Search the whole station Crushing Equipment

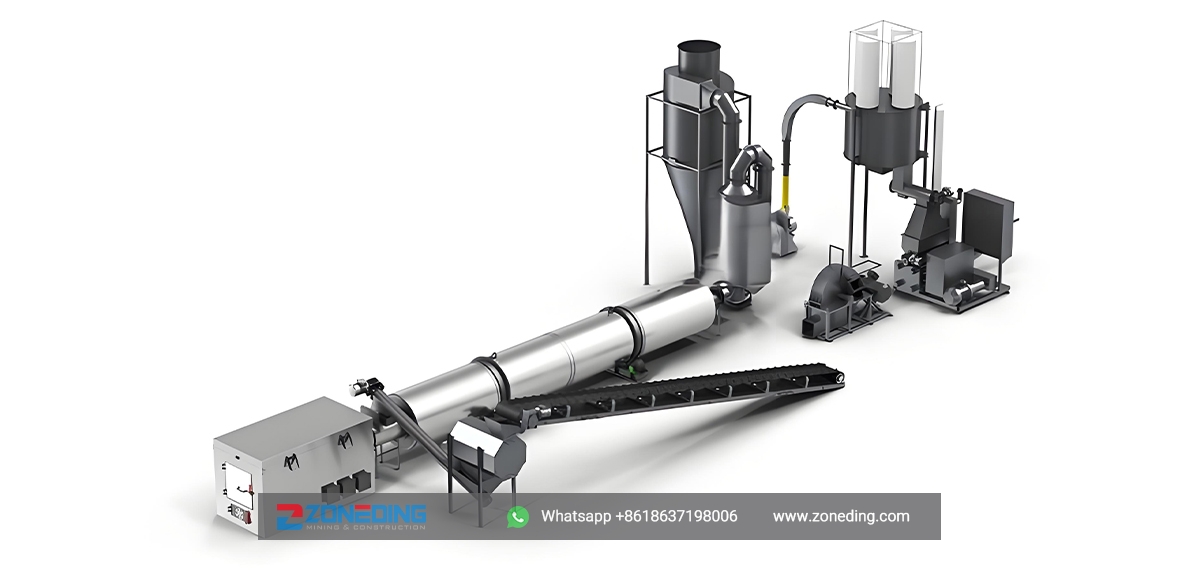

Bentonite, a versatile clay, varies in color with iron content. Zoneding’s dryer boosts efficiency with custom, high-capacity design and advanced blades for optimal material retention.

Bentonite is a kind of clay rock, which often contains a small amount of illite, kaolinite, chlorite, zeolite, etc. Due to the changes of iron content, it is usually in white and pale-yellow color and easily become light gray, light green, pink, brown-red, etc. Aimed at the adsorptivity and other characteristics of bentonite, bentonite dryer is designed with large capacity. Zoneding bentonite drying technology adopts new grouped lifting blades equipment to improve the material filling rate and extend the stay time of wet bentonite in the cylinder. With improved production efficiency, Zoneding bentonite dryer machine is customized.

Bentonite is a type of absorbent clay formed from volcanic ash. Its most important component is montmorillonite. Think of the molecular structure of bentonite as a stack of microscopic playing cards. When water gets between these “cards,” it pushes them apart, causing the clay to swell dramatically. This super-absorbent property is what makes bentonite so valuable.

Wet bentonite is a low-value, heavy paste. Drying is the essential step that turns it into a high-value, functional product.

Dried and processed bentonite is used in dozens of industries. The final application is critical because it determines how the bentonite must be dried.

The most important secret in drying bentonite is this: you are not selling dry clay; you are selling “swelling potential.” Its value comes from its ability to absorb water. If you overheat the bentonite, you permanently destroy this ability. This process, called calcination, happens when you drive off the “crystalline water” from the clay’s molecular structure, not just the surface water. You have turned your high-value clay into low-value ceramic filler. The drying process must be a gentle conditioning process with precise temperature control, not just a brute-force heating process.

The other major difficulty is the material’s consistency. Wet bentonite is like a thick, sticky dough. If you feed it directly into a standard dryer, it will coat every surface, build up into massive clumps, and quickly plug the entire machine. Your project will fail. This is why the process must be engineered specifically for bentonite’s unique challenges.

A successful bentonite processing plant follows a specific, non-negotiable workflow.

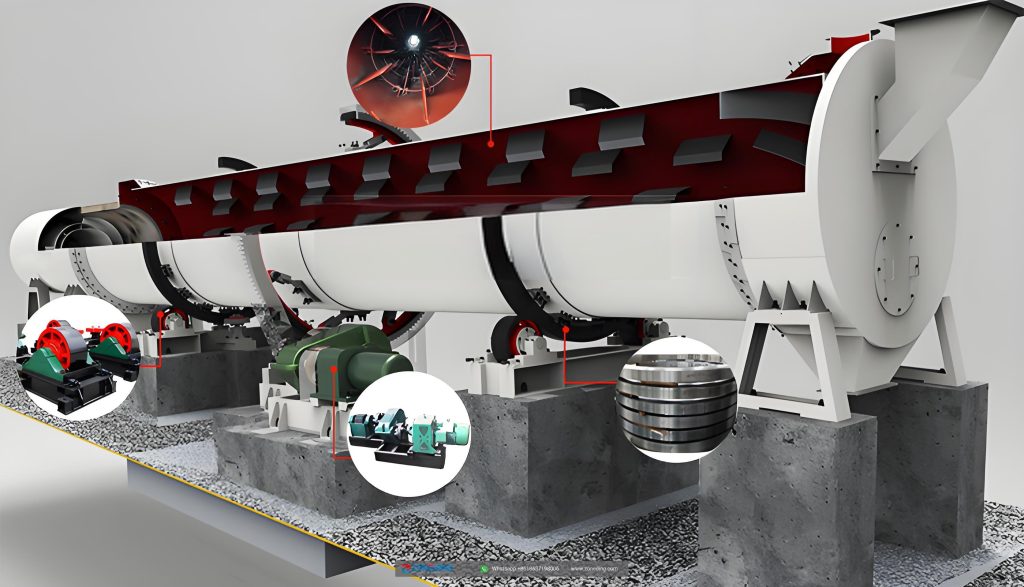

A bentonite dryer is a type of industrial dryer that has been heavily modified to handle the unique challenges of bentonite clay. It is not an off-the-shelf machine. A true rotary dryer for bentonite has special internal components designed to break up clumps and prevent sticking, along with a precision control system to avoid overheating the product.

While most bentonite is dried in rotary dryers, the specific design depends on the end product.

The bentonite dryer is simple and reliable, which can dry various kinds of materials which are of huge humidity and large specific gravity, such as cement, concentrate powder, slag, limestone, coal, slag, clay and kaolin in building materials, metallurgy, chemical industry, etc.

Examples of Bentonite Dryer Application

When bentonite drying machine is operated, the law of heat transformation and the effect of gravity play the main role. The drum is set at an angle of about 3-5。. Wet bentonite is conveyed into the higher end of the cylinder by feeding system and falls down into a screen, which favors the efficiency of heat transformation. When the drum rotating, bentonite is raised by the blades and falls. Here heat transformation between scorching wind and wet materials works best. Under the gravity, dried bentonite steps down to the lower end of the drum and is blenched out. In the gradual stepping down, the excessive liquid is removed. There equips a professional dust collector to collect waste gas.

A standard rotary dryer will fail when drying bentonite. The sticky clay will immediately pack onto the lifters, and within hours, the dryer will become a solid plug. A proper bentonite dryer must have a specialized “breaker section” in the first third of the drum. This section does not have standard lifters. Instead, it is filled with heavy-duty breaker bars or, even better, a dense curtain of massive, case-hardened steel chains. As the drum rotates, these chains swing and slam into the material. This violent mechanical action is what breaks up the clumps and prevents buildup, creating the surface area needed for drying to begin.

The drying of bentonite always adopts bentonite dryer, which can process a large number of materials. Bentonite dryer machine has reliable running, flexible operation, strong adaptability, large capacity, and strong adaptability. It is suitable for drying various materials with simple and reliable operation.

The bentonite dryer operating principle is a two-part process. First, the back-mixing system prepares the material so it can flow. Then, the dryer itself takes over. The conditioned, crumbly bentonite enters the dryer and is first attacked by the chain or breaker section. This breaks it down into smaller pieces. As it moves further down the drum, it enters a section with more conventional lifters that cascade the now semi-dry material through a stream of hot gas.

The temperature of this gas and the product itself is precisely controlled. We use sensors to monitor the product temperature at the discharge end. This data is fed back to the burner, which adjusts the heat input automatically. This ensures we remove the surface water efficiently without ever reaching the temperature that would cause calcination and destroy the bentonite’s valuable swelling properties.

The cost of drying bentonite is tied to a complete system, not just the dryer. A full system, including a back-mixing pug mill, the rotary dryer, and dust collection, can range from $250,000 to over $3,000,000. The price depends on the capacity (tons per hour) and the complexity of the system. Remember, the cheapest way to remove water is with mechanical pressure, not expensive fuel. Investing in a filter press first can dramatically reduce the required size of your dryer and your long-term energy bills.

To choose the right system, you must look beyond the dryer itself.

Maintenance focuses on wear and buildup.

At ZONEDING, we engineer successful bentonite processing plants, not just sell machines.

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Buy industrial gypsum dryer for sale. Efficiently remove moisture from gypsum rock & powder. Improve product quality & processing speed.

Rotary cooler for sale. Efficiently cool hot materials discharged from kilns & dryers. Improve process speed & material quality.

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Find high-efficiency sludge dryers for sale. Reduce sludge volume, cut disposal costs, and improve handling. Ideal for municipal & industrial applications.

Discover high-performance aggregate and sand dryers for sale. We offer triple-pass and rotary drum models for efficient moisture removal. Get a quote today!

Looking for a high-efficiency triple-drum rotary dryer? Saves energy, space, and cost; suitable for drying sand, coal, and biomass. Rugged and reliable.

Specialized Coal Dryer machines for power generation, coking, and briquetting. Improve fuel efficiency, reduce transport costs & enhance combustion.

Professional slurry dryer manufacturer with CE/ISO certification. Customizable 5-50t/h capacity, 35% energy saving. Get instant technical specs download.

Professional slag dryer manufacturer with CE/ISO certification. Energy-saving 30%, global delivery to 50+ countries. Get custom solutions for mining waste processing.

This mineral powder dryer is specifically designed for use with mineral concentrates, iron ore powder, and metallurgical slag. It ensures uniform drying, improving product quality and recovery rates.

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy