Search the whole station Crushing Equipment

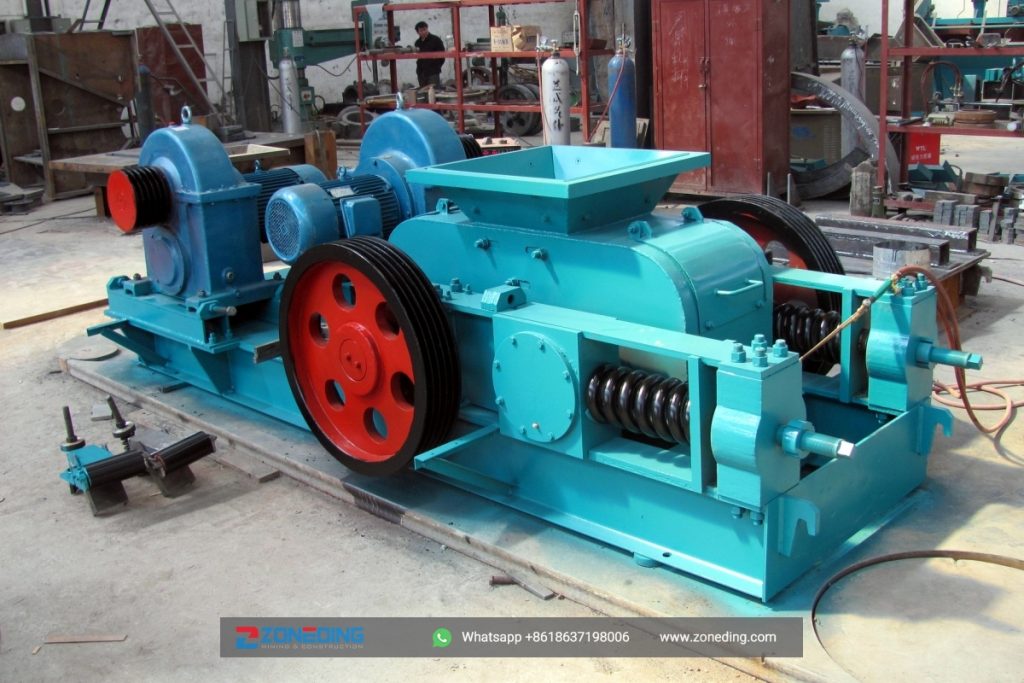

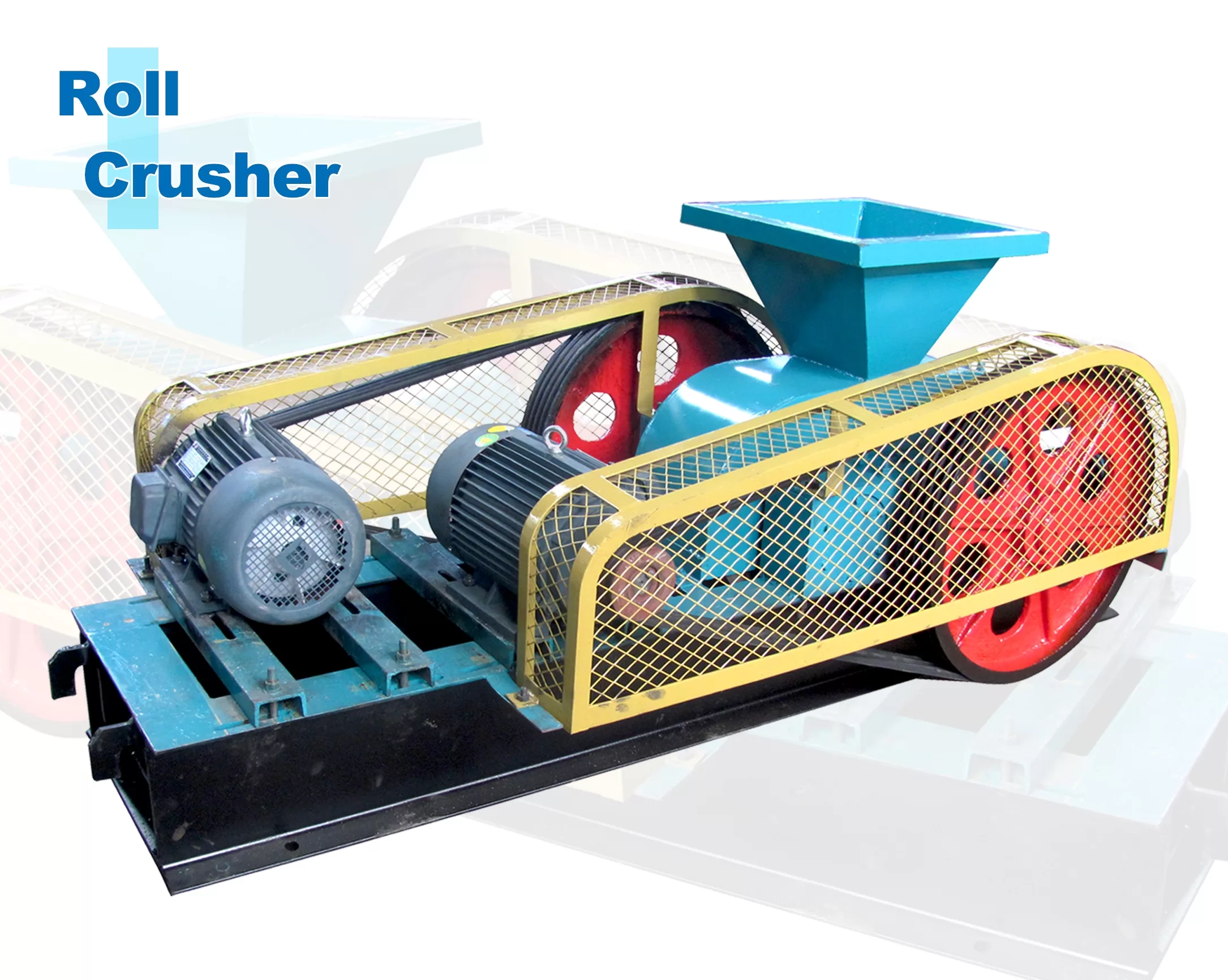

Roller crusher is also known as roll crusher, which relies on the high-speed rotation of roll wheel to crush materials. The commonly used roll crusher types include double roller crusher, toothed roller crusher, four roller crusher, etc.

Roll crusher is also called double roll crusher, double teeth roll crusher, etc. The surface of the roller crusher is made of high manganese steel, which can stand up to heat treatment.

A Roll Crusher, also known as a roller crusher, is a machine that uses compression to crush materials. Imagine squeezing something between two heavy, spinning cylinders—that’s the basic idea. Material is fed into the gap between the rolls. The spinning rolls grab the material and pull it through, crushing it to a predetermined size. Its main job is to create a very uniform final product, making it a sizing machine more than just a simple reduction machine.

The main advantage of a roll crusher is its ability to produce a consistent product with minimal fines. Unlike impact crushers that shatter rock, a roll crusher applies slow, high pressure. This breaks the material along its natural weak points without creating extra dust or stress fractures. A double roll crusher in particular gives you excellent control over this process. This means you get a stronger, more stable aggregate, which is perfect for high-quality blocks.

Another key benefit is its ability to handle difficult materials.

1.Crushing various rocks

Double toothed roller crusher is generally used for crushing medium-hard rocks with compressive strength of less than 200 Mpa, such as limestone phosphate, basalt, granite, river pebbles, iron ore, gold ore, copper ore lead-zinc ore, nickel ore, asphalt, bricks, cement, and other materials.

2. The first choice for crushing coal

Double toothed roller crusher is a new type of equipment recommended by major coal plants for crushing raw coal, coke, lignite, and activated carbon. lt crushes the coal by squeezing the double toothed rollers and easily removes the materials adhering to the rollers.

The roller crusher has dual functions of pre-screening and crushing. Small and medium-sized materials in the coal mine are directly leaked from the gap between the toothed rollers to avoid reprocessing. The phenomenon of over-crushing is improved.

3.Crushing sticky materials

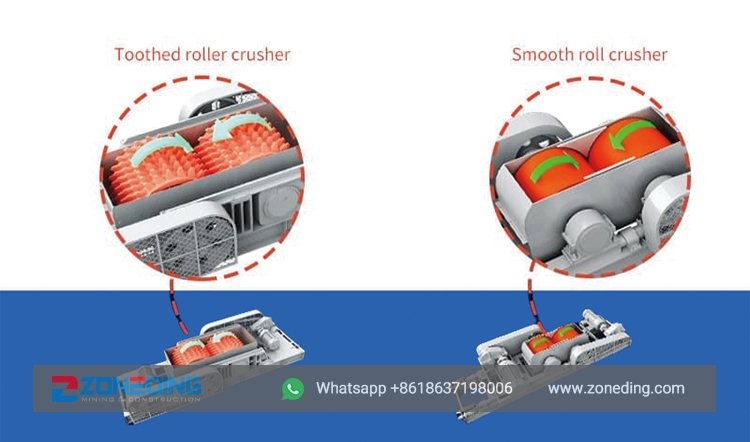

Roll crushers come in a few main configurations, designed for different tasks. The choice depends on your material and the reduction ratio you need.

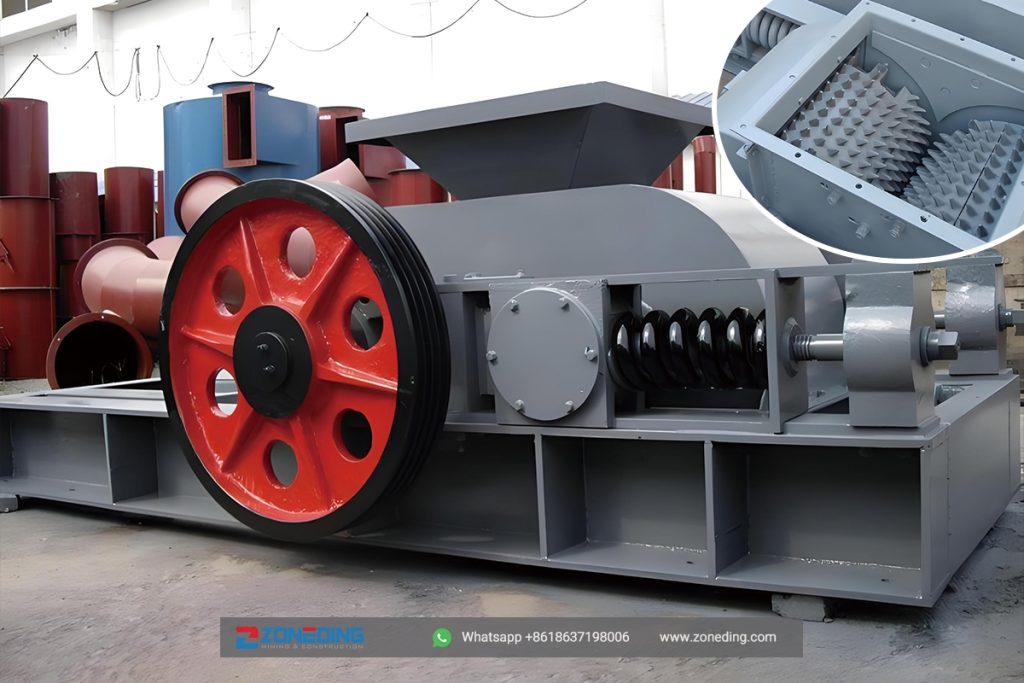

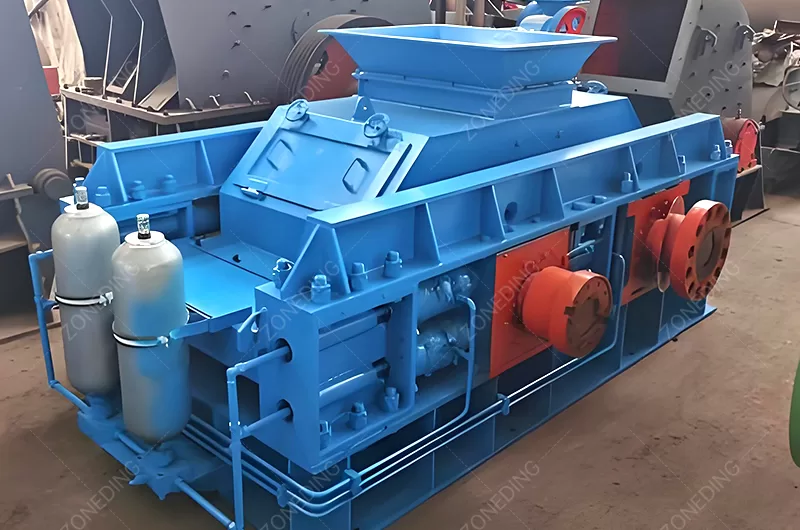

Our company produces 3 types of roll breakers: Roller crushers,Toothed rollers and hydraulic rollers.

Roll Crusher

Toothed Roll Crusher

Hydraulic Roller Crusher

The crusher working principle is simple but precise. Material is fed into the top of the machine. The rotating rolls create a “nip angle.” This is the angle where the rolls grip a particle. If the particle is the right size, the rolls pull it into the gap. The immense pressure from the crush roll action breaks the particle. The crushed material then falls out of the bottom of the machine.

The key to high efficiency is feeding the crusher correctly. The feed material must be small enough for the rolls to “bite.” If the feed is too large, the machine will not be able to grip it and will spit it back out. This is why controlling the size of the material going into the crusher is so important.

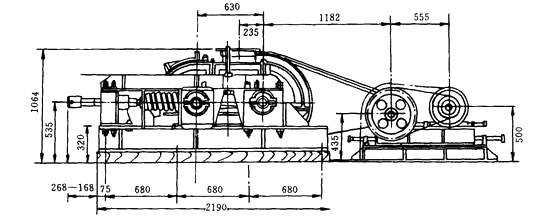

The main working parts of the roller crusher is the cylindrical rollers. The rollers are supported by the fixed and movable bearings, and they are relatively rotating which are driven by the motor. The materials are crushed by the friction of the rotating rollers, and the finished products are discharged from the gap of the rollers.

The roller crusher, also known as roll crusher machine, has a wide range of applications across various industries.

Roll Crusher is suitable for River gravel, iron ore, limestone, basalt, quartz, granite and other medium or hard ores and rocks in metallurgy industry, cement industry, power department, construction, phosphate, refractory industry, etc.

A mining crusher like this is built to be tough. At ZONEDING, we focus on a robust structure to ensure long life and reliable operation.

The counter-roller crusher pulls the material on the roller surface into the crushing cavity, so that the material is crushed by the stress mainly caused by squeezing, and is taken out of the crushing cavity by the rotating roller and discharged as the crushed product.

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Roller Diameter(mm) | Ф400 | Ф600 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

| Roller Width(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Input Size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Discharging Gate(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

| Processing Capacity(t/h) | 5-10 | 10-20 | 15-30 | 20-40 | 30-50 | 40-70 | 60-110 |

| Power Models | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

| Motor Power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

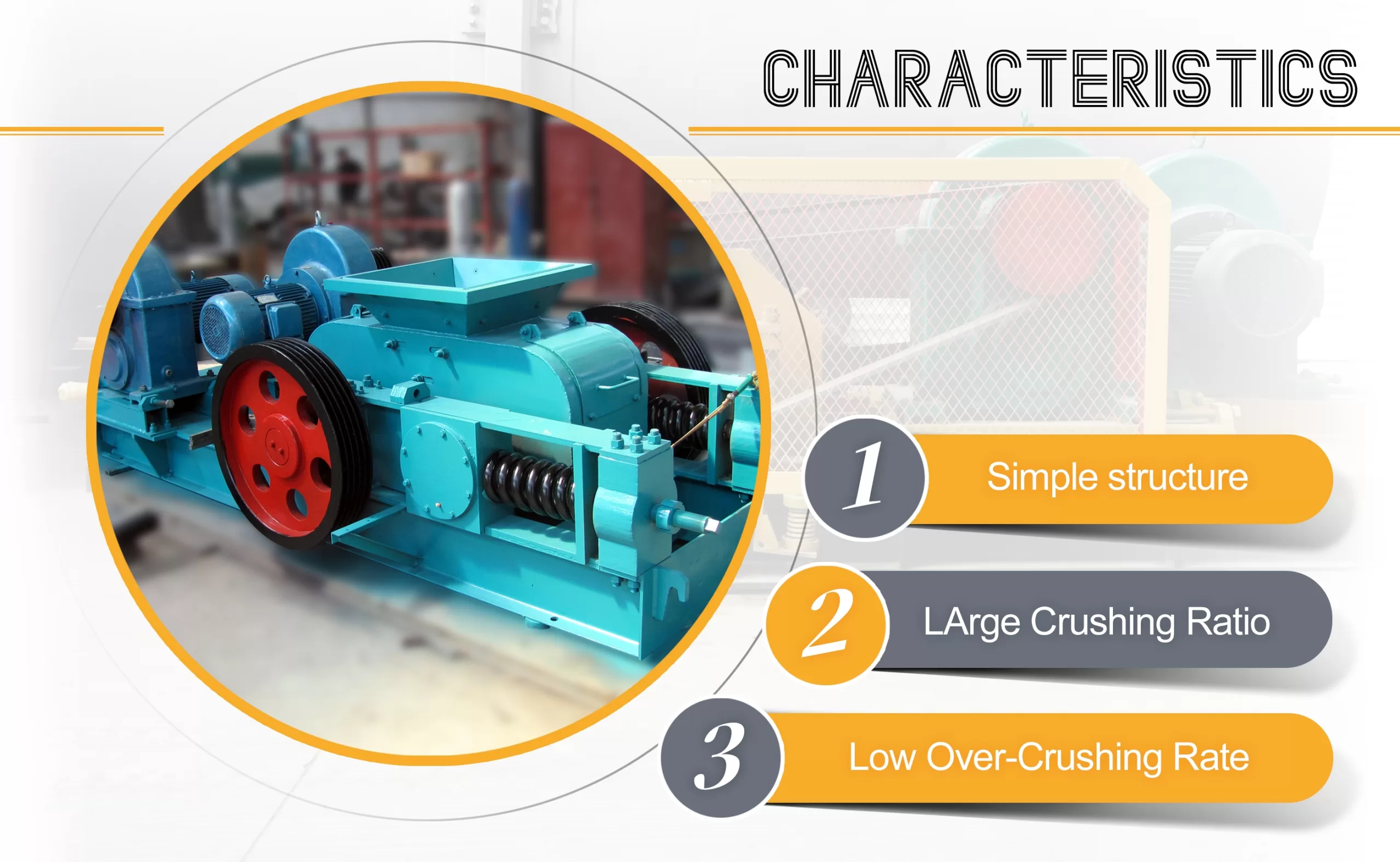

① It has a simple and compact structure with small occupation and convenient operation and maintenance.

② The cost is low and the operation is stable, with high energy and crushing efficiency, and adjustable discharge port.

③ It has a light weight, small size, significantly saving investment.

④ The roller crusher is equipped with safety protection devices. When metal pieces enter the crushing chamber, the protective device works and lets the metal leak out of the machine without stopping it.

⑤ The inside is equipped with dustproof board, which has good sealing performance, avoids splashing of fine materials after crushing, with less dust, low working noise, largely improving the working environment.

⑥ The gap of the abrasive roller can be adjusted arbitrarily between 1mm and 20mm. After adjusting the roll gap according to the requirements, the crushing particle size can be reliably controlled, and all of them are discharged from the lower part of the crushing cavity with the ideal size.

The roller crusher is working in low speed and high pressure with extruding materials which fall vertically into the crushing chamber from the upper part, and are crushed by the strong pressure generated between the two rolls.

⑦ Most of the material has become powdery, and a large number of cracks have been generated in the interior of the small granular material. Thus, in the further pulverization process, the grinding energy consumption can be greatly reduced and the yield can be increased.

⑧ The roller crusher is equipped with a replaceable wear-resistant lining plate which adopts domestic advanced technology, and has the advantages of long service life, easy damage and convenient maintenance.

The continuous service life can be more than one year, and can be easily changed when the wear is seriously damaged. The maintenance quantity is small and the cost is low, which is unmatched by other types of crushers.

When we design our roll crushers, we focus on reliability and low operating costs for you. Our machines are built with features that make a real difference in your daily operations. The roll shells we use are made from a high-manganese steel alloy for excellent wear life. We also offer hard-facing options to rebuild the roll surface, which can extend its life by up to 500%.

Our spring protection system is another key feature. It acts as a mechanical fuse. We use oversized, durable springs that are easy to inspect and tension. This system is crucial for protecting your investment from damage caused by tramp metal. A reliable protection system means you have less downtime and fewer expensive repairs.

These versatile roll crushers excel with certain types of materials. They are not the best choice for very hard, abrasive rock like granite. They shine when crushing soft to medium-hard materials.

The Roll Crusher Price can vary widely, from around $10,000 for a small laboratory model to over $150,000 for a large, high-capacity mine crusher. The final cost for your specific roll crusher depends on several factors:

Remember, the purchase price is only part of the total cost. The ongoing cost of wear parts and maintenance is also a major factor.

Choosing between a Smooth Roll Crusher and a toothed one depends entirely on your material. Using the wrong type will lead to poor performance and high costs.

These three crushers do different jobs. Choosing the right one is critical for an efficient plant.

Controlling your final product size is easy with a roll crusher. The distance between the two rolls is called the “gap.” This gap setting directly determines the maximum size of the material that comes out. You can adjust this gap using a simple system of shims. You add or remove these metal plates to move one of the rolls closer to or farther from the other. Some more advanced models use a hydraulic system that allows for faster and easier adjustments.

Like any crusher, a roll crusher has parts that wear out over time and need to be replaced. The main wear parts are:

The roll shells are the most significant wear cost. Proper maintenance and operation can greatly extend their life.

Good maintenance is the key to long life and low operating costs. There are a few critical tasks.

At ZONEDING, we have been building block machines and crushing equipment since 1990. We don’t just sell machines; we provide complete, reliable solutions. And We understand that a crush roller is part of a larger system. Our engineers will help you choose the right double roll crusher for your material and integrate it into your production line. We build our roll crushers with heavy-duty frames, superior wear parts, and reliable protection systems to ensure you get consistent performance day after day. Our goal is to be your partner, providing the equipment and expertise you need to succeed.

ZONEDING has exported crushing plants in 100+ countries, providing customers with versatile and ideal crushing plant solutions.

Reliable Jaw Crushers for efficient primary crushing in mining, quarrying & aggregate production. Heavy-duty design, high throughput.

Cone Crusher For Sale: Highly efficient, stable and durable, ideal for all ore crushing needs. It can improve production efficiency and reduce operating costs.

High-efficiency VSI sand making machines for producing premium artificial sand from rock & gravel. Excellent particle shape, low wear cost.

PF Series Impact Crusher for secondary crushing of limestone, rock, and efficient recycling of concrete & asphalt. High throughput, excellent shape. Get Specs!

Looking for a high-performance Vibrating Feeder? Explore our durable industrial feeding machines for mining & aggregate plants.

Sand Washing Machines (Wheel & Spiral types) to remove impurities & improve sand quality for construction & industry. High cleanliness, reliable performance. Get Your Quote!

The YK series circular vibrating screens are high-performance and suitable for heavy-duty quarrying and aggregate screening operations. Multi-layer screen options are available for precise grading.

Looking for a high-efficiency fine crusher? Explore our industrial fine crushing machines for sale. Factory-direct pricing and large capacity.

Compound Crushers (Vertical Shaft) for efficient fine crushing of medium-hard materials like limestone & clinker. Simple structure, high ratio, ideal for sand making & aggregate. Get Quote!

Looking for a high-performance Hammer Crusher? Our heavy-duty machines offer large crushing ratios and stable operation. Get your factory-direct quote today!

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy