Search the whole station Crushing Equipment

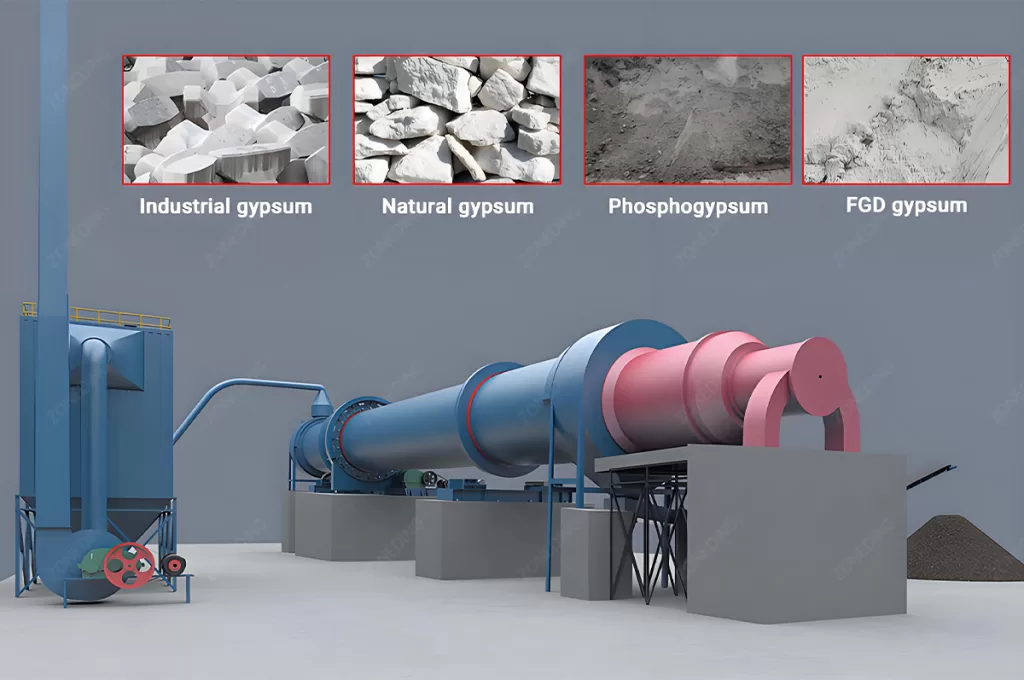

ZONEDING MACHINE focuses on material processing equipment manufacturing. Post-processing gypsum is often wet and difficult to handle. Our Gypsum Dryer is an efficient drying solution, bringing your gypsum to quality standards and making it ready.

Gypsum comes from natural sources. It also comes as a byproduct from industrial processes. Two common types are FGD gypsum (from cleaning power plant exhaust) and phosphogypsum (from making fertilizer). These types are often very wet. They can hold a lot of water. You cannot use gypsum with high moisture content for most applications.

For example, if you make plasterboard, you need dry gypsum. Wet gypsum makes the board weak. It does not set correctly. If you use gypsum for cement production, moisture causes problems. It can affect the grinding process. It can change the final cement quality. If you sell gypsum as a product, customers expect it to be dry. Wet gypsum is heavier. You pay more to transport water you do not need. It is harder to handle and store. It can freeze in cold weather. It can get moldy.

More importantly, water in gypsum affects its chemistry when you heat it later. Gypsum is calcium sulfate dihydrate (CaSO₄·2H₂O). It has two water molecules. When you heat it to make plaster (like Plaster of Paris), you remove some or all of this chemically bound water. This process is called calcination. It is done at specific temperatures. If the free water (moisture) is still there, it takes a lot of energy to evaporate it first. This wastes fuel. Also, the extra water vapor can make temperature control difficult during calcination. This can lead to uneven heating. It can cause the gypsum to dehydrate incorrectly. This gives you a lower quality product. It might not set properly. It might be weaker. You need to remove the free moisture efficiently before calcination. Drying gypsum is the first step to making a good final gypsum product. It saves you money on transport and processing later. It ensures your product meets quality standards. It makes handling easier.

There are different machines you can use to dry gypsum. The best type depends on the gypsum source, how wet it is, how much you need to dry, and what final moisture content you need. One common type is the Rotary Dryer. This is a long, rotating cylinder. It is set at a small angle. Wet gypsum enters one end. It moves through the cylinder as it turns. Hot air passes through the cylinder at the same time. The hot air heats the gypsum. The water in the gypsum turns into vapor and is carried away by the air.

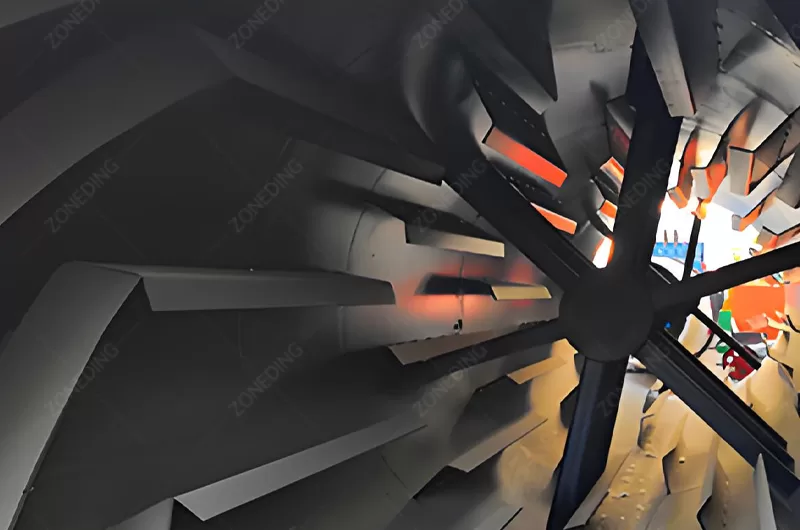

Rotary dryers are popular for many materials because they can handle large amounts of material continuously. They mix the material well as it tumbles inside. This helps the hot air touch all the particles. For gypsum, especially sticky types, the design inside the rotary dryer is very important. Special structures called lifters or flights lift the material and drop it through the hot air stream. This increases the contact area. It helps drying happen faster.

Other types of dryers exist too. Fluidized bed dryers use hot air blown up through a bed of material. The air lifts the particles. The material acts like a boiling liquid. This gives very good contact between air and particles. They are good for fine materials. Flash dryers dry material very quickly by mixing wet material into a stream of hot air. The particles are carried along with the air. This is also good for fine, light materials. However, for sticky, lumpy, or high-moisture gypsum like FGD or phosphogypsum, the tumbling action of a Rotary Dryer is often better. It helps break up lumps. It moves the sticky material along without clogging. So, while other dryers exist, the Rotary Gypsum Dryer is a common and effective choice, especially for certain types of gypsum.

FGD gypsum and phosphogypsum are known for being wet and sticky. They are industrial byproducts. Their properties can be different from natural gypsum. They often have fine particles. They hold a lot of moisture. This stickiness makes drying difficult in a standard dryer. The material can clump together. It can stick to the inside of the dryer drum. This causes blockages. It reduces drying efficiency. It means you have to stop the dryer often to clean it. This costs you time and money.

Drying these sticky types of gypsum needs special design and operation. A standard single-pass Rotary Dryer can work, but it needs specific features. The inside of the drum is key. The lifting flights (lifters) must be designed not just to lift the material but also to help break up clumps and prevent sticking. The angle and shape of these flights matter a lot. For very sticky gypsum, sometimes a multi-pass rotary dryer, like a triple-pass dryer, is better. This type has inner drums. The material travels back and forth inside before coming out. This increases the drying time in a smaller space. It also changes how the material moves. This can help with stickiness.

Another important factor is the temperature profile inside the dryer. You need enough heat to evaporate the water. But you must not overheat the gypsum. Overheating causes dewatering (removing the chemically bound water), which you usually want to do later during calcination, not now. Proper temperature control and airflow prevent this. For sticky materials, you might also need internal chains or breaker bars. These hang inside the drum and hit the material as it tumbles. They help break up sticky lumps. The material of construction inside the dryer should be smooth and maybe even have special coatings in some areas to reduce sticking. The inlet and outlet design must also be wide enough and shaped to let sticky material pass through without building up. We design our Gypsum Dryers specifically for materials like FGD gypsum. We choose the right size, internal structure, and temperature control to handle their unique sticky nature. This means you get reliable operation and consistent drying.

Drying gypsum creates dust. As the material tumbles and gets hot, small particles can become airborne. The hot air moving through the dryer picks up these fine particles. This dusty air comes out of the dryer. Dust is a big problem. It is bad for the environment. It is bad for workers’ health. Dust must be captured and cleaned from the exhaust gas to meet environmental rules. Controlling dust in a Gypsum Dryer system is very important.

A complete Gypsum Drying Plant includes more than just the dryer itself. It needs a dust collection system. The most basic part is a cyclone separator. Cyclones use centrifugal force to spin the dusty air. Heavier dust particles are thrown to the sides and fall down. Cyclones remove larger dust particles. But they are not enough for fine dust. For finer particles and to meet stricter emission standards, you need a baghouse (also called a fabric filter) or sometimes a wet scrubber or electrostatic precipitator (ESP). A baghouse has many fabric bags. Dusty air passes through the bags. The dust gets trapped on the outside of the bags. Clean air goes through. Periodically, the dust is shaken or blown off the bags into a hopper.

The design of the dryer system affects how much dust is created. The speed of the hot air inside the dryer is important. If the air moves too fast, it picks up more fine particles. The amount of material in the dryer (fill level) and how it tumbles also matter. Good seals at the inlet and outlet of the Gypsum Dryer drum are essential. They prevent uncontrolled air leaks which can create dust leaks too. They also ensure the hot air flows correctly through the dryer and into the dust collection system. A well-designed hood at the dryer outlet helps capture the initial dust before it escapes into the air. The collected dust can sometimes be added back to the dried gypsum product or disposed of safely. A good dust control system is a significant part of the cost of a Gypsum Drying Plant, but it is necessary for environmental compliance and a cleaner working area. We design our systems with effective dust control in mind, using appropriate collection technology and good sealing.

Drying uses a lot of energy, mostly for heating the air or gas to evaporate the water. Fuel costs are a big part of running a Gypsum Dryer. Making your dryer more energy efficient can save you a lot of money over time. It also helps the environment by reducing fuel use.

One way to save energy is to use the hot exhaust gas smartly. After the dusty air is cleaned in the dust collector, it is still hot. Instead of just releasing this hot air into the atmosphere, you might be able to use some of its heat. This is called heat recovery. For example, the hot exhaust air could be used to preheat the wet gypsum before it enters the dryer. Or it could preheat the incoming cold air for the burner. This lowers the amount of fresh fuel needed to reach the required drying temperature. The hot air from other processes in your plant might also be usable as the heat source for the dryer. Using waste heat from a nearby Rotary Kiln or other high-temperature equipment can significantly cut fuel costs for the dryer.

The design of the dryer itself affects efficiency. Good insulation on the dryer shell reduces heat loss to the surroundings. The internal lifters should be designed to provide excellent contact between material and hot air. This makes heat transfer more efficient. If heat transfer is good, you use the heat from the air effectively to evaporate water. Controlling the amount and temperature of the hot air going into the dryer is also key. Using too much hot air wastes energy. Using air that is too hot risks damaging the gypsum. Modern dryers use precise control systems. These systems measure temperature and moisture. They adjust the burner and airflow automatically. This keeps the drying process stable and efficient. Using an efficient burner also helps. A burner that burns fuel completely produces more usable heat. For very wet gypsum, using a multi-pass dryer or a pre-dryer step can sometimes improve overall energy use compared to a single-pass dryer. Our engineers design Gypsum Dryers with energy saving features in mind. We look at your specific process and see where heat recovery and optimization can happen.

Sticky materials like FGD gypsum and phosphogypsum can cause big problems in a dryer. They tend to clump. They stick to the sides. They can block the flow of material and air. This makes drying uneven. Some parts get dry, others stay wet. It can even stop the machine if a blockage is severe. Optimizing the parts where material enters, moves through, and exits the dryer is critical for smooth operation and good drying.

The inlet chute where wet gypsum enters the dryer is the first point where sticking can happen. The shape and material of the chute should help the material flow smoothly into the drum. It should avoid sharp corners where material can build up. Sometimes, vibrators or air cannons are used at the inlet to keep sticky material moving. Inside the drum, the lifters (flights) must lift the material effectively as the drum turns. They should drop the material through the hot air. For sticky gypsum, the lifters are not just simple angles. They often have specific shapes or arrangements to help break up lumps as they lift and drop. Their spacing and angle along the drum are important. The goal is to get constant mixing and showering of material through the air. This ensures all the material gets heated and dries evenly.

The speed of the drum rotation and the slight angle (slope) of the drum affect how fast the material moves through the dryer. This is called retention time. Sticky material might need a slower speed or a steeper angle to move well. But you also need enough retention time for the material to dry completely. Finding the right balance is key. The outlet end of the dryer also needs careful design. Dried material should flow out freely. The outlet must be large enough and shaped to prevent buildup, especially if the dried material is still slightly warm or contains fines. Using wear-resistant materials for the lifters and inner surfaces is also important, as constant tumbling can cause wear. Our design engineers look closely at your material’s stickiness and flow properties. We design the inlet, internal flights, and outlet to ensure smooth, continuous movement of material through the dryer. This prevents clogging and ensures your gypsum is dried uniformly.

Precise temperature control is very important when drying gypsum. Gypsum (CaSO₄·2H₂O) has water in its chemical structure. If you heat it too much, you can remove this bound water. This changes the gypsum into different forms (like hemihydrate CaSO₄·½H₂O or anhydrite CaSO₄). This is what you want to do during calcination to make plaster. But during the initial drying step, you only want to remove the free moisture. You do not want to start the calcination process too early or unevenly.

The temperature inside the Gypsum Dryer must be hot enough to evaporate the free water quickly. But it must stay below the temperature where gypsum starts to lose its bound water significantly. This temperature limit is usually around 150-180°C (300-350°F), depending on the gypsum type and other factors. If the temperature is too high, especially at the dryer inlet where the hot gas first meets the wet material, you risk “burning” the gypsum or causing unwanted dehydration. This results in a lower quality product. The final moisture content needs to be consistent. If some material is too wet and other parts are too dry or partially calcined, your product is not uniform. This affects its performance in later uses.

To ensure consistent product quality, the dryer system needs reliable temperature measurement and control. Temperature sensors are placed at different points, especially at the dryer inlet, outlet, and sometimes along the drum. A control system uses these temperature readings to adjust the hot air flow and the burner’s fuel rate automatically. This keeps the temperature within the desired range. The design of the dryer’s heating system (the furnace or hot air generator) is also important. It should produce a steady supply of hot gas at a consistent temperature. Good material tumbling inside the dryer ensures all particles are exposed to the same drying conditions for a similar amount of time. This leads to uniform moisture removal. By carefully controlling temperature and material flow, you get dried gypsum with the right moisture content and intact crystal structure, ready for the next processing step with predictable quality.

Buying a Gypsum Dryer is a significant investment. The total cost is not just the price of the machine itself. You need to think about the initial purchase price, the cost of installing it, and the ongoing costs to run it. The price of the Gypsum Drying Machine depends a lot on its size. A larger dryer can handle more material per hour but costs more to buy and install. The type of dryer (single drum, triple pass), the materials used to build it (especially for wear parts or corrosion resistance), and any special features for sticky material or energy saving will also affect the price.

You also need other equipment to make a complete Gypsum Drying Plant. This includes a furnace or hot air generator to produce the hot gas, fans to move the hot air and exhaust gas, ducting to connect everything, a dust collection system (like a baghouse) to clean the air, conveyors or feeders to bring wet gypsum to the dryer and take dry gypsum away, and an electrical control system. All these auxiliary machines add to the initial capital cost. Installation costs include building the foundations, putting the machine parts together, and connecting all the pipes and wires. This requires skilled workers and can take time.

Running the Gypsum Dryer also costs money. The biggest ongoing cost is usually fuel for the furnace. This is why energy efficiency is so important. Electricity is needed to run the motors for the dryer drum, fans, conveyors, and dust collector. Maintenance costs include replacing wear parts like internal lifters and seals, lubricating moving parts, and doing regular checks and repairs. The frequency and cost of maintenance depend on how abrasive your gypsum is and how well the dryer is built and maintained. Labor costs for operators and maintenance staff are also part of the total. When you look at the total cost over the life of the dryer, the initial purchase price is just one part. The operating and maintenance costs add up over years. A more expensive dryer that is more energy efficient and needs less maintenance might be cheaper in the long run. We can help you calculate the expected costs for your specific Gypsum Drying Plant design.

ZONEDING Gypsum dryer specifications can be custom designed to meet the unique processing needs of your material.

| Cost Category | Main Components | How it Affects You |

|---|---|---|

| Capital Cost | Dryer machine price, furnace/hot air generator, fans, ducting, dust collector, conveyors, electrical control, installation | Initial investment, requires funding |

| Operating Cost | Fuel (for heating), electricity (motors, fans), water (if used), labor (operators) | Daily/monthly expenses, affects profitability |

| Maintenance Cost | Spare parts (lifters, seals, bearings), labor (repair), planned shutdowns | Can be high if equipment is poor or material abrasive |

| Environmental Cost | Dust collection system running costs, meeting emission standards | Compliance, potential fines if not controlled well |

| Think about all these costs when you plan your Gypsum Drying Plant investment. |

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Choosing the right company to build your Gypsum Dryer is as important as choosing the right dryer type. You are buying a complex machine. You need a supplier you can trust. Looking only at the lowest price can lead to problems later. A cheap dryer might break down often. It might not dry the gypsum well. It might use too much energy.

You need to check the supplier’s experience. Have they built Gypsum Dryers before? Have they handled sticky gypsum like FGD or phosphogypsum? Drying these materials requires special knowledge. A supplier with this experience knows the challenges and how to design the dryer to overcome them. Ask for references. Talk to their past customers who have similar drying needs. This shows if the supplier’s machines work well in real life. We have been building processing equipment since 2004 and have experience with various materials, including challenging ones.

Look at their engineering team. Do they have engineers who understand drying technology, heat transfer, and mechanical design for heavy machinery? Can they design a Gypsum Dryer specifically for your material properties and required output? Our team of 15 professional engineers focuses on designing efficient and reliable equipment. Visit their factory if you can. See how they build the machines. Check the quality of their welding and materials. Our 8000 square meter factory has the equipment to build large, strong dryers.

Service after the sale is also critical. Will they help you install the dryer? Will they train your staff to operate and maintain it safely and correctly? What about spare parts? Wear parts like lifters and seals will need replacing. Can they supply these parts quickly? Good after-sales support reduces downtime and keeps your plant running smoothly. A reliable supplier offers a complete package: expert design, quality manufacturing, help with installation and startup, training, and readily available spare parts. They become your partner. This full support gives you confidence in your Gypsum Drying Plant.

Q1: Can a Gypsum Dryer also calcine the gypsum?

A1: No, a Gypsum Dryer is designed to remove only the free moisture. Calcination is a separate process at a higher temperature to remove the chemically bound water. Running a dryer too hot can accidentally start calcination, which harms product quality.

Q2:How wet can the gypsum be for a Rotary Dryer?

A2: Rotary dryers can handle gypsum with high moisture content, especially if designed properly with features for sticky materials and sufficient length/diameter for drying time. Triple-pass dryers are often used for very wet feed.

Q3: Is dust from gypsum drying harmful?

A3: Yes, gypsum dust can cause respiratory irritation and other health problems. It is also an environmental pollutant. Effective dust collection is essential for safety and environmental compliance.

Rotary cooler for sale. Efficiently cool hot materials discharged from kilns & dryers. Improve process speed & material quality.

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Find high-efficiency sludge dryers for sale. Reduce sludge volume, cut disposal costs, and improve handling. Ideal for municipal & industrial applications.

Discover high-performance aggregate and sand dryers for sale. We offer triple-pass and rotary drum models for efficient moisture removal. Get a quote today!

Looking for a high-efficiency triple-drum rotary dryer? Saves energy, space, and cost; suitable for drying sand, coal, and biomass. Rugged and reliable.

Purchase an industrial bentonite dryer suitable for various applications such as drilling mud, cat litter, and foundry work. Achieve optimal moisture content and uniform drying.

Specialized Coal Dryer machines for power generation, coking, and briquetting. Improve fuel efficiency, reduce transport costs & enhance combustion.

Professional slurry dryer manufacturer with CE/ISO certification. Customizable 5-50t/h capacity, 35% energy saving. Get instant technical specs download.

Professional slag dryer manufacturer with CE/ISO certification. Energy-saving 30%, global delivery to 50+ countries. Get custom solutions for mining waste processing.

This mineral powder dryer is specifically designed for use with mineral concentrates, iron ore powder, and metallurgical slag. It ensures uniform drying, improving product quality and recovery rates.

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy