Search the whole station Crushing Equipment

Fine crusher is also called tertiary crusher, which adopts the principle of “stone hit stone” to crush materials. It upgrades the traditional three crushing stages to the two crushing stages.

A Fine Crusher is a type of machine applying in the final stage of crushing. Its purpose is to take stone that has already been crushed once or twice and reduce it to small, uniform sizes, like sand or fine gravel. We often call it a Sand Making Crusher. But its real secret is not just making things small. It is about creating a perfect particle size distribution. This means you get the right blend of coarse sand, fine sand, and micro-fines. This blend reduces empty spaces in your concrete mix, leading to stronger blocks with a better finish.

Using a high-quality fine crusher brings many benefits to your operation. The most important advantage is product quality. The machine produces aggregates with a cubical shape. This shape is much better for concrete than flaky or elongated particles. Cubical particles lock together better, making your final product stronger.

Another big advantage is the control over “fines,” which are tiny particles smaller than dust. Many people think these fines are a problem. But in block making, they are a feature. A controlled amount of these micro-fines acts like tiny ball bearings in your concrete mix. This helps the concrete flow better into the molds. It also fills the smallest gaps, giving you a denser block with a very smooth surface. This is a key feature of our ZONEDING machines. We design them to help you control the amount of fines you produce.

The fine crusher is suitable for grinding and processing in metallurgy, building materials, chemical, mining, railway, water conservancy and other industries. It applys before the ball mill to increase the production efficiency of the ball mill by 50%.

The Aggregate Crusher is essential in many industries. Its main use is in creating high-quality M sand for concrete and asphalt. It is a key part of any modern Sand Production Line. You will also find it in mining operations to process minerals.

Standard crushers make dangerous, sharp glass shards. We used a special fine crusher, a Vertical Shaft Impactor (VSI), to make the glass particles hit each other. This rounded their edges and created a beautiful, safe glass sand. They used this sand to make high-end architectural pavers that sold for a premium price. This shows how a fine crusher can turn waste into value.

It is especially suitable for fine and medium crushing of materials with hardness below 9 such as quartz, feldspar, calcite, marble, ceramics, iron ore, copper ore, gangue, phosphate rock, granite, basalt, silicon carbide, corundum, insulation materials and other brittle materials.

The type of material you crush directly impacts the machine’s wear parts. For harder, more abrasive materials like granite, you need tougher parts to avoid constant replacements.

The working principle depends on the type of fine crusher. The two most common types are Vertical Shaft Impactors (VSI) and high-speed hammer mills. In a VSI, the stone is fed into the center of a rapidly spinning rotor. The rotor throws the stone outwards at high speed. The stone then smashes against other rocks in the crushing chamber. This is “rock-on-rock” crushing. It is very effective at creating a good cubical shape.

In a hammer mill or Impact Crusher For Sand, the stone is hit by hammers that are spinning on a rotor. The stone shatters upon impact and is thrown against liner plates inside the machine for further size reduction.

Once the crushing process is complete, the crushed materials are expelled or belched out of the machine.

1.High crushing efficiency. The use of grate plate, rigid hard extrusion crushing and solid rotor body greatly improve the crushing efficiency.

2.Good crushing effect. The fine crusher can arbitrarily control the discharging size of materials, so the required material size can reach more than 95% and ideal material size control and classification can be realized.

3.Small wear parts wearing. Compared with hammer crushers and impact crushers, it only wears the hammerhead, while the wheel core and hammer frame have no wear.

4.Simple installation. It is light in weight, diverse in installation (removable installation) and easy to operate.

5.Convenient maintenance. It only needs to lift the upper case and open the lowercase during maintenance. A person can complete a comprehensive inspection and maintenance of the whole machine within 20 minutes with a wrench.

6.Timely discharging. Three discharging channels are adopted to discharge qualified materials in time.

7.Adjustable discharging. The discharging granularity of the fine crusher can be adjusted, and the adjusting plate can be turned over at both ends.

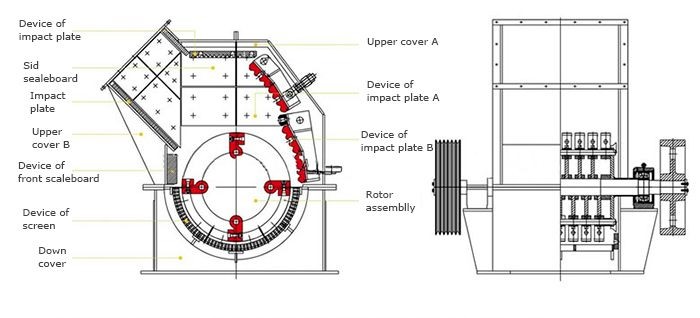

The fine crusher key components are mainly the rotary part, guard plate and box part.

Some non-overlapping hammer carriers are arranged on the wheel core of the rotary part. The hammer head, whose width is larger than the hammer carrier and the wheel hub, is fixed on the hammer carrier. The wheel core is composed of several wheel hubs, which are fixed on the main shaft. The two ends of the main shaft are supported on the frame with rolling bearing seats.

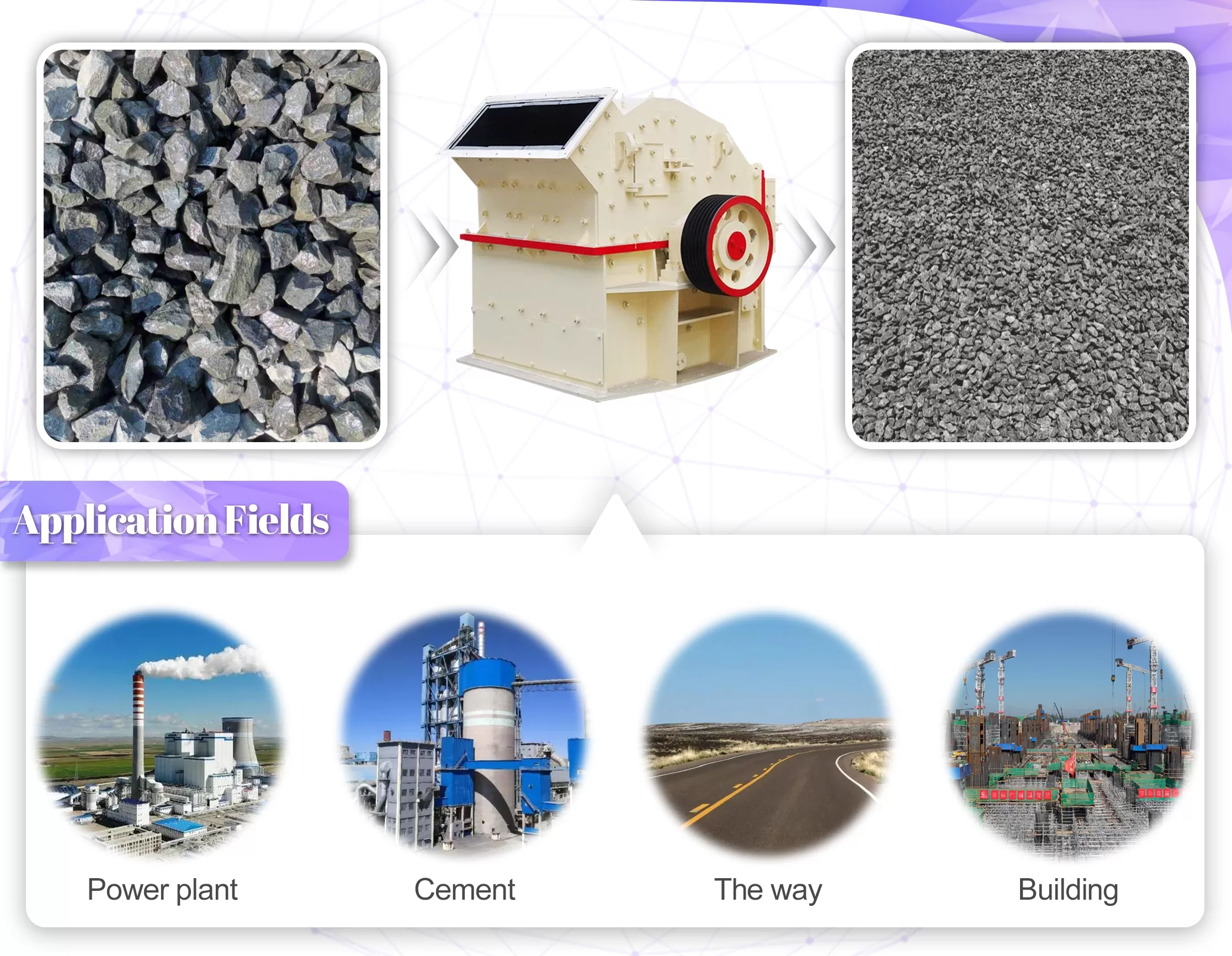

Comparison of Materials before Crushing and After Crushing by Tertiary Crusher

A fine crusher has several key components that work together. Understanding these parts helps with operation and maintenance. The main parts are:

At ZONEDING, we build our fine crushers to solve real-world problems. Our machines are not just powerful; they are smart and durable. We focus on features that increase your uptime and lower your operating costs. For example, the rotors in our crushers are dynamically balanced with extreme precision. This prevents the destructive vibrations that can destroy bearings and crack the machine’s frame.

We also use advanced materials for our wear parts. We offer high-chromium iron and tungsten carbide options. These parts cost more initially but last much longer, saving you money on downtime and replacements. Our crushers also come with options for a Variable Frequency Drive (VFD). This lets you adjust the rotor speed easily, giving you total control over your final product size and shape.

Choosing the right fine crusher is about more than just the machine. You must think about your whole system. I always tell clients that feeding a fine crusher with bad material is a costly mistake. The machine needs a consistent feed size to work properly. This is why a fine crusher should always be part of a closed-circuit system with a screen.

The screen separates the correctly sized material. Any oversized particles are sent back to the crusher for another pass. This process guarantees a consistent, high-quality output. When you talk to us at ZONEDING, we don’t just sell you a machine. We help you design the entire system to ensure you get the best results and avoid common operational problems.

The most powerful tool you have to control your final product is the rotor speed. The speed changes the amount of energy that hits the rock. It is a simple concept with a huge impact.

An experienced operator uses a Variable Frequency Drive (VFD) to fine-tune the rotor speed. They adjust it based on the rock’s hardness and the exact product they need to make. This level of control is essential for any high-specification operation.

The purchase price of a fine crusher can range from $20,000 for a Small Stone Crusher to over $200,000 for a large, high-capacity VSI. The price depends on the size, brand, and features. But the initial cost is only a small part of the story. The real cost of owning a crusher is in the wear parts.

Fine crushers are tough on their wear parts like hammers and liners. Buying the cheapest replacement parts is a big mistake. They wear out quickly, leading to constant production downtime. We advise our clients to calculate the cost per ton of material produced. High-quality wear parts, like those made from high-chromium iron or tungsten carbide, may cost more upfront. But they can last many times longer. This drastically reduces downtime and lowers your true operating cost.

Proper maintenance is critical for a high-speed machine like a fine crusher. The biggest enemy is vibration. Even a small imbalance from uneven wear can create huge vibrations. These vibrations will destroy your main bearings and can even crack the machine’s housing. We strongly recommend installing a vibration sensor with an automatic shutdown switch. It is a cheap insurance policy against a major failure.

Your daily routine should include checking the inside of the rotor for any caked material, as this can cause imbalance. Also, follow a strict lubrication schedule for the bearings. After you replace any wear parts like hammers, the entire rotor must be re-balanced professionally. A few hours of proper maintenance can save you tens of thousands of dollars in repairs.

| PXJ tertiary impact crusher | Rotorø×Width (mm) | |||||||

| Specification | 800×400 | 800×600 | 800×800 | 1010×1010 | 1200×1200 | 1400×1400 | 1600×1600 | 1800×1800 |

| Feed opening size(mm) | 400×185 | 500×250 | 550×300 | 1000×350 | 1200×450 | 1500 | 1600×550 | 1800×800 |

| Feeding size (mm) | <120 | <180 | <180 | <180 | <180 | <190 | <190 | <190 |

| Discharging size (mm) | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 |

| Adjustable range of discharge opening (mm) | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 |

| Cement Clinker(t/h) | 10-30 | 1040 | 20-45 | 25-55 | 35-90 | 50-150 | 85-210 | 125-270 |

| Limestone(t/h) | 18-45 | 23-55 | 28-65 | 35-75 | 45-110 | 50-150 | 95-260 | 140-310 |

| Power(kw) | 4P 37KW | 4P 45KW | 4P 45KW | 4P 55KW | 6P 110KW | 6P 160KW | 4P 250KW | 4P 315KW |

| Theoretical weight | 3.9 | 4.5 | 6 | 10.5 | 14.4 | 22 | 35 | 49.7 |

What is the difference between a primary and a fine crusher?

A primary crusher, like a jaw crusher, handles very large rocks directly from the quarry. A fine crusher is a secondary or tertiary machine that takes smaller rocks and turns them into sand or fine aggregate.

Can a fine crusher produce different sizes of sand?

Yes. By adjusting the rotor speed and other settings, you can control the particle size distribution and produce different grades of sand, from coarse to fine.

How often do I need to change the wear parts?

This depends entirely on the type of rock you are crushing and your daily production volume. For abrasive rock like granite, you might inspect parts daily. For softer limestone, it might be weekly.

Is a VSI crusher better than a cone crusher for making sand?

A VSI is generally better for producing highly cubical sand, which is ideal for concrete. A cone crusher is very efficient but may produce a more angular particle, depending on the model and application.

Reliable Jaw Crushers for efficient primary crushing in mining, quarrying & aggregate production. Heavy-duty design, high throughput.

Cone Crusher For Sale: Highly efficient, stable and durable, ideal for all ore crushing needs. It can improve production efficiency and reduce operating costs.

High-efficiency VSI sand making machines for producing premium artificial sand from rock & gravel. Excellent particle shape, low wear cost.

PF Series Impact Crusher for secondary crushing of limestone, rock, and efficient recycling of concrete & asphalt. High throughput, excellent shape. Get Specs!

Looking for a high-performance Vibrating Feeder? Explore our durable industrial feeding machines for mining & aggregate plants.

Sand Washing Machines (Wheel & Spiral types) to remove impurities & improve sand quality for construction & industry. High cleanliness, reliable performance. Get Your Quote!

The YK series circular vibrating screens are high-performance and suitable for heavy-duty quarrying and aggregate screening operations. Multi-layer screen options are available for precise grading.

Smooth Roll Crushers for finer sizing or Toothed Roll Crushers for better grip on materials like coal & shale. Reliable, low maintenance crushers for various industries.

Compound Crushers (Vertical Shaft) for efficient fine crushing of medium-hard materials like limestone & clinker. Simple structure, high ratio, ideal for sand making & aggregate. Get Quote!

Looking for a high-performance Hammer Crusher? Our heavy-duty machines offer large crushing ratios and stable operation. Get your factory-direct quote today!

loading…

已经是到最后一篇内容了!