Search the whole station Crushing Equipment

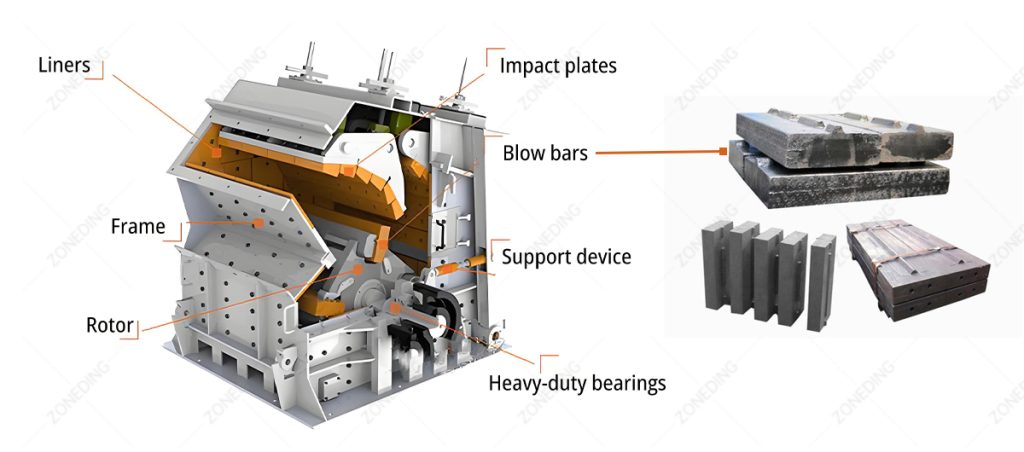

A Tracked Impact Crusher is essentially an Impact Crusher (a machine that uses high-speed rotating blow bars to strike material, causing it to collide with impact plates and break) mounted on a tracked chassis, integrated with feeding, conveying, and power systems. In a mobile crushing and screening plant, it typically serves as secondary or tertiary crushing equipment, primarily responsible for material shaping and fine crushing, producing well-shaped (cubical) finished aggregates.

The greatest advantages of a Tracked Impact Crusher are its excellent product shape (high cubical content) and relatively large reduction ratio (it can break material down significantly in a single pass). However, its limitation is its sensitivity to material hardness; when processing very hard or highly abrasive materials, wear parts like blow bars can wear out quickly, leading to higher operating costs.

| Feature | Tracked Impact Crusher | Tracked Jaw Crusher | Tracked Cone Crusher |

|---|---|---|---|

| Primary Use | Secondary/tertiary crushing, shaping, processing medium-soft materials, C&D waste | Primary crushing (coarse), handles various hardness materials | Secondary/tertiary crushing, handles medium-hard to very hard materials |

| Product Shape | Excellent (cubical) | Fair (more angular) | Good (depends on chamber type) |

| Reduction Ratio | Large | Moderate | Moderate to Large |

| Material Hardness | Medium-soft to medium-hard (e.g., limestone, C&D waste) | All hardness levels (excels with hard rock) | Medium-hard to very hard (e.g., granite, basalt) |

| Wear Part Cost | Blow bars, impact plates wear relatively faster (Insight #2, #4) | Jaw plates wear relatively slower | Mantle & concave wear moderately |

| Investment Cost | Medium | Medium | Higher |

| Operating Cost | Medium for soft materials, higher for hard/abrasive materials | Relatively lower | Medium-high for hard materials |

Limestone, dolomite, and other medium-soft materials, as well as complex construction waste, are ideal for Tracked Impact Crushers. It can crush and shape these materials to produce high-quality aggregates with extremely low flaky/elongated content, approaching perfect cubical shapes, which is highly beneficial for improving concrete strength and asphalt pavement quality.

Compared to jaw plates in jaw crushers or liners in cone crushers, the blow bars in an impact crusher are indeed a core wear part that wears out relatively quickly. The lifespan of a set of blow bars varies greatly depending on material hardness, abrasiveness, feed size, operation, etc., ranging from tens to hundreds of hours. Replacement costs vary by blow bar material, size, and equipment brand, and are a major operating expense.

The maximum allowable feed size for a Tracked Impact Crusher typically ranges from tens to hundreds of millimeters, depending on the model. Its output size can be adjusted by changing the gap between the impact plates and blow bars, and sometimes rotor speed (on some models), generally adjustable from a few millimeters to tens of millimeters, meeting various finished aggregate specifications.

The actual throughput (tons/hour) of a Tracked Impact Crusher also varies by model, material characteristics, feed/output size settings, operator skill, etc., ranging from tens of tons for small units to hundreds of tons for large ones. Note that the “theoretical maximum capacity” stated by manufacturers is measured under ideal conditions; actual production usually reaches only 60%-80% of this value.

Because impact crushers use high-speed impact to break material, and material movement within the chamber is vigorous, they typically generate more dust than jaw or cone crushers. However, modern Tracked Impact Crushers are usually equipped with effective dust suppression systems.

Environmental protection is a trend. Choosing a Tracked Impact Crusher with good dust control design not only complies with regulations but also improves the working environment.

In addition to the fastest-wearing blow bars, other major wear parts on a Tracked Impact Crusher include impact plates (liners), side liners, and components like bearings and belts. These parts wear more slowly than blow bars but still require regular inspection and replacement as needed.

Establishing a detailed equipment maintenance plan and regularly inspecting these wear parts is key to ensuring the long-term stable operation of the Tracked Impact Crusher.

For efficient production, a Tracked Impact Crusher is usually closely paired with a Tracked Mobile Screening Plant. The impact crusher handles crushing and shaping, while the screening plant grades the crushed material. The key is to ensure matching processing capacities, smooth material transfer, and potentially a closed-circuit setup to optimize product quality.

A typical combination:

Key Points for Efficient Synergy:

| Model | WT110 | WT110S | WT1213 | WT1213S | WT1315 | |

| Dimensions of Transmission Devices | Length | 14000mm | 16000mm | 15500mm | 19000mm | 17000mm |

| Width | 3000mm | 3200mm | 3200mm | 3600mm | 3200mm | |

| Height | 3600mm | 3600mm | 3800mm | 3800mm | 3800mm | |

| Weight | 40t | 45t | 53t | 60t | 65t | |

| Feeder | Hopper Volume | 3m³ | 3m³ | 5m³ | 5m³ | 5m³ |

| Loading Height | 3900mm | 4000mm | 3900mm | 4100mm | 4000mm | |

| Primary Screen | Power | 5.2kw | 5.2kw | 6.12kw | 6.12kw | 6.12kw |

| Sieve Dimensions | 1040×924mm | 1040×924mm | 1140×924mm | 1140×924mm | 1240×930mm | |

| Crusher | Model | CI1110M | CI1110M | CI1213M | CI1213M | CI1315M |

| Inlet Dimensions | 1020×860mm | 1020×860mm | 1320×900mm | 1320×900mm | 1540×900mm | |

| Max.Feeding Size | 400mm | 400mm | 500mm | 500mm | 600mm | |

| The Feeder at the Bottom | Hopper Volume | 0.8m³ | 0.8m³ | 1m³ | 1m³ | 1.5m³ |

| Power | 5.2kw | 5.2kw | 5.2kw | 5.2kw | 6.12kw | |

| Unearthed Belt Conveyors | Dimensions(Width×Length) | 650×3500mm | 650×3500mm | 650×3500mm | 650×3500mm | 650×3500mm |

| Dumping Height | 2200mm | 2200mm | 2200mm | 2200mm | 2400mm | |

| Main Belt Conveyor | Dimensions(Width×Length) | 1000×8500mm | 1000×8500mm | 1000×9900mm | 1000×9900mm | 1200×11000mm |

| Dumping Height | 3300mm | 3300mm | 3500mm | 3500mm | 3800mm | |

| Secondary Screen | Power | ○ | 6.12kw | ○ | 6.12kw | ○ |

| Sieve Dimensions | ○ | 1500×3600 | ○ | 1500×4200 | ○ | |

| Belt Conveyors at the Bottom | Dimensions(Width×Length) | ○ | 1000×5800mm | ○ | 1000×6200mm | ○ |

| Dumping Height | ○ | 2900mm | ○ | 3000mm | ○ | |

| Transferring Belt Conveyor | Dimensions(Width×Length) | ○ | 650×2500mm | ○ | 650×2800mm | ○ |

| Dumping Height | ○ | 1400mm | ○ | 1400mm | ○ | |

| Belt Conveyors for Discharging Material | Dimensions(Width×Length) | ○ | 500×8000mm | ○ | 500×9200mm | ○ |

| Dumping Height | ○ | 4200mm | ○ | 4500mm | ○ | |

| Iron Remover | Model | RCYQ-10 | RCYQ-10 | RCYQ-10 | RCYQ-10 | RCYQ-10 |

| Diesel Engine | Power | 96kw | 106kw | 106kw | 132kw | 132kw |

| Manufacturer | Carter Perkins | Carter Perkins | Carter Perkins | Carter Perkins | Carter Perkins | |

| The Main Machine | Power | 253kw | 274kw | 304kw | 324.4kw | 366kw |

| Ways of Controlling | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | |

Q1. What exactly is a mobile crushing station used for? How is it better than a stationary production line?

A1: The biggest advantage of a mobile crushing station is its flexibility and convenience. It doesn’t require foundation work and can be quickly relocated or moved closer to the working face. For you, this means significant savings in civil engineering costs and time, enabling faster production startup. It also reduces the internal material transport distance on site, lowering transportation costs and dust. It’s particularly suitable for projects with tight schedules, scattered sites, or those requiring phased progression.

Q2. Crawler-type vs. tire-type mobile crushing station, which is more suitable for me?

A2: It mainly depends on your mobility needs and site conditions. Crawler-type is like a tank, suitable for moving within mines or rugged construction sites, offering flexible relocation but troublesome for long-distance transport; tire-type is like a trailer, suitable for projects with better road conditions that require frequent long-distance transfers across regions. Simply put, choose crawler for on-site flexibility, choose tire for long-distance transfers.

Q3. Mobile crushing stations have several main machine types (jaw crusher/impact crusher/cone crusher). How should I choose?

A3: Choose based on your material and output requirements. Mobile jaw crushers are suitable for primary crushing, handling large, hard materials; mobile impact crushers are suitable for processing medium-soft materials (like limestone, construction waste) and produce good particle shapes; mobile cone crushers are suitable for medium-fine crushing of hard rocks (like granite, river pebbles). Not sure? Tell us your raw materials and finished product needs, and we’ll help you configure the setup.

Q4. What capacity mobile crushing station do I need? How can I estimate reliably?

A4: The capacity stated by manufacturers is usually the “maximum capacity” under ideal conditions; actual output will be lower. You need to consider: What material needs processing (hardness)? What’s the feed size? How much soil/clay content? How fine does the output need to be? Provide this information to the supplier, and let them use their experience to help you choose a model with sufficient margin. Don’t just rely on paper figures.

Q5: Is maintaining a mobile crushing station troublesome? Is the fuel/power consumption high?

A5: Routine maintenance (lubrication, tightening, cleaning) isn’t complex, but hydraulic and electrical systems require some professional knowledge. Mobile stations have compact structures, so maintenance in some areas might be less convenient than stationary plants. Fuel/power consumption is a major operating cost, highly related to equipment power, load, and power system (diesel/electric/hybrid). Choosing a diesel-electric hybrid might save more money in the long run.

Q6: What if one mobile crushing station isn’t enough? Can they be combined into a production line?

A6:Absolutely! Mobile crushing stations are very suitable for combined use, forming a complete mobile crushing and screening production line. For example, use a mobile jaw crusher for primary coarse crushing, followed by a mobile impact crusher or mobile cone crusher for medium-fine crushing, and then add a mobile screening plant for sizing. This combination can meet complex production needs with extreme flexibility.

Q7: When selecting a mobile crushing station, what key points should I focus on besides price?

A7: Price is important, but definitely not the only criterion! Pay more attention to: 1. Quality of core components (main crusher, engine/motor, hydraulic system); 2. Match between actual output and working conditions; 3. Durability of structural parts (chassis, frame); 4. Cost-effectiveness and supply of wear parts; 5. Ease and safety of operation and maintenance; 6. Manufacturer’s after-sales service and technical support capabilities.

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy