Search the whole station Crushing Equipment

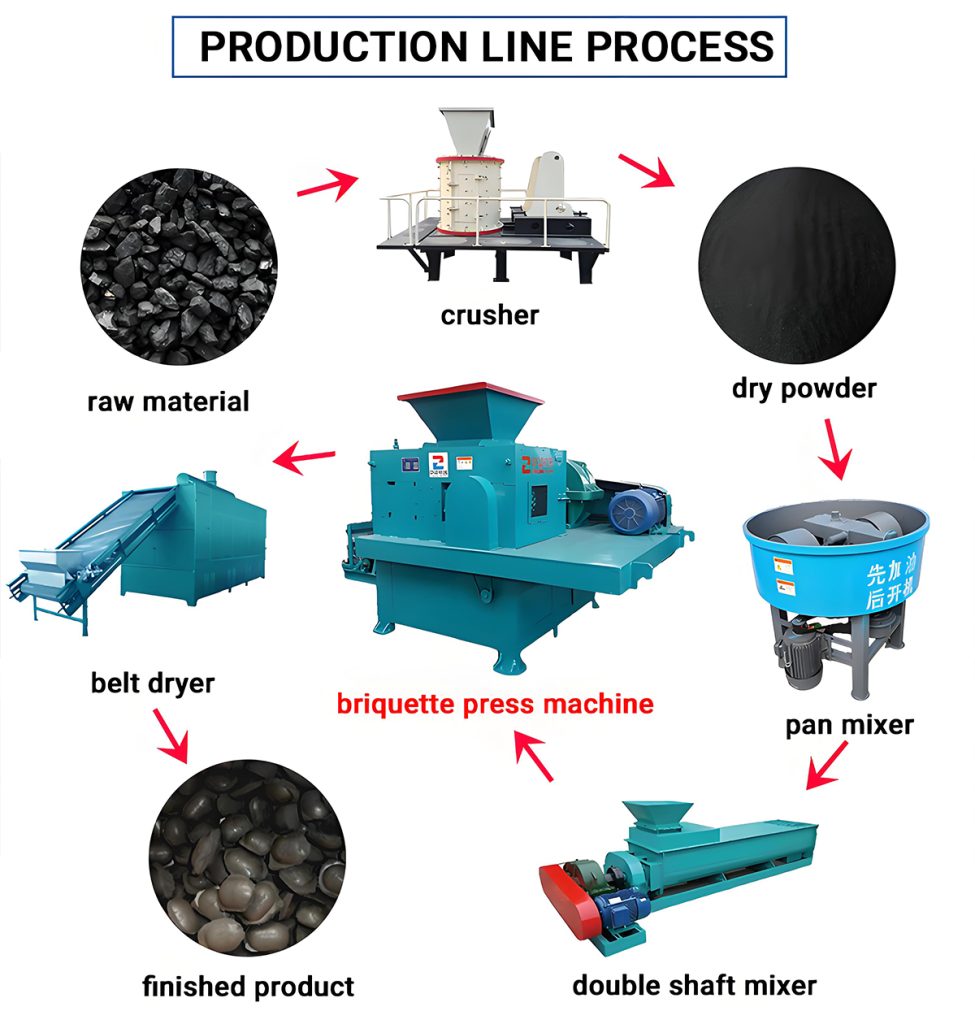

Dry powder briquetting machine, also known as dry powder briquetting machine, can be used to suppress coal, iron powder, coking coal, aluminum powder, iron scrap, tin oxide, carbon, coal, slag, gypsum, tailings, sludge, kaolin, activated carbon and other low water content or do not contain water powder materials. The material formed by the ball press is energy saving, environmental protection and convenient for transportation, which improves the utilization rate of waste materials and has good economic and social benefits.

Briquettes are simply better than powder. When you briquette your fine powders, you create a product that is dense, uniform in size, and easy to manage. This solves several major problems. It drastically reduces dust, leading to a safer and cleaner workplace. It makes the material easier to store and transport without loss. Most importantly, for industries like steelmaking or chemical processing, briquettes provide a consistent, predictable feed for furnaces and reactors, improving process efficiency. This turns a low-value or waste powder into a premium industrial product.

The biggest challenge with dry powders is air. Fine powders like quicklime or mineral fines can be over 70% air by volume. If you try to compress this in a standard press, the air gets trapped. When the briquette leaves the rollers, this trapped, high-pressure air expands, causing the briquette to crack or even explode back into dust. A true dry powder briquetting machine is designed specifically to solve this de-aeration problem before compaction.

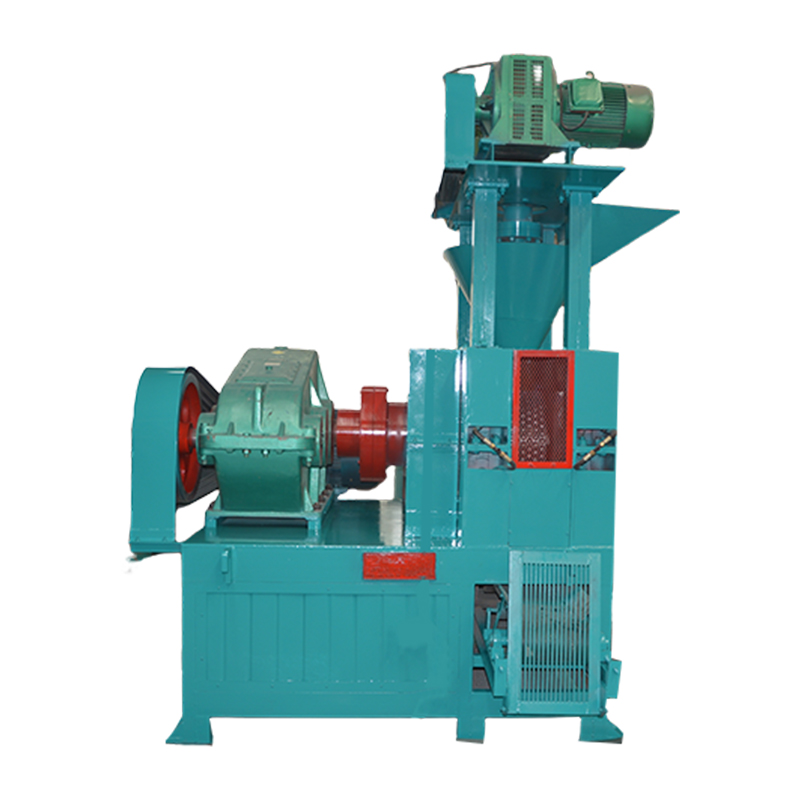

A dry powder briquetting machine, also known as a high pressure roller press, is an industrial machine built for extreme compaction. Unlike standard briquetting machines that rely on binders and moisture, this machine uses immense mechanical and hydraulic force to press dry materials directly into solid blocks. The entire machine, from the feeding system to the frame, is engineered to handle the unique challenges of dry, abrasive powders and the massive forces required for powder compaction.

The structure of this machine is all about strength and pressure.

The process is a masterclass in pressure management.

Features of Dry Powder Briquetting Machine

Dry powder briquette machine is suitable for the cold pressing of magnesium powder, iron powder, manganese powder, activated carbon, bauxite, caustic soda, graphite powder, clay, cryolite, fertilizers, plastics, limestone, pigment, potassium salt, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, aluminum, aluminum powder, dolomite, calcium carbide, sludge, dust, oxide, copper powder, zinc powder, flux, soil vanadium ore and various industrial powder, waste powder, stainless steel, non-ferrous metal powder, metallurgy powder and so on. The pressed briquettes can be directly used in metallurgy, coal, building materials, chemical industry, electric power, refractory, and other industries.

Applications of Dry Podwer Briquetting Machine

The dry powder ball press is transmitted to the reducer by the main motor through the v-shaped belt, and the reducer passes through the coupling to the driveshaft and then ensures the synchronization of the two rollers by a pair of gears (equal speed reverse). The piston of the passive roller hydraulic cylinder is supported (the constant pressure is supported by the inclined iron), and the pressure of the system is guaranteed by the hydraulic circuit, hydraulic control valve, and accumulator.

Materials from the storage bin into the molding machine hopper, by adjusting the gate on the hopper, the material uniform into the middle of the roller. The pressure of the material compressed by the roller with equal speed reverse operation increases from small to large, and the forming pressure reaches the maximum at the connecting line of the center of the matching roller. After the material passes the line, the forming pressure decreases rapidly, making the material enter the state of falling off the ball and falling off the ball smoothly.

The difference is night and day. A wet briquetting press uses low to medium pressure and relies on a binder (like starch) and water to stick the particles together. The resulting briquettes are weak and must be sent to a large, energy-intensive dryer for hours to cure and gain strength. A binderless briquetting machine uses 5 to 10 times the pressure. It requires no binder and no water, which means there is no need for a dryer. The strength comes entirely from achieving extreme density, which mechanically interlocks the particles. This saves massive costs on binders and energy.

This technology is ideal for a wide range of dry, inorganic powders that are difficult to handle.

At ZONEDING, we always recommend a material test first, as different powders require specific machine configurations for optimal results.

Choosing the right machine is critical for long-term success. You must look beyond the basic specs.

The price of a dry powder briquetting machine can vary significantly, from around $50,000 for a small, basic model to over $500,000 for a large-scale, high-performance system. The price is much higher than a standard wet briquetting press because every component is massively over-engineered to handle extreme pressure and abrasion. Investing in a cheaper, under-built machine is a common mistake that leads to constant downtime and a very short service life. The lime powder briquetting machine price, for example, is directly tied to the quality of its wear parts.

The final price is determined by the machine’s specification and capabilities.

Maintenance is focused on managing wear and pressure.

At ZONEDING, we understand that a briquetting machine is part of a larger process. A cheap, standalone press often fails because it doesn’t account for the whole production flow. We design complete industrial briquetting solutions. This includes a crucial fines recycling loop. No process is 100% efficient; some powder and broken pieces will fall through the screen. Our systems automatically capture these fines and return them to the feed hopper. This closed-loop design turns a 90% yield process into a >98% yield process, directly adding to your bottom line and paying for the system over time.

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

Can I really make briquettes without a binder?

Yes. For many mineral and inorganic powders, how to make briquettes without a binder is a matter of applying extreme pressure. The force is so great that it causes the particles to mechanically interlock and bond through microscopic forces, creating a dense and strong briquette.

What is the main challenge when briquetting quicklime?

Quicklime powder is extremely fine, light, and full of air. The primary challenge is de-aeration. It requires a machine with a very aggressive force-feeding system and extremely high pressure to create a dense briquette that won’t fall apart.

How do you handle abrasive materials like iron ore fines?

For highly abrasive briquetting machine for mineral fines applications, the roller material is everything. You must use rollers made from forged, high-chromium alloy steel (like 9Cr2Mo) that has been properly heat-treated. Standard steel rollers would be destroyed in a matter of weeks.

Are these machines good for metal dust recycling?

Absolutely. These machines are a core part of many metal dust recycling solutions. They can compact steel mill dust, copper fines, and aluminum dross into briquettes that can be easily remelted in a furnace, allowing for the recovery of valuable metals.

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq…

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly …

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for…

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. …

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin…

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach…

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin…

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z…

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. …

Applied Materials:nCoal powder, iron powder, coke coal, aluminum powder, iron scrap, iron oxide sheet, charcoal powder, carbon powder, slag, sludge,etc. Charcoal briquette machine or charcoal briquetting mac…

loading…

已经是到最后一篇内容了!