Search the whole station Crushing Equipment

Sand dryer, also known as the three layers of drum dryer or three return cylinder dryer, is developed and manufactured based on the single-cylinder dryer. It’s an industrial dryer for non-viscous, liquid material.

Sand dryers can be classified based on two main factors: volume and the materials to be dried.

Sand dryer is a drying equipment for dehydrating granular materials, especially suitable for artificial sand, river sand, quartz/silica sand, etc. The dryer has the advantages of high production capacity, wide range of application, small flow resistance, large operation fluctuation range, and convenient operation. Sand dryers are also commonly used to dry mineral powder, cinder, slag, etc. The sand dryer is suitable for a variety of fuels, such as coal, oil, and gas.

According to the body integration, sand dryers can be divided into large sand dryers and small sand dryers; According to the materials to be dried, it can be divided into silica sand dryer, quartz sand dryer, river sand dryer, yellow sand dryer, zircon sand dryer, garnet sand dryer, etc.

Controlling moisture is controlling your business. The return on investment from drying your materials is clear and measurable.

First, you meet demanding product specifications. High-performance materials like hot mix asphalt and specialty concrete have strict moisture limits. Wet aggregate prevents proper bonding with asphalt and ruins the critical water-to-cement ratio in concrete. A quality rotary sand dryer ensures your product meets spec every time.

Second, you enable year-round operation. In many regions, winter means frozen clumps of aggregate that can shut down an entire plant. A reliable construction sand dryer provides a steady stream of workable material, allowing you to generate revenue when competitors are idle.

Third, you slash transportation costs. Why pay to ship water? Drying aggregate can reduce its total weight by 5% to 15%. If you ship thousands of tons, the savings on fuel and freight are enormous. This cost reduction goes directly to your bottom line.

Dried aggregates are the foundation of modern construction. The final application is critical because it determines the entire drying process.

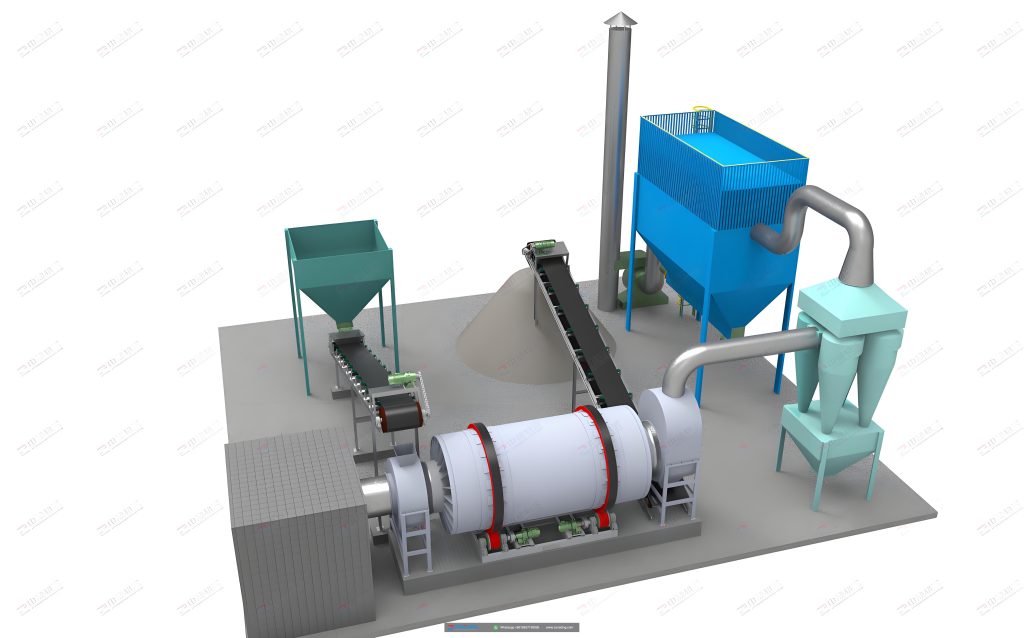

A drying plant is a complete system, not just a single machine.

Drying rock and sand is a tough, abrasive process. Understanding the challenges is the first step to building a reliable plant.

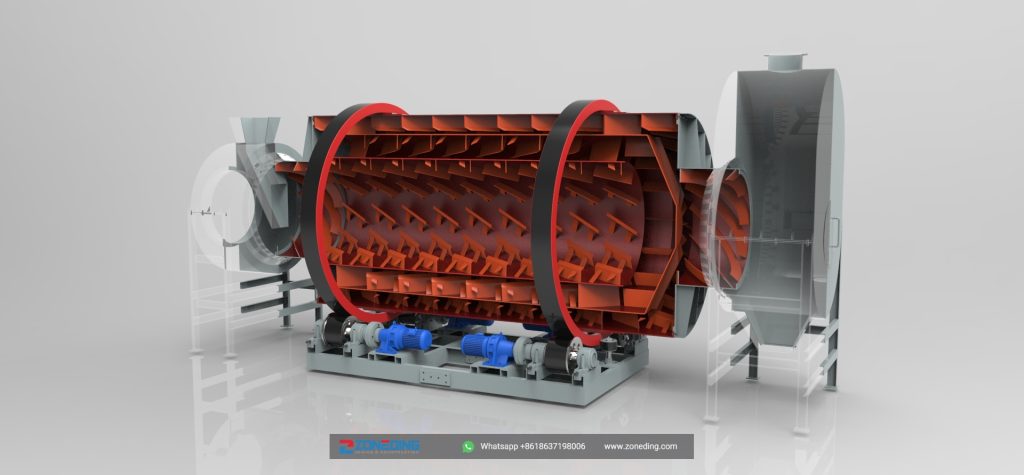

The biggest challenge is managing heat transfer efficiency. You need to get the heat from the burner into the material, not send it up the exhaust stack. This is controlled by the design of the internal “flights” or lifters that cascade the material through the hot gas.

Another major difficulty is abrasion. Sand and stone will wear through standard steel in a surprisingly short amount of time. The feed and discharge chutes are especially vulnerable.

Finally, you must manage dust. The drying process creates fine dust that must be captured. The dust collection system is often a major source of maintenance headaches and downtime if not designed correctly.

An aggregate and sand dryer is a piece of heavy industrial equipment designed for continuous duty. It’s essentially a large, rotating drum that uses hot gas to evaporate moisture from a stream of material.

These are not one-size-fits-all machines. A small gravel dryer for a landscape supplier is very different from a massive dryer for a high-capacity asphalt plant. As a factory-direct manufacturer, ZONEDING custom-engineers each dryer for the specific material, capacity, and fuel source of the customer.

Beyond the main uses in asphalt and concrete, these versatile machines are found in many industries:

Applications of Sand Dryer

A well-designed aggregate drying machine can handle a wide range of materials. The key is to match the dryer design to the material properties.

A rotary dryer is a system of heavy-duty components working together.

The sand drying machine working principle is all about maximizing “residence time.” It’s not just the temperature of the hot gas, but how long each particle spends in contact with it.

The residence time is controlled by three factors: the rotation speed of the drum, the slope of the drum, and the design of the flights. A good dryer design balances these three things perfectly for your specific material.

When the sand dryer is running, there are three main systems working, the boiler system, the heat exchange system and the dust removal system. The first system uses hot blast furnace technology. The heat exchange system mainly refers to a three-cylinder drum in which the wet sand is lifted in full contact with the gale. The lifting blade fixed to the inner wall has a spiral-shaped structure. Dry materials are easily blown away by flowing air. Here, the dust collector gets to work to avoid waste of resources or air pollution.

Working Principle of Sand Dryer

The sand dryer is mainly composed of a rotary cylinder, air induction equipment, high-speed scattering equipment, lifting plate, automatic cleaning device, transmission device, conveying equipment, hot air equipment, reducer, support and sealing device, etc.

Exquisite workmanship: wear-resistant manganese plate is used, and the wear resistance is 3-4 times that of ordinary steel plate;

Stable performance and advanced technology: the output humidity of the sand can be controlled below 0.5-1% according to your requirements, and the sand in the dryer can maintain its quality;

Small footprint and reasonable design: compared with traditional dryers, the new sand drying equipment covers 60% less area;

Other advantages: low maintenance costs, low energy consumption, high degree of mechanization.

The industrial aggregate dryer cost is a major factor, but you must consider the “Total Installed Cost,” not just the equipment price.

Another key cost is the fuel. Your choice of fuel (natural gas, diesel, propane, or even coal) impacts both the burner cost and your daily operating expense. Natural gas burns cleanest, but diesel may be more available in remote locations. It’s a critical decision to discuss with your supplier.

Proper rotary dryer maintenance for sand is about regular, disciplined checks. This prevents unplanned downtime.

| Frequency | Task | Why It’s Important |

|---|---|---|

| Daily | Visual inspection. Listen for new sounds. Check bearing temperatures. | Catches small problems before they become major failures. |

| Weekly | Grease all bearings. This is the most crucial task. | Prevents bearing failure, the #1 cause of major downtime. |

| Weekly | Check drive system (belt/chain tension, gear lubrication). | Ensures efficient power transmission. |

| Monthly | Inspect the internal flights for wear, especially at the feed end. | Helps you plan for future repairs and avoid a sudden failure. |

| Quarterly | Check alignment. Inspect the wear pattern on the trunnions and riding rings. | An aeven wear pattern is an early warning of misalignment that can destroy bearings and the drum itself. |

>> The sand dryer should be installed on a horizontal concrete bed and fixed with anchor bolts;

>>The main body of the rotary dry sand machine should be perpendicular to the horizontal ground;

>>Check each anchor bolt and door of the main machine to see if it is locked;

>>Distribute wires and control switches as instructed;

At ZONEDING, we build solutions, not just machines. Our designs are based on decades of experience in the toughest applications.

| Item/Unit/Model | Φ2.5×7m | Φ2.7×7m | Φ3.0×7.0m | Φ3.2×7.0m | Φ3.6×8m |

| Diameter of outer cylinder(m) | 2.5 | 2.7 | 3.0 | 3.2 | 3.6 |

| Length of outer cylinder(m) | 7 | 7 | 7.0 | 7.0 | 8 |

| Cylinder volume( m³ ) | 16.63 | 16.63 | 52.678 | 52.678 | 81.38 |

| Rotating speed of cylinder(rpm) | 4-10 | 4-10 | 4 -10 | 4 -10 | 4 -10 |

| Initial moisture of slag(%) | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 |

| Final moisture of slag(%) | 1 | 1 | 1 | 1 | 1 |

| Initial moisture of yellow ground(%) | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 |

| Final moisture of yellow ground (%) | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 |

| Highest intake air temperature(℃) | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ |

| Production capacity(T/h) | Yellow sand:25-30 Slag: 20-25 | Yellow sand:30-35 Slag:25-30 | Yellow sand:35-40 Slag:30-35 | Yellow sand:45-50 Slag:35-40 | Yellow sand:65-70 Slag:60-65 |

| Motor type | Y2-132m-4E | Y2-132m-4E | Y2-160m-4 | Y2-160m-4 | Y2-160m-4 |

| Motor power(kw) | 7.5×2 | 11×2 | 7.5×4 | 7.5×4 | 15×4 |

| Reducer type | XWD7-23-11W | XWD7-23-11W | XWD6-23-7.5KW | XWD6-23-7.5KW | XWD8-23-15KW |

| Velocity ratio of reducer | 29 | 29 | 29 | 29 | 29 |

1. How do you dry sand for an asphalt plant?

You use a high-temperature rotary dryer to heat the sand to 150-180°C (300-350°F) and reduce moisture to less than 0.5%. This ensures the hot sand will bond properly with the liquid asphalt. Control of the final temperature is critical.

2. What is a typical sand dryer fuel consumption?

This is a key metric. A modern, efficient dryer might use 300,000 BTU to remove one ton of water, while an older, leaky design could use twice that amount. Fuel choice (natural gas, diesel, etc.) also affects the cost.

3. What is the sand drying machine working principle?

The principle is direct heat exchange. Material is lifted and cascaded (curtained) through a stream of hot gas inside a rotating drum. The goal is to maximize the time each particle spends surrounded by the hot gas to efficiently evaporate moisture.

4. What is involved in rotary dryer maintenance for sand?

The most critical task is regular lubrication of the main support bearings (trunnions) and the drive system. Regular inspection for wear in the feed chute and internal flights is also essential to prevent unplanned shutdowns.

Buy industrial gypsum dryer for sale. Efficiently remove moisture from gypsum rock & powder. Improve product quality & processing speed.

Rotary cooler for sale. Efficiently cool hot materials discharged from kilns & dryers. Improve process speed & material quality.

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Find high-efficiency sludge dryers for sale. Reduce sludge volume, cut disposal costs, and improve handling. Ideal for municipal & industrial applications.

Looking for a high-efficiency triple-drum rotary dryer? Saves energy, space, and cost; suitable for drying sand, coal, and biomass. Rugged and reliable.

Purchase an industrial bentonite dryer suitable for various applications such as drilling mud, cat litter, and foundry work. Achieve optimal moisture content and uniform drying.

Specialized Coal Dryer machines for power generation, coking, and briquetting. Improve fuel efficiency, reduce transport costs & enhance combustion.

Professional slurry dryer manufacturer with CE/ISO certification. Customizable 5-50t/h capacity, 35% energy saving. Get instant technical specs download.

Professional slag dryer manufacturer with CE/ISO certification. Energy-saving 30%, global delivery to 50+ countries. Get custom solutions for mining waste processing.

This mineral powder dryer is specifically designed for use with mineral concentrates, iron ore powder, and metallurgical slag. It ensures uniform drying, improving product quality and recovery rates.

loading…

已经是到最后一篇内容了!