Search the whole station Crushing Equipment

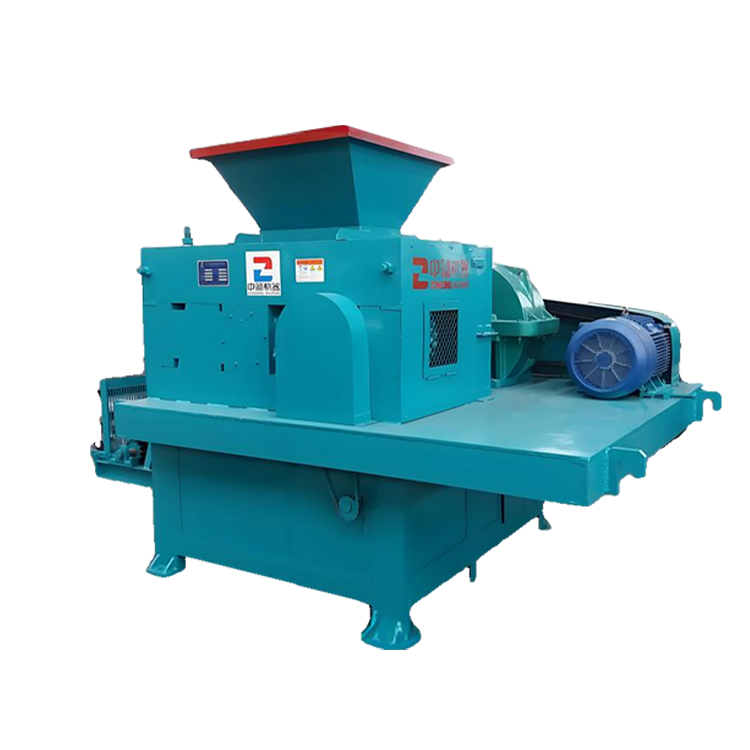

Pulverized coal briquetting machine is a kind of equipment which can press powdered materials into balls, such as pulverized coal, slime, medium coal, coke powder, coke coal and metallurgical powder, refractory materials, and so on. The pulverized coal ball briquetting machine not need to add water when pressing the materials, and can be used for pressing and molding after crushing the raw material directly. It also called coal powder briquetting machine.

Pulverized coal briquettes are simply coal fines—dust, powder, and small particles—that have been mixed with a binder and compressed under immense pressure. This process turns loose, low-density powder into a solid, uniform block. These briquettes have a consistent shape, size, and calorific value, making them an ideal fuel source for industrial boilers, power plants, and even for home heating or BBQ, depending on the production process. They solve the handling and transportation problems associated with raw coal fines.

The benefits of coal dust briquetting go far beyond simple waste management. It’s a strategic business decision. Firstly, it creates a new revenue stream from a product you were previously discarding or selling for pennies. Secondly, it drastically improves logistics. Briquettes are dense and easy to transport, load, and store. Thirdly, it is an environmental and safety upgrade. Briquetting reduces dust pollution in your facility. And here is the most critical point many overlook: finely pulverized coal dust, when suspended in air, is highly explosive. A simple spark can detonate your facility. A professionally designed briquetting plant from ZONEDING incorporates explosion-proof motors, proper equipment grounding, and explosion vents, turning a dangerous liability into a safe, profitable asset.

Almost any type of coal fine can be turned into briquettes. The key is understanding the properties of your specific coal to select the right binder and process parameters. We have successfully designed lines for:

While several technologies exist, the most dominant and efficient type is the roller press machine. This is the machine we specialize in at ZONEDING. Within roller presses, the main difference lies in the pressure system:

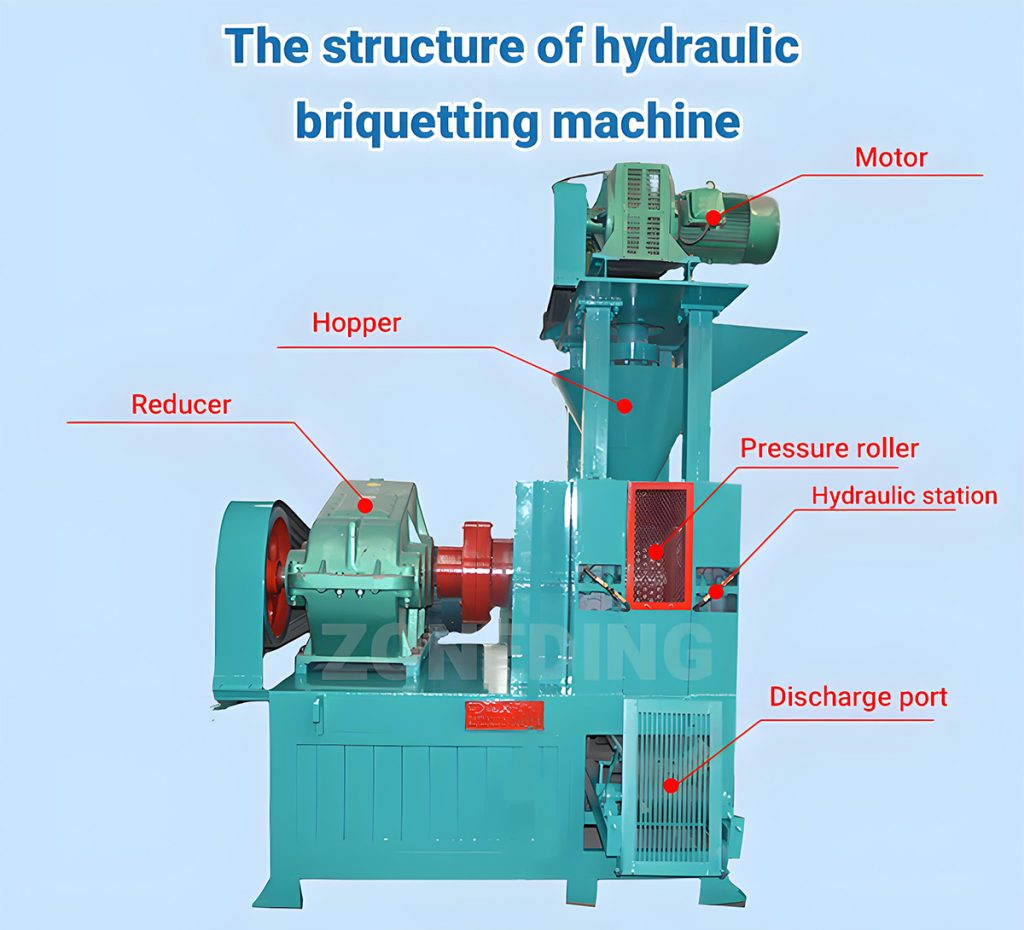

A coal briquette machine looks simple, but its performance depends on precision engineering. The core components are:

Pulverized coal ball press is mainly used for pulverized coal, coal slime, medium coal, coke and metallurgical powder pressure pellets, refractory materials. All powdery materials, which are used for burning in the furnace need to be completed by briquetting machine. The main function of pulverized coal ball press is to improve transportation characteristics, return utilization, facilitate control capacity, reduce dust and improve the utilization of resources.

Applications of Pulverized Coal Briquetting Machine

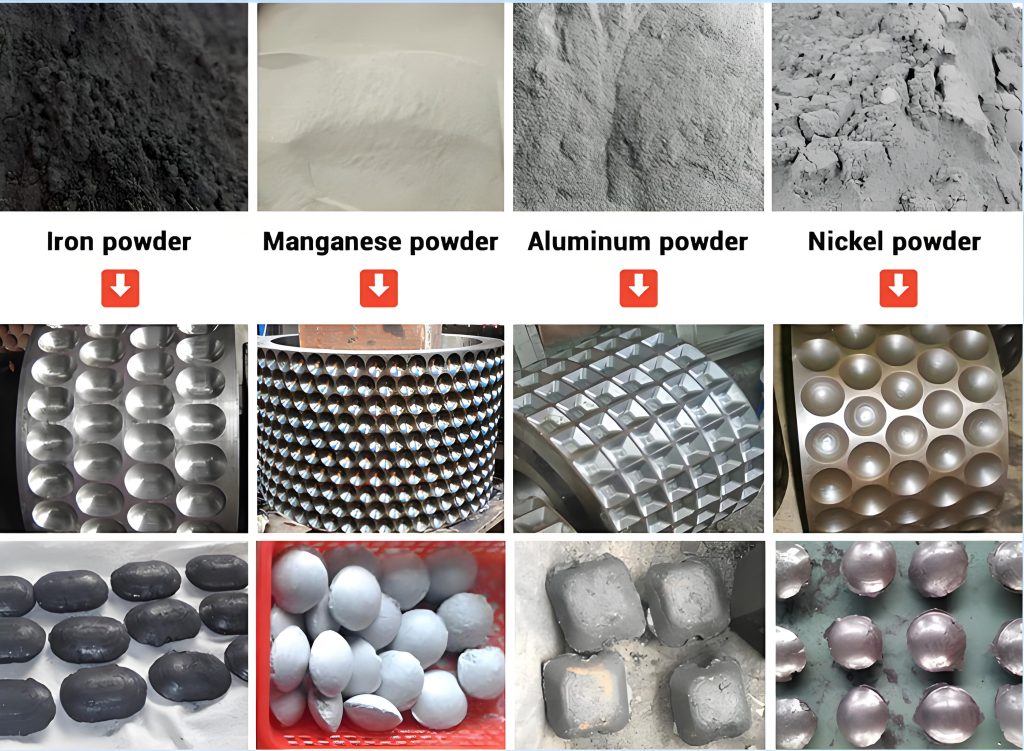

One machine multipurpose

The pulverized coal pressure ball machine is widely used for pressing, granulating or pressing the following materials, such as aluminum chips, activated carbon, alumina, bauxite, caustic soda, charcoal, clay, coke, coal, ice crystal, stone, fertilizer, plastic, limestone, pigment, urea, potassium salt and other materials. With a multi-function.

Energy Saving

The pulverized coal briquetting machine greatly improves the utilization efficiency of the coal resources and reduces the energy wasted in the combustion process of the coal. Because of the sufficient combustion of pressed briquette, the exhaust gas (sulfur dioxide) is very little, and the dust and soot emitted into the air are greatly reduced.

Reasonable Design

The main engine of pulverized coal briquetting machine is powered by electromagnetic speed regulating motor and transmitted to the active shaft through belt wheel, reducer, and coupling. The compaction process can maintain a constant feeding pressure to stabilize the quality of the pellets.

1.The rotating speed is stable; the molding rate is high, and the appearance of the product is beautiful.

2.The molding pressure is greater than before, and the quality of the finished product is good.

3.The molding system is safe and reliable; the replacement of components is convenient, and the maintenance workload is small.

4.The structure is simple and compact; the site is saved and the work is reliable.

5.Smooth demoulding, low noise and less dust.

6.According to customer requirements, it can suppress all shapes of finished products.

The pulverized coal briquetting machine is mainly composed of three parts: feeding part, transmission part and forming part. The feeding part is to ensure that the material can enter the roller room evenly. The material supplied is too large or too small will affect the quality of pellets, so it is necessary to have the operation skills of clinker in order to ensure the normal operation of the equipment.

Structure of pulverized coal briquetting machine

The machine itself is just one step in a carefully controlled process. The typical workflow for a coal fines recycling solution is:

The shape and size are determined by the pockets on the rollers and can be fully customized. The most common shapes are:

The size typically ranges from 25mm to 65mm. The right shape and size depend on the end-user’s requirements for combustion and material handling systems.

Choosing the right machine involves looking at your entire operation, not just tonnage.

1.First of all, we should look at the material quality of the whole machine, such as the quality of the steel material of the Pulverized coal briquetting machine equipment, and the good steel material can increase the production life of the machine.

2.The second is coal powder ball press body appearance paint. The painting of pulverized coal ball press equipment is not only for the good appearance of it, but also to protect the body of pulverized coal briquetting machine from rust and increase its service life.

3.Customers should look at the pulverized coal briquetting machine gear, copper and other important components. Whether the material specification of pulverized coal ball press can conform to the national standard specification, and it is not allowed one millimeter short.

A standalone pulverized coal briquetting machine can range from $15,000 for a small, basic model to over $150,000 for a large-capacity, hydraulic press. However, the machine price is only part of the total investment. A complete production line, including crushers, mixers, dryers, and conveyors, will be a larger investment. The final coal briquetting machine price is determined by capacity (tons per hour), roller material (e.g., 9Cr2Mo steel), and whether it uses a mechanical or advanced hydraulic system. Investing in a robust, hydraulic machine from a reputable manufacturer like ZONEDING costs more upfront but saves you a fortune in downtime and repairs later.

Proper maintenance is key to a long and productive life for your machine.

Anyone can sell you a press. We provide a complete, engineered coal fines processing solution. When you work with us, you get a system where every component is perfectly balanced.

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd…

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly …

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for…

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. …

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin…

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach…

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin…

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z…

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. …

Applied Materials:nCoal powder, iron powder, coke coal, aluminum powder, iron scrap, iron oxide sheet, charcoal powder, carbon powder, slag, sludge,etc. Charcoal briquette machine or charcoal briquetting mac…

loading…

已经是到最后一篇内容了!