Search the whole station Crushing Equipment

Jaw Crusher Applicable Material:Quartz, granite, basalt, limestone, river stone, marble, shale, iron ore, copper ore, gold ore etc.

A Jaw crusher is mainly used for medium-sized crushing of various ores and bulk materials. It can crush materials with compressive strength not more than 320Mpa. There are two kinds of crushing methods: coarse crushing and fine crushing.

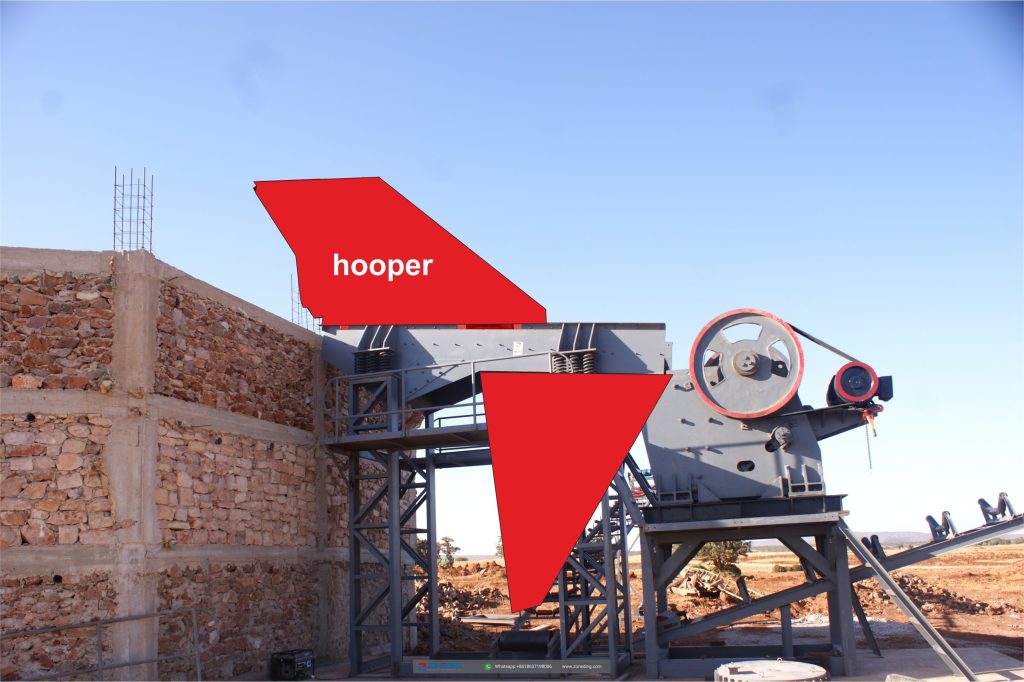

A jaw crusher is a compression-type crusher to break large, hard materials into smaller pieces. The machine has a simple structure: a fixed jaw plate and a moving jaw plate form a V-shaped crushing chamber. Material is fed into the top of the chamber, and the moving jaw squeezes it against the fixed jaw, crushing it until it is small enough to fall out of the bottom opening.

It can apply for quartz, granite, basalt, marble, calcite, dolomite, limestone, gypsum, pebble, bluestone, feldspar, glass, cement clinker, concrete, coal gangue, construction waste, copper ore, manganese ore, gold ore, iron ore, and other ores.

Jaw crusher is a new product absorbing world advanced technology, bases on our present traditional jaw crusher, and adopts three-dimensional design theory. Comparing with traditional jaw crusher, it has larger capacity and crushing ratio, bigger range of input size, evener product size, and easier maintenance.

The primary function of a jaw crusher is coarse primary crushing. This is the very first stage of size reduction. Imagine you have just blasted a rock face in your quarry. You are left with boulders that can be a meter wide or even larger. These are too big for any other type of crusher. You feed these large rocks directly into the jaw crusher mining equipment.

The jaw crusher’s job is to achieve a healthy reduction ratio, typically between 4:1 and 6:1. This means it takes a 600mm rock and turns it into a product around 100-150mm. This smaller rock is now the perfect feed size for the next stage in your circuit. Trying to get too much reduction from your jaw is a common mistake. It doesn’t create good, cubical stone. Instead, it produces long, thin, “slabby” pieces that cause major problems for your cone crushers and screens down the line. The jaw crusher is a team player; its job is to set up the rest of your plant for success.

The reason jaw crushers are so popular is because they offer a fantastic combination of power and practicality. For any plant manager, these benefits translate directly to better a bottom line.

While all jaw crushers work on the same basic principle, there are a few key types you will encounter. The main distinction is in how the moving jaw is pivoted.

Applicable Fields: Widely used in various industries, such as mining, road and railway construction, building construction,water conservation and chemical industry.

As ideal primary or secondary crusher equipment, jaw crushers with different types are often used in various industries. Depending on different ways of moving or engine, jaw crushers are divided into three types: PE/PEX Motor jaw crusher, Diesel jaw crusher, and Mobile jaw crusher.

The PE Jaw Crusher is a classic primary crusher that uses reciprocating squeezing to break materials.

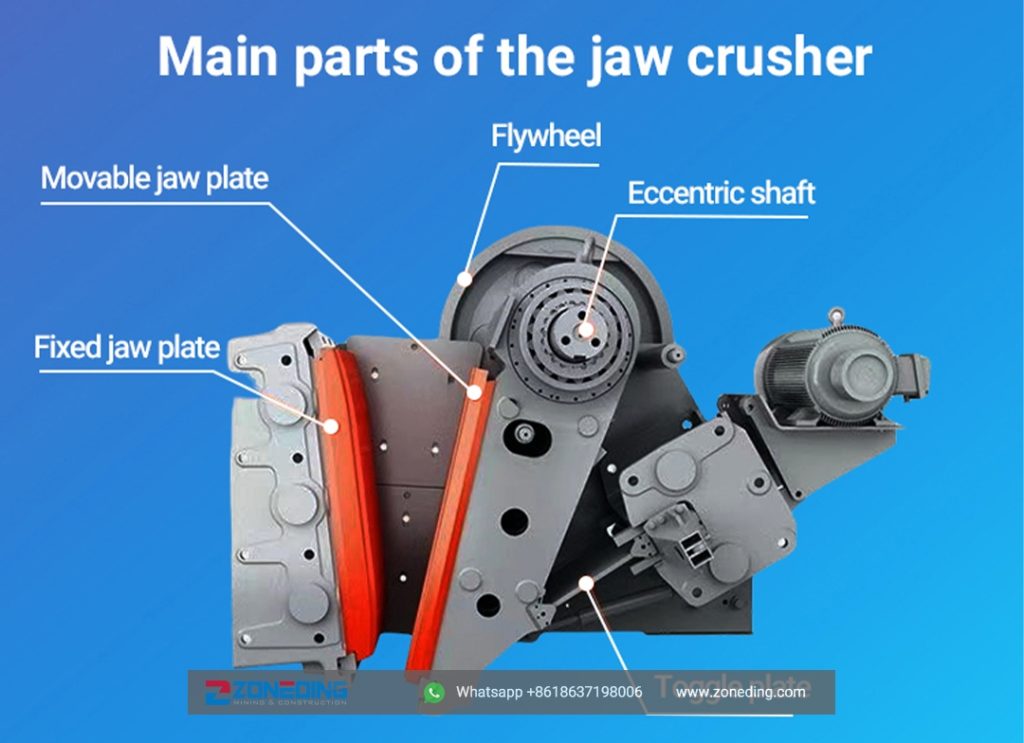

A motor drives a belt and pulley, powering an eccentric shaft that causes the movable jaw to reciprocate. During its upward stroke, the movable jaw advances towards the fixed jaw, crushing material between them through compressive forces (squeezing, rubbing, and grinding). On the downward stroke, the movable jaw retracts (assisted by a tension rod and spring), widening the gap and allowing crushed material to discharge from the bottom.

| Model | Feeder OpeningSize(mm) | Max. FeedingSize (mm) | Outlet adjustingSize(mm) | Capacity(t/h) | Motor Power(kw) | Overall Dimension(mm) |

| PE250x400 | 250×400 | 210 | 25-60 | 5-20 | 15 | 1215x1240x1210 |

| PE400x600 | 400×600 | 350 | 40-90 | 15-60 | 30 | 1700x1750x1680 |

| PE500x750 | 500×750 | 425 | 50-100 | 40-130 | 45 | 2150x1900x1950 |

| PE600x900 | 600×900 | 500 | 60-125 | 90-180 | 55 | 2500x2010x2350 |

| PE750x1060 | 750×1060 | 630 | 60-150 | 110-380 | 110 | 2630x2310x3110 |

| PE900x1200 | 900×1200 | 750 | 95-165 | 220-450 | 132 | 3720x2850x3250 |

| PE1000x1200 | 1000×1200 | 850 | 200-300 | 280-560 | 160 | 3820x2850x3250 |

| PE1200x1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 220 | 4590×3342×3553 |

| PE1500x1800 | 1500×1800 | 1200 | 210-360 | 520-1100 | 280 | 5100x4700x4300 |

The PEV jaw crusher, or European version, is an advanced, new-generation crushing unit optimized from traditional jaw crushers by integrating modern technology and production practices to deliver higher efficiency, greater stability, and more convenient operation. Its working principle is similar to traditional models, utilizing a motor-driven eccentric shaft that causes the movable jaw to periodically exert compressive forces—squeezing, rubbing, and grinding—on material against a fixed jaw, with the crushed product then discharged by gravity for mass production.

| Model | Max Input size (mm) | Discharge port size (mm) | Capacity (t/h) | Main shaft speed (r/min) | Power (KW) | Weight (t) |

| PEV400x600 | 380 | 40-80 | 20-65 | 270 | 30 | 7.02 |

| PEV500x750 | 450 | 50-100 | 45-107 | 250 | 55 | 10 |

| PEV600x900 | 500 | 60-165 | 50-160 | 235 | 75 | 17 |

| PEV750x1100 | 630 | 80-175 | 110-320 | 225 | 110 | 23.1 |

| PEV860x1100 | 700 | 70-200 | 190-336 | 210 | 132 | 26.5 |

| PEV900x1200 | 750 | 100-220 | 220-380 | 200 | 132 | 42.5 |

The PEX jaw crusher, a secondary crushing device often used for intermediate or fine crushing of smaller feed materials to produce finer products within a crushing line, operates similarly to PE jaw crushers, with a motor driving a belt and pulley system that causes the movable jaw to periodically crush material against the fixed jaw via an eccentric shaft, enabling continuous production as crushed material is discharged.

| Model | Feeder OpeningSize(mm) | Max. FeedingSize (mm) | Outlet adjustingSize(mm) | Capacity(t/h) | Motor Power(kw) | Overall Dimension(mm) |

| PEX150x750 | 150×750 | 120 | 10-40 | 5-16 | 15 | 1310x1118x1145 |

| PEX250x750 | 250×750 | 210 | 15-50 | 15-30 | 22 | 1440x1751x1515 |

| PEX250x1000 | 250×1000 | 210 | 15-60 | 15-52 | 30 | 1730x1950x1400 |

| PEX250x1200 | 250×1200 | 210 | 15-60 | 25-80 | 37 | 1730x2150x1400 |

| PEX300x1300 | 300×1300 | 250 | 25-60 | 30-105 | 55 | 2000x2320x1730 |

A mobile jaw crusher is a track or wheel-mounted crushing plant with integrated feeding, crushing, and conveying systems for direct on-site processing, eliminating extensive infrastructure needs. Its main benefits are high mobility for tight or shifting work sites, simplified installation and reduced consumption due to its integrated design, lower costs by minimizing material transport, and versatile configurations. Used widely in quarrying, mining, construction waste recycling, and infrastructure, it operates like a stationary jaw crusher, crushing material between a motor-driven movable jaw and a fixed jaw. Ultimately, it’s an efficient, convenient, and adaptable alternative to fixed crushing lines, overcoming their site and environmental constraints.

The 3 in 1 Mobile jaw crusher is an efficient solution for the processing of various materials in the mining, construction, and recycling industries. This integrated system combines three essential functions — feeding, crushing, and screening—into a single mobile unit, providing a compact and flexible approach to material processing.

The ZONEDING 4 in 1 mobile crushing plant is an innovative solution that combines four different crushing processes into a single unit. It generally includes a primary jaw crusher, secondary crusher(e.g.cone crusher and impact crusher), screening unit, and a belt conveyor, providing a complete crushing and screening solution. The 4 in 1 design minimizes the need for multiple machines, saving space and reducing operational costs.

The track system offers excellent maneuverability, making the track mounted jaw crusher to navigate rough terrains and tight spaces with ease. Equipped with a jaw crusher machine for sale, track crusher delivers impressive crushing force, making it effective for various materials, especially for construction waste.

| Model | ZDM938HD80 | ZDM1149HD98 | ZDM1349HD110 | ZDM1349HD125 |

| Transportation Length(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Length(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dual-axial | Dual-axial | Dual-axial | Dual-axial |

| Jaw Crusher | HD80 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge Opening Size(mm) | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Model | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5M | B1000×9.5M | B1000×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3M | B650×3.5M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 200 | 250 | 270 | 400 |

| Iron Separator (Optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

Deciding between single jaw crusher machine or mobile jaw crushing plants is simple; it mainly depends on whether frequent relocation is required. In addition, for some applications, the jaw crusher equipment can not only be used alone, but also combined with other kinds of crushing equipment to achieve a more efficient production process. You can combine primary jaw crusher for sale with impact crusher, cone crusher and other equipment to form a crushing production line to improving the overall crushing effect and production capacity. Next, let’s explore take a deeper look at the application of jaw crusher in crushing production line.

From stationary setups in mining quarries to mobile units on urban construction sites, jaw crusher application proves its reliability across every crushing projects. Whether paired with cone crushers for secondary cone crushers or impact crushers for shaping aggregates, jaw crushers consistently deliver the robust primary crushing performance your operation demands.

Ready to optimize your crushing plant with the right jaw crusher? Whether you’re processing granite for a highway project or recycling concrete on-site, choosing the ideal machine is crucial. In the next section, we’ll guide you through how to select a suitable jaw crusher. More technical details and performance factors need to be considered Let’s find the perfect fit for your crushing needs!

If you plan to buy jaw crusher China for business, it is necessary to consider a lot of things ahead, such as capacity, feeding size, discharge aggregate size, applications, mobility, prices, service, returns, etc.

Worth mentioning, among these factors, the importance of service cannot be overstated. A reliable jaw crusher supplier that offers strong support and communication can significantly enhance the efficiency and longevity of your equipment. This is particularly vital in the mining sector, where customized solutions and ongoing assistance are key to success. In the following section, I will introduce what ZONEDING jaw crusher company can do for you regarding service, ensuring you get the most out of your investment.

ZONEDING’s service is truly the icing on the cake, providing invaluable support to you. However, what truly sets us apart is our unwavering commitment to crusher plant quality and performance. You can rest assured that our jaw crushers for sale are built to the highest standards, ensuring reliability and efficiency in your operations. In the following section, you can discover more about the distinctive features of ZONEDING jaw crushers.

Many people think a jaw crusher slowly squeezes rock. That is not entirely correct. A well-run jaw crusher is more like a percussion instrument than a press. The crushing action happens in a very short, violent “snap.” This is powered by the eccentric shaft, which is rotated by a large electric motor. As the shaft turns, it forces the moving jaw (called a pitman) to swing towards the fixed jaw.

The real secret to its power is the large flywheel. This heavy wheel stores kinetic energy from the motor for about 90% of its rotation. Then, it releases all that stored energy in an instant to deliver the crushing blow. This is why the V-belts connecting the motor to the flywheel are so critical. If they are loose or worn, the flywheel can’t get fully “charged,” and the crusher loses its punch. Your motor will draw a lot of power, but your production will drop. Understanding that it works through impact and energy release, not just pressure, is key to operating it efficiently.

Many people think a jaw crusher slowly squeezes rock. That is not entirely correct. A well-run jaw crusher is more like a percussion instrument than a press. The crushing action happens in a very short, violent “snap.” This is powered by the eccentric shaft, which is rotated by a large electric motor. As the shaft turns, it forces the moving jaw (called a pitman) to swing towards the fixed jaw.

When the jaw crusher is working, the motor starts the V-belt and pulley, and then drives the eccentric shaft to make the movable jaw plate move up and down. The movable jaw plate squeezes and grinds the materials, and the crushed stones gradually fall down. When the particle size meets the requirements, they are discharged by the jaw crusher.

The versatility of the jaw crusher means you will find it in many different industries. Its ability to handle large, abrasive materials makes it essential for primary size reduction.

| Application Area | How Jaw Crushers are Used | ZONEDING Solution |

|---|---|---|

| Mining | For the primary crushing of hard ores like iron, copper, gold, and manganese ore right at the mine site. | Our heavy-duty PE series mining jaw crusher is designed to withstand the high abrasion of mineral ores. |

| Aggregates | Crushing large quarry rock like granite, basalt, and limestone to produce aggregate for concrete and asphalt. | We provide complete stationary and mobile crushing lines for aggregate producers of all sizes. |

| Construction Waste Recycling | Breaking down demolished concrete, bricks, and asphalt into reusable aggregate. | This is a special case. For concrete with rebar, you need a jaw crusher with a hydraulic release system. A standard crusher will jam. ZONEDING offers specialized recycling models that can let rebar pass through in minutes, not hours. |

| Cement Production | The initial crushing of limestone and other raw materials before they go to the raw mill. | Our crushers are a key component in the cement production lines we design and supply. |

A rock jaw crusher is designed to be tough. It can handle a huge variety of materials, making it a flexible first step in any processing plant.

The key is to match the crusher’s specifications, especially the type of manganese steel used in the jaw plates, to the material you are processing. For very abrasive materials, you need a higher manganese content (e.g., Mn18Cr2) to ensure a reasonable wear life. Our engineers at ZONEDING will help you select the right configuration for your specific rock type.

Understanding the main jaw crusher parts helps you operate and maintain it better. While the design is simple, each component has a critical role.

The price of a Jaw Crusher can vary immensely, making it impossible to give a single definitive figure. It depends on a multitude of factors, ranging from a few thousand dollars for a small lab-scale unit to over a million dollars for a large, high-capacity mobile setup.

Buying a jaw crusher is a major investment. Rushing this decision can lead to years of operational headaches. Here are the most important things our engineers advise clients to consider:

Selecting the right size is about matching the crusher’s capacity to your plant’s target Tons Per Hour (TPH).

The parts that are in direct contact with the rock will wear out and need to be replaced. Budgeting for these is a normal part of operations. The main wear parts are:

A critical point that many operators miss is the condition of the jaw plate seats. This is the machined surface on the frame and pitman where the jaw plates sit. If you run your jaw plates until they have holes in them, the rock will start to wear away these seats. When you install new plates, they won’t sit flat. They will crack and fail very quickly. You must change your jaw plates before they are completely worn through to protect the expensive components behind them.

When you choose a jaw crusher from ZONEDING, you are getting more than just a machine. You are getting a complete solution backed by decades of engineering experience.

We are the manufacturer, not a trader. We build our jaw crushers in our own 80,000-square-meter factory. This means we have full control over quality, from the raw steel to the final coat of paint. This factory-direct model also means we can offer you a more competitive price by cutting out the middleman.

Our team of 15 engineers doesn’t just sell you a standard model. We work with you to understand your rock, your site, and your goals. We then customize a solution, optimizing the crushing chamber and selecting the right manganese alloys for your specific application. With products exported to over 120 countries, we have the global experience to ensure your project is a success. From design and manufacturing to installation and after-sales support, we are your long-term partner in crushing.

Cone Crusher For Sale: Highly efficient, stable and durable, ideal for all ore crushing needs. It can improve production efficiency and reduce operating costs.

High-efficiency VSI sand making machines for producing premium artificial sand from rock & gravel. Excellent particle shape, low wear cost.

PF Series Impact Crusher for secondary crushing of limestone, rock, and efficient recycling of concrete & asphalt. High throughput, excellent shape. Get Specs!

Looking for a high-performance Vibrating Feeder? Explore our durable industrial feeding machines for mining & aggregate plants.

Sand Washing Machines (Wheel & Spiral types) to remove impurities & improve sand quality for construction & industry. High cleanliness, reliable performance. Get Your Quote!

The YK series circular vibrating screens are high-performance and suitable for heavy-duty quarrying and aggregate screening operations. Multi-layer screen options are available for precise grading.

Smooth Roll Crushers for finer sizing or Toothed Roll Crushers for better grip on materials like coal & shale. Reliable, low maintenance crushers for various industries.

Looking for a high-efficiency fine crusher? Explore our industrial fine crushing machines for sale. Factory-direct pricing and large capacity.

Compound Crushers (Vertical Shaft) for efficient fine crushing of medium-hard materials like limestone & clinker. Simple structure, high ratio, ideal for sand making & aggregate. Get Quote!

Looking for a high-performance Hammer Crusher? Our heavy-duty machines offer large crushing ratios and stable operation. Get your factory-direct quote today!

loading…

已经是到最后一篇内容了!