Search the whole station Crushing Equipment

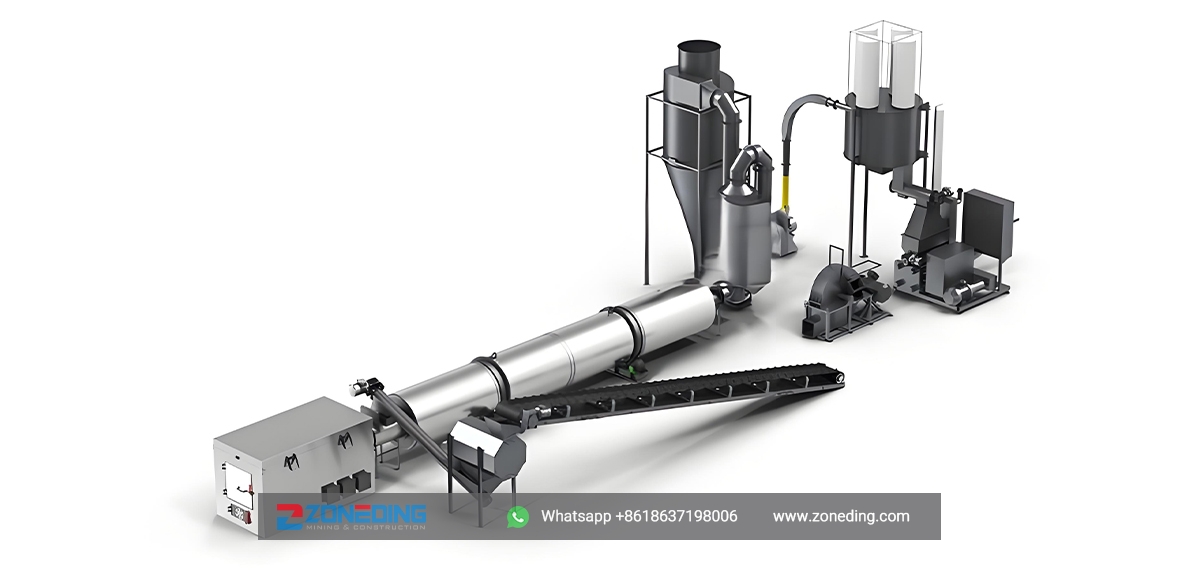

The high-efficiency slurry-residue dryer uses hot air to reduce material moisture from 65%-75% to 13%. With electromagnetic speed adjustment and automatic temperature control, it dries quickly while preserving material quality.

The slurry dryer is a rotary dryer that specializes in drying various slurries, including slime, which can be called a slime dryer. In addition, it is used for the drying of sludge, metallic and non-metallic ores, clays in the cement industry, etc. The slurry dryer uses a unique scattering device that disperses the bonded slurry and enters the drying process.

The contact area between the slurry and the hot air is enlarged, which can significantly improve the heat utilization. After drying, the humidity of the slurry can be reduced by 50-80%, and it can be used directly. Therefore, it can be said that the slurry dryer can turn waste into treasure. In addition, the slurry dryer has a considerable production capacity. For example, the slime dryer can effectively solve the slime reuse problem with a slime processing capacity of 200 tons, 300 tons, 500 tons, 800 tons, 1000 tons, 1200 tons, 1500 tons and 2000 tons. The R&D and production of slime dryers is the most effective way to recycle slime.

Slurry is a simple mixture of a solid material and a liquid, usually water. The solid particles do not dissolve in the water. They are just suspended in it. Think of wet cement, mining waste (tailings), or the sludge from a wastewater treatment plant. These materials can range from thin and watery, like milk, to thick and paste-like, a bit like toothpaste or wet dough. The consistency of your slurry is one of the most important factors in drying it.

Drying slurry is about saving and making money. When you remove the water, you get several key benefits.

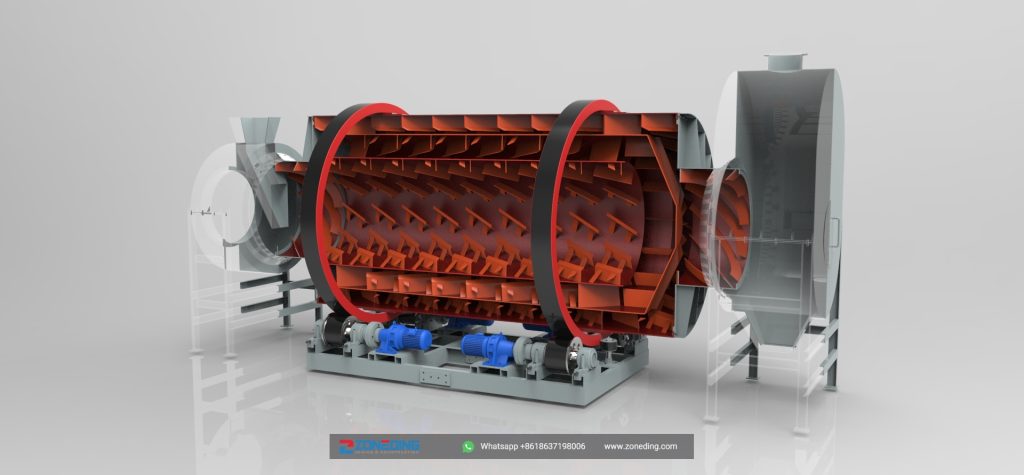

The most important feature of your slurry is its consistency, or viscosity. This will define the entire drying process. As you remove water, many slurries go through a “sticky phase.” This is a critical stage where the material is not wet anymore, but not yet a dry powder. It becomes like a thick, sticky glue or dough. In a standard dryer, this glue-like material will coat the walls, clog the machine, and form large, half-dried clumps. This can completely shut down your operation.

The solution to this problem is a process called “back-mixing.” We design a system that takes a controlled amount of the final, dry powder from the end of the dryer and blends it with the wet feed at the beginning. This immediately changes the consistency of the incoming material. It turns the sticky paste into a more manageable, crumbly material that can flow through the slurry dryer without sticking. For many materials, this back-mixing step is not an option; it is the only way to make the drying process work successfully. At ZONEDING, understanding this sticky phase is the first thing we investigate.

A slurry dryer, also known as a sludge dryer, is a piece of industrial equipment designed specifically to evaporate the liquid out of a slurry mixture. The goal is to leave only the dry solid material behind. These are not simple heaters. They are complex systems engineered to handle different material types, viscosities, and the challenging “sticky phase.” The right dryer is a key part of an efficient slurry drying process.

You can find slurry dryers in almost any industry that uses water in its processes. They provide solutions for waste reduction and product creation.

You do not choose a dryer based on your solid material. You choose it based on your slurry’s viscosity. The wrong choice will lead to clogs and failure.

Another key classification is how the dryer is heated. An indirectly heated dryer is often the smart long-term choice. The burner flame is separate, and it heats the walls of the dryer. The product never touches the combustion gases. This guarantees product purity, improves safety with flammable materials, and prevents a lot of corrosion.

High-efficiency and energy-saving slurry dryer is a new type of dryer developed on the basis of rotary dryer, which can be widely used in the following fields:

>>Drying of slime, raw coal, flotation concentrate, mixed coal and other materials in the coal industry;

>>Drying of blast furnace slag, clay, limestone, sand, quartz stone in the construction industry;

>>tailings of various metal ores and mineral processing industries;

>>Non-heat-sensitive materials in the chemical industry.

Slurry Dryer Application

A complete slurry dryer system has several key parts that work together.

The way a slurry dryer works depends on its type. In a spray dryer, the process is all about the atomizer. This precision device is the heart of the machine. It spins at high speed or forces slurry through a tiny nozzle to create a fine mist. If your slurry is abrasive (contains hard particles like minerals), it will act like a sandblaster and wear out the nozzle. A worn nozzle creates larger droplets. Larger droplets do not dry completely and fall to the bottom as a wet mess, forcing a shutdown. This is why for abrasive slurries, we must use atomizers made of ultra-hard materials like tungsten carbide.

The dust collector is just as important. It is not just for pollution control; it is your product bin. A simple cyclone might only catch 90% of your powder. The other 10%—the finest, most valuable particles—will blow out the exhaust stack. This is like throwing away money. A professional system uses two stages. First, a cyclone collects the bulk of the product. Then, the air stream goes to a baghouse filter. The baghouse captures the remaining ultra-fine powder, ensuring you recover nearly 100% of your product and meet environmental rules.

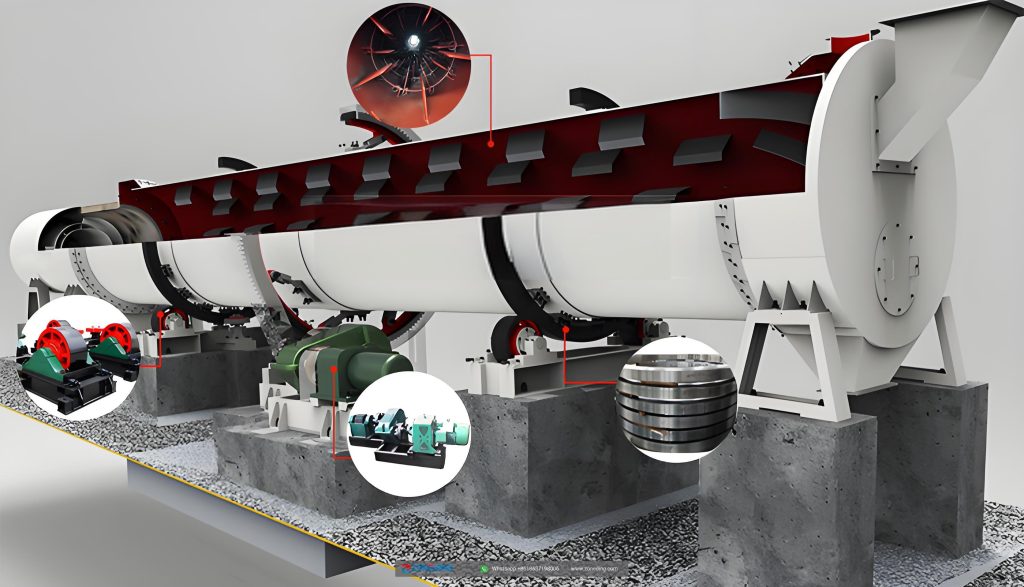

The slurry dryer is mainly composed of heating system, feeding system, conveying system, drying system, dust removal system, induced draft fan and electronic control system. Since slurry dryers are specially designed to dry high humidity materials, the feeder is designed with scattering. The cylinder is set at an angle. When the slurry dryer is working, the feeder first disperses the viscous material through the biaxial circular push process. On the basis of heat exchange, the hot air of the fan takes away the moisture in the material, and under the action of gravity, the lifting plate rotates the moisture spirals forward. Gradually, the wet material dries to a qualified humidity.

Large processing power and stable performance. The main heat source is provided by a blowing system that works continuously. In addition, the material is lifted by means of a screw-ordered lifting plate, which increases drying efficiency and reduces energy consumption. When drying unbound materials, the humidity can be reduced by about 60%

The structure design is reasonable and the energy consumption is low. Wheel riding adjustment allows for linear contact at all times. This process ensures great energy savings. In addition, this structure allows the dryer to be used in a wide range of applications.

There will always be a run-in period before the first operation of the slurry dryer, usually 3 days, which is to ensure the normal operation of the subsequent manufacturing process, reduce the failure rate and extend the service life. Therefore, more attention should be paid to the first operation.

First of all, operators should be trained in structure, operation, and solutions to common problems before the break-in period. In addition, he or she should be familiar with the manual. Secondly, during the break-in period, more inspections are carried out on lubrication, cooling and sealing functions, braking, etc. In addition, the operator should follow the instructions for proper operation and maintenance. The dryer workload should not exceed 80% to avoid overheating the drying equipment. Third, it should be noted that at the end of the run-in period, each part should be inspected and replaced and the dryer maintained.

At ZONEDING, our strength is in engineering a complete solution, not just selling a machine. We know the expensive mistakes and how to avoid them.

The price of a slurry dryer can range from $150,000 to over $2,000,000. The biggest factors are capacity (tons per hour) and technology (spray dryer vs. paddle dryer). But the purchase price is only part of the story. The biggest hidden cost is the energy bill.

It takes a huge amount of thermal energy (heat from gas or electricity) to evaporate water. But it takes very little mechanical energy (pressure from a pump) to squeeze water out. A smart sludge dewatering process always starts with a mechanical device, like a filter press. A filter press can take a very wet slurry and turn it into a firm “cake” with much less water. By doing this first, you remove more than half the water for a tiny fraction of the cost. The dryer is then only needed for the last bit of moisture. Anyone who tries to sell you a giant dryer for a watery slurry is really selling you a giant, permanent energy bill.

Selecting the right industrial dryer is a process of asking the right questions. Follow these steps to make a smart investment.

Good maintenance is about preventing problems before they happen.

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

How can you turn waste sludge into fertilizer?

First, mechanically dewater the sludge with a filter press. Then, use an indirect-heat sludge dryer to dry the sludge cake to a low moisture content (around 10%). The resulting dry, granular material is rich in nutrients and can be sold as a commercial fertilizer.

What is the typical sludge dryer fuel consumption?

Fuel consumption depends heavily on the incoming moisture content. This is why pre-dewatering is so critical. A dryer that receives a 35% moisture cake will use less than half the fuel of a dryer that receives a 70% moisture slurry to produce the same amount of dry product.

What is the best way to learn how to dewater and dry slurry?

The best way is to send a sample of your slurry to a manufacturer’s lab. At ZONEDING, we can test your material to determine its viscosity, sticky point, and the most energy-efficient way to dry it. This data is essential for designing the right system.

Can drying reduce slurry disposal costs?

Yes, dramatically. Disposal is often charged by weight. Since slurry can be 70-95% water, removing that water reduces the disposal weight by a huge amount, directly cutting costs.

Buy industrial gypsum dryer for sale. Efficiently remove moisture from gypsum rock & powder. Improve product quality & processing speed.

Rotary cooler for sale. Efficiently cool hot materials discharged from kilns & dryers. Improve process speed & material quality.

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Find high-efficiency sludge dryers for sale. Reduce sludge volume, cut disposal costs, and improve handling. Ideal for municipal & industrial applications.

Discover high-performance aggregate and sand dryers for sale. We offer triple-pass and rotary drum models for efficient moisture removal. Get a quote today!

Looking for a high-efficiency triple-drum rotary dryer? Saves energy, space, and cost; suitable for drying sand, coal, and biomass. Rugged and reliable.

Purchase an industrial bentonite dryer suitable for various applications such as drilling mud, cat litter, and foundry work. Achieve optimal moisture content and uniform drying.

Specialized Coal Dryer machines for power generation, coking, and briquetting. Improve fuel efficiency, reduce transport costs & enhance combustion.

Professional slag dryer manufacturer with CE/ISO certification. Energy-saving 30%, global delivery to 50+ countries. Get custom solutions for mining waste processing.

This mineral powder dryer is specifically designed for use with mineral concentrates, iron ore powder, and metallurgical slag. It ensures uniform drying, improving product quality and recovery rates.

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy