Search the whole station Crushing Equipment

Applicable Materials:Various aggregates, river pebbles, quarry waste, and slag.

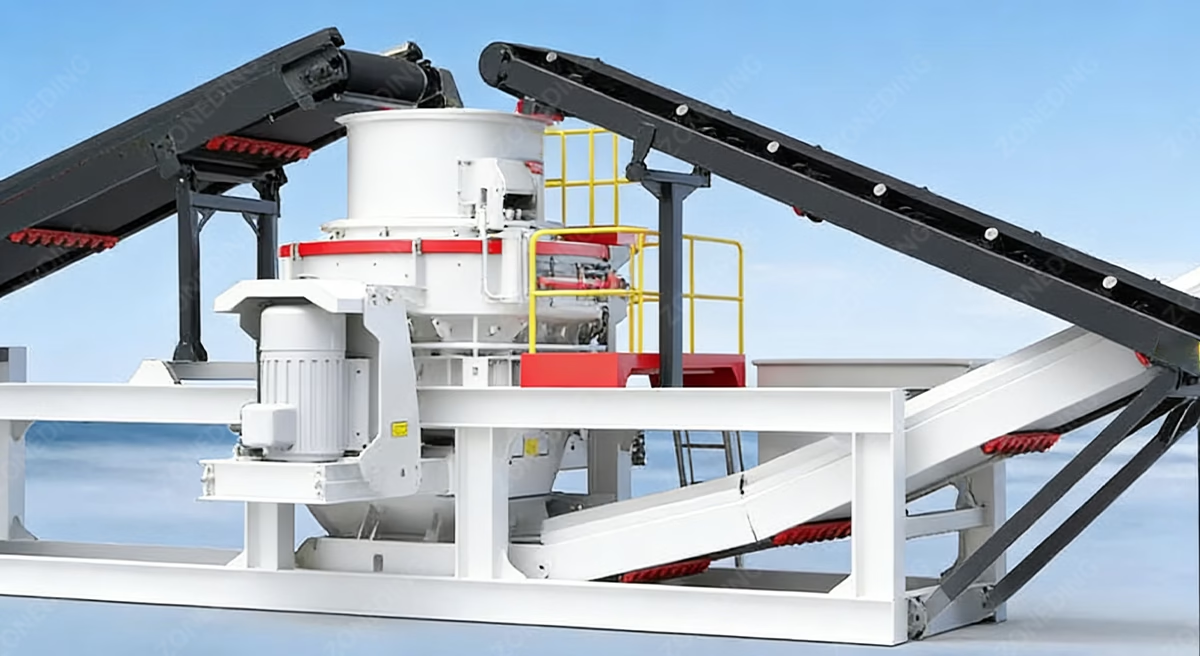

Modularized sand making plants are changing the way we produce aggregate. They offer a modern, efficient, and flexible solution for the industry. Customers benefit from predictable project timelines. They also get high-quality, factory-built equipment. These plants adapt to changing needs. They provide rapid deployment sand making and easy installation. They ensure excellent performance. This is true whether processing raw stone, construction waste sand making, or tailings sand making. This comes from their high crushing ratio and robust design. They also feature integrated safety measures. Advanced automation technology enables intelligent sand making control.

A modularized sand making plant is a complete and integrated system. It goes beyond simply putting a sand making machine onto a frame. It takes the entire process of making sand. This includes everything from initial crushing and shaping to final screening and washing. Then, it optimizes and integrates these steps. All these processes occur within self-contained, pre-engineered modules. These modules are built in a factory. This method ensures high quality and precision. It also makes setting up on-site much faster. ZONEDING’s approach brings together the entire sand production process into one efficient unit.

The design of a modularized sand making plant focuses on systematic optimization. This means every part works well with others. For example, it might combine a with multi-layer vibrating screens. It also integrates fine sand recovery units. The goal is to produce specific sand types. These types meet the needs of modern construction. This approach handles complex on-site assembly and debugging work at the factory. It greatly reduces uncertainties. It also ensures consistent product quality. This means a customer gets more than just a machine. They get a carefully planned and tested “sand manufacturing equation.” This helps businesses get up and running quickly. It also helps them produce high-quality sand from the start.

In essence, a modularized sand making plant represents a significant leap forward. It moves sand production from simple crushing to advanced aggregate shaping. This process ensures each sand particle is optimally impacted and shaped. The result is better quality sand. This sand meets strict industry standards. This system improves efficiency. It also addresses environmental concerns. It does this by integrating water management and fine sand recovery. This leads to a more sustainable and profitable operation. ZONEDING designs its modular plants to provide robust performance. They are reliable and easy to maintain. These plants are built for long-term use.

A modularized sand making plant provides significant advantages. These benefits address common challenges in the aggregates industry. We have seen these advantages develop over many years in the field. These plants are designed to handle various materials. They improve product quality and reduce costs. This makes them a smart choice for many projects.

Firstly, modular plants significantly reduce civil engineering costs. Traditional sand plants need extensive concrete foundations. These involve much planning and labor. ZONEDING’s modular units come pre-assembled on sturdy steel frames. These frames distribute operational loads efficiently. This often means only minimal groundwork is needed on site. This saves time and money. It streamlines project execution. This is a critical factor for many operations.

Secondly, these plants allow for rapid deployment sand making. Most manufacturing and assembly happen at ZONEDING’s factory. This reduces on-site work. It also speeds up the commissioning process. Customers can start production weeks faster than with traditional setups. This quick start leads to quicker returns on investment. It also minimizes disruptions. This is especially useful for projects with tight deadlines.

Thirdly, modularized sand making plants offer unmatched flexibility. We can easily scale them up or down. This happens by adding or removing modules. This adaptability helps businesses respond to changing market demands. It also allows for efficient resource allocation. They are easy to relocate. This makes them suitable for temporary projects or changing resource availability. This flexibility protects long-term investments. It ensures equipment remains productive.

Finally, these plants focus on producing high-quality manufactured sand. They use advanced crushing and shaping technologies. For example, VSI Sand Maker units are often included. These machines optimize particle shape and gradation. This leads to superior sand for concrete and asphalt. The integrated systems also manage fine sand recovery. This maximizes usable product. It minimizes waste. This improves the overall profitability of the operation. ZONEDING ensures each modular plant delivers these benefits consistently.

| Advantage | Description | Impact on Your Business |

|---|---|---|

| Lower Upfront Costs | Less need for extensive civil works | Saves capital, improves budget control |

| Faster Set-Up | Pre-assembled units, quick connection | Quicker revenue generation, reduced project delays |

| Flexible Operation | Easy to scale, relocate, or reconfigure | Adapts to market changes, maximizes asset utilization |

| Superior Sand Quality | Optimized particle shape, controlled gradation | Higher selling price, better concrete performance, less cement |

Producing high-quality manufactured sand with excellent particle shape is a primary goal for ZONEDING. We know that sand is more than just broken rocks. Its shape directly affects the quality and cost of concrete and asphalt. A modularized sand making plant achieves superior particle shape through a carefully engineered process. It focuses on turning rough aggregates into cubical, well-graded sand.

At the heart of this process is the VSI Sand Maker, a key component in our sand making production line. Unlike traditional crushers that compress material, the VSI (Vertical Shaft Impact) machine uses high-speed impact. Material enters the center of a rapidly spinning rotor. It then gets accelerated and thrown against fixed impact plates or a curtain of material. This “stone-on-stone” or “stone-on-iron” crushing action breaks particles along their natural cleavage planes. This method naturally produces more cubical-shaped particles. It reduces flat or elongated pieces. Such shapes are undesirable in high-performance concrete mixes.

The modular design integrates this advanced crushing technology with precise screening and classification. After the VSI process, the material goes through multi-deck vibrating screens. These screens separate sand into different sizes. This ensures a consistent gradation. Material that is too large or not yet cubical enough is often recirculated back to the VSI Sand Maker for further processing. This closed-circuit operation refines the product. It guarantees the final sand meets strict shape and gradation requirements. This process is like having a “sand engineer” on site. It constantly monitors and adjusts for optimal particle quality.

Furthermore, the entire sand making production line includes intelligent control systems. These systems monitor operational parameters. They adjust settings automatically. This ensures consistent performance. Operators can fine-tune rotor speed and feeding rates. This optimizes the impact force and material flow. This creates the desired particle shapes and sizes. By controlling every stage, ZONEDING’s modular plants deliver high-quality manufactured sand. It meets the most demanding construction standards.

Modularized sand making plants are highly versatile, effectively converting various waste materials—such as stone chips, tailings, and construction waste—into valuable sand. This capability positions them as key players in resource recycling, transforming environmental liabilities into profitable assets.

For stone chips, these plants handle varied sizes and shapes, producing uniform, high-quality manufactured sand. This reduces quarry waste, creates new revenue, and meets commercial standards through integrated screening and shaping.

Tailings sand making addresses mining waste. Modular plants process fine-grained mine tailings into usable sand, reducing environmental footprint and recovering valuable resources. Washing and classification units ensure impurity removal and correct particle size distribution.

Regarding construction waste, these plants are particularly impactful. They efficiently crush concrete, asphalt, and brick debris into recycled aggregate and sand. This reduces landfill burden and provides sustainable building materials. The mobility of some units allows on-site deployment, minimizing transport costs and carbon emissions.

These plants often incorporate specialized features, such as magnetic separators for metals and advanced washing systems for contaminated materials. This comprehensive approach ensures high-quality recycled sand, supporting circular economy principles and sustainable construction. ZONEDING is committed to efficient and environmentally sound processes.

Controlling wear part lifespan and simplifying maintenance are crucial for the long-term profitability of any sand making production line. A modularized sand making plant is specifically designed with these aspects in mind. We understand that wear parts are significant operational costs. So, we focus on designs that extend their life and make replacements easier. This ensures low operating cost crushing for our customers.

The core of our strategy begins with selecting high-quality, durable materials for wear parts. These parts are made from advanced alloys. They resist abrasion and impact. This extends their service life even when processing tough materials. Moreover, the design of our VSI Sand Maker often incorporates “stone-on-stone” crushing. This means the material crushes itself. It reduces direct wear on metal components. This significantly increases wear part lifespan.

Beyond material selection, our modular plants are designed for convenient maintenance. Critical components, such as the rotor and crushing chamber, offer easy access, minimizing inspection and replacement time. For example, VSI units often feature hydraulic lifting systems for quick internal access, simplifying tasks like blow bar or liner changes, leading to less downtime and more productive operating hours.

Intelligent monitoring systems track wear patterns and operating conditions, providing alerts for potential issues. This enables predictive maintenance, preventing unexpected failures by allowing part replacement during scheduled downtimes. This proactive approach minimizes costly emergency repairs and ensures a stable operating plant, ultimately boosting efficiency and lowering maintenance expenses for a better ROI for ZONEDING’s clients.

Selecting a suitable modularized sand making plant requires careful consideration of raw material type, desired output, and environmental concerns. ZONEDING assists in choosing solutions that maximize investment and meet unique operational needs.

First, material type and characteristics are paramount. Whether hard granite, abrasive basalt, softer limestone, construction waste, or quarry stone chips, different materials dictate crushing technologies. Abrasive materials, for instance, require specific wear part designs, influencing consumption and overall production line efficiency.

Second, required output and product specifications are crucial. This includes target production capacity (tons per hour), precise particle size distribution, and cubicity for the final manufactured sand. Projects demanding high-quality concrete sand, for example, prioritize efficient shaping, often leading to the selection of a VSI Sand Maker for superior particle shape control.

Third, site conditions and project duration are vital. Considerations include whether the plant is for a permanent quarry or a temporary construction site, space limitations, ground conditions, and local climate. Modularized sand making plants offer flexible deployment, adapting to various sites. Ease of relocation and rapid deployment are significant advantages for remote or short-term projects.

Fourth, budget and long-term investment require careful evaluation. Beyond initial investment, the total cost of ownership—including energy consumption, wear part lifespan, and maintenance—is critical. A seemingly cheaper solution might incur higher operating costs over time. The goal is achieving low operating cost crushing and a strong return on investment.

Finally, environmental regulations and sustainability goals are increasingly important. This encompasses noise and dust control, water management, and tailings sand making. Modern modularized sand making plants offer solutions for these challenges, including integrated fine sand recovery and water recycling systems. ZONEDING’s solutions ensure meeting environmental standards.

The sand making field is constantly advancing, with ZONEDING identifying clear trends for modular plants by 2026, emphasizing greater efficiency, smarter operations, and improved environmental performance to drive more productive and sustainable sand production.

Future developments include enhanced automation and AI integration for real-time monitoring and automatic parameter adjustments, optimizing throughput and high-quality sand. Advanced sensor technology and IoT will enable remote monitoring, predictive maintenance, and increased equipment uptime. Focus on energy efficiency and sustainable design will be evident in new VSI Sand Maker units and improved motor technologies, with optimized drive systems cutting energy loss by up to 15% for lower operational costs. Integrated water and slurry management systems will achieve over 90% water recirculation and convert residual mud into reusable materials, minimizing consumption and addressing environmental challenges. Finally, greater customization and flexibility will allow precise tailoring to specific material properties and product specifications, optimizing each customer’s sand making production line.

Q1: What kind of raw materials can a modularized sand making plant process?

A modularized sand making plant is highly versatile. It can process a wide range of raw materials. This includes various rocks like granite, basalt, limestone, and pebbles. It also efficiently handles industrial by-products such as stone chips sand making, tailings sand making, and recycled construction waste sand making.

Q2: How does the modular design impact the investment cost compared to a traditional fixed plant?

A modularized sand making plant typically involves a lower overall initial investment. This is mainly because it significantly reduces civil engineering costs. Most of the complex assembly happens in the factory. This means less on-site construction work. This makes it a more cost-effective option for many projects.

Q3: What makes ZONEDING’s manufactured sand “high-quality”?

ZONEDING’s high-quality manufactured sand results from advanced crushing and shaping technology. Our plants use VSI Sand Maker units. These produce cubical particles with minimal flat or elongated shapes. We also control the particle size distribution. This leads to superior performance in concrete and asphalt mixes.

Q4: Can a modularized sand making plant be moved to different project sites?

Yes, mobility is a key advantage of modularized sand making plants. They are designed for rapid deployment sand making and easy relocation. The pre-assembled modules can be disassembled and transported. Then, they are reassembled at a new site. This makes them ideal for temporary projects or changing operational needs.

Q5: How does a modularized sand making plant address environmental concerns like dust and water usage?

ZONEDING’s modularized sand making plants include integrated environmental controls. These are dust suppression systems and efficient water recycling units. Fine sand recovery systems minimize waste. These features help clients meet strict environmental regulations. They also promote energy-saving and eco-friendly sand making practices.

Reliable Jaw Crushers for efficient primary crushing in mining, quarrying & aggregate production. Heavy-duty design, high throughput.

Cone Crusher For Sale: Highly efficient, stable and durable, ideal for all ore crushing needs. It can improve production efficiency and reduce operating costs.

High-efficiency VSI sand making machines for producing premium artificial sand from rock & gravel. Excellent particle shape, low wear cost.

PF Series Impact Crusher for secondary crushing of limestone, rock, and efficient recycling of concrete & asphalt. High throughput, excellent shape. Get Specs!

Looking for a high-performance Vibrating Feeder? Explore our durable industrial feeding machines for mining & aggregate plants.

Sand Washing Machines (Wheel & Spiral types) to remove impurities & improve sand quality for construction & industry. High cleanliness, reliable performance. Get Your Quote!

The YK series circular vibrating screens are high-performance and suitable for heavy-duty quarrying and aggregate screening operations. Multi-layer screen options are available for precise grading.

Smooth Roll Crushers for finer sizing or Toothed Roll Crushers for better grip on materials like coal & shale. Reliable, low maintenance crushers for various industries.

Looking for a high-efficiency fine crusher? Explore our industrial fine crushing machines for sale. Factory-direct pricing and large capacity.

Compound Crushers (Vertical Shaft) for efficient fine crushing of medium-hard materials like limestone & clinker. Simple structure, high ratio, ideal for sand making & aggregate. Get Quote!

loading…

已经是到最后一篇内容了!