Search the whole station Crushing Equipment

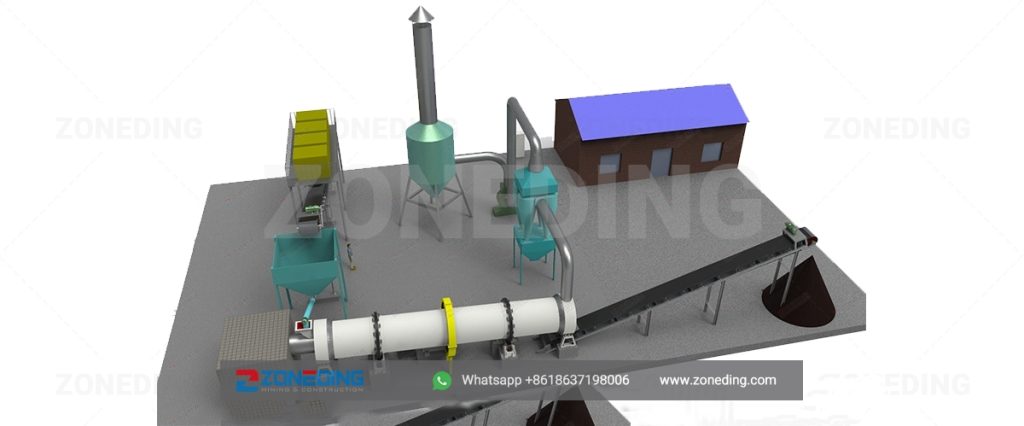

Zoneding Company conducted technical research on sludge treatment, created a new generation of sludge rotary drum drying system that can reduce product moisture to less than 25%, with mature technology and easy operation and maintenance.

Sludge drying is a process to dewater and recycle high-moisture sludge as resource. there are mainly two ways to dry sludge, natural drying and mechanical drying. The latter is more efficient. The removal of water reduces the sludge quality and volume, which is to make it convenient to be store and transport the sludge. With mature and advanced international technology from Europe, etc., Zoneding solution on sludge drying process is based on the properties, like high water content, high organics content, and low specific gravity, etc.

According to different customers’ needs, Zoneding offers sludge drying machine with different heat sources.

Sludge is the semi-solid waste left over from industrial or municipal wastewater treatment processes. Think of it as the thick, muddy material that settles at the bottom of treatment tanks. The biggest problem with sludge is its water content. Fresh sludge can be over 99% water. Even after some mechanical dewatering, it is still often 70% to 80% water.

This high water content makes it very heavy, smelly, and difficult to handle. Hauling and disposing of this wet, heavy material is extremely expensive. The weight is what drives up your transportation and landfill fees. In effect, you are paying a high price to transport and dispose of water. This is the core problem that a sludge management solution must solve.

You should dry your sludge for one primary reason: massive sludge disposal cost reduction. It is a simple equation. Disposal services charge based on weight and volume. When you use a thermal sludge drying process, you evaporate the water. This can reduce the total weight and volume of your sludge by as much as 90%.

Imagine you produce 10 tons of wet sludge (80% water) per day. That means 8 tons of that weight is just water. After drying it to 10% moisture, you are left with just over 2 tons of material to dispose of. Your hauling and disposal costs can drop by 75-80%. This is one of the biggest benefits of sludge drying. It directly impacts your bottom line. Drying also sterilizes the sludge, eliminates foul odors, and creates a stable, easy-to-handle product that is no longer considered hazardous waste.

Drying sludge does more than just reduce waste. It can transform a costly liability into a valuable asset. The dry, granular product has several useful applications. This turns your waste stream into a revenue stream.

A modern industrial sludge dryer is a very versatile machine. It can handle a wide variety of sludge types from different industries. The key is to have a system that can be adjusted for different moisture levels and material characteristics.

At ZONEDING, we design our sludge drying system to handle:

The important thing is to analyze your sludge first. This helps determine the right drying temperature, retention time, and any pre-treatment needed for the best results.

A sludge dryer is a piece of industrial equipment designed specifically for thermal sludge drying. Its job is to use heat to evaporate the water from wet sludge. This leaves behind a dry, solid, granular product. The most common and effective type for this job is the rotary drum dryer. Its design is perfect for continuously processing the sticky and challenging nature of sludge.

A complete sludge drying system is more than just the dryer itself. It includes a feeding system to get the wet sludge into the drum. It has a heat source, like a gas burner or furnace. And It includes a dust collection system to capture fine particles from the exhaust air. It also has a discharge system to cool and convey the final dry product. It is a complete, integrated process.

Produced from sewage disposal, sludge actually can be transformed by special designed sludge dryer equipment into a kind of green fuel and resource. Sludge is an extremely complex heterogeneous material composed of organic fragments, bacteria, inorganic particles, colloids, etc. And Sludge has the characteristics of high moisture, high organic matter content, fine particle and small specific gravity.

Sludge dryer plays a key role in dehydrating and drying wet sludge to a certain moisture. Dried sludge can be used in agriculture to improve the soil, in building materials production to be the raw material of cement and in brick making. Besides, sludge dryer can be used to make biochemical fiberboard.

Applications of Sludge Dryer

It is mainly composed of barrel, supporting device, driving device and sealing device, etc. The working areas include discharging area, lifting board area, cleaning area and feeding area.

What a Sludge Dryer Brings to You?

An efficient use of sludge brings environmental protection as well as over-expected economic benefits.

Ⅰ. Reducing Weight and Volume

Sludge dryer reduces the sludge volume and weight by evaporation of water in it, making it easier to store and transport.

Ⅱ. Stabilize Sludge

Drying can stabilize the sludge, thus reducing the putrid smell and improving the disinfection effect.

Ⅲ. Simplify the Next Process

Either in following sludge disposal or in direct recycle process, sludge drying equipment plays an essential part of boosting the calorific value of sludge, which makes sludge easier to be used as fuel.

There are two commonly used types of sludge dryer machine, single-cylinder rotary sludge dryer and high-viscosity sludge drying equipment.

The first is newly developed from ordinary rotary dryer with cleaning device, breaking device and others inside. For drying material with a certain viscosity and smaller particle size, single-cylinder rotary sludge dryer is the better choice.

The latter usually uses hot-air spiral-blade drying technology with double or three shafts alternative according to the viscosity of the sludge. This drying machine can dry sludge with humidity below 85% to 12% or below just one time. And this drying process takes less time like 2-10 mins.

The heart of an effective industrial sludge dryer is the rotary drum. At ZONEDING, we build these to be extremely tough. The structure consists of a large, slightly inclined steel cylinder that rotates slowly.

Inside the drum, there are a series of specially designed lifters, or “flights.” As the drum rotates, these flights lift the sludge and shower it down through the stream of hot gas. This maximizes contact between the hot air and the sludge particles. We also often include internal crushing devices or chains. These break up the large clumps of sticky sludge as it dries. This prevents the material from forming large, hard balls. This internal design is critical for achieving a uniformly dry final product. The drum is supported by heavy-duty steel tires and trunnion wheels and is driven by a powerful gear and motor system.

The sludge dryer working principle is a continuous process of heat transfer and mass transfer. It is a simple but effective process.

The price of a complete sludge drying system can range from $250,000 to over $2,500,000. The final cost depends on several key factors. The most important factor is the capacity. This means how many tons of sludge you need to dry per hour.

Other factors include the initial moisture content of your sludge and the desired final moisture content. The type of fuel you use for the heat source will also affect the cost. A system for a highly corrosive type of industrial sludge will need to be built with more expensive stainless steel, which increases the price. When you request a quote, an experienced industrial sludge dryer manufacturer like ZONEDING will ask for these details. We will then design a system specifically for your needs. The initial investment is significant, but the ROI from disposal cost savings is often realized in just 1 to 3 years.

A sludge dryer is a heavy-duty machine that works in tough conditions. Proper maintenance is key to keeping it running reliably for many years. We design our dryers for easy maintenance.

Here are the key maintenance tasks:

Choosing the right sludge dryer is a critical decision. You need a machine that is specifically designed for your material and your operational goals.

At ZONEDING, we have over 30 years of experience building heavy-duty rotary equipment. We apply this expertise to design and build the most reliable and efficient sludge dryer on the market.

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

How much can I really save with a sludge dryer?

Most of our clients see a 70-90% reduction in their sludge weight. This typically translates to a 60-80% reduction in their total sludge disposal costs. The return on investment is often achieved in under three years.

Is the dried sludge hazardous?

The thermal sludge drying process is a form of sterilization. The high temperatures kill pathogens and bacteria. In many cases, this process changes the waste classification of the material from hazardous to non-hazardous, making it much cheaper and easier to handle.

What kind of fuel can the sludge dryer use?

Our systems are very flexible. The heat source can be fueled by natural gas, diesel, coal, or even biomass. We can design the furnace to use the most cost-effective fuel available at your location.

Does the drying process create a lot of pollution?

No. A modern sludge drying system is a closed-loop system. The exhaust air passes through a high-efficiency cyclone and baghouse filter. These devices capture over 99.9% of the dust particles, ensuring the system complies with all environmental air quality standards.

Buy industrial gypsum dryer for sale. Efficiently remove moisture from gypsum rock & powder. Improve product quality & processing speed.

Rotary cooler for sale. Efficiently cool hot materials discharged from kilns & dryers. Improve process speed & material quality.

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Discover high-performance aggregate and sand dryers for sale. We offer triple-pass and rotary drum models for efficient moisture removal. Get a quote today!

Looking for a high-efficiency triple-drum rotary dryer? Saves energy, space, and cost; suitable for drying sand, coal, and biomass. Rugged and reliable.

Purchase an industrial bentonite dryer suitable for various applications such as drilling mud, cat litter, and foundry work. Achieve optimal moisture content and uniform drying.

Specialized Coal Dryer machines for power generation, coking, and briquetting. Improve fuel efficiency, reduce transport costs & enhance combustion.

Professional slurry dryer manufacturer with CE/ISO certification. Customizable 5-50t/h capacity, 35% energy saving. Get instant technical specs download.

Professional slag dryer manufacturer with CE/ISO certification. Energy-saving 30%, global delivery to 50+ countries. Get custom solutions for mining waste processing.

This mineral powder dryer is specifically designed for use with mineral concentrates, iron ore powder, and metallurgical slag. It ensures uniform drying, improving product quality and recovery rates.

loading…

已经是到最后一篇内容了!