Search the whole station Crushing Equipment

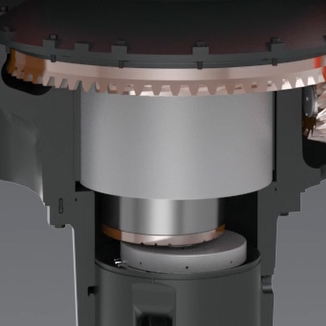

A Tracked Cone Crusher is a Cone Crusher – a compression-type crusher that breaks rock between a gyrating mantle and a stationary concave (bowl liner) – mounted on a tracked chassis with integrated power, feeding, and conveying systems. In a mobile crushing and screening plant, it primarily handles secondary, tertiary, or even quaternary (fine) crushing tasks, excelling at processing hard, abrasive materials and producing well-shaped aggregates.

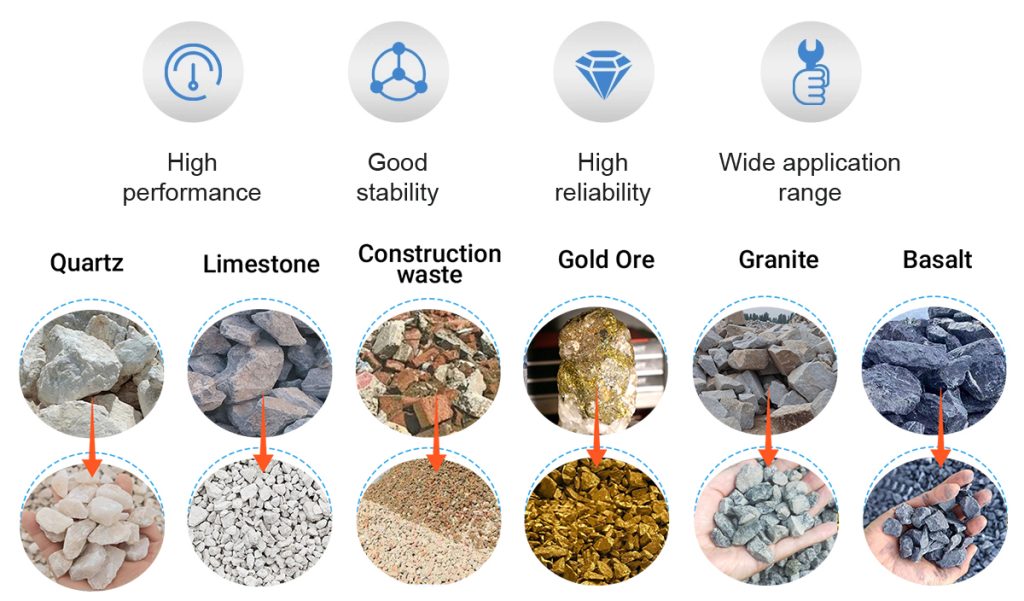

Tracked Cone Crushers are specifically designed to tackle hard, abrasive, and tough materials that would quickly wear out an impact crusher or be beyond the optimal reduction range of a primary jaw crusher in secondary/tertiary stages.

| Crusher Type | Primary Application & Material Strength | Product Shape | Key Advantage for “Tough Stuff” |

|---|---|---|---|

| Tracked Jaw Crusher | Primary Crushing, all rock types, large feed sizes | Angular | Handles oversized, hard feed |

| Tracked Impact Crusher | Secondary/tertiary, medium-soft to medium-hard, C&D waste, shaping | Excellent (cubical) | Superior shaping, but high wear on very hard/abrasive rock |

| Tracked Cone Crusher | Secondary/tertiary/quaternary, hard to very hard, abrasive materials | Good to Excellent (cubical) | Efficiently crushes hard/abrasive rock with manageable wear |

A Tracked Cone Crusher is your go-to when dealing with materials like granite, basalt, gabbro, hard river stone, and abrasive ores. It excels where impact crushers would suffer excessive wear costs and where jaw crushers have reached their limit in terms of product size reduction.

Tracked mobility offers significant benefits: rapid setup and relocation, reduced civil engineering costs, ability to follow the quarry face, and easier integration into multi-stage mobile crushing trains. This is especially valuable in:

Tracked Cone Crushers typically accept feed sizes ranging from approximately 40mm up to 250mm (or more for larger models), depending on the specific crusher size and chamber configuration (coarse, medium, fine). To match your jaw crusher’s output, ensure the P80 (80% passing size) of the jaw crusher product is comfortably smaller than the cone crusher’s maximum recommended feed size for the selected chamber.

Tracked Cone Crushers can crush hard rock down to very fine sizes, typically producing products from 5mm to 50mm, depending on the CSS (Closed Side Setting) and chamber type. They are renowned for producing good to excellent cubical product shape, especially when choke-fed. Yes, certain cone crusher models, particularly those with fine or extra-fine chambers and optimized settings, can produce manufactured sand (0-5mm).

Liner (concave/mantle) wear is a significant operating cost. Lifespan varies dramatically – from a few hundred to several thousand hours – depending on rock abrasiveness, hardness, feed conditions, CSS, and operating practices. To extend life: maintain choke feed, use correct CSS, select appropriate liner material/profile , ensure proper lubrication , and remove fines before feeding.

Factors Influencing Wear:

Chamber types (e.g., Extra Coarse, Coarse, Medium, Fine, Extra Fine) are designed for specific feed sizes and product requirements. Coarser chambers accept larger feed and have higher throughput for a given CSS but produce coarser products. Finer chambers accept smaller feed, produce finer products, but typically have lower throughput for a very tight CSS and may experience higher wear rates if not fed correctly. Choosing depends on your feed material size, desired product size, and overall plant balance.

| Chamber Type | Typical Feed Size | Typical Product Size | Throughput Potential (for given CSS) | Wear Characteristics |

|---|---|---|---|---|

| Coarse | Larger | Coarser | Higher | Generally good if choke-fed |

| Medium | Medium | Medium | Moderate | Balanced wear if operated correctly |

| Fine | Smaller | Finer | Lower (especially at tight CSS) | Can be higher if not choke-fed or if CSS is too tight |

uneven feed can lead to poor performance and accelerated, uneven liner wear. Tramp iron (uncrushable metal objects) can cause significant damage. Modern Tracked Cone Crushers have sophisticated protection systems: hydraulic overload protection (allowing the bowl to lift and pass tramp iron) and hydraulic clearing of a choked or stalled crusher.

Actual throughput varies widely based on crusher size, chamber type, CSS, material hardness, abrasiveness, moisture content, feed gradation, and operational efficiency (e.g., choke feeding). It can range from under 100 tph for smaller units to over 500 tph for large ones. Manufacturer ratings are typically for optimal conditions and specific materials.

Perfect pairing involves matching the cone crusher’s output capacity and product size distribution with the Tracked Mobile Screening Plant‘s screening area, screen media, and throughput capabilities. Often, a closed-circuit system is used where oversized material from the screen is recirculated back to the cone crusher for further reduction. This ensures maximum production of spec-compliant material.

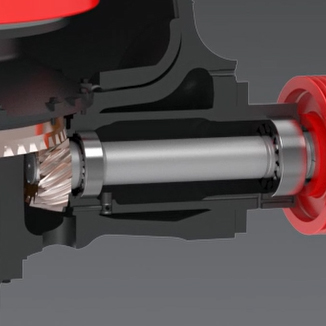

It is generally considered that operating and maintaining a mobile cone crusher is more complex and demandiBeyond price, “king” factors include: crusher design and size (head diameter, power), chamber/liner options , CSS adjustment mechanism (hydraulic, automation), lubrication and hydraulic system quality , tramp iron protection system , pre-screen effectiveness , intelligent controls and telematics , chassis durability , and crucially, manufacturer support and parts availability.ng than for a mobile jaw or impact crusher. This is mainly because its structure is more precise, featuring more sophisticated hydraulic systems, lubrication systems, and automation controls.

| Key Parameter/Configuration | Why It’s “King” | Your Benefit from a Good Choice |

|---|---|---|

| Crusher Size & Power | Determines base throughput potential and ability to handle tough rock. | Meets production targets, avoids underpowering. |

| Chamber/Liner Selection | Critical for product quality, throughput, and wear life. Variety of options for different applications. | Optimized performance, better product shape, lower wear costs. |

| CSS Adjustment | Hydraulic adjustment is standard. Automated CSS control maintains product consistency and optimizes performance as liners wear. | Easy and precise product size control, consistent output, optimized liner usage. |

| Lubrication System | The “lifeblood” of a cone crusher. Needs robust filtration, cooling, and monitoring. | Prevents catastrophic failures (bearings, bushings), extends component life, reduces downtime. |

| Tramp Iron Protection | Essential for protecting against uncrushable objects. Effectiveness of release and reset. | Prevents major damage, reduces downtime and costly repairs. |

| Pre-Screen Unit | Removes fines/soil before crushing. Size and efficiency matter. | Increases cone capacity, reduces liner wear, improves product quality (less contamination). |

| Intelligent Controls | PLC-based systems for load sensing, automated adjustments, diagnostics, telematics. | Optimized performance, proactive maintenance, higher uptime, better operational insights. |

| Chassis & Track System | Durability to withstand crushing forces and travel stresses. Ease of maintenance for tracks. | Long machine life, reliable mobility, lower undercarriage maintenance costs. |

| Environmental Adapt. | Suitability for extreme cold/heat, high altitude. Proper cooling, heating options. | Reliable operation in diverse climates, prevents environment-related failures. |

| Manufacturer Support & Parts | Availability of technical support, training, and genuine spare parts. Service network. | Minimizes downtime, ensures correct maintenance, protects investment. |

| Model | WT160SC | WT250SC | WT300HPM | WT400HPM | |

| Dimensions of Transmission Devices | Length | 16800mm | 19000mm | 19000mm | 19500mm |

| Width | 3500mm | 3600mm | 3900mm | 3900mm | |

| Height | 3700mm | 3800mm | 3800mm | 3800mm | |

| Weight | 50t | 60t | 55t | 65t | |

| Belt Conveyor | Hopper Volume | 3m³ | 3m³ | 3m³ | 3m³ |

| Loading Height | 2600m | 2600m | 2600m | 2800m | |

| Loading Width | 1900mm | 1900mm | 1900mm | 1900mm | |

| Dimensions (Width×Length) | 1000×6300mm | 1000×6300mm | 1000×6300mm | 1200×6500mm | |

| Crusher | Model | SC160 | SC250 | HP300 | HP400 |

| Inlet Dimensions | 75-360mm | 75-450mm | 60-200mm | 68-280mm | |

| Max.Feeding Size | 360mm | 450mm | 200mm | 280mm | |

| Min. Discharging Size | 8-25mm | 8-35mm | 8-45mm | 8-51mm | |

| Main Belt Conveyor | Dimensions (Width×Length) | 1000×9000mm | 1000×10000mm | 1000×10000mm | 1000×11000mm |

| Dumping Height | 3100mm | 3490mm | 3490mm | 3690mm | |

| Secondary Screen | Dumping Height | 4200mm | 4200mm | 4400mm | 4400mm |

| Model | HX1536 | HX1536 | HX1536 | HX1536 | |

| Sieve Dimensions | 1500×3600mm | 1500×3600mm | 1500×3600mm | 1500×3600mm | |

| Belt Conveyors at the Bottom | Dimensions (Width×Length) | 1000×5600mm | 1000×5600mm | 1000×5600mm | 1000×6500mm |

| Dumping Height | 3020mm | 3020mm | 3020mm | 3300mm | |

| Belt Conveyors to the Sieve | Dimensions (Width×Length) | 650×2100mm | 650×2100mm | 650×2100mm | 650×2100mm |

| Dumping Height | 1370mm | 1370mm | 1370mm | 1370mm | |

| Belt Conveyors for Discharging Material | Dimensions (Width×Length) | 650×10000mm | 650×10000mm | 650×11000mm | 650×11000mm |

| Dumping Height | 4200mm | 4200mm | 4400mm | 4400mm | |

| Diesel Engine | Power | 96kw | 132kw | 106kw | 132kw |

| Manufacturer | Carter Perkins | Carter Perkins | Carter Perkins | Carter Perkins | |

| The Main Machine | Power | 207.12kw | 297.12kw | 267.12kw | 362.12kw |

| Ways of Controlling | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | |

Q1. What exactly is a mobile crushing station used for? How is it better than a stationary production line?

A1: The biggest advantage of a mobile crushing station is its flexibility and convenience. It doesn’t require foundation work and can be quickly relocated or moved closer to the working face. For you, this means significant savings in civil engineering costs and time, enabling faster production startup. It also reduces the internal material transport distance on site, lowering transportation costs and dust. It’s particularly suitable for projects with tight schedules, scattered sites, or those requiring phased progression.

Q2. Crawler-type vs. tire-type mobile crushing station, which is more suitable for me?

A2: It mainly depends on your mobility needs and site conditions. Crawler-type is like a tank, suitable for moving within mines or rugged construction sites, offering flexible relocation but troublesome for long-distance transport; tire-type is like a trailer, suitable for projects with better road conditions that require frequent long-distance transfers across regions. Simply put, choose crawler for on-site flexibility, choose tire for long-distance transfers.

Q3. Mobile crushing stations have several main machine types (jaw crusher/impact crusher/cone crusher). How should I choose?

A3: Choose based on your material and output requirements. Mobile jaw crushers are suitable for primary crushing, handling large, hard materials; mobile impact crushers are suitable for processing medium-soft materials (like limestone, construction waste) and produce good particle shapes; mobile cone crushers are suitable for medium-fine crushing of hard rocks (like granite, river pebbles). Not sure? Tell us your raw materials and finished product needs, and we’ll help you configure the setup.

Q4. What capacity mobile crushing station do I need? How can I estimate reliably?

A4: The capacity stated by manufacturers is usually the “maximum capacity” under ideal conditions; actual output will be lower. You need to consider: What material needs processing (hardness)? What’s the feed size? How much soil/clay content? How fine does the output need to be? Provide this information to the supplier, and let them use their experience to help you choose a model with sufficient margin. Don’t just rely on paper figures.

Q5: Is maintaining a mobile crushing station troublesome? Is the fuel/power consumption high?

A5: Routine maintenance (lubrication, tightening, cleaning) isn’t complex, but hydraulic and electrical systems require some professional knowledge. Mobile stations have compact structures, so maintenance in some areas might be less convenient than stationary plants. Fuel/power consumption is a major operating cost, highly related to equipment power, load, and power system (diesel/electric/hybrid). Choosing a diesel-electric hybrid might save more money in the long run.

Q6: What if one mobile crushing station isn’t enough? Can they be combined into a production line?

A6:Absolutely! Mobile crushing stations are very suitable for combined use, forming a complete mobile crushing and screening production line. For example, use a mobile jaw crusher for primary coarse crushing, followed by a mobile impact crusher or mobile cone crusher for medium-fine crushing, and then add a mobile screening plant for sizing. This combination can meet complex production needs with extreme flexibility.

Q7: When selecting a mobile crushing station, what key points should I focus on besides price?

A7: Price is important, but definitely not the only criterion! Pay more attention to: 1. Quality of core components (main crusher, engine/motor, hydraulic system); 2. Match between actual output and working conditions; 3. Durability of structural parts (chassis, frame); 4. Cost-effectiveness and supply of wear parts; 5. Ease and safety of operation and maintenance; 6. Manufacturer’s after-sales service and technical support capabilities.

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy