Search the whole station Crushing Equipment

Gypsum briquette machine is mainly used to suppress desulfurization gypsum powder, and the pressed balls can be used as a retarder in cement plant. In recent years, its application in building material industry is very extensive. It has characteristics of high molding pressure, easy demoulding, high-efficiency, low energy consumption, low failure rate, and convenient repair. It has five types according to the yield. The direct pressing without subsequent drying process is more conducive to the existing production process of convergence and transformation, which has high forming strength. It is suitable for all kinds of transportation, so as to reduce the packaging cost.

Gypsum compactor and its supporting equipment can compress desulfurized gypsum powder into disposable ball products without any help of adhesive. Through the characteristics of high yield and good hardness, it has been put into production in many power plants and cement plants in China with good results.

Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate. It is a very common material found all over the world. You can think of it in two main forms. The first is natural gypsum, which we mine directly from the earth. It has been used in construction for thousands of years.

The second form is synthetic gypsum. This is a byproduct of industrial processes. The most common type is Flue Gas Desulfurization (FGD) gypsum. Power plants that burn coal produce this when they remove sulfur dioxide from their exhaust gases. This process, also called gypsum recycling, creates large amounts of pure, wet gypsum powder. This FGD gypsum is the main material we see customers wanting to process with a .

You should briquette waste gypsum for several key reasons that directly impact your bottom line. Storing fine, wet gypsum powder is difficult. It takes up a lot of space, can be blown away by the wind, and is messy to transport. Turning it into solid briquettes solves these problems immediately.

Here are the main benefits for your business:

The applications for gypsum briquettes depend on how you make them. The two biggest markets are for wallboard and cement production, and they have very different needs. Understanding this is key to your success.

When you make briquettes for wallboard manufacturing, the briquette is just a temporary shape for easy transport. The wallboard plant will grind it back into a fine powder. For this reason, purity is the most important factor. You cannot use chemical binders like lime or cement because they would contaminate the final wallboard. The only “binder” used is water, which allows the gypsum to naturally recrystallize and harden.

For cement production, the rules are different. Gypsum acts as a retarder, controlling how fast the cement sets. The briquettes are added directly into the cement mill. Here, small amounts of other materials are more acceptable. This means you can sometimes use binders like hydrated lime to make the briquettes stronger right after they leave the press. This choice becomes a business decision. You must weigh the cost of the binder against the benefits of faster production and less machine downtime.

A gypsum briquetting machine, also known as a gypsum briquette press, is a piece of heavy equipment designed for one specific job. It takes fine, often damp gypsum powder and uses extreme pressure to form it into solid, uniform blocks called briquettes. The core of the machine consists of two large, counter-rotating rollers.

These rollers have pockets or molds machined into their surfaces. As the rollers turn towards each other, the gypsum powder is fed between them. The immense pressure forces the powder into the molds, compacting it into a solid shape. The finished briquettes then fall out from the bottom of the machine onto a conveyor belt. It is a simple concept, but making it work reliably with a sticky material like gypsum requires very specific engineering.

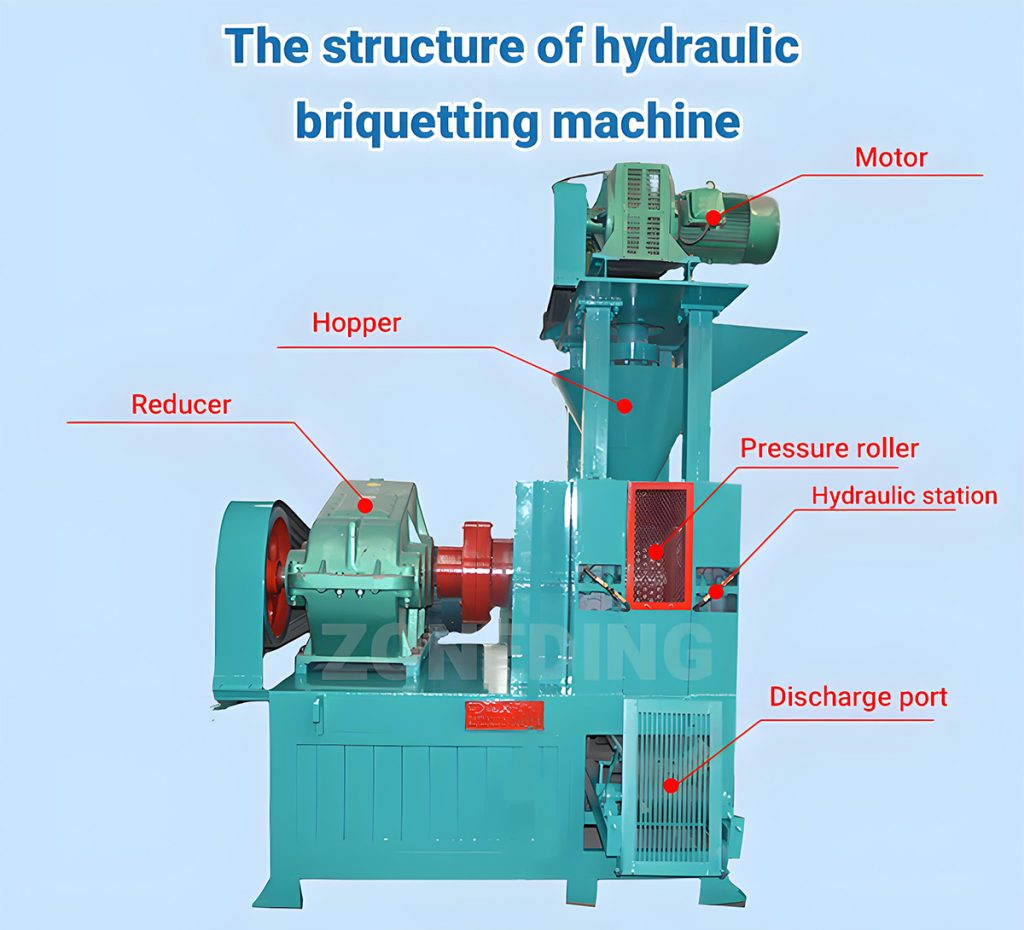

The structure of a gypsum briquetting machine is built for strength and durability. It has several main parts that work together to create the briquettes. Think of it like a team where each member has a crucial role.

Gypsum briquetting machine can press desulfurized gypsum powder, phosphor gypsum and natural gypsum into balls at one time without adding any binder, which has high ball forming rate, high yield, high strength, convenient transportation and storage. It has been put into use in many power plants and cement plants put into operation.

Short process, low failure rate, high-quality alloy steel material (patent) is used in the main roll to greatly improve wear and pressure resistance, so that the machine has a long service life.

Energy conservation and environmental protection, improving the utilization rate of waste and saving cost

The desulfurization gypsum ball press machine does not cause sticking after the formed gypsum is put into the grinding machine, and does not affect the output of the mill.

Compact structure, convenient maintenance, simple operation, and convenient installation.

The gypsum press obtains power from the hydraulic circuit, the hydraulic control valve and the accumulator. The material enters the feeder hopper quantitatively through the storage box and then enters the space between the two rollers after the adjustment gate of the hopper is changed. When the forming pressure changes from low to high and reaches the maximum pressure at the double roller connector, the roll material is run in reverse at a constant speed. When passing through the production line, the material is in the state of ball separation, and the molding pressure is rapidly reduced, thus completing the separation process.

Many people think the gypsum briquette press just squeezes powder hard to make a strong block. For gypsum, this is incorrect. The machine is more of a shaper than a strength-builder. The real strength comes from a chemical reaction after the briquette is formed. The process is more about chemistry than pure force.

The press initiates a chemical setting reaction. When you add the right amount of water to FGD gypsum, pressing it creates close contact between the fine particles. This starts a process of rehydration and recrystallization, just like plaster of Paris hardening. The machine’s job is not to build final strength, but to form a briquette with the perfect density to allow this chemical curing to happen uniformly. If you apply too much pressure, the briquette becomes too dense, trapping moisture inside and preventing it from ever curing properly. If you apply too little pressure, the briquette falls apart. It is about finding the sweet spot where the machine forms a stable shape, and then letting chemistry do the rest during the drying and curing stage.

Our machines are versatile and can handle several different types of gypsum. Each type has slightly different characteristics, which may require adjustments to the machine’s pressure and the amount of water added.

Here are the most common types we work with:

Choosing the right machine is critical. A key decision is whether to use a mechanical or a hydraulic press. For a sensitive material like gypsum, a hydraulic briquetting press is far superior. A mechanical press has a fixed stroke, so any small change in how much material is fed can cause big swings in pressure and briquette quality.

A hydraulic briquetting machine provides constant pressure. You set the ideal pressure, and the hydraulic system automatically adjusts to make sure every briquette gets that exact same pressure. This consistency is the secret to making high-quality gypsum briquettes all day long.

When selecting a machine for your project, consider these points:

At ZONEDING, our gypsum briquetting machines are designed to solve the specific problems that come with processing gypsum. Fine, damp gypsum powder is incredibly sticky. Under pressure, it can build up on the rollers and slowly turn into solid plaster, a problem we call the “plastering effect.” This can damage the machine and halt production.

Our machines have a multi-stage defense against this. First, our rollers are made of high-chromium forged steel polished to a mirror finish, which makes it harder for gypsum to stick. Second, we use a robust, precisely adjustable scraper system made from hardened tool steel to continuously clean the rollers.

Corrosion is another silent killer. FGD gypsum can be slightly acidic and contain chlorides that eat away at steel. Our machines feature a fully seam-welded frame with a two-part epoxy marine-grade coating. We use stainless steel fasteners and design our bearing housings to be purged with grease, pushing contaminants out. This design philosophy may add a small amount to the initial cost, but it can double the operational lifespan of the machine in a harsh gypsum environment.

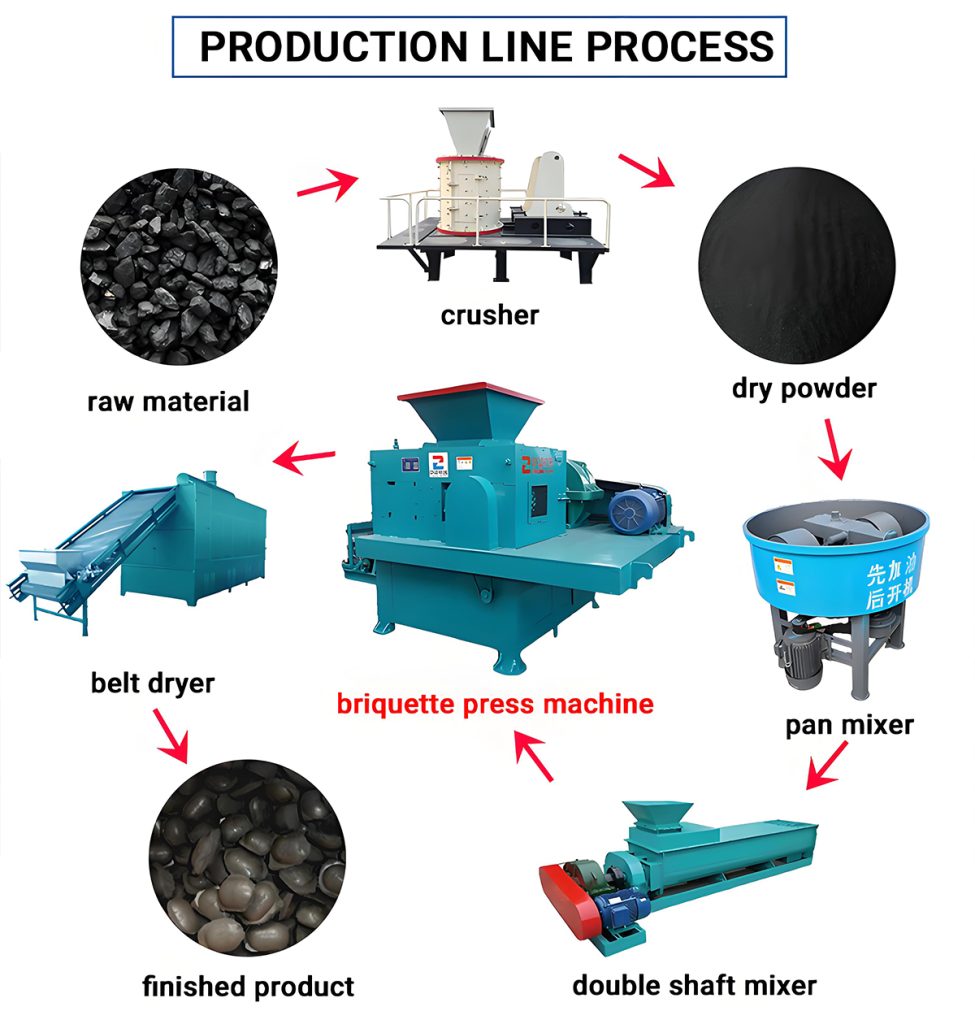

A gypsum briquette press is only one part of a full production line. The equipment you need before and after the press is just as important for success. A common mistake is underestimating the cost and space required for the curing and drying process.

A typical complete briquetting plant includes:

Finished Shapes of Briquetting Machine

The gypsum briquetting machine is typically composed of two main parts: the feed part and the drive part

The price of a gypsum briquetting machine can vary widely, from around $15,000 for a small, basic model to over $200,000 for a large-capacity, fully automated hydraulic machine. It is not just about size; the quality of the components makes a huge difference in performance and longevity.

Here are the main factors that determine the cost:

Proper maintenance is key to keeping your gypsum briquetting machine running efficiently for years. Because gypsum is abrasive and corrosive, a regular maintenance schedule is not optional. It is essential for protecting your investment.

Here is a basic maintenance schedule you should follow:

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

1. Do I need to add a binder to make gypsum briquettes?

For FGD gypsum, you usually do not need an additive binder. The gypsum acts as its own binder through a chemical reaction with water. However, controlling the moisture content perfectly is critical for this to work.

2. How strong are the gypsum briquettes right after pressing?

They are not very strong. We call them “green” briquettes. They are fragile and must be handled gently. They gain their full strength only after they have gone through the curing and drying process, which can take 24-48 hours.

3. What is the ideal moisture content for briquetting gypsum?

The ideal moisture content is typically between 10% and 14%. The exact percentage depends on the specific properties of your gypsum powder. Our engineers can help you determine the perfect moisture level during commissioning.

4. Can the shape and size of the briquette be customized?

Yes. We can manufacture the rollers with molds of various shapes and sizes, such as pillow, oval, or square. We can work with you to choose a shape that best suits your handling and application needs.

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd…

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq…

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for…

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. …

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin…

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach…

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin…

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z…

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. …

Applied Materials:nCoal powder, iron powder, coke coal, aluminum powder, iron scrap, iron oxide sheet, charcoal powder, carbon powder, slag, sludge,etc. Charcoal briquette machine or charcoal briquetting mac…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy