Search the whole station Crushing Equipment

After high-temperature processes, like those in a Rotary Kiln, materials are very hot. They need cooling before you can handle or store them. They need cooling before the next steps like grinding in . The Rotary Cooler does this job. It cools hot material in a gentle way. This stops product damage. It reduces dust. It makes the material ready for the next step.

After materials come out of a high-temperature furnace or a Rotary Kiln, they are often extremely hot. You cannot just leave these hot materials exposed. This is because hot materials can cause many problems. They can damage equipment downstream. Hot material going into a conveying system can damage belts. Hot material in storage can be a fire risk. It can hurt people working nearby. Also, hot material creates a lot of dust when it is handled. This dust causes air pollution. It is bad for workers’ health. It is bad for the environment. Stricter rules mean you must control dust.

Cooling the material properly is more than just making it safe to handle. For many materials, the cooling process itself is very important for the final product quality. Think about cement clinker. It comes out of the kiln at over 1000 degrees Celsius (1800 F). How you cool it affects its structure. Fast, even cooling helps form structures that are easier to grind later. It helps make strong cement. If cooling is too slow or uneven, the material’s structure can change in bad ways. It might become harder to grind. It might react incorrectly later. This means you use more energy in the grinding process. The final product quality might be lower. Your tailing piles might hide usable materials that were damaged during cooling. So, proper cooling is not just about temperature. It is about making sure your product is high quality and easy to process later. Ignoring this step can cost you a lot in lost product quality and higher operating costs later.

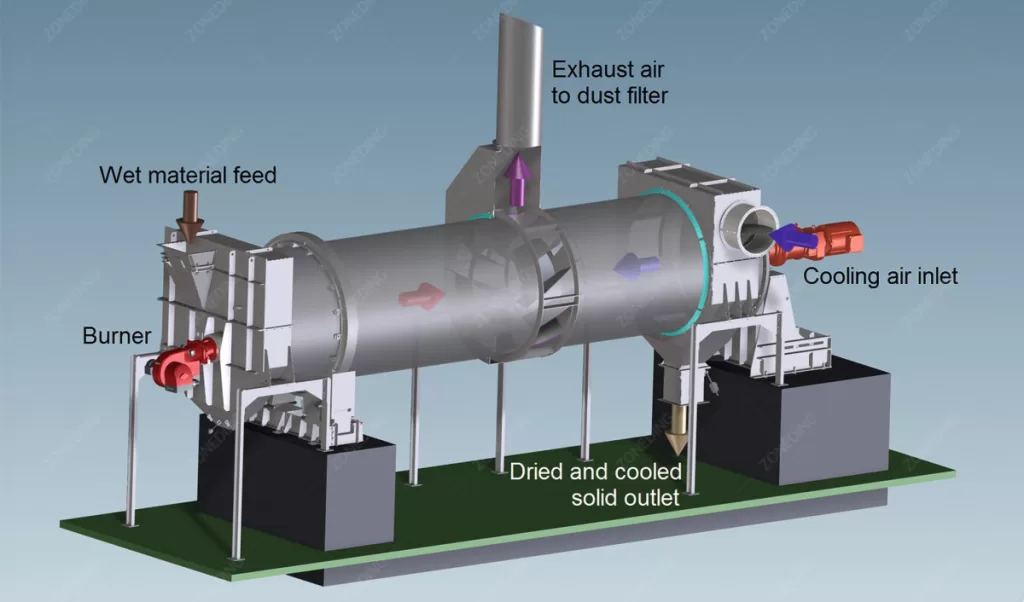

The Rotary Cooler is designed to take very hot material and bring its temperature down quickly and safely. It looks a lot like a Rotary Kiln but its job is the opposite. It is a large, rotating cylinder. It is also placed at a slight angle. Hot material enters the higher end of the cylinder. As the cylinder turns, the material moves slowly towards the lower end. While the material moves, a cooling medium passes through the cylinder. This medium takes heat away from the material.

There are two main types of Rotary Coolers based on the cooling medium: air-cooled and water-cooled.

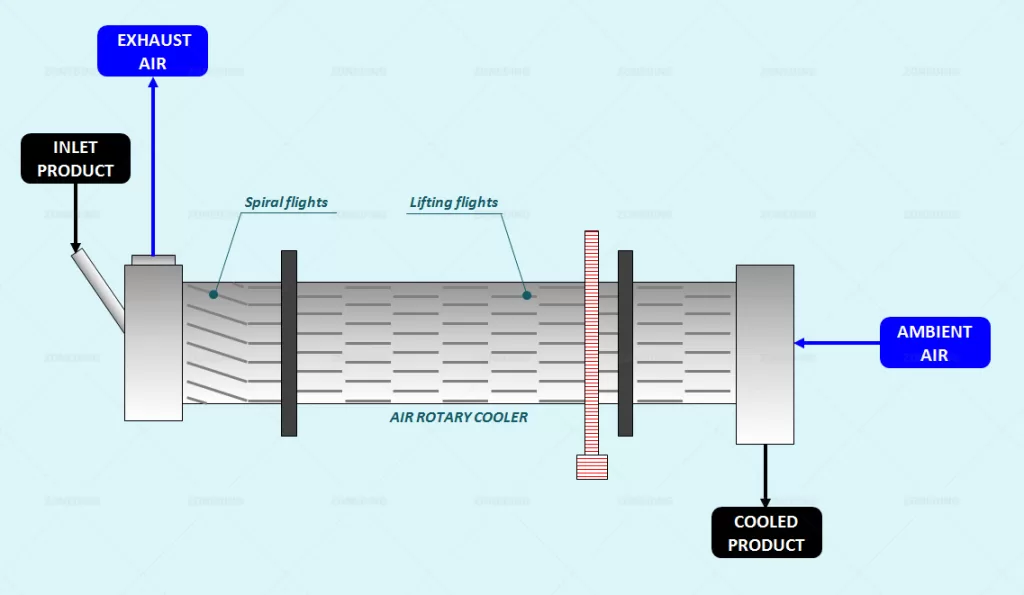

In an air-cooled Rotary Cooler, large volumes of air are blown through the cylinder. The air flows around and through the hot material. The material tumbles inside the cylinder as it rotates. Special plates called lifters (or flights) are attached to the inside of the cylinder. These lifters scoop up the material and drop it through the air stream. This action exposes more of the material surface to the cooling air. This helps the heat transfer from the material to the air happen faster. The hot air then exits the cooler, often carrying some dust with it. This hot air can sometimes be used elsewhere in the plant, like in a drying process, to save energy.

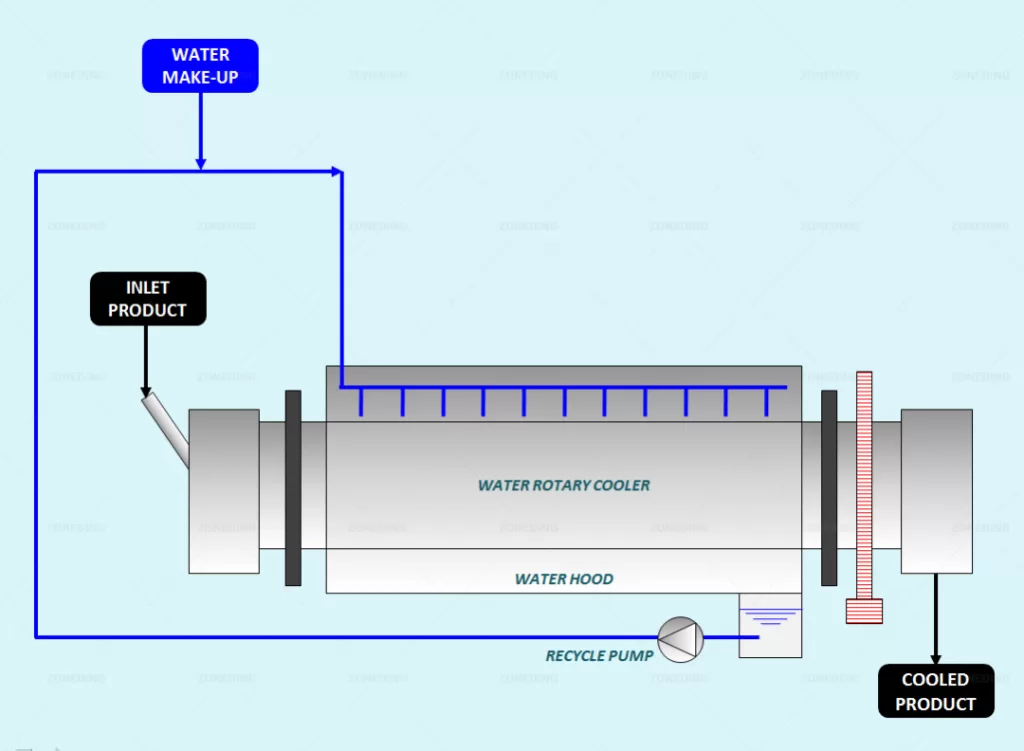

In a water-cooled Rotary Cooler, water is used to cool the material. The water might be sprayed directly onto the material or the outside of the cylinder. For materials that cannot get wet, the water can flow through special tubes or jackets around the cylinder. This cools the material indirectly. Water cooling can be very efficient for some materials. The choice between air and water depends on the material and the process needs. The structure includes the steel shell, internal lifters (for air cooling), support rollers, a drive system, and inlet/outlet seals, similar to a kiln but designed for cooling instead of heating.

The Rotary Cooler is widely used for cooling cement clinker. But many other materials get hot during processing. They need careful cooling too. Any material that comes out of a kiln, calciner, roaster, or dryer at high temperature is a possible candidate for a Rotary Cooler. It is used in mineral processing, chemical production, and other heavy industries.

In mineral processing, after minerals are heated to remove moisture or change their properties, they are often cooled in a rotary cooler. This includes calcined limestone (for lime production), calcined bauxite (for aluminum), or other processed ores. Sometimes, concentrates or filter cakes from processes using machines like a Flotation Machine or Magnetic Separator are dried in a dryer or kiln, then cooled. Materials from gold processing, like activated carbon used in recovery, might also need cooling after regeneration in a kiln. River sand used in construction often needs drying in a rotary dryer and then cooling. The cooler prepares these diverse materials for storage, packaging, or further processing like grinding in a Ball Mill or screening with a Vibrating Screen.

The specific material properties matter a lot. Materials like cement clinker are hard and granular. Others, like certain chemical powders or mineral concentrates, might be sticky or have high fines content. Some materials require very rapid cooling to “freeze” their structure. Others need slower cooling. The Rotary Cooler can be adapted by changing its internal design, size, or cooling method (air vs. water) to suit these different material needs. For materials that tend to stick or form lumps, the internal design might need special features to prevent buildup. For very dusty materials, the outlet and dust collection system design is crucial. The versatility of the Rotary Cooler makes it suitable for a wide range of “hot” industrial materials that need controlled cooling.

Choosing the right Rotary Cooler model is very important. It is not a one-size-fits-all decision. The best choice depends mainly on your material and what you need the cooling to achieve. You need to think about the material type, its temperature, its size distribution (granules, powder, lumps), its stickiness, its abrasiveness, and how much material you need to cool per hour.

The first big decision is often air cooling versus water cooling. Air cooling is simpler. It uses ambient air blown through the drum. It is good for materials where getting wet is not an issue and where you might want to recover the heat in the hot air. This is common for cement clinker. Water cooling can be faster and more efficient for some materials, especially if you need to reduce the temperature significantly or the material has properties that make air cooling difficult. Water can be sprayed on the material or used indirectly in jackets. However, water cooling adds complexity and might not be suitable for materials that react with water. You might also need water treatment or cooling towers.

Then you consider the size and configuration. A single-drum Rotary Cooler is the most basic type. It works well for many applications. For materials that are hard to cool, or where you need very high cooling efficiency, you might consider multi-drum or multi-stage coolers. These can include double-drum coolers or combinations with other cooling methods. The length and diameter of the drum depend on the material’s heat content and the required cooling time. Materials that give up heat slowly or need a longer cooling time need a longer cooler. Higher throughput requires a larger diameter. We look at your material samples and your process data. We calculate the heat load. We consider how fast the material should move through the cooler. We design the internal structure, like the lifters, based on your material’s properties to ensure good contact with the cooling medium. Choosing the right size and type ensures the cooler performs well and fits your plant’s needs.

| Feature | Air Cooled Rotary Cooler | Water Cooled Rotary Cooler (Direct/Indirect) | What it Means for You |

|---|---|---|---|

| Cooling Medium | Ambient air | Water (sprayed or in jackets) | Air is simpler, water can be faster for some cases |

| Efficiency | Depends on airflow & material contact | Can be higher for certain materials | Water might cool faster but adds system complexity |

| Material Suitability | Non-sticky, non-reactive with air | Can handle sticky or materials sensitive to air | Consider if water contact is okay for your product |

| Heat Recovery | Hot air can be reused (e.g., for drying) | Less easy to recover heat | Possible energy savings with air cooling |

| Complexity | Simpler mechanical design | More complex, needs water system | Air cooling usually has lower upfront mechanical cost |

| Choosing the right cooler is a technical task. It needs expert evaluation of your specific situation. |

Two common problems with Rotary Coolers are uneven cooling and dust emissions. Uneven cooling means some parts of the material are cool, but others are still too hot. This can lead to quality problems. Dust flying out of the cooler is bad for the environment and workers. But you can improve these things with smart design and good operation.

Uneven cooling often happens because the hot material is not properly exposed to the cooling air. In an air-cooled dryer, the lifters are key. They must lift the material and drop it through the air stream efficiently. If the lifters are worn down, or if their design (angle, shape, spacing) is wrong for your material, the material just slides along the bottom of the drum. It does not get lifted and showered through the air. This means heat transfer is poor. The material on the bottom stays hot. The material on top cools faster. The solution is to check the lifters regularly. Replace worn ones. Make sure the lifter design matches your material properties and desired cooling rate. Also, the amount of material inside the drum (fill level) and how fast the drum turns affect how well the material tumbles and mixes. You need to find the right balance for your specific material. The cooling air flow must also be right. Too little air, and you cannot remove heat fast enough. The material’s particle size also matters. Too many fine particles can block air flow paths inside the material bed.

Dust emission is mainly an issue at the inlet and outlet seals and where the hot air exits. Seals on a Rotary Cooler are very important. They stop air from entering or leaving where it should not. They stop dust from escaping. High-quality seals, like specialized labyrinth seals or air seals, minimize leaks. Investing in better seals reduces dust loss and makes your dust collection system more effective. It also improves the cooler’s efficiency by controlling air flow. The dusty hot air leaving the cooler must go through a dust collection system. This is usually a baghouse or an electrostatic precipitator. A well-designed hood at the cooler outlet also helps capture dust before it escapes. Proper maintenance of seals and the dust collection system is vital to keep emissions low. We use robust seals and design systems to minimize dust points.

Cooling hot materials is not just about reducing temperature. It is also about preserving the quality and quantity of your final product. An efficient Rotary Cooler cools the material to the right temperature while minimizing damage to the particles. This damage is called breakage. Breakage creates fines (very small particles). Too many fines can be a problem. They can be harder to handle. They might reduce the value of your product if a certain size range is required. They also create more dust.

How do you reduce breakage in a Rotary Cooler? The design of the cooler is important. The lifters should be designed to lift and drop the material gently, not crash it around. The speed of rotation and the angle of the drum also affect how forcefully the material tumbles. Running the cooler at the right speed and with the right fill level helps material move smoothly. The design of the inlet and outlet is also key. Material should enter and leave without large drops or impacts that could cause breakage. Choosing the right type of cooler for your material also helps. Some materials are more fragile when hot. They might need a specific type of cooling or a slower cooling rate in certain zones.

To maximize recovery, you need to minimize losses. Dust is a major loss. Material that becomes dust and is captured in the dust collection system is often lost product. Effective seals and a good dust collection system reduce this loss. Properly sized and operated cooling air flow helps too. Too much air can pick up more fine particles and carry them out. The goal is to remove heat, not material. By minimizing dust and breakage, you keep more of your material in the desired form and size range. This directly improves your product yield and reduces waste. My team focuses on cooler designs that balance efficient cooling with gentle material handling. We select materials and internal structures that reduce wear and impact on your product particles.

Maintaining a Rotary Cooler is important for its long life and good performance. It is similar to maintaining a Rotary Kiln in some ways, but with different focus areas. It is a heavy piece of equipment. It needs regular checks and care. It is not overly difficult, but it needs consistent attention. Knowing which parts need the most focus helps you plan your maintenance work.

The parts that see the most wear and tear are the internal lifters and the seals at the ends. Lifters are constantly exposed to the hot, moving material. If your material is abrasive, these lifters will wear down over time. Worn lifters do not lift the material well, which hurts cooling efficiency. You need to check the lifters regularly and plan to replace them when they show significant wear. The seals at the inlet and outlet also wear out. They are crucial for controlling air flow and dust. If seals are damaged, cold air leaks in (reducing cooling efficiency) and dust leaks out (environmental problem). Checking and replacing seals is a frequent maintenance task. The type of seal affects how often they need attention. High-quality, more advanced seals might last longer but cost more initially.

Other parts need attention too. The support rollers that carry the drum’s weight need regular lubrication and checks for alignment. The riding rings (tires) on the drum can also wear. Misaligned rollers or worn rings can cause the drum to turn unevenly, putting stress on the shell. The drive system (motor, gearbox) needs standard mechanical maintenance, like lubrication and checking for strange noises or vibrations. The steel shell itself should be checked for hot spots (which might mean the internal lining is failing, though coolers usually do not have high-temp refractory like kilns) or cracks. For water-cooled types, you need to check for leaks and maintain the water system. A structured maintenance plan with daily checks, weekly lubrication, and periodic detailed inspections during planned stops is the best way to keep your cooler running smoothly. My team can provide you with a detailed maintenance schedule specific to the cooler model we supply.

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

The cost of a Rotary Cooler is a big part of the total cost for a processing line. It involves more than just buying the cylinder itself. You need to look at the initial purchase price and the costs over the cooler’s working life. The upfront price of the cooler depends on its size (diameter and length), the type of cooling (air or water, single or double drum), the materials used in construction (especially for lifters and seals), and any special features needed for your material (like anti-stick linings). A larger, more complex cooler costs more.

Beyond the cooler drum, you need auxiliary equipment. For an air-cooled cooler, this includes large fans to move the air and ducting. You also need a dust collection system (like a baghouse) to clean the hot exhaust air. These systems add significantly to the capital cost. For a water-cooled cooler, you need pumps, pipes, and potentially a water cooling system or treatment. Installation costs are also part of the initial investment. The civil work for foundations and supports must be done.

Long-term operating costs are also important. Electricity for running the fans (for air cooling) or pumps (for water cooling) is a major expense. The power needed for the main drive motor is usually less but still a cost. Maintenance costs include replacing wear parts like lifters and seals. The frequency depends on your material and how well you maintain the cooler. Energy costs for the dust collection system are also part of operating costs. Labor for operating and maintaining the cooler is another expense. When you look at the total cost, you should compare the initial investment plus estimated operating and maintenance costs over the cooler’s life to the value it brings. A well-chosen and well-maintained cooler improves product quality, reduces material loss (less dust, less breakage), lowers energy use in subsequent steps (like grinding), and ensures smooth plant operation. These benefits can outweigh the costs over time. We can help you estimate the total cost of ownership and the potential savings a properly selected cooler can bring to your specific operation.

| Cost Type | Key Factors | Impact on Your Business |

|---|---|---|

| Capital Cost | Cooler size, type, materials, auxiliary systems (fans, dust collector, water system), installation | Initial investment, total project budget |

| Operating Costs | Electricity (fans/pumps, dust system), maintenance (lifters, seals, parts), labor, water (if used) | Ongoing expenses, affects profitability |

| Maintenance Costs | Material abrasiveness, cooler design quality, spare parts availability | Downtime, repair costs, long-term reliability |

| Value/Savings | Improved product quality, reduced material loss (dust/breakage), lower grinding energy, stable operation | Higher revenue, lower processing costs, reliable plant |

| Look at the total picture, not just the purchase price, to see the true value. |

Choosing the right rotary cooler supplier is crucial. We start by understanding the needs of your material to design the cooler that best fits your application. We have extensive experience in material handling in mineral processing and other industries since 2004. We have 15 professional engineers specializing in heat transfer, material flow and mechanical strength for heavy heat loads. Our 8000 square meter factory has the facilities to manufacture heavy equipment, large drums and use high-quality materials. We have supplied equipment to more than 120 countries around the world.

Before you buy, we help you analyze your material and determine the best cooler design and size. Including material testing. During the manufacturing process, we keep you informed. During your on-site installation and commissioning, you need expert supervision to ensure that all parts are assembled and started up properly. We provide training for your team on cooler operation and maintenance. Once the cooler is running, we provide reliable spare parts and troubleshooting support. Quick access to the right parts is essential to avoid long downtime. We provide complete solutions, not just a piece of equipment. This all-round support can help you maximize your investment and ensure your plant runs smoothly for many years.

Q1: What is the difference between a Rotary Kiln and a Rotary Cooler?

A1: A Rotary Kiln uses high heat to change material through drying, calcining, or sintering. A Rotary Cooler uses air or water to reduce the temperature of hot material coming from a high-temperature process. They look similar (rotating cylinders) but do opposite jobs.

Q2: Air-cooled or water-cooled – which is better?

A2: Yes, Rotary Kilns are designed to use various fuels including coal powder, natural gas, oil, and sometimes alternative fuels like waste-derived fuels. The burner system is key to handling different fuels.

Q3: How is the temperature controlled inside the kiln?

A3: Temperature is controlled by adjusting the fuel feed rate and the airflow for combustion. Modern kilns also use advanced sensors and automatic control systems to maintain desired temperature profiles in different zones.

Buy industrial gypsum dryer for sale. Efficiently remove moisture from gypsum rock & powder. Improve product quality & processing speed.

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Find high-efficiency sludge dryers for sale. Reduce sludge volume, cut disposal costs, and improve handling. Ideal for municipal & industrial applications.

Discover high-performance aggregate and sand dryers for sale. We offer triple-pass and rotary drum models for efficient moisture removal. Get a quote today!

Looking for a high-efficiency triple-drum rotary dryer? Saves energy, space, and cost; suitable for drying sand, coal, and biomass. Rugged and reliable.

Purchase an industrial bentonite dryer suitable for various applications such as drilling mud, cat litter, and foundry work. Achieve optimal moisture content and uniform drying.

Specialized Coal Dryer machines for power generation, coking, and briquetting. Improve fuel efficiency, reduce transport costs & enhance combustion.

Professional slurry dryer manufacturer with CE/ISO certification. Customizable 5-50t/h capacity, 35% energy saving. Get instant technical specs download.

Professional slag dryer manufacturer with CE/ISO certification. Energy-saving 30%, global delivery to 50+ countries. Get custom solutions for mining waste processing.

This mineral powder dryer is specifically designed for use with mineral concentrates, iron ore powder, and metallurgical slag. It ensures uniform drying, improving product quality and recovery rates.

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy