Search the whole station Crushing Equipment

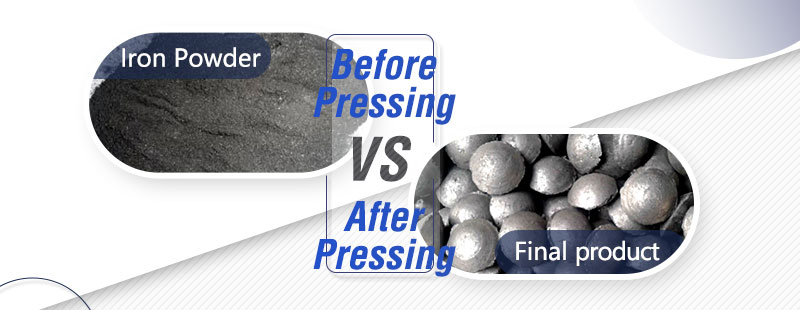

An Iron Powder Briquetting Machine is a high-pressure press designed specifically for metal powders. It is not like a standard biomass briquetter. It is built to handle extremely abrasive materials under immense force. This machine uses two counter-rotating rollers to compact iron fines into a solid block, or briquette. The goal is to create a product that is strong enough to be handled and transported without breaking. This process is often called cold pressing. It turns a low-value, problematic waste into a high-value, standardized furnace charge.

The iron powder briquetting machine is also called powdered iron briquetting machine or oxide scale briquetting machine. The raw material can be directly put into production after crushing without adding water. Iron ore powder (iron powder, iron ore) is one of the most important metal powder materials in metallurgical industry, which is used in large amount in the powder metallurgy production and its consumption accounts for about 40% of the total consumption of metal powder. The iron powder briquetting machine can guarantee the intensity and density of iron powder briquettes.

The iron briquette machine is a kind of high-pressure ball press which is used to press the hard-granular material. And The iron powder briquette machine is characterized by large forming pressure, adjustable revolution of main engine and screw feeding device. It is widely used, and many materials can be pressed into a ball.

You are not making briquettes; you are making a reliable furnace charge. This is the most important advantage. Furnace operators need a consistent, predictable material. Loose powder is inefficient. Briquettes solve this problem. They provide significant operational and financial benefits.

Iron powder is an industrial abrasive. This is the most critical feature to understand. Materials like mill scale and iron ore fines are hard and sharp. When you mix them with a little water for briquetting, you create a perfect grinding paste. This paste is then forced between two rollers under massive pressure. This puts extreme stress on every part of the machine. A standard machine will be ground to pieces in a short time. Your Iron Briquetting Machine must be built specifically to resist this constant wear and tear.

A machine’s long-term performance is determined by its frame and rollers. These two components handle the incredible forces needed for metal powder briquetting. At ZONEDING, we focus on building machines that last in the harshest environments.

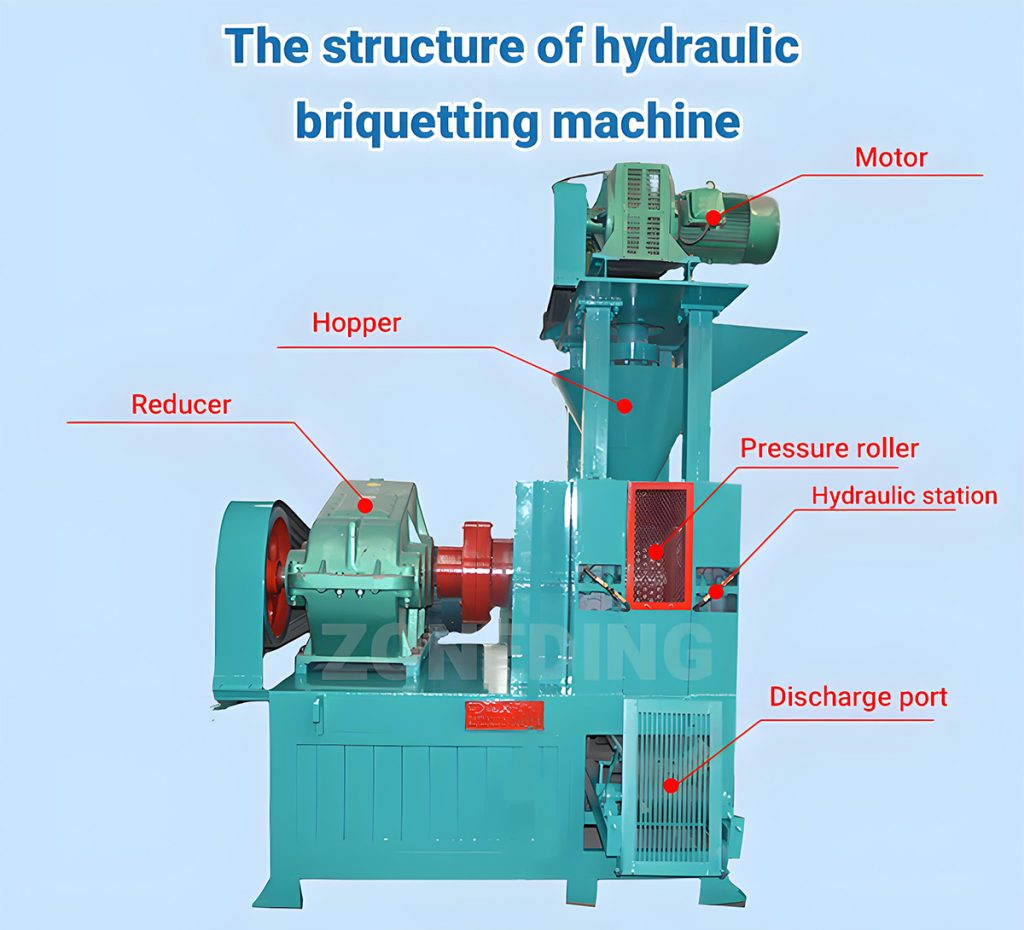

A modern iron briquetter is a combination of heavy mechanics and precise hydraulics. Each part has a specific job in creating a high-quality briquette.

There are mainly two types of iron briquette machines offered by Zoneding Machinery. One is the machine that has the qualified product and unqualified product are discharged at the same side. The other is to discharge these two kinds of products at different sides.

The feeding system realizes uniform feeding of iron powder which can prevent the machine from idling. This can save power energy and reduce cost.

Hydraulic protection device iron powder ball press has hydraulic protection device.

As a key part, the mould is made of composite components with 65Mn, which is wearable and can be replaced in case of being worn.

This type of briquette machine is equipped with shock absorbers, which can better protect the equipment from the impact of hard materials.

Iron powder briquetting machine is designed with ball bowl adjustable device to ensure that the ball bowl of two rollers is always in the adjustable range.

The iron powder briquetting machine is a kind of widely used metal powder processing equipment in coal industry, metallurgy industry and chemical industry materials. The briquettes made by this equipment can be used as metal smelting materials and chemical reactant. Some good cases in point are as follows. Steel plant reprocess iron ore powder briquettes to make steel; chemical plant uses mill scale briquettes to make ferrosilicon.

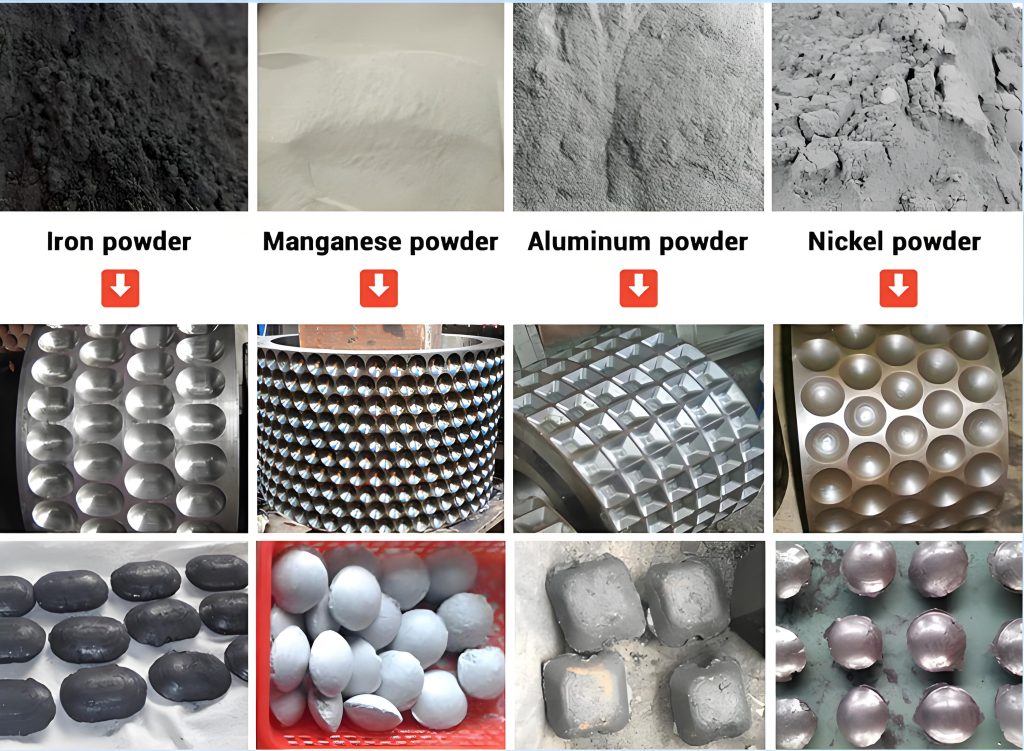

It can be used to suppress coal powder, iron powder, coking coal, aluminum powder, iron filings, iron oxide sheet, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke and other powder material and waste residue in power plants, metallurgy, refractory material industry, chemical industry, energy, transportation, heating, etc.

>>Size Requirements:

It is suitable for particles of no larger than 8mm, and the smaller, the better. Because it is good for make high-density balls. Besides, the materials are preferably powdery and granular.

>>Moisture Requirements:

Humidity below 12% is better for the material to be briquetted. It’s not easy to press the powder into ball.

If the material is of large size, the crusher machine is needed.

If the material is of high humidity, a dryer machine is needed.

and If the material is too dry, adhesive or water is needed; or you can select a dry powder briquette machine.

Oxide Scale Briquetting Machine

Oxide scale briquetting machine mainly adopts waste iron materials such as oxidation, dust, ash, blast furnace slag,manganese powder, silicon manganese alloy powder, iron ore concentrate powder as well as minerals of nonferrous metal industry. It can complete the smelting and ball pressing of all powdery materials which require to be melted by the furnace.

Powdered Iron Briquetting Machine

Powdered iron briquetting machine is specially used to suppress iron powder. In the pressing process, it needs to add special dry powder adhesives. The one-time molding and forming rate can reach about 90%. The iron concentrate after pressing can be used in various industries, which can reduce the loss of resources and greatly increase the production efficiency. In China, many large iron ore mines have bought powderediron briquetting machines and put them into use, which have good effect with less investment and soon benefits.

The powdered iron briquetting machine is suitable for pressing wet powders, which means that it is necessary to add the proper amount of water or other liquid adhesives into the materials. This product has an excellent pressing effect on various materials such as caustic-burned magnesia powder, sinter, sludge in steel plant and an iron fine meal. Iron powder briquette machine is equipped with reducer, and the motor and the reducer drive the machine through arc tooth coupling and the two rollers of the main engine rotate in the opposite direction driven by the synchromesh gear.

The process is simple in concept but requires a very powerful machine. It works by applying extreme pressure to a prepared mixture of iron powder.

Almost any type of iron-bearing dust or sludge can be briquetted. The key is to prepare the material correctly. Common materials processed by a mill scale briquetter and iron fines press include:

A successful operation is a complete process, not just a single machine. The briquetting machine is the centerpiece, but the preparation steps are what guarantee a good result.

Start with your final product, not the machine’s capacity. The first question is not “how many tons per hour?” The right question is, “What strength does my briquette need to survive the journey to the furnace?” You must define the required Cold Crushing Strength with your furnace operator. This single specification will determine the pressure needed from the machine. From there, you can select the right model, roller material, and motor size. A supplier who asks about your tonnage before asking about your strength requirements is selling you a machine, not a solution.

The price is directly related to the machine’s ability to survive. A cheap machine will not last. The key cost drivers are the parts designed to handle extreme pressure and abrasion.

Maintenance is about managing the constant wear from abrasive material. A proactive maintenance schedule is essential to keep the plant running and avoid expensive, unplanned downtime.

We build our machines to survive the reality of processing abrasive iron powders. For over 30 years, ZONEDING has focused on engineering robust, reliable equipment. We understand that downtime costs you more than the price of any machine. We are a high pressure briquetting machine manufacturer that prioritizes long-term performance.

We start by analyzing your material and understanding your strength requirements. Then, we build a solution around that. Our machines feature:

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

A binder acts like glue to hold the iron particles together. The choice of binder is critical and depends on where the briquettes will be used. For a Blast Furnace, you can use a cheap binder like hydrated lime and molasses. For a high-quality Electric Arc Furnace, you must use a clean-burning organic binder like sodium lignosulfonate that won’t contaminate the steel.

Briquettes create a permeable bed in the furnace, allowing hot gases to flow through evenly. This speeds up the chemical reduction process and reduces fuel consumption. They also stop fine material from being blown out of the furnace, which means you get more final product from your raw materials. This directly translates to lower production costs.

High pressure forces the iron particles into close contact, reducing the voids between them. This creates a dense, compact briquette. This initial “green strength” from the press is critical. It allows the briquette to hold its shape while it is moved to a dryer, where the binder will cure and give the briquette its final, high handling strength.

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd…

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq…

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly …

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for…

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. …

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin…

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach…

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin…

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. …

Applied Materials:nCoal powder, iron powder, coke coal, aluminum powder, iron scrap, iron oxide sheet, charcoal powder, carbon powder, slag, sludge,etc. Charcoal briquette machine or charcoal briquetting mac…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy