Search the whole station Crushing Equipment

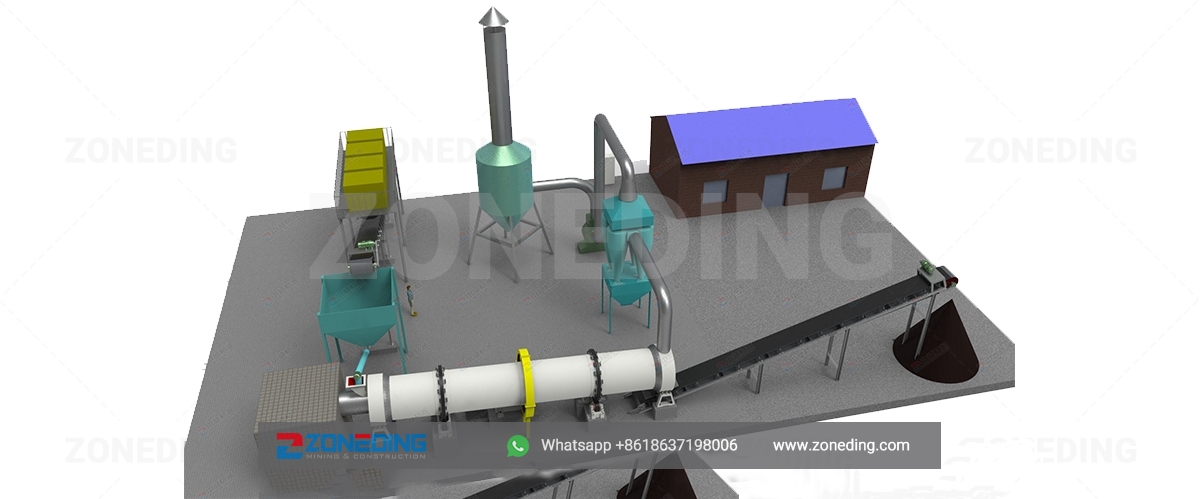

Zoneding’s coal dryer is designed to handle high-humidity coal, suitable for various coal particles. It efficiently smashes and dries coal, making it a versatile source for power plants and industrial raw materials, with applications in construction, metallurgy, and mining.

Coal dryer is a new type drying equipment grown from rotary dryer to dry all kinds of coal. And Coal itself is usually of high humidity and high agglutination. The coal dryer developed by Zoneding is targeted at these characters and suitable for various particles in coal industry like coal slime, fine coal, tail coal, etc. The special device smashes wet coal, which improves the heat transformation efficiently. Dried coal can be used as the source of the power plant as well as raw material in industry. In addition, coal drying machine is also applied for drying other material of certain humidity and particle size in building materials, metallurgy, mining and so on.

Drying coal directly impacts your bottom line in several powerful ways. When you remove excess moisture, you gain significant advantages.

The single biggest difficulty is that the goal is not “dry coal”; it is “stable coal.” Newcomers to coal drying make a dangerous mistake: they try to get the moisture to zero to maximize the BTU value. This is a recipe for disaster. All coal, especially lower-rank coals like lignite, has a natural “equilibrium moisture” level. When you dry it below this level, you create a highly reactive product.

The coal’s structure opens up, and it will immediately try to oxidize when it contacts air. This reaction generates heat. In a large pile, this heat gets trapped, leading to a runaway reaction called spontaneous combustion. The professional’s goal is to dry coal to its lowest stable moisture content, which might be 5-10%, not zero. Over-drying creates a serious fire hazard and can also cause the coal to shatter into low-value dust.

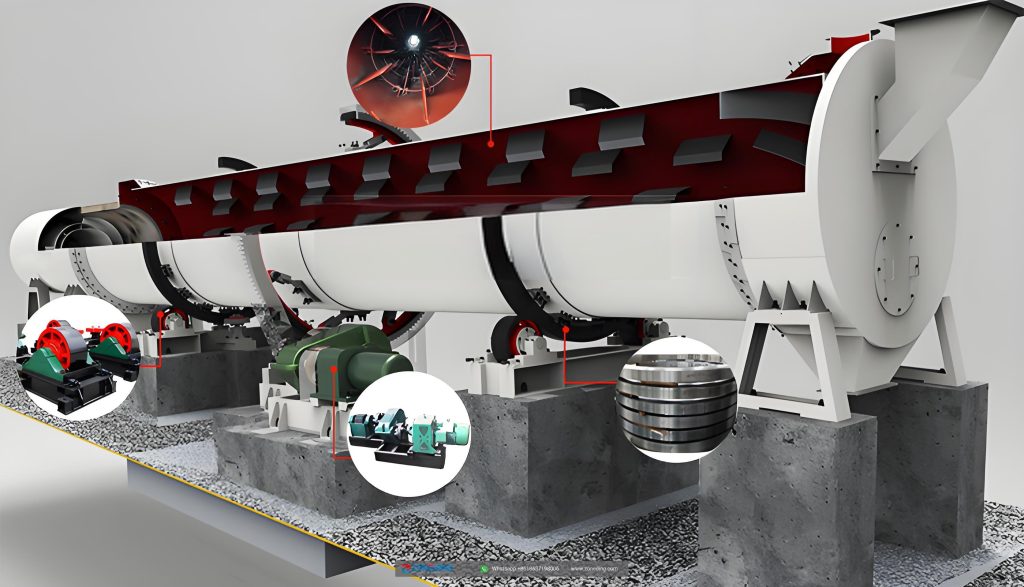

A coal dryer is a heavy-duty industrial machine specifically designed to safely and efficiently remove moisture from various types of coal. It is far more than a simple heater. It is an integrated system that includes a rotating drum or fluid bed chamber, a specialized heating system, and a multi-layered set of safety and dust collection components. A true rotary coal dryer is engineered to handle the unique risks of coal dust and spontaneous combustion.

Coal dryers are used across the energy and industrial sectors to add value and improve processes.

Applied Materials:nCoal, slime, anthracite, lean coal, Mongolian coal, clean coal, nickel coal, coking coal, lignite, raw coal, soft coal, tail coal, middings coal, fly ash, flotation concentrate, mixed coal, slag, clay, bentonite, limestone, quartz, metal ore, etc. in coal industry, construction industry, mineral industry, chemical industry and so on.

Our dryers are engineered to handle the full spectrum of coal ranks and related materials.

The type of coal dictates the type of dryer you need. Thinking a one-size-fits-all approach works is a dangerous mistake.

A professional coal drying process is a closed-loop system focused on safety and efficiency.

Wet coal of a certain humidity firstly passes through a professionally designed dispersion device. The well-dispersed coal is conveyed to the feeder, by which it is then fed into the cylinder. Here in the rolling drum, wet coal is thrown up and down by blades and gets water and heat exchanged. The dried coal is belched out of the drum by the star-shaped unloader and conveyed to the package. The entire drying process is completed.

The structure of a coal dryer is built around safety. The most important instrument is not a thermometer, but an oxygen (O₂) analyzer in the exhaust stack. An uncontrolled fire needs fuel, an ignition source, and oxygen. We cannot eliminate the coal dust (fuel), and we cannot guarantee we eliminate sparks. The only thing we can reliably control is oxygen.

By recycling the low-oxygen exhaust gas, we create an inert atmosphere in the dryer (e.g., below 8-10% O₂). The O₂ analyzer is tied to the emergency shutdown system. If oxygen levels spike, it means air is leaking in, and the system must be immediately flooded with steam or nitrogen to prevent a fire. The seals on the rotating drum are also a critical safety device. A leaky seal allows fresh, 21% oxygen air to rush in, feeding a fire. That is why professional systems use advanced, positive-pressure seals, not simple labyrinth seals.

>> Provide solutions to the pollution and occupied area problems of coal slime in coal separating plants.

>> Reduce the power generation cost of coal and power plants.

>> Promote the comprehensive utilization of coal.

Inside the dryer, the coal is gently lifted and cascaded through the stream of hot, inert gas. The design of the lifters is critical. Aggressive lifters will act like a hammer mill, shattering the coal and creating excessive “fines” (dust). Since you are paid for specific sizes of coal, creating fines is literally destroying your profit. The lifters in a ZONEDING coal dryer are designed to create a “veil” of cascading coal for gentle, efficient drying that protects your product’s value.

Another hidden enemy is sulfuric acid. All coal contains sulfur. The hot, wet, sulfur-rich gas inside the dryer will condense on the cold steel at the feed end, forming liquid sulfuric acid. This acid will eat through standard steel in just a few years. To prevent this, the feed chute and the first section of our dryer shells are built from corrosion-resistant materials like 316L stainless steel or Corten steel. This is not an upgrade; it is a requirement for long-term survival.

As a leading coal dryer manufacturer, ZONEDING builds safety and profitability into every system.

The price of a complete coal drying system can range from $300,000 to over $5,000,000. The cost depends on the capacity (tons per hour), the type of coal (lignite systems are more complex), and the scope of the safety and emissions control systems. The coal dryer operating cost is primarily driven by fuel and electricity. A well-designed, efficient system with proper process controls will have a significantly lower operating cost and a faster return on investment. A cheap dryer is one that compromises on safety features, and the cost of an accident is immeasurable.

Choosing the right dryer means prioritizing safety and long-term value over upfront cost.

Maintenance is a core part of safe operation.

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

What is the best way to learn how to dry high moisture coal?

The best way is through lab testing. A qualified manufacturer like ZONEDING can test a sample of your coal to determine its specific equilibrium moisture, reactivity, and friability. This data is essential to design a safe and efficient lignite coal drying process.

What is a coal slime dryer?

A coal slime dryer is a specific type of dryer, usually a rotary dryer, designed to handle the very fine, wet material recovered from coal washing operations. It requires a specialized feed system and often a back-mixing system to handle its paste-like consistency.

Can a dryer really increase my coal’s BTU value?

A dryer does not add BTUs, but it dramatically increases the BTU-per-pound value. By removing the non-combustible water, you concentrate the energy content in each ton of product you sell.

Is spontaneous combustion a real risk?

Yes, it is a very real and serious risk, especially with lower-rank coals. Over-drying coal and then storing it in a large pile or silo without proper management is one of the leading causes of fires in the coal industry.

Buy industrial gypsum dryer for sale. Efficiently remove moisture from gypsum rock & powder. Improve product quality & processing speed.

Rotary cooler for sale. Efficiently cool hot materials discharged from kilns & dryers. Improve process speed & material quality.

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Find high-efficiency sludge dryers for sale. Reduce sludge volume, cut disposal costs, and improve handling. Ideal for municipal & industrial applications.

Discover high-performance aggregate and sand dryers for sale. We offer triple-pass and rotary drum models for efficient moisture removal. Get a quote today!

loading…

已经是到最后一篇内容了!