Search the whole station Crushing Equipment

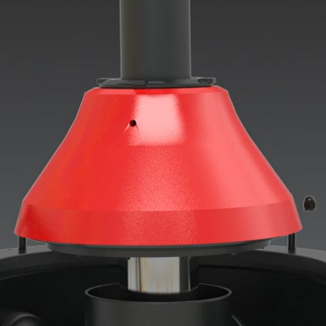

A mobile cone crusher is essentially a (device utilizing the principle of lamination crushing for medium-fine crushing) mounted on a mobile chassis (track or tire) and integrated with feeding, conveying, power, and other systems. Compared to a mobile jaw crusher (primary coarse crushing workhorse) and a mobile impact crusher (adept at crushing/shaping medium-soft materials), its strength lies in efficiently handling the medium-fine crushing of high-hardness materials with superior finished particle shape (cubic); its weakness is the strict requirement for feed size (cannot be too large), a more complex structure, higher demands on operation and maintenance, and typically a higher price.

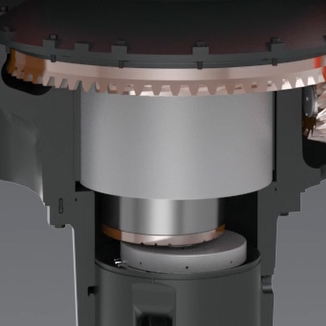

The crushing process: the mobile jaw crusher acts like a “big mouth,” turning large rocks into smaller ones (coarse crushing). The mobile cone crusher then acts like a “precision finishing master,” taking these smaller pieces (usually material processed by a jaw crusher) and, through squeezing and grinding between the movable cone and fixed cone (mainly lamination crushing), makes them smaller, more uniform, and better shaped (secondary or tertiary crushing). While the mobile impact crusher can also perform medium-fine crushing, it relies mainly on impact force, struggling with hard materials and experiencing rapid blow bar wear, making it more suitable for medium-soft materials like limestone. Therefore, when dealing with large quantities of hard rock and requiring high-quality finished products, the advantage of the mobile cone crusher becomes evident.

| Comparison Equipment | Main Crushing Stage | Best Suited Material | Finished Particle Shape | Structural Complexity | Cost |

|---|---|---|---|---|---|

| Mobile Cone Crusher | Medium-Fine Crushing | High-Hardness | Excellent (Cubic) | High | Higher |

| [Mobile Jaw Crusher] | Coarse Crushing | Various Hardness Lumps | Fair | Low | Medium |

| [Mobile Impact Crusher] | Medium-Fine Crushing | Medium-Low Hardness | Good | Medium | Medium |

Because the cone crusher employs the unique “lamination crushing” principle, where material within the crushing chamber undergoes multiple squeezing and bending actions, rather than single impacts. This method is particularly suitable for crushing hard, abrasive materials (like granite, river pebbles, iron ore) with high efficiency and relatively lower liner wear (compared to impact crushers processing hard rock). Therefore, the mobile cone crusher naturally becomes the preferred mobile solution for medium-fine crushing in the hard rock sector.

A mobile cone crusher can control the output particle size by adjusting the Closed Side Setting (CSS). Depending on the chamber type and model, the minimum output size can reach the level of several millimeters (e.g., for sand making). Its lamination crushing principle indeed significantly improves the finished particle shape, making it more cubic with low flaky and elongated content, superior to jaw and impact crushers under similar conditions.

How fine the output can be depends on the mobile cone crusher model you choose and the configured crushing chamber type . Using a fine or extra-fine chamber type cone crusher can crush material down to 10mm or even below 5mm. Adjusting the Closed Side Setting (CSS) is the primary means of controlling the finished product size; a smaller CSS results in finer output, but also correspondingly lower throughput. Regarding particle shape, lamination crushing encourages the rock to break along its natural grain and cleavage structures, reducing the randomly fractured flaky and elongated particles. This is crucial for applications requiring high-quality aggregates (like producing high-performance concrete), as cubic particles pack better, enhancing concrete strength and durability.

The core basis for selecting a crushing chamber type is your “feed size” and “desired output size.” Coarse chambers are suitable for processing larger feed for secondary crushing; Medium chambers are a general-purpose choice; Fine and Extra Fine chambers are used for tertiary or quaternary crushing to produce finer finished products. The key is to ensure the chamber type matches your actual operating conditions (especially the reduction ratio), otherwise efficiency will be low and wear will be rapid.

Think of the crushing chamber as “funnels” with different opening sizes and shapes. Different chamber designs (determined by the mantle and concave liner pairing) correspond to different optimal working ranges:

| Chamber Type | Applicable Crushing Stage | Typical Feed Size Range | Typical Output Size Range (CSS) | Key Features |

|---|---|---|---|---|

| Coarse (C) | Secondary Crushing | Larger | Coarser | High capacity, suitable for feeding subsequent fine crushers |

| Medium (M) | Secondary/Tertiary Crushing | Medium | Medium | Wide application range, versatile |

| Fine (F) | Tertiary Crushing | Smaller | Finer | Good fine crushing effect |

| Extra Fine (EF) | Tertiary/Quaternary/Sand Making | Small | Very Fine | Produces manufactured sand or ultra-fine aggregates |

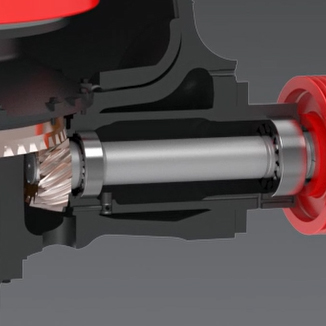

Liners (mantle and concave) are the main wear parts of a mobile cone crusher. Their wear rate primarily depends on the hardness and abrasiveness of the material being crushed, as well as proper operation (e.g., whether choke feeding is maintained). Processing hard rock will definitely cause faster wear than soft rock. A set of liners is not cheap and constitutes a significant portion of operating costs, but high-quality liners combined with good operating practices can significantly extend service life and reduce cost per ton.

The maximum feed size a mobile cone crusher can accept depends on its model specifications and the selected crushing chamber type (coarse chambers have the largest feed opening), typically ranging from tens of millimeters to three or four hundred millimeters. Its actual throughput (tons/hour) varies widely, from tens of tons for small machines to hundreds of tons for large ones. However, “actual throughput” is influenced by multiple factors, especially whether stable, uniform “choke feeding” can be achieved.

The selection logic is similar to that for mobile jaw crushers: it mainly depends on site conditions and relocation needs. Track-mounted mobile cone crushers are suitable for moving within rough, uneven sites and offer flexible relocation; wheel-mounted mobile cone crushers are convenient for long-distance road transport and suit users with flat sites who need frequent inter-regional moves.

It is generally considered that operating and maintaining a mobile cone crusher is more complex and demanding than for a mobile jaw or impact crusher. This is mainly because its structure is more precise, featuring more sophisticated hydraulic systems, lubrication systems, and automation controls.

The performance of a cone crusher heavily relies on precise settings and good maintenance:

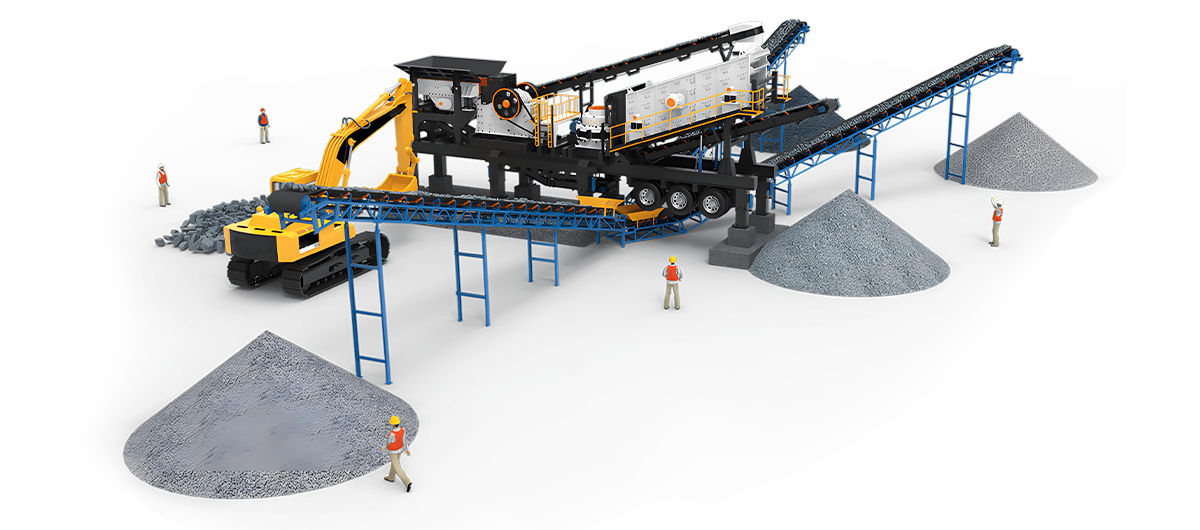

A mobile cone crusher rarely operates alone; it is usually a key component in a mobile crushing and screening plant. The most common combination is: one mobile jaw crusher (for primary coarse crushing) + one or more mobile cone crushers (for secondary/tertiary medium-fine crushing) + one or more mobile screening plants (for material sizing and creating a closed-circuit system).

A typical hard rock mobile crushing process might look like this:

| Model | ZDM3S185GYS300 | ZDM3S216GYS400 | ZDM3S216HP300 |

| Transportation Length(mm) | 14500 | 15000 | 16000 |

| Transportation Width(mm) | 3000 | 3000 | 4550 |

| Transportation Height(mm) | 4400 | 4500 | 17000 |

| Maximum Length(mm) | 17000 | 16000 | 4600 |

| Maximum Width(mm) | 3400 | 3900 | 6900 |

| Maximum Height(mm) | 5800 | 6500 | 4700 |

| Weight(t) | 34.5 | 49.5 | 41 |

| Tyre Configuration | biax fitted | triaxial fitted | triaxial fitted |

| Tire Configuration | GYS300 | GYS400 | HP300 |

| Feeding Belt Conveyor | B650×15M×2 | B800×15M×2 | B800×15M×2 |

| Discharging Belt Conveyor | B650×14M | B800×14M | B800×16M |

| Conveyor Belt for final products | B500×15M | B800×6M | B650×15M×2 |

| Under vibrating screen | B800×7M | B800×8M | B800×9M |

| Vibrating Screen Model | 3YK1854 | 3YK2160 | 3YK2160 |

Q1. What exactly is a mobile crushing station used for? How is it better than a stationary production line?

A1: The biggest advantage of a mobile crushing station is its flexibility and convenience. It doesn’t require foundation work and can be quickly relocated or moved closer to the working face. For you, this means significant savings in civil engineering costs and time, enabling faster production startup. It also reduces the internal material transport distance on site, lowering transportation costs and dust. It’s particularly suitable for projects with tight schedules, scattered sites, or those requiring phased progression.

Q2. Crawler-type vs. tire-type mobile crushing station, which is more suitable for me?

A2: It mainly depends on your mobility needs and site conditions. Crawler-type is like a tank, suitable for moving within mines or rugged construction sites, offering flexible relocation but troublesome for long-distance transport; tire-type is like a trailer, suitable for projects with better road conditions that require frequent long-distance transfers across regions. Simply put, choose crawler for on-site flexibility, choose tire for long-distance transfers.

Q3. Mobile crushing stations have several main machine types (jaw crusher/impact crusher/cone crusher). How should I choose?

A3: Choose based on your material and output requirements. Mobile jaw crushers are suitable for primary crushing, handling large, hard materials; mobile impact crushers are suitable for processing medium-soft materials (like limestone, construction waste) and produce good particle shapes; mobile cone crushers are suitable for medium-fine crushing of hard rocks (like granite, river pebbles). Not sure? Tell us your raw materials and finished product needs, and we’ll help you configure the setup.

Q4. What capacity mobile crushing station do I need? How can I estimate reliably?

A4: The capacity stated by manufacturers is usually the “maximum capacity” under ideal conditions; actual output will be lower. You need to consider: What material needs processing (hardness)? What’s the feed size? How much soil/clay content? How fine does the output need to be? Provide this information to the supplier, and let them use their experience to help you choose a model with sufficient margin. Don’t just rely on paper figures.

Q5: Is maintaining a mobile crushing station troublesome? Is the fuel/power consumption high?

A5: Routine maintenance (lubrication, tightening, cleaning) isn’t complex, but hydraulic and electrical systems require some professional knowledge. Mobile stations have compact structures, so maintenance in some areas might be less convenient than stationary plants. Fuel/power consumption is a major operating cost, highly related to equipment power, load, and power system (diesel/electric/hybrid). Choosing a diesel-electric hybrid might save more money in the long run.

Q6: What if one mobile crushing station isn’t enough? Can they be combined into a production line?

A6:Absolutely! Mobile crushing stations are very suitable for combined use, forming a complete mobile crushing and screening production line. For example, use a mobile jaw crusher for primary coarse crushing, followed by a mobile impact crusher or mobile cone crusher for medium-fine crushing, and then add a mobile screening plant for sizing. This combination can meet complex production needs with extreme flexibility.

Q7: When selecting a mobile crushing station, what key points should I focus on besides price?

A7: Price is important, but definitely not the only criterion! Pay more attention to: 1. Quality of core components (main crusher, engine/motor, hydraulic system); 2. Match between actual output and working conditions; 3. Durability of structural parts (chassis, frame); 4. Cost-effectiveness and supply of wear parts; 5. Ease and safety of operation and maintenance; 6. Manufacturer’s after-sales service and technical support capabilities.