.

A briquetting plant is a complete system of machines that work together to make briquettes. Think of it as a full production line. Raw material goes in one end, and finished, valuable briquettes come out the other. The heart of the plant is the briquette machine, but it cannot work alone. It needs other equipment to prepare the material correctly. A true plant includes machines for crushing, drying, mixing, and conveying the material before it ever reaches the press. This integrated approach is the key to producing high-quality briquettes consistently.

A briquetting plant aims to create solid fuel or compact materials for easier handling. Its main purpose is value addition. You take a material that is difficult to transport, store, or use. Then you transform it into a uniform product with a higher density and value.

Common applications include:

We need briquetting plants to solve waste problems and create sustainable energy. In a world focused on recycling and efficiency, leaving waste materials to rot is no longer acceptable. A briquetting plant offers a powerful solution with many advantages.

There are two main technologies, and they are not interchangeable. The type of briquette machine you need depends entirely on your raw material. Choosing the wrong one will result in complete failure. This is a critical distinction many people miss. It is about the difference between cold pressing and hot pressing.

You can use a huge variety of materials, but they must be prepared correctly. Almost any kind of biomass or fine powder can be made into a briquette. The key is controlling the particle size and moisture content before it goes to the press.

Making good briquettes is a step-by-step process where every stage is important. It is a chain, and a weakness in any link will affect the final product. The press gets all the attention, but the preparation steps are what truly determine your success.

As before, the whole briquetting plant needs different equipment. Taking the charcoal briquetting plant in India as an example, here introduces the general briquetting plant flowchart.

Carbonized biomass materials is aslo as charcoal. When crushed or broken into powder by compound crusher, charcoal is conveyed into the batcher, the biaxial mixer and the binder mixer to realize a full mixing of raw material and binder.

Next, a mixing mill is to stir and mill the mixed material to ensure the shaping technology of the mixture. Then, vibrating feeder applys to feed the briquetting machine evenly and continuously to assure the briquetting efficiency. If needed, a belt dryer willl apply to dewater the finished products for more convenient storage and transportation.

A successful plant is more than just the press; it is an ecosystem of supporting machines. Skimping on the “in-between” equipment is a common mistake that leads to endless problems. The reliability of your entire operation depends on every single component.

The core equipment includes:

But do not forget the unsung heroes:

Zoneding customizes a complete briquette production line according to customer’s raw materials, discharge sized, production capacity, the work environment, etc. Besides, Zoneding offers solutions of different briquettes shape like oval shape, pillow shape, egg shape and so on.

In addition for convenient storage and transportation, briquetting plant is for calcination or burning.

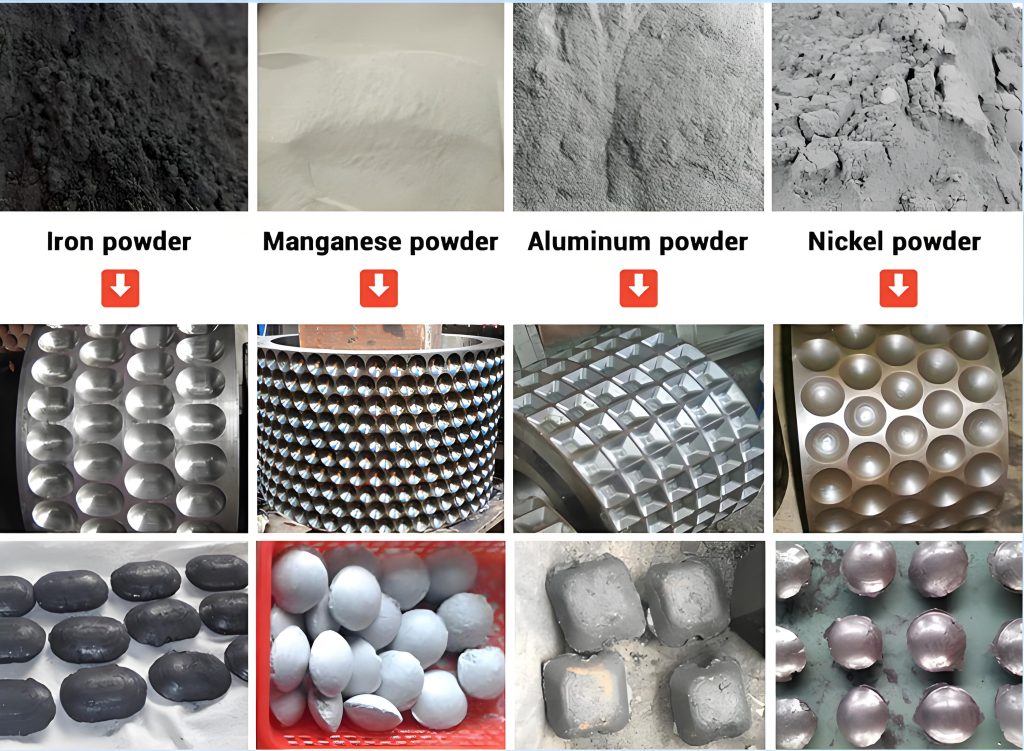

Briquetting plant usually aims to press those solid and powdery materials that are not easy to be shaped like various metal ore powder, non-metallic mineral powder, steel slag and other particles such as clay, cryolite, kaolin, gypsum, etc.

Based on different materials, Zoneding Machinery supplies customized briquetting plant solutions including coal briquetting plant, charcoal briquetting plant, fluorite powder briquetting plant, mineral powder briquetting plant, dry powder briquetting plant, desulfurization gypsum briquetting plant, iron scrap and various metal ore powder briquetting plant, etc.

In the whole briquetting plant, the briquetting machine plays a core and crucial part. The following paragraph mainly describes the types of briquetting machines and their main usages:

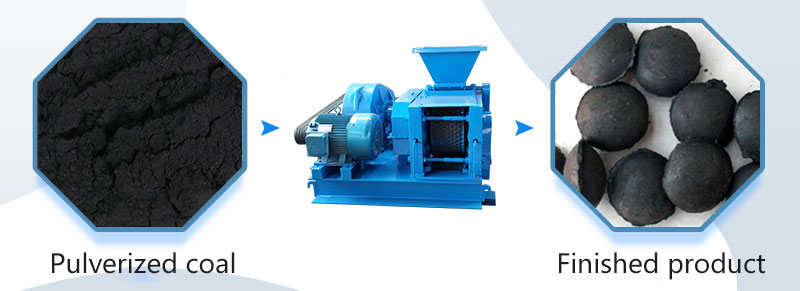

Coal briquetting machine is mainly used in processing coal powder into balls. The materials can be directly put into the furnace for smelting, so as to increase the extra value.

Dry powder briquetting machine mainly applies for pressing materials without water into bricks, such as lime powder, magnesium oxide powder, copper powder, chromium powder, zinc scrap, bauxite, non-ferrous metal powder, refractory material, ceramic material and so on. The powder material will shape into high capacity ball eggs through high pressure.

Mineral powder briquette machine is mainly used for ball making of non-ferrous and ferrous metal mineral powder, and the materials can be directly put into the furnace for smelting, so as to increase the added value. For example, dust, sludge, oxide skin, slag, iron powder, aluminum ash, silicon manganese ore, etc.

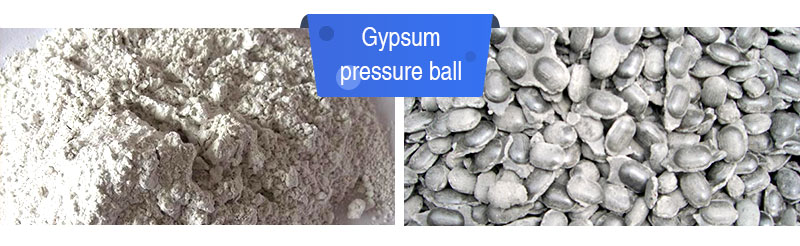

Desulfurization gypsum briquette machine can press desulfurization gypsum powder into balls at one time, which has high yield and high ball forming rate. The equipment can press desulfurized gypsum powder into balls at one time without adding any adhesive, and the briquetting rate is above 90%.

The finished balls have strong hardness, which is not easy to be broken during transportation, and the finished product is used as cement retarder in cement plant to take place of natural gypsum.

Strong pressure briquetting machine is mainly used for the cold pressing pellet of refractory material, coal powder, coal slime, middling coal, coke powder, coke coal and metallurgical powder materials.

Capacity: 50TPH

Feed size: about 2mm

Discharge size: 15mm

Ancillary equipment: batcher, biaxial mixer, binder mixer, mixing mill, vibrating feeder, etc.

A complete briquetting plant can cost anywhere from $20,000 for a very small setup to over $500,000 for a large industrial line. The briquetting plant project cost depends on capacity, raw material, and automation level. But the purchase price is only the beginning.

You must consider the total cost of ownership. The single largest ongoing operational cost after labor and energy is replacing the wear parts, specifically the press rollers. Abrasive materials can wear out cheap rollers in months. At ZONEDING, we offer rollers made from high-chromium alloys. They might cost more upfront but can last five times longer. This dramatically lowers your cost per ton and reduces downtime. When you ask for a price, always ask for the price and lifespan of a replacement set of rollers.

You are not buying a machine; you are buying a material recipe. This is the most important mindset shift you can make. The press just executes the commands given to it by the material preparation. The wrong question is, “What is your 10-ton-per-hour machine?” The right question is, “I have sawdust with 30% moisture. How do I turn it into a strong briquette?”

The answer defines the entire plant. It tells you the size of the dryer you need, the type of press (screw press), and the conveyors required. At ZONEDING, our process starts with your material. We test it. and We analyze it. We design a process flow first, and then we select the machines to fit that process. Investing 80% of your planning time on material preparation will save you 50% of your operational headaches.

We build complete, heavy-duty systems based on a deep understanding of your material. For over 30 years, ZONEDING has been a leading briquette machine manufacturer. We know that a profitable plant is a reliable plant. We focus on engineering solutions that minimize downtime and operational costs.

High density comes from three things: immense pressure, optimized moisture, and correct particle size. A well-built press provides the pressure. Your dryer and crusher control the moisture and particle size. Getting these three factors right is the secret to a strong, dense briquette that won’t fall apart.

High calorific value, or the energy content, is mainly determined by your raw material. Hardwood sawdust has more energy than rice straw, for example. The briquetting process itself slightly increases the energy density by removing water and compacting the material.

Yes, if you have a cheap and steady supply of raw material and a local market for the briquettes. The business model is simple. You take low-cost or free waste. Then you convert it into a valuable, in-demand product like fuel. If you have to pay a lot for raw materials or transport them long distances, it becomes much harder to be profitable. A proper feasibility study is the first and most important step before you invest.

A well-designed plant requires regular but straightforward maintenance. It is not overly demanding if you are proactive. Daily tasks include checking lubrication points, monitoring bearing temperatures, and cleaning dust collection systems. Dust is an abrasive killer that can destroy bearings and gears, so cleaning is crucial. Weekly checks involve inspecting conveyor belts and tightening bolts on the press. The most important thing is preventative maintenance to avoid costly breakdowns.

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

What is a binder and do I always need one?

A binder is like a glue that helps hold particles together. You need it for materials like coal and charcoal, which don’t stick to themselves under pressure. Starch is a common binder. For biomass like sawdust, you usually do not need a binder because the hot pressing process releases natural lignin, which acts as the glue.

How much space does a complete briquetting plant need?

This depends on the capacity. A small plant producing 1-2 tons per hour might fit in a 500 square meter (about 5,400 sq ft) building. A larger industrial plant producing 10 tons per hour or more will need several thousand square meters for the machinery, raw material storage, and finished product storage.

Can I make different shapes of briquettes?

Yes. With a roller press, you can change the molds on the rollers to produce various shapes like oval, pillow, square, or round. The shape is chosen based on the final application and customer preference.

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd…

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq…

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly …

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for…

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. …

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin…

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach…

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin…

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z…

Applied Materials:nCoal powder, iron powder, coke coal, aluminum powder, iron scrap, iron oxide sheet, charcoal powder, carbon powder, slag, sludge,etc. Charcoal briquette machine or charcoal briquetting mac…

loading…

已经是到最后一篇内容了!