Search the whole station Crushing Equipment

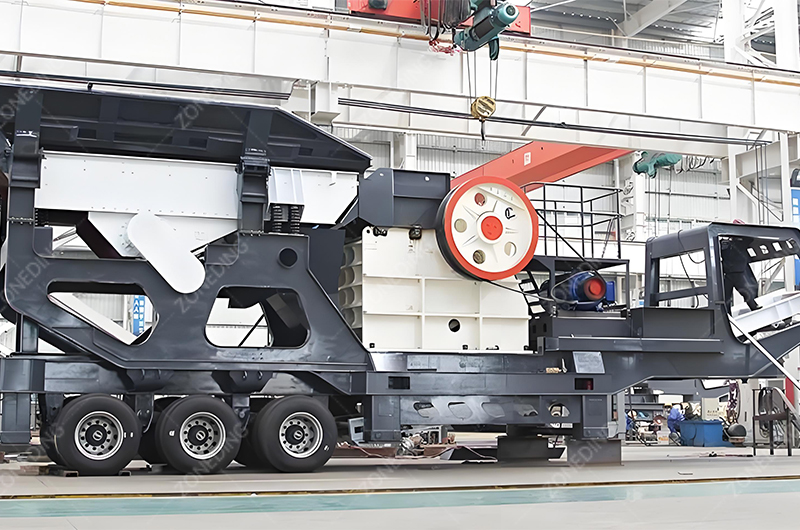

A mobile jaw crusher is essentially a (core equipment for primary material crushing) mounted on a movable chassis (track-mounted or wheeled), integrating auxiliary systems like feeding and conveying. Compared to stationary jaw crushers, its core advantages lie in eliminating the need for complex foundation construction, allowing rapid site transfer, and enabling flexible positioning close to the working face, significantly shortening project construction cycles and material transport distances.

Because the jaw crusher itself is the most classic and reliable primary crushing equipment, adept at handling large blocks of various hardness, with a simple structure that is robust and durable. Making it “mobile” perfectly meets the needs of many projects for source processing and rapid production startup. The mobile jaw crusher thus becomes the most common “vanguard” in mobile crushing lines.

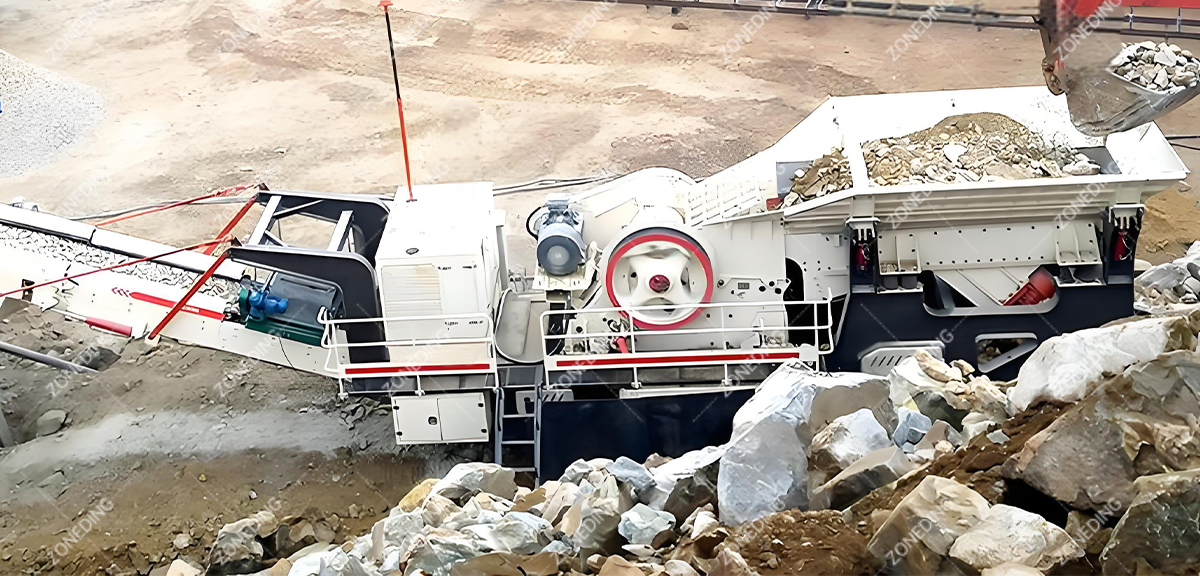

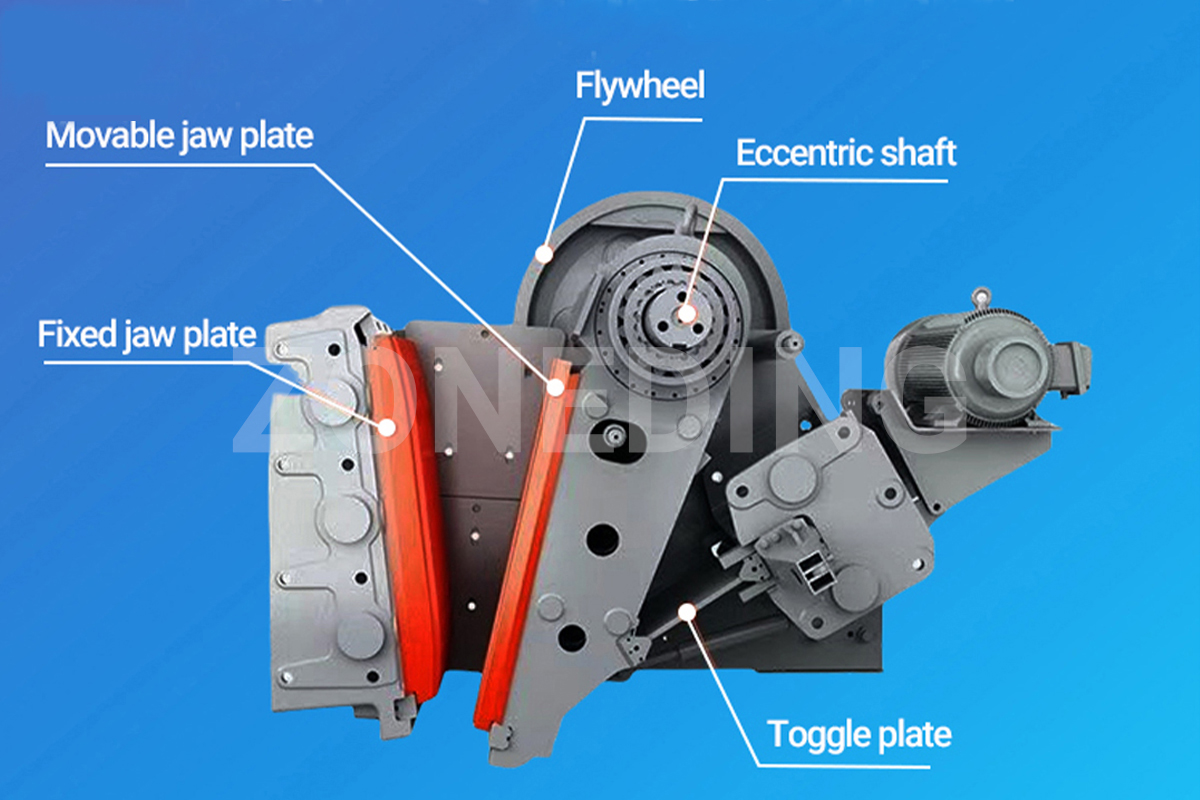

Imagine large rocks freshly blasted from a mountain or huge concrete blocks from a demolition site—they vary in size, shape, and potentially high hardness. At this point, you need equipment with a good “appetite” and sufficient power to perform the first crushing stage, reducing them to a size suitable for secondary crushing or screening. The jaw crusher breaks materials through the squeezing and bending action of its movable and stationary jaw plates. It has a large crushing force and strong material adaptability, effectively processing hard and abrasive materials. Integrating it onto a mobile chassis allows this powerful primary crushing capability to be applied directly at the worksite, eliminating the hassle of transporting large, difficult-to-move raw materials to a fixed plant, naturally boosting efficiency significantly.

Choosing between a track-mounted or wheeled mobile jaw crusher mainly depends on your mobility scenarios and site conditions. Track-mounted is better for short-distance movement within harsh, uneven sites and doesn’t require towing for relocation; Wheeled is convenient for long-distance road transport, suitable for relatively flat sites and situations requiring frequent transfers between different work sites.

| Comparison Dimension | Track-mounted Mobile Jaw Crusher | Wheeled Mobile Jaw Crusher | What it means for you |

|---|---|---|---|

| Site Adaptability | Strong, adapts to harsh terrain, can climb | Average, needs relatively flat, firm ground | Choose tracked for mines, complex sites; wheeled for flat ground, road transfers |

| Mobility Method | Self-propelled tracks (on-site) | Needs tractor towing (road/site) | Tracked is flexible on-site, wheeled is efficient for long distances |

| Deployment Efficiency | Fast, remote control positioning | Relatively fast, needs tractor & leveling | Both are much faster than stationary |

| Transport Cost | Low for short distance, needs trailer for long (high cost) | Needs tractor for short, convenient long-distance (relatively low cost) | For frequent long-distance transfers, wheeled might have lower overall cost |

| Initial Investment | Relatively higher | Relatively lower | Balance based on budget and primary application scenarios |

The feed size a mobile jaw crusher can handle depends on its model specification (usually indicated by the feed opening width, e.g., PE750x1060 means a 1060mm feed opening width). Common models can handle maximum feed edge lengths from several hundred millimeters to over a meter. Their processing capacity (throughput) varies widely, from tens of tons per hour for small machines to hundreds or even thousands of tons per hour for large ones. However, actual throughput is affected by multiple factors and is often much lower than the theoretical maximum.

The mobile jaw crusher is a reliable choice for processing these materials, especially as a primary crusher. It adapts well to high-hardness granite, abrasive river pebbles, and complex composition construction waste (note the issue with rebar). The key lies in selecting the appropriate specifications, configuration, and materials for the equipment. Core keywords: mobile jaw crusher processing granite, mobile jaw crusher processing river pebbles, mobile jaw crusher processing construction waste.

The mobile jaw crusher is best suited for the “first gate” of the crushing process, i.e., the primary crushing (coarse crushing) stage. Its main task is to break down large raw materials to a size suitable for secondary crushing equipment (like a mobile impact crusher or mobile cone crusher) to handle. It is not suitable for fine crushing or applications requiring high product shape quality.

In a typical multi-stage crushing process:

When purchasing a mobile jaw crusher, besides focusing on feed opening size and theoretical throughput, you must delve deeper into the core configurations that affect actual performance and reliability: the heart of the crushing host (eccentric shaft assembly), jaw plate selection, feeder unit compatibility, power and hydraulic system efficiency and reliability, and the robustness of the chassis structural components. These often determine the true value of the equipment more than the price.

Jaw plates are the main wear parts of a mobile jaw crusher. Their wear resistance depends on material hardness and jaw plate material/design; there’s no absolute “wear resistance.” Replacement cycles range from tens to hundreds of hours. Daily maintenance is relatively simple, mainly involving lubrication, tightening, cleaning, and regular inspection, but maintaining the hydraulic and electrical systems requires some professional knowledge.

Fuel/electricity costs are a major part of mobile jaw crusher operating expenses, second only to wear parts and labor. Fuel/power consumption varies depending on equipment power, load rate, and power system efficiency. Transport costs depend on distance, equipment type (track-mounted has high long-distance transport costs), and local freight rates. These operating costs constitute a large portion of the equipment’s total life cycle cost and must be considered during selection.

| Model | ZDM938HD80 | ZDM1149HD98 | ZDM1349HD110 | ZDM1349HD125 |

| Transportation Length(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Length(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dual-axial | Dual-axial | Dual-axial | Dual-axial |

| Jaw Crusher | HD80 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge Opening Size(mm) | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Model | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5M | B1000×9.5M | B1000×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3M | B650×3.5M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 200 | 250 | 270 | 400 |

| Iron Separator (Optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

Q1. What exactly is a mobile crushing station used for? How is it better than a stationary production line?

A1: The biggest advantage of a mobile crushing station is its flexibility and convenience. It doesn’t require foundation work and can be quickly relocated or moved closer to the working face. For you, this means significant savings in civil engineering costs and time, enabling faster production startup. It also reduces the internal material transport distance on site, lowering transportation costs and dust. It’s particularly suitable for projects with tight schedules, scattered sites, or those requiring phased progression.

Q2. Crawler-type vs. tire-type mobile crushing station, which is more suitable for me?

A2: It mainly depends on your mobility needs and site conditions. Crawler-type is like a tank, suitable for moving within mines or rugged construction sites, offering flexible relocation but troublesome for long-distance transport; tire-type is like a trailer, suitable for projects with better road conditions that require frequent long-distance transfers across regions. Simply put, choose crawler for on-site flexibility, choose tire for long-distance transfers.

Q3. Mobile crushing stations have several main machine types (jaw crusher/impact crusher/cone crusher). How should I choose?

A3: Choose based on your material and output requirements. Mobile jaw crushers are suitable for primary crushing, handling large, hard materials; mobile impact crushers are suitable for processing medium-soft materials (like limestone, construction waste) and produce good particle shapes; mobile cone crushers are suitable for medium-fine crushing of hard rocks (like granite, river pebbles). Not sure? Tell us your raw materials and finished product needs, and we’ll help you configure the setup.

Q4. What capacity mobile crushing station do I need? How can I estimate reliably?

A4: The capacity stated by manufacturers is usually the “maximum capacity” under ideal conditions; actual output will be lower. You need to consider: What material needs processing (hardness)? What’s the feed size? How much soil/clay content? How fine does the output need to be? Provide this information to the supplier, and let them use their experience to help you choose a model with sufficient margin. Don’t just rely on paper figures.

Q5: Is maintaining a mobile crushing station troublesome? Is the fuel/power consumption high?

A5: Routine maintenance (lubrication, tightening, cleaning) isn’t complex, but hydraulic and electrical systems require some professional knowledge. Mobile stations have compact structures, so maintenance in some areas might be less convenient than stationary plants. Fuel/power consumption is a major operating cost, highly related to equipment power, load, and power system (diesel/electric/hybrid). Choosing a diesel-electric hybrid might save more money in the long run.

Q6: What if one mobile crushing station isn’t enough? Can they be combined into a production line?

A6:Absolutely! Mobile crushing stations are very suitable for combined use, forming a complete mobile crushing and screening production line. For example, use a mobile jaw crusher for primary coarse crushing, followed by a mobile impact crusher or mobile cone crusher for medium-fine crushing, and then add a mobile screening plant for sizing. This combination can meet complex production needs with extreme flexibility.

Q7: When selecting a mobile crushing station, what key points should I focus on besides price?

A7: Price is important, but definitely not the only criterion! Pay more attention to: 1. Quality of core components (main crusher, engine/motor, hydraulic system); 2. Match between actual output and working conditions; 3. Durability of structural parts (chassis, frame); 4. Cost-effectiveness and supply of wear parts; 5. Ease and safety of operation and maintenance; 6. Manufacturer’s after-sales service and technical support capabilities.

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy