Search the whole station Crushing Equipment

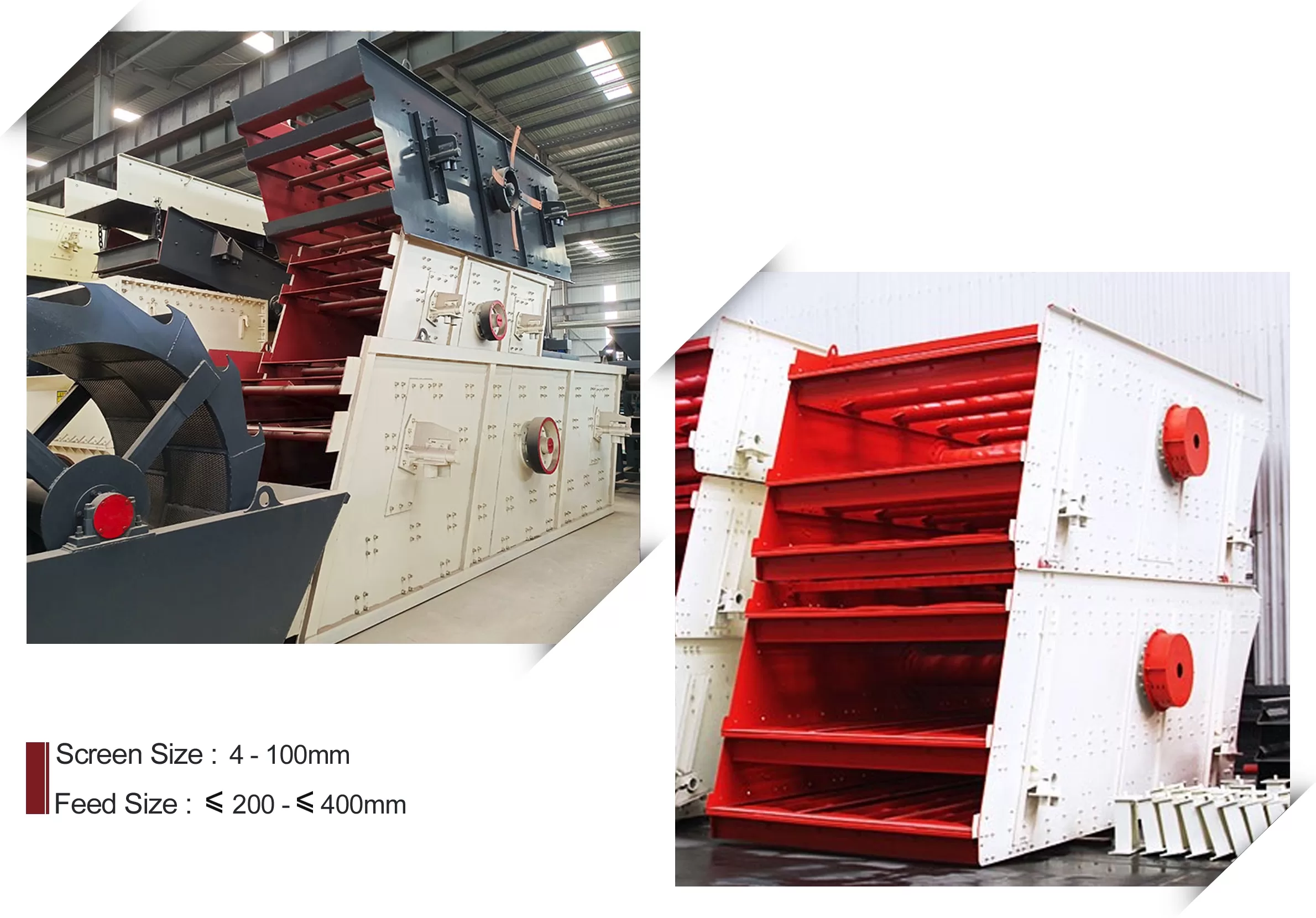

Vibrating Screen characterizes simple structure, high efficiency, reliable use and convenient installation, and can perform multi-special segmentation screening of loose materials. It is main equipment to separate soild materials, it can serve in mineral, building material, coal dressing,energy, chemical industry,etc.

A Vibrating Screen, sometimes also a vibratory screen or shaker, is a mechanical device for separation. And It uses vibration to pass smaller particles through a screen deck, while larger particles remain on top. The machine consists of a screen box, a vibrator mechanism, springs, and a support structure. It’s the workhorse of any material screening operation, designed to handle high volumes of material reliably and efficiently.

You need a vibrating screen to achieve product consistency and operational efficiency. Without proper aggregate screening, your product will be a mix of different sizes, making it low-value and unsuitable for most applications. The key benefits are:

There are several types of vibrating screens, each designed for different tasks. The most common ones you’ll encounter are:

The working principle of a vibratory screen is quite simple, which makes it easy to operate. The crucial parts of the machine include vibrating screens, exciter, motor, screen decks, liners, and side plates.

Vibrating source comes from an exciter that transmits vibration to the screen deck by the V-belt, which makes material shaking and distributing evenly on the screen. During the process, the large size of material will stay on the top while the small and fine size material can go throughout the screen mesh to the bottom, then you’ll get different sizes of materials.

The structure of a vibrating screen is built for durability. The main parts are:

A vibrating screen works by using a motor to power a vibrator unit. This unit, which has eccentric weights, creates a strong vibration. This vibration is transferred to the screen box, causing it to shake rapidly. You can think of this process as “tuning” the machine like a musical instrument. The amplitude (how much it shakes) and frequency (how fast it shakes) have a huge impact. Higher amplitude can move more material, but it might damage fragile particles. Higher frequency can improve the accuracy of separation, but it can also cause the screen mesh to clog. The optimal settings depend entirely on your material.

The “throw angle,” or the angle of the vibration, is another critical detail. A steeper throw angle makes particles jump up and down more, allowing smaller particles to quickly find the screen openings. A shallower angle creates a rolling action, which is better for separating materials that are close in size. Adjusting these factors allows you to perfectly optimize the screening process for maximum efficiency.

The vibrating sieve can be divided into mining vibrating screen, light fine vibrating screen, experimental vibrating screen, also can be divided into linear vibrating screen, circular vibrating screen, high frequency vibrating screen, double deck vibrating screen, single deck vibrating screen, and so on.

HX Series Vibrating Screen VS YK Series Vibrating Screen

It is widely used for screening of granite, river stone, quarry stone, rock, boulder, gravel, aggregate, basalt, limestone, gold ore, iron ore, chrome ore, etc. Adjustable final size meeting different needs.

Industrial screening equipment is used in almost any industry that handles bulk materials. One key application is sizing aggregate in a quarry. The vibrating screen must accurately separate the crushed stone into different size fractions (like G1, G2) for use in road construction and concrete. Its performance is constantly monitored to ensure the final product meets strict government standards. Other major applications include:

Application of Vibrating Screen

Choosing the right vibrating screener requires more than just knowing your desired tons per hour. A common mistake is assuming all screen media are the same. The type of screen media—whether woven wire, polyurethane, or rubber—is critical. Abrasive rock will destroy a simple wire screen quickly, while sticky, wet sand will clog a polyurethane screen. You must analyze your material’s size, shape, moisture content, and abrasiveness first.

Consider these key factors:

Our industrial vibrating screens are engineered for superior material separation and classification. Whether you’re in mining, agriculture, chemical processing, or recycling, our equipment delivers exceptional throughput and accuracy. Built with robust materials and a low-maintenance design, our screeners minimize downtime and maximize your operational efficiency.

Factors influences the cost of Vibrating Screens:

Selecting the screen mesh involves two key elements: the aperture (the size of the opening) and the wire diameter. The aperture determines the size of the material that will pass through. The wire diameter affects the screen’s durability and its open area. A thicker wire is stronger and lasts longer but reduces the open area, which can lower your screening capacity. You must find a balance between durability and throughput for your specific operation. Always consult with a screen media expert to choose the best combination for your material.

Blinding and clogging are major problems that stop a vibrating screen from working properly. Blinding is when fine, sticky particles plug the screen openings. Clogging is when near-sized particles get stuck in the openings. Both problems reduce your efficiency and can halt production.

A common, overlooked cause is improper screen tension. A loose screen vibrates poorly, which prevents the material from stratifying correctly and leads to blinding. It also causes the screen media to wear out much faster. To prevent this, you should:

You adjust the screen’s performance by changing the eccentric weights on the vibrator unit. Most vibrating screen models allow you to add or remove counterweights and change their angular position.

Regular maintenance is essential for the long-term performance of your screening equipment. Foundation stability is a critical but often ignored factor. A vibrating screen creates huge dynamic forces, and an unstable foundation can lead to cracks in the structure and damage to the machine.

Here is a simple daily checklist:

In a typical crushing and screening plant, the vibrating screen acts as the quality controller. After large rocks are broken down by a primary crusher (like a jaw crusher), the material is fed onto a vibrating screen. The screen separates the material into different sizes. Oversized material that is still too large is sent back to a secondary crusher (like a cone crusher) for further reduction. Correctly sized material is sent to stockpiles via conveyor belts. This closed-circuit system ensures that all products meet the required size specifications.

At ZONEDING, we have been building robust and reliable vibrating screen solutions since 1990. We understand that uptime and accuracy are what matter most to your bottom line. Our screens are engineered with high-strength steel and feature advanced vibrator technology for consistent performance. We use top-quality components, like heavy-duty bearings, to ensure a long service life. As a direct manufacturer, we can work with you to customize a screening machine with the right number of decks and the perfect screen media for your unique application. We provide a one-stop solution, from design to installation, at a competitive price because there are no middlemen.

| Model | Sieve layer | Vibrating Frequency(r/min) | Mesh size(mm) | Max.feeding size(mm) | Processing capacity(m³/h) | Vibrating Frequency(r/min) | Vibrating Frequency(r/min) | Motor power(kw) | Sieve obliquity(°) | Sievespecification (mm) | >Dimensions (mm) |

| 2YK1225 | 2 | 6 | 4-50 | 200 | 8-60 | 800-970 | 8 | 6P 5.5KW | 20 | 1200×2500 | 2930×1860×870 |

| 3YK1225 | 3 | 9 | 4-50 | 200 | 10-70 | 800-970 | 8 | 6P 5.5KW | 20 | 1200×2500 | 3070×1860×1210 |

| 2YK1230 | 2 | 7.2 | 4-50 | 200 | 12-78 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3000 | 3430×1860×870 |

| 3YK1230 | 3 | 10.8 | 4-50 | 200 | 13-80 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3000 | 3570×1860×1210 |

| 2YK1237 | 2 | 8.88 | 4-50 | 200 | 15-86 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3700 | 4050×1860×870 |

| 3YK1237 | 3 | 13.32 | 4-50 | 200 | 16-90 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3700 | 4270×1860×1210 |

| 2YK1535 | 2 | 10.5 | 5-50 | 200 | 20-125 | 800-970 | 8 | 6P 11KW | 20 | 1500×3500 | 4120×2210×1230 |

| 3YK1535 | 3 | 15.75 | 5-50 | 200 | 21-125 | 800-970 | 8 | 6P 11KW | 20 | 1500×3500 | 4360×2210×1610 |

| 2YK1545 | 2 | 13.5 | 5-50 | 200 | 22-150 | 800-970 | 8 | 6P 11KW | 20 | 1500×4500 | 5120×2210×1230 |

| 3YK1545 | 3 | 20.25 | 5-50 | 200 | 22-150 | 800-970 | 8 | 6P 15KW | 20 | 1500×4500 | 5360×2210×1610 |

| 4YK1545 | 4 | 27 | 5-50 | 200 | 22-155 | 800-970 | 8 | 6P 15KW | 20 | 1500×4500 | 5930×2210×2060 |

| 2YK1548 | 2 | 14.4 | 5-50 | 200 | 22.5-162 | 800-970 | 8 | 6P 11KW | 20 | 1500×4800 | 5420×2210×1230 |

| 3YK1548 | 3 | 21.6 | 5-50 | 200 | 22.5-162 | 800-970 | 11 | 6P 15KW | 20 | 1500×4800 | 5660×2210×1610 |

| 4YK1548 | 4 | 28.8 | 5-50 | 200 | 22.5-162 | 800-970 | 8 | 6P 18.5KW | 20 | 1500×4800 | 6230×2210×2060 |

| 2YK1848 | 2 | 17.28 | 5-80 | 200 | 25-206 | 750 | 8 | 6P 18.5KW | 20 | 1800×4800 | 5420×2550×1420 |

| 3YK1848 | 3 | 25.92 | 5-80 | 200 | 32-276 | 750 | 8 | 6P 18.5KW | 20 | 1800×4800 | 5660×2550×1780 |

| 4YK1848 | 4 | 34.56 | 5-80 | 200 | 32-285 | 750 | 8 | 6P 22KW | 20 | 1800×4800 | 6290×2550×2160 |

| 2YK1854 | 2 | 19.44 | 5-80 | 200 | 32-312 | 800-970 | 8 | 6P 22KW | 20 | 1800×5400 | 5960×2550×1420 |

| 3YK1854 | 3 | 29.16 | 5-80 | 200 | 32-312 | 800-970 | 8 | 6P 22KW | 20 | 1800×5400 | 6260×2550×1780 |

| 4YK1854 | 4 | 38.88 | 5-80 | 200 | 32-336 | 800-970 | 8 | 6P 22KW | 20 | 1800×5400 | 6830×2550×2160 |

| 2YK2160 | 2 | 25.2 | 5-100 | 200 | 50-475 | 970 | 8 | 6P 30KW | 20 | 2100×6000 | 6720×2840×1530 |

| 3YK2160 | 3 | 37.8 | 5-100 | 200 | 50-475 | 970 | 8 | 6P 30KW | 20 | 2100×6000 | 7030×2840×1910 |

| 4YK2160 | 4 | 50.4 | 5-100 | 200 | 50-497 | 970 | 8 | 6P 37KW | 20 | 2100×6000 | 7300×2840×2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 200 | 65-550 | 970 | 8 | 6P 30KW | 20 | 2400×6000 | 7020×3140×1530 |

| 3YK2460 | 3 | 43.2 | 5-100 | 200 | 70-620 | 970 | 8 | 6P 37KW | 20 | 2400×6000 | 7300×3140×1910 |

| 4YK2460 | 4 | 57.6 | 5-100 | 200 | 80-680 | 970 | 8 | 6P 45KW | 20 | 2400×6000 | 7600×3140×2380 |

| 2YK2870 | 2 | 39.2 | 5-100 | 200 | 120-680 | 750 | 8 | 8P 22×2KW | 20 | 2800×7000 | 7600×4320×1620 |

| 3YK2870 | 3 | 58.8 | 5-100 | 200 | 180-720 | 750 | 8 | 8P 22×2KW | 20 | 2800×7000 | 7800×4320×2120 |

| 2YK3072 | 2 | 43.2 | 5-100 | 200 | 200-700 | 750 | 8 | 8P 22×2KW | 20 | 3000×7200 | 7800×4520×1750 |

| 3YK3072 | 3 | 64.8 | 5-100 | 200 | 230-800 | 750 | 8 | 8P 22×2KW | 20 | 3000×7200 | 8000×4520×2300 |

What’s the difference between an inclined and a horizontal vibrating screen?

An inclined screen uses gravity to help move material, making it very energy-efficient for sizing. A horizontal screen requires more vibrational force to move material but is ideal for situations with limited vertical space or for dewatering applications.

How often should I replace the screen mesh?

This depends entirely on the abrasiveness of your material and your operating hours. For highly abrasive rock, you might replace a wire mesh every few weeks. With less abrasive material, a polyurethane screen can last for many months. Regular inspection is key.

Can a vibrating screen be used for washing materials?

Yes. By adding spray bars above the screen decks, a vibrating screen can be used to wash sand, gravel, or other materials. The vibration scrubs the material while the water rinses away dirt, clay, and other unwanted fines.

What causes excessive noise in a vibrating screen?

Excessive noise can be caused by loose bolts, worn-out bearings, a broken spring, or an unstable foundation. It’s important to shut down the machine and inspect it immediately if you notice a significant increase in noise.

Reliable Jaw Crushers for efficient primary crushing in mining, quarrying & aggregate production. Heavy-duty design, high throughput.

Cone Crusher For Sale: Highly efficient, stable and durable, ideal for all ore crushing needs. It can improve production efficiency and reduce operating costs.

High-efficiency VSI sand making machines for producing premium artificial sand from rock & gravel. Excellent particle shape, low wear cost.

PF Series Impact Crusher for secondary crushing of limestone, rock, and efficient recycling of concrete & asphalt. High throughput, excellent shape. Get Specs!

Looking for a high-performance Vibrating Feeder? Explore our durable industrial feeding machines for mining & aggregate plants.

Sand Washing Machines (Wheel & Spiral types) to remove impurities & improve sand quality for construction & industry. High cleanliness, reliable performance. Get Your Quote!

Smooth Roll Crushers for finer sizing or Toothed Roll Crushers for better grip on materials like coal & shale. Reliable, low maintenance crushers for various industries.

Looking for a high-efficiency fine crusher? Explore our industrial fine crushing machines for sale. Factory-direct pricing and large capacity.

Compound Crushers (Vertical Shaft) for efficient fine crushing of medium-hard materials like limestone & clinker. Simple structure, high ratio, ideal for sand making & aggregate. Get Quote!

Looking for a high-performance Hammer Crusher? Our heavy-duty machines offer large crushing ratios and stable operation. Get your factory-direct quote today!

loading…

已经是到最后一篇内容了!