Search the whole station Crushing Equipment

Three drum Dryer is an improved version based on a single drum dryer with advanced German technology, mainly composed of three concentric circles, and is used to dry granular materials with certain moisture and particle size.

three-drum dryer is also known as a three-cylinder dryer or a three-drum dryer. It is an improved version based on a single drum dryer and is supported by modern and advanced German technology. The three-cylinder dryer is mainly composed of three concentric circles of different diameters. Compared with the traditional drum dryer, the three-drum dryer has better sealing technology and is equipped with a more scientific machine. This dryer is usually used to dry granular materials with a certain moisture and a certain particle size range. For example, a three-drum dryer can be used to dry clinker, sand, molding sand, slag, cinder, fine-grained clay, high-temperature resistant and dusty particles.

A three drum dryer is an industrial drying machine. It has three concentric, nested rotating drums. The material you are drying travels back and forth three times inside these drums. This long path maximizes the contact time between your material and the hot gases. This allows the burner’s heat to be used very efficiently.

You must understand this machine is not one simple unit. It is actually three different drying processes forced to work together. It is like a three-act play. If one actor misses their cue, the entire performance fails. This interconnected design makes controlling the process complex. One small problem can quickly shut down the entire system. We believe it is crucial for you to understand this inner complexity before you invest. This is because the operational reality is very different from the sales brochure.

The three drum dryer is used in industries where space is very limited but high throughput is still required. It is also chosen for drying materials that are not sticky or abrasive. Its high thermal efficiency makes it appealing for drying large volumes of uniform material.

Good applications include clean sand for construction or glass making. It is also used for sawdust or wood fibers for pellet production. In these cases, it functions as a very effective industrial sand dryer or biomass dryer. The key is that the material must be very free-flowing and have a consistent particle size. For these specific materials, a triple pass dryer can be an elegant solution. But its application range is very narrow. Many materials will cause serious operational problems inside this complex machine.

Three-drum dryer is widely used in building materials industry, metallurgical industry, mineral processing industry, chemical industry, cement and other industries. It is suitable for the drying of various granules and powders in the above industries. After drying, the humidity of the material can reach below 1%. Some application examples of three-drum dryers:

You might need a three drum dryer for two main reasons. The first and most important reason is a lack of space. The machine’s design offers the drying capacity of a single-pass dryer three times its length. This makes it a powerful compact industrial dryer. If your factory floor is small and expensive, this can be a major benefit.

The second reason is the promise of lower fuel bills. Because the hot gases make three passes over the material, very little heat is wasted. The exhaust gas temperature is very low. This means the thermal efficiency is very high. In theory, this leads to significant fuel savings over the machine’s life. However, this high efficiency is fragile. It depends on perfect operation. Leaky seals or internal blockages can destroy these savings instantly. You need to weigh the potential fuel savings against the much higher risk of expensive downtime and complex maintenance.

The structure of a three drum dryer consists of three steel cylinders nested inside one another. The inner drum sits inside the middle drum. The middle drum sits inside the outer drum. All three drums rotate together as a single unit. They are supported by large steel tires and trunnion wheels.

The most critical parts of the structure are hidden inside. These are the internal supports that hold the drums apart. Also critical are the “crossover chutes” or scuppers. These are the channels that move the material from one drum to the next. These crossover chutes are the system’s Achilles’ heel. I have seen countless failures right at these points. Any sticky or oversized particle gets caught here. The buildup grows with every rotation until it forms a solid dam. This causes a clog that can shut down your entire operation for days of difficult, manual cleanout.

Compared with traditional dryers, three-drum dryers have obvious advantages;

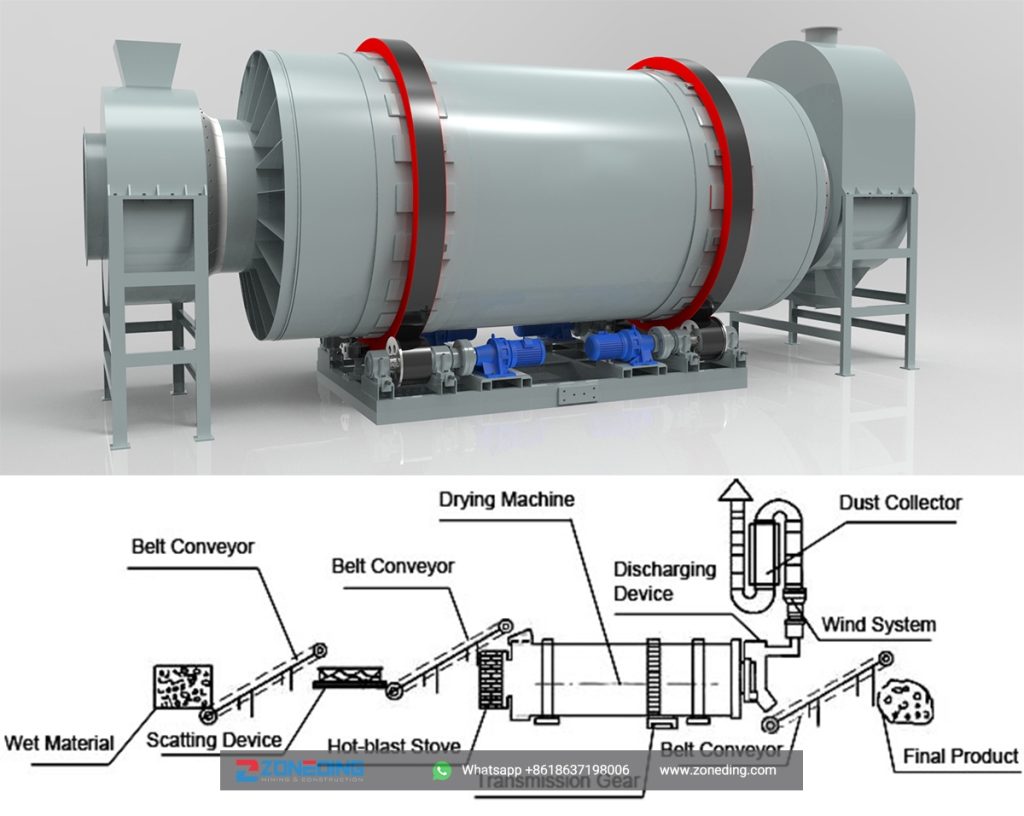

Radiation, convection, and heat conduction are mainly used in the drying process. The dryer is set at an angle to take advantage of gravity. When the hot air in the oven reaches the set temperature, the dryer works according to the order of the PC system. The wet pellets are then evenly fed into the inner layer by the feeder and carried away by the gale. The wet material is spirally conveyed through the fixed shovel plate. Next, the material moves to the other end of the oven and into the middle layer. This time, the wet powder inside leaned against the blower and moved forward, taking two steps back.

In the middle layer, the heat from the inner and middle layers is fully utilized, which increases the drying efficiency to the optimum. Finally, the dried material reaches the other end of the middle layer and enters the outer layer in a rectangular and multi-loop pattern. Drying to solidify the moisture of the granular material is blown out of the dryer. The rest move more slowly due to their weight and dry again in the outer layer to the desired humidity. In this way, the drying process is realized.

Working Principle of Three-Cylinder Dryer

The triple pass rotary dryer working principle is based on a long, folded material path. First, your wet material enters the centermost, inner drum. Here, it is exposed to the hottest gases from the burner. This first pass flashes off the easily removed surface moisture.

Next, the material reaches the end of the inner drum and falls through crossover chutes into the middle drum. Now it travels in the opposite direction, back toward the burner. The temperature is lower here. This pass allows the stubborn moisture trapped inside the particles to migrate to the surface.

Finally, the material drops through a second set of chutes into the outermost drum. It travels a third time toward the discharge end. Here, the coolest gases remove the last bit of moisture. The finished, dry product then exits the machine. This complex journey allows for very efficient heat transfer, but only if the material flows perfectly.

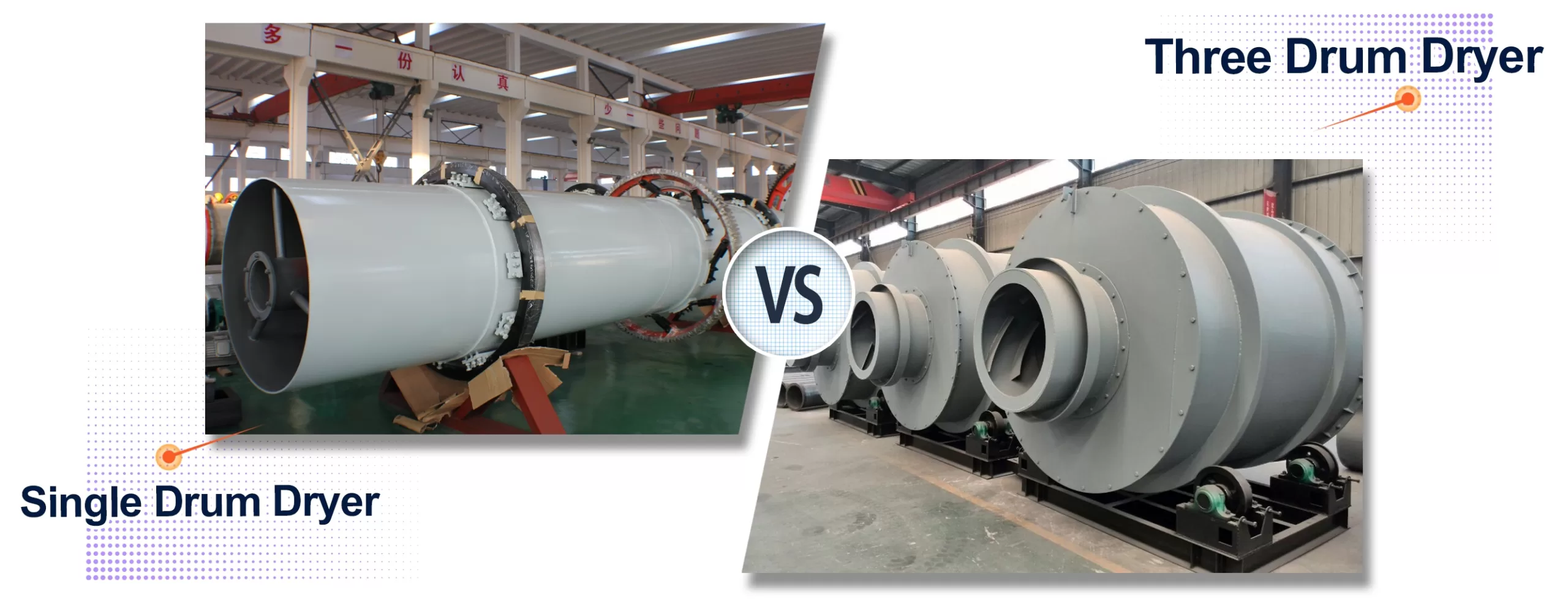

The main differences are in simplicity, cost, and reliability. This three drum dryer vs single drum dryer comparison is crucial for your investment decision. A single drum dryer is simple and robust. A three drum dryer is complex and delicate.

A single drum dryer has one large, long shell. The material flows in a straight line from one end to the other. Maintenance is simple. You can easily access any part of the interior for cleaning or repairs. A single drum dryer is a workhorse. It can be a 40-year asset for your plant.

A triple pass dryer is like a ship in a bottle. Everything is nested. To access the middle drum, you must first remove the inner drum. A simple bearing replacement can become a multi-day ordeal requiring specialized rigging crews. The true cost is not the purchase price; it is the cost of specialized downtime. A single major repair on a three-drum machine can cost 3 to 5 times more than the same repair on a single drum dryer. This often wipes out any fuel savings you might have gained.

You must be very careful when choosing a material for a three drum dryer. This machine demands a perfectly free-flowing, non-abrasive material with a uniform particle size.

Good Materials:

Bad Materials (You should avoid using a three drum dryer for these):

The price of a three drum dryer system can range from $400,000 to over $4,000,000. The final cost depends on the capacity you need and the quality of construction. A higher price often reflects the use of thicker steel and better welding techniques. This is critical to resist the immense thermal stress that causes metal fatigue.

A cheaply built three-cylinder dryer manufacturer might offer a lower initial price. But that machine is a ticking time bomb. The internal supports will crack from the constant heating and cooling cycles. This leads to catastrophic failure. We advise our clients to focus on the total cost of ownership. A well-built machine from a reputable manufacturer like ZONEDING will have a higher purchase price but much lower lifetime costs due to its durability and reduced downtime.

There are types of drum dryers, such as single drum dryers, double drum dryers, triple drum dryers, and air dryers. It’s always confusing for customers to make decisions. Take a single-drum dryer and a three-drum dryer as an example to clarify how to choose the right dryer.

| Single Drum Dryer | Three Drum Dryer | |

| Diameter of Outer Cylinder(m) | 1.2-3.6 | 2.5-3.6 |

| Length(m) | 8.0-28.0 | 7.0-8.0 |

| Volume(m3) | 9.0-285.0 | 16.63-81.38 |

| Capacity(T/H) | 1.9-76.0 | Yellow Sand: 25-70Slag: 20-65 |

Three-Drum Dryer VS Single-Drum Dryer

Choosing the right three drum dryer means looking past the sales brochure. You must act like an experienced engineer.

Maintaining a three drum dryer is difficult and requires a specific, disciplined approach. You must treat this machine as a 15 to 20-year consumable asset, not a permanent fixture.

At ZONEDING, we prioritize reliability and long-term value. We build our three drum dryers to overcome the common failure points we have seen in other designs.

When you choose ZONEDING, you are not just buying a machine. you are gaining a partner for the life of your operation. We provide complete support.

| Item/Unit/Model | Φ2.5×7m | Φ2.7×7m | Φ3.0×7.0m | Φ3.2×7.0m | Φ3.6×8m |

| Diameter of outer cylinder(m) | 2.5 | 2.7 | 3.0 | 3.2 | 3.6 |

| Length of outer cylinder(m) | 7 | 7 | 7.0 | 7.0 | 8 |

| Cylinder volume( m³ ) | 16.63 | 16.63 | 52.678 | 52.678 | 81.38 |

| Rotating speed of cylinder(rpm) | 4-10 | 4-10 | 4 -10 | 4 -10 | 4 -10 |

| Initial moisture of slag(%) | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 |

| Final moisture of slag(%) | 1 | 1 | 1 | 1 | 1 |

| Initial moisture of yellow ground(%) | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 |

| Final moisture of yellow ground (%) | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 |

| Highest intake air temperature(℃) | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ |

| Production capacity(T/h) | Yellow sand:25-30 Slag: 20-25 | Yellow sand:30-35 Slag:25-30 | Yellow sand:35-40 Slag:30-35 | Yellow sand:45-50 Slag:35-40 | Yellow sand:65-70 Slag:60-65 |

| Motor type | Y2-132m-4E | Y2-132m-4E | Y2-160m-4 | Y2-160m-4 | Y2-160m-4 |

| Motor power(kw) | 7.5×2 | 11×2 | 7.5×4 | 7.5×4 | 15×4 |

| Reducer type | XWD7-23-11W | XWD7-23-11W | XWD6-23-7.5KW | XWD6-23-7.5KW | XWD8-23-15KW |

| Velocity ratio of reducer | 29 | 29 | 29 | 29 | 29 |

Is a three drum dryer always more fuel-efficient?

In theory, yes. In practice, its efficiency is very fragile. A small air leak or a minor internal clog can make it less efficient than a simple single drum dryer. Consistent, real-world efficiency often favors simpler designs.

What is the best material for a triple pass dryer?

The ideal material is clean, dry, uniform silica sand. It flows like water and is not abrasive or sticky. This allows the machine to operate close to its theoretical design performance. Most other materials introduce complications.

How do I prevent clogs in my three drum dryer?

You must have a very strict material quality control program before the dryer. You must also commit to a rigorous schedule of internal inspections and manual cleanouts, even when the machine seems to be running well.

Can a single drum dryer be as efficient?

A well-designed single drum dryer with good insulation, modern seals, and a heat-recycling system can achieve very high thermal efficiency. It may not match a perfect three-drum system on paper, but its real-world, year-over-year efficiency is often higher due to its superior uptime and reliability.

Buy industrial gypsum dryer for sale. Efficiently remove moisture from gypsum rock & powder. Improve product quality & processing speed.

Rotary cooler for sale. Efficiently cool hot materials discharged from kilns & dryers. Improve process speed & material quality.

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Find high-efficiency sludge dryers for sale. Reduce sludge volume, cut disposal costs, and improve handling. Ideal for municipal & industrial applications.

Discover high-performance aggregate and sand dryers for sale. We offer triple-pass and rotary drum models for efficient moisture removal. Get a quote today!

Purchase an industrial bentonite dryer suitable for various applications such as drilling mud, cat litter, and foundry work. Achieve optimal moisture content and uniform drying.

Specialized Coal Dryer machines for power generation, coking, and briquetting. Improve fuel efficiency, reduce transport costs & enhance combustion.

Professional slurry dryer manufacturer with CE/ISO certification. Customizable 5-50t/h capacity, 35% energy saving. Get instant technical specs download.

Professional slag dryer manufacturer with CE/ISO certification. Energy-saving 30%, global delivery to 50+ countries. Get custom solutions for mining waste processing.

This mineral powder dryer is specifically designed for use with mineral concentrates, iron ore powder, and metallurgical slag. It ensures uniform drying, improving product quality and recovery rates.

loading…

已经是到最后一篇内容了!