Search the whole station Crushing Equipment

Slurry refers to the semi solid materials formed by coal and water, which is a kind of product in the coal production process. Due to the varieties and formation natures of materials, their properties difference is very big, which is the same as their usages. Slurry briquetting machine or coal slime briquetting machine is mainly used for pressing slurry into balls and blocks, which can be directly put into the furnace for smelting, so as to increase the added value.

Slurry briquetting machine or coal slime press is mainly used for grouting with high pressure, automatic feeding and other characteristics. The pressed particles have high density and hardness. The series of briquetting machine equipment also includes coal briquetting machine, desulfurization gypsum briquetting machine, ore powder briquetting machine.

A slurry briquetting machine is not just one machine; it is a complete system designed to dewater and compact wet materials. Many people think you can just pump wet slurry into a press, but this is not true. The real heart of the system is a high-intensity, dual-shaft mixer that comes before the press. This powerful mixer takes your high-moisture slurry, blends it with a precise amount of binder (like lime or cement) and sometimes dry recycled material, and kneads it into a consistent, damp, pressable feedstock. Only after this critical conditioning step does the material go to the roller press for compaction.

Managing wet slurry is a major operational headache. It is heavy, takes up a lot of space, and is expensive to transport for disposal. Briquetting this material fundamentally changes the equation. Instead of paying to get rid of a waste product, you create a new revenue stream or a valuable feedstock for your own processes.

You are essentially taking a low-value, high-volume waste and concentrating it into a high-value, low-volume product. This process reduces your landfill needs, cuts transportation costs by more than half, and turns an environmental liability into a component of a circular economy. It is a smart financial decision that also improves your company’s environmental credentials.

Investing in a slurry briquetting machine system offers clear, measurable benefits that impact your bottom line and your operations. It goes beyond just waste management; it is a process optimization tool.

This technology is incredibly versatile and is used across many heavy industries to solve waste problems. The key is that we can customize the system to handle the specific challenges of your material, whether it is corrosive or highly abrasive.

The slurry briquette machine is the key equipment of the slurry pressing technology, and its structure directly affects the quality of the size. The main type of press machine is roller press, and it has a pair of parallel shaft, the same diameter and a certain gap of a cylindrical wheel, and there are many hemispherical pits of the same shape and size arranged in regular order.

Driven by an electric motor, the twin cylinders rotate at the same speed and in opposite directions. As the material falls into the joint of the twin-cylinder wheels, they begin to withstand pressure and generate volume compression between the two ball pits. As the cylinder wheel continues to rotate, the pit will gradually close and the pressure will increase. Pressure peaks when the distance between the two ball pits is minimized. The cylindrical wheel would then rotate away from each other and the pressure would drop rapidly. When the pressing pressure drops to zero, the precipitated slurry expands and falls off.

The slurry briquette machinery is widely used in the coal industry, power plants, metallurgy industry, refractory material, chemical industry, energy, transportation, heating, and other industries. For processing coal slimes into briquettes that can be utilized for electricity-generating in power plant, gas making, boiler burning, calcining lime, metal smelting, etc. This coal lime briquetting machine manufactured by Zoneding Machinery is a great project that is energy-saving and eco-friendly. Using this roller press briquetting machine, your enterprise will obtain enormous economic benefit.

Applications of Slurry Briquetting Machine

A robust and reliable slurry briquetting machine system is built from several key components that must work together seamlessly. The quality of each part determines the long-term performance of the whole system.

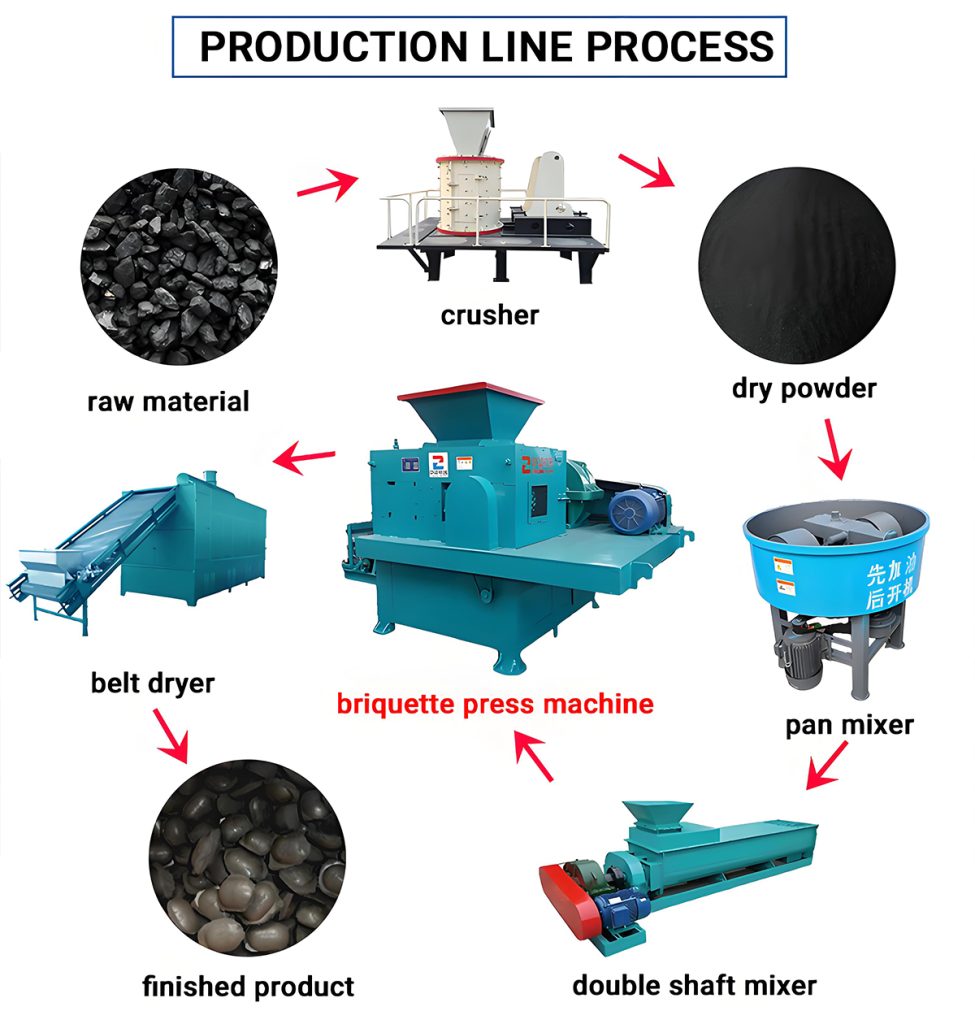

The process is a logical flow from a wet waste to a dry, valuable product. Understanding this flow helps you see how each step adds value and contributes to the final briquette quality.

The principle is based on conditioning followed by compaction. First, the raw slurry and binders are precisely metered into the dual-shaft mixer. The mixer’s paddles shear and knead the material, ensuring every wet particle is coated with binder and the moisture is evenly distributed. This transforms the slurry into a damp, soil-like material. This conditioned feed is then force-fed into the gap between the two rollers of the press.

As the rollers turn, the material is squeezed into the pockets at extreme pressures, compacting it and forming the briquette. The critical goal here is to achieve good “green strength”—the ability of the wet briquette to hold its shape after leaving the press. The final hardness is achieved later, in the dryer.

A wide variety of industrial sludges and slurries can be successfully briquetted. The main requirement is that we can condition the material to a pressable consistency.

Here is a list of common materials:

Creating a high-quality briquette is a multi-stage industrial process. Each step is carefully controlled to ensure the final product meets your specifications.

The size and shape of the briquettes are fully customizable. They are determined by the pockets machined into the surface of the rollers. This allows you to create a product that is perfectly suited for your end-use.

Common shapes include pillow, oval, round, and square. The most popular is the pillow shape because it is robust and easy to handle. Typical sizes range from 25 mm to 60 mm. We work with you to design a briquette size and shape that provides the best performance for your application, whether it is for charging into a furnace or for easy packaging.

The price of a slurry briquetting system can range from $30,000 for a small, basic press to over $500,000 for a large, complete, automated line. It is important to understand that you are not just buying a press. The biggest mistake customers make is focusing only on the cost of the briquetting machine.

The reality is that the dryer is the real factory in this process. A dryer capable of handling the output of a medium-sized press can easily cost as much as, or even more than, the press itself. Furthermore, the single largest ongoing operational cost will be the energy (natural gas, coal, etc.) required to run the dryer. We believe in being transparent about these costs so you can plan your project for long-term success.

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

The system handles high moisture not in the press, but in the mixer. The key is the conditioning step, where the wet slurry is blended with dry binders. This process absorbs excess water and creates a homogenous feedstock with a consistent, lower moisture content (typically 15-20%) that is ideal for pressing.

For high-volume industrial applications like sludge briquetting, a Roller Press is the superior choice. It offers continuous, high-throughput operation and is designed for the immense pressures needed for densification. A screw press is generally used for dewatering or lower-volume extrusion and cannot achieve the same density or throughput.

The primary wear parts are the roller shells and the mixer paddles and liners. Their lifespan depends entirely on the abrasiveness of your material. For highly abrasive materials like iron ore tailings, we use advanced materials like forged high-chrome steel, which can last for thousands of hours. For less abrasive materials, they can last for years. Regular inspection is key.

Our technology is creating value across multiple heavy industries. The steel sector is a major beneficiary, recycling iron-rich sludge. The energy sector uses it for FGD gypsum. The mining industry is increasingly adopting it for sustainable tailings management. We also provide solutions for the non-ferrous metals, chemical, and refractory industries.

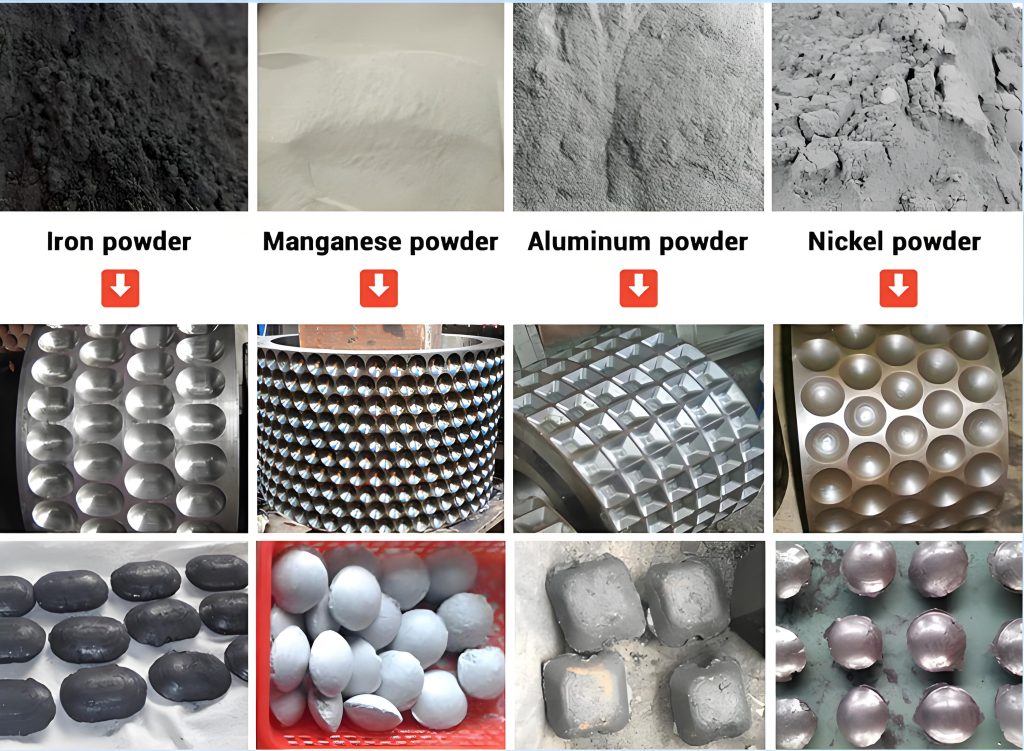

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd…

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq…

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly …

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for…

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin…

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach…

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin…

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z…

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. …

Applied Materials:nCoal powder, iron powder, coke coal, aluminum powder, iron scrap, iron oxide sheet, charcoal powder, carbon powder, slag, sludge,etc. Charcoal briquette machine or charcoal briquetting mac…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy