Search the whole station Crushing Equipment

Applicable Materials:Soft to medium-hard, less abrasive materials like limestone, coal, construction waste, and asphalt.

Modularized impact crushing plants offer a modern solution for efficient material processing, providing a powerful mix of efficiency, flexibility, and cost savings. Predictable project timelines and high-quality, factory-built equipment are delivered. Adaptation to changing site needs is achieved through flexible deployment and quick setup, ensuring excellent performance for materials like limestone and construction waste processing. This performance stems from a high crushing ratio and robust design. Integrated safety features are incorporated, alongside advanced automation for intelligent crushing control.

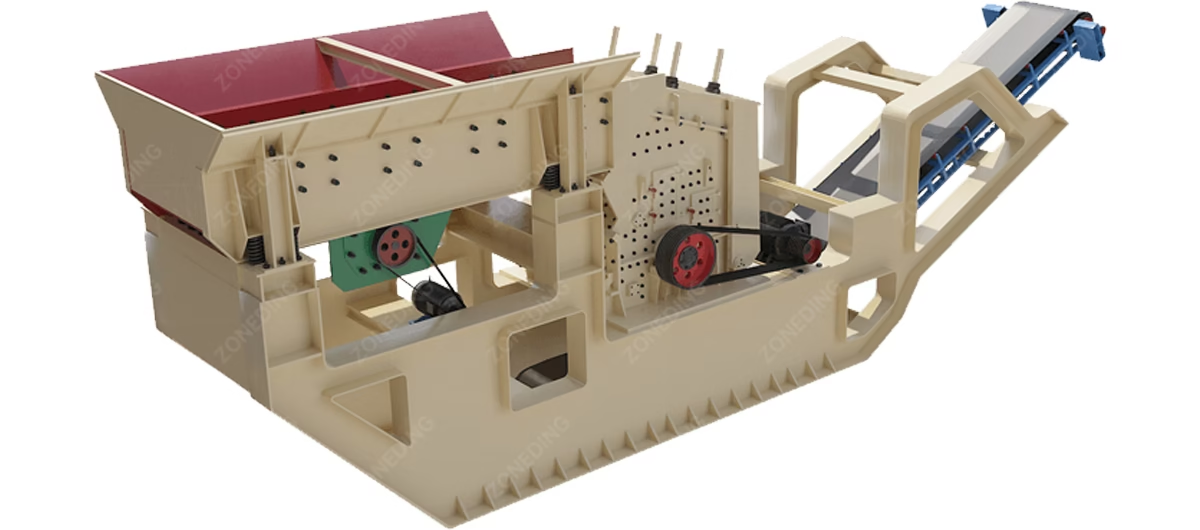

A modularized impact crushing plant is a fully integrated system, combining a high-performance crusher with all necessary support equipment: feeders, conveyors, screens, and advanced control systems. These components are meticulously assembled onto sturdy, pre-fabricated frames, with entire systems built in modular sections. Often manufactured and pre-assembled off-site, this delivers a complete, ready-to-deploy solution – a full modular crushing plant, not merely a single crusher. This approach dramatically reduces on-site construction, simplifying installation and commissioning. It transforms sand and aggregate production line management, providing reliable, high-quality results from inception.

Traditional methods involved separate component procurement and extensive on-site assembly, leading to delays and unexpected costs. Modular plants overcome these challenges through designs optimized for quick assembly and rapid operation. This allows for faster material production, aiding in meeting project deadlines and financial objectives. The system marks a significant advancement in mineral processing efficiency and reliability, ideal for operations demanding speed and precision. Central to the plant is an impact crusher, adept at processing various materials into precise, cubical aggregate shapes crucial for modern construction. Integrating this powerful crusher within a modular frame creates a solution that is easily transportable, simple to install, and highly effective at producing exact final products. This makes the modularized impact crushing plant a pivotal innovation, ensuring consistent quality and high output with fewer complications.

Modular design provides significant flexibility, allowing easy addition or removal of sections to adapt to evolving requirements. This enables plant scalability to grow with operations or suit diverse project sizes. Offering both fixed and mobile capabilities, the system is suitable for various work environments, representing a smart investment for long-term success.

Modular design offers significant advantages, drastically cutting project expenses and accelerating setup. Unlike traditional “stick-built” plants, which demand extensive concrete foundations, modular crushing plants arrive pre-mounted on robust steel frames. These frames absorb and distribute operational loads, often requiring only simple footings or minimal ground preparation. This approach substantially reduces civil engineering costs and project timelines.

Modular construction shifts assembly to the factory, ensuring higher quality and precision in a controlled environment. This strategy reduces on-site labor needs, particularly beneficial given the expense and scarcity of skilled workers in remote locations. Factory assembly further lowers costs and mitigates risks from inclement weather or labor shortages. Rapid project commissioning is ensured as plants arrive in large, transportable modules, quickly connected on-site. This dramatically cuts installation timelines; projects operational in weeks, not months, accelerating revenue generation.

This streamlined process also simplifies project management. It requires fewer on-site contractors and less complex coordination. Integrated design minimizes errors and rework, enhancing predictability. The result is a highly efficient setup, delivering a fast return on investment. With every aspect targeting efficiency and cost-effectiveness, modularized impact crushing plant solutions represent a smart investment, engineered to directly address common project challenges.

| Feature | Cost Reduction Benefit | Installation Speed Benefit | Your Practical Gain |

|---|---|---|---|

| Pre-fabricated Frame | Less concrete, fewer foundations | Faster ground prep, quicker assembly | Lower upfront costs, quicker revenue generation |

| Factory Assembly | Reduced field labor costs | Higher quality, fewer delays | Predictable timeline, less risk of cost overruns |

| Standardized Connections | Fewer complex welds on-site | Rapid module integration | Faster setup, earlier production, increased ROI |

Modularized impact crushing plants are excellent at producing high-quality aggregates. They specifically focus on achieving superior aggregate shaping with a high cubicity. This means the crushed particles are more cubic and less flaky. This quality is crucial for modern construction. It improves the strength and workability of concrete and asphalt mixes. Our impact crusher equipment uses a unique crushing principle. Material hits rotating hammers or blow bars. It is then thrown against impact plates. This high-speed impact causes the material to break along its natural cleavage planes. This action creates well-shaped, stress-free particles.

This method minimizes internal cracks. This makes the final product stronger and more durable. Traditional crushers, like jaw crushers, rely more on compression. This can create more elongated or flaky particles. It can also introduce micro-cracks. Our impact crushers, on the other hand, promote a more natural fracture. This ensures the integrity of the aggregate. This is essential for applications demanding high-performance materials. These include high-strength concrete or specialized road construction. The plant’s design for high crushing ratio means it significantly reduces material size in one pass. This also contributes to better aggregate quality.

To ensure consistent quality, our modular impact crushing plants integrate precision control. Operators can adjust the rotor speed and impact apron settings. This allows for fine-tuning of the crushing action. It optimizes the production of desired particle shapes and sizes. The integrated screening system works in harmony with the crusher. It immediately separates out finished products. This prevents over-crushing. Over-crushing can reduce cubicity and increase fines. This meticulous control over every stage guarantees that you consistently produce premium, cubical aggregates. This meets even the strictest industry standards. This makes our plants ideal for demanding sand and aggregate production line applications.

Modularized impact crushing plants are incredibly versatile. They excel at processing a wide range of materials efficiently. This includes materials like limestone. They are also highly effective for construction waste processing. This makes them a key tool for resource recycling and utilization. Impact crushers are especially good at handling materials that vary in hardness. This is due to their design. It involves high-speed impact. This breaks materials along natural fault lines. This results in consistent product quality.

When it comes to construction waste, our plants truly shine. They can efficiently crush concrete, asphalt, bricks, and mixed demolition debris. This ability transforms waste materials into valuable recycled aggregates. This not only reduces landfill burden but also creates new revenue streams. The high reduction ratio of the impact crusher is crucial here. It can take large pieces of waste. It quickly breaks them down into reusable sizes. The modular nature of the plant means it can be quickly set up. This is true at demolition sites or urban recycling centers. This brings the processing power closer to the source of the waste. It cuts down on transportation costs.

Furthermore, these plants are designed to handle contaminants often found in waste. Impact crushers can deal with rebar in concrete to a certain extent. This makes them ideal for recycling applications. Our modular crushing plants often integrate features for material separation. This can include magnetic separators to remove metals. It also includes air classifiers to remove light fractions. This complete processing capability ensures the recycled aggregate is clean and ready for reuse. This efficient processing of waste and other materials supports sustainable construction practices. It boosts the economic viability of recycling operations. It makes valuable contributions to environmental conservation. It is an ideal on-site crushing plant for these types of projects.

Proper maintenance of your modularized impact crushing plant is crucial. It ensures continuous operation and minimizes downtime. Impact crushers are known for their efficiency. But they can experience wear, especially on specific parts. We design our plants for convenient maintenance. This focuses on maximizing your uptime and extending the wear part lifespan. Regular checks and timely replacements are key to low operating cost crushing and efficient production.

The main wear parts in an impact crusher are the hammers (or blow bars) and the impact plates (or liners). These parts directly hit the material. So they wear out over time. The wear rate depends on the type and abrasiveness of the material you crush. For example, processing hard, abrasive rock will cause faster wear than crushing soft limestone. Our modular plants are specifically designed to make replacing these parts easier. They feature built-in platforms, easy-access hatches, and quick-release mechanisms. Sometimes, they even include integrated lifting aids like jibs or monorails. These design elements drastically reduce the time and effort needed for maintenance. This directly impacts your plant’s overall availability.

Beyond specific wear parts, regular maintenance includes routine inspections of other components. Check bearings, belts, and the overall structural integrity of the modular frame. The control system needs regular checks too. Ensure all sensors are clean and working. Keep the hydraulic system in good condition. All these steps contribute to the plant’s long-term performance. Our commitment is to provide an impact crusher equipment solution that is not only efficient but also easy to maintain. This saves you money and keeps your operations running smoothly.

Choosing the right modularized impact crushing plant is a critical decision. It directly impacts your project’s success. It affects efficiency, product quality, and profitability. I will guide you through the crushing equipment selection process. This will help you find the most suitable solution for your unique needs. We consider your material, desired output, site conditions, and budget.

The mineral processing industry is always moving forward. New technologies and evolving demands constantly reshape the field. Modular crushing plants are at the forefront of these changes. In 2026, we observe clear trends. These trends focus on even greater efficiency, smarter operations, and improved environmental care. These advancements make crushing operations more productive. They also make them more sustainable. We continuously enhance our modular crushing plants to lead these developments.

The global market for modular crushing plants is growing fast. This is because they offer great flexibility and cost-effectiveness. We see more adoption in developing regions. These areas need quick infrastructure development. They also have diverse mining projects. Companies are choosing solutions that offer fast deployment crushing. They also want the ability to easily move assets. This trend will likely continue. It will drive more innovation in design and technology for crushing plant solutions.

Question 1: How long does it typically take to install a modularized impact crushing plant?

Installation times vary. It depends on the plant size and site conditions. However, our modular plants are designed for rapid project commissioning. They can be fully assembled and running much faster than traditional fixed plants. You can often expect the plant to be operational within 4-8 weeks after arriving on site.

Question 2: Are modular impact crushing plants suitable for very hard and abrasive rocks?

Impact crushers are generally better for medium to soft, or moderately abrasive materials. While they can handle some harder rocks, wear part lifespan can be shorter than with cone crushers. For very hard, abrasive rock, a modularized cone crushing plant might be a better primary or secondary option.

Question 3: Can ZONEDING provide a complete sand and aggregate production line using modular units?

Yes, we specialize in providing complete sand and aggregate production line solutions. Our modular approach allows us to integrate various crushing, screening, and conveying modules. This includes sand making machine units. This creates a full processing plant. It is tailored to your specific output and product requirements.

Question 4: What kind of control system is included with a modular impact crushing plant?

Our modular impact crushing plants typically come with integrated electrical and control systems. These often include advanced PLCs and HMI interfaces. They offer features like remote monitoring, real-time data analysis, and precise control over crusher settings. This enables intelligent crushing control for optimized operation and increased safety.

Question 5: What is the main benefit of “superior aggregate shaping” for my business?

Superior aggregate shaping (cubicity) means your aggregate is stronger and performs better in construction. It leads to higher quality concrete and asphalt. This can allow you to sell your products at a premium price. It also reduces the amount of binder needed in asphalt mixes. This saves you money and contributes to a low operating cost crushing.

Reliable Jaw Crushers for efficient primary crushing in mining, quarrying & aggregate production. Heavy-duty design, high throughput.

Cone Crusher For Sale: Highly efficient, stable and durable, ideal for all ore crushing needs. It can improve production efficiency and reduce operating costs.

High-efficiency VSI sand making machines for producing premium artificial sand from rock & gravel. Excellent particle shape, low wear cost.

PF Series Impact Crusher for secondary crushing of limestone, rock, and efficient recycling of concrete & asphalt. High throughput, excellent shape. Get Specs!

Looking for a high-performance Vibrating Feeder? Explore our durable industrial feeding machines for mining & aggregate plants.

Sand Washing Machines (Wheel & Spiral types) to remove impurities & improve sand quality for construction & industry. High cleanliness, reliable performance. Get Your Quote!

The YK series circular vibrating screens are high-performance and suitable for heavy-duty quarrying and aggregate screening operations. Multi-layer screen options are available for precise grading.

Smooth Roll Crushers for finer sizing or Toothed Roll Crushers for better grip on materials like coal & shale. Reliable, low maintenance crushers for various industries.

Looking for a high-efficiency fine crusher? Explore our industrial fine crushing machines for sale. Factory-direct pricing and large capacity.

Compound Crushers (Vertical Shaft) for efficient fine crushing of medium-hard materials like limestone & clinker. Simple structure, high ratio, ideal for sand making & aggregate. Get Quote!

loading…

已经是到最后一篇内容了!