Search the whole station Crushing Equipment

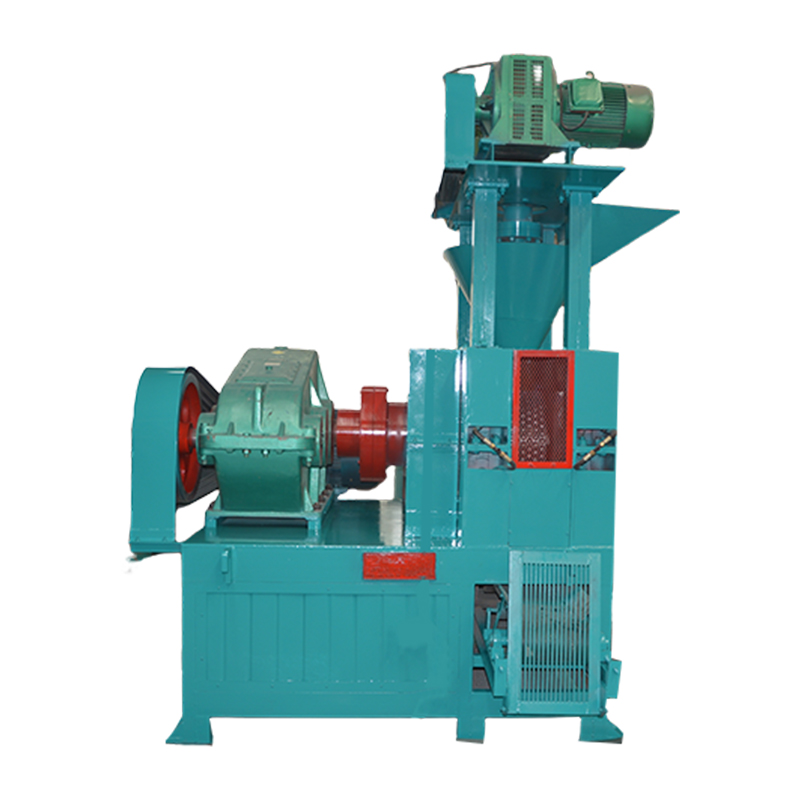

The aluminite powder briquetting machine can press granular or powdery materials such as aluminate powder, aluminum ash and copper powder into elliptic, spherical and flat shapes. The aluminum powder can be also used in metal reduction, blast-furnace smelting and other fields after pressing. It can not only put aluminum materials into full use, but also save great deal of resources consumption as well as economic cost for you. Thus, our aluminum briquetting machine is your best choice for processing aluminum wastes.

You need to briquette aluminum powder to increase its value and usability. Loose powder is inefficient and costly. When you add it directly to a furnace, a significant amount is lost as dust, blown away by the exhaust gases. This is a direct loss of valuable metal. Briquetting solves this. It compacts the powder into a dense, solid form. This drastically reduces material loss, makes storage and transport cheaper, and creates a safer, dust-free work environment. It turns a waste problem into a revenue stream.

Aluminum powder is extremely abrasive. This is the single most important feature you must understand. Think of it like diamond dust. It will destroy standard steel parts very quickly. A machine that is not specifically designed for this material will fail. At ZONEDING, we understand this challenge. The rollers, the mixer blades, and the feeder screw on our Aluminum Powder Briquetting Machine are all in a constant battle with wear. That is why we build them with specialized, ultra-hard alloys to ensure a long and productive service life.

A briquetter transforms your fines from a liability into a high-grade asset. The process adds value at every step.

The aluminum briquette machine is widely used, and its purpose is to reduce dust, control the density of accumulation, reuse and improve transport performance. It has been applied in many countries, which can not only increase the profits of enterprises, but also reduce the waste of resources. By using this aluminum briquetting machine, you can make full use of these industrial wastes and their high added value, without abandoning them or slightly processing them.

The aluminum powder briquette machine can be used for processing aluminum powder, aluminum ash and other industrial waste or aluminum products produced in the process of aluminum metallurgy into bulk, which can be used as chemical additive in blast furnace for further metallurgy. It widely used in chemical, energy, power plants, metallurgy, transportation, heating and other industries.

Applications of Aluminite Powder Briquetting Machine

The most effective type is the high-pressure roller briquette press. While other types exist, the roller press is the industry standard for handling the abrasive nature and high volume of aluminum fines.

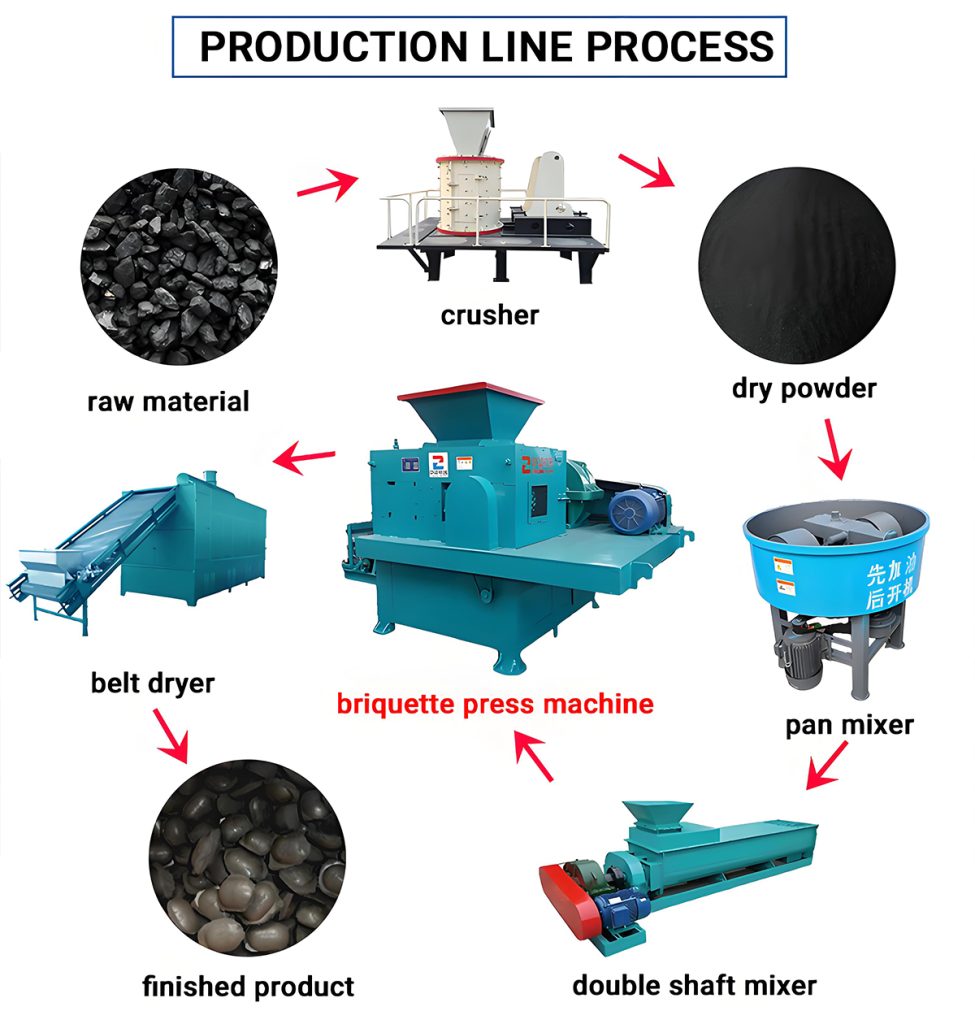

A successful operation needs a complete system, not just a press. The aluminum briquetter is the core, but the supporting equipment is just as critical for making high-quality briquettes.

It works by using force and precision. Brute force alone is not enough. The powder first goes into a high-intensity mixer to ensure every particle is coated with binder. Then, it enters the Aluminum Powder Briquetting Machine. A special forced feeder screw pre-compacts the material and pushes out trapped air before it even reaches the rollers. This is critical for creating a solid briquette without a weak core. Then, two massive rollers, driven by a powerful motor and hydraulic system, squeeze the material into shape with immense pressure. This combination of proper mixing, pre-compaction, and high pressure is the secret to a strong, dense final product.

Zoneding aluminum briquette machine is very suitable for making recycled compactor from aluminum powder, ash and so on. How to deal with aluminum powder and residue is a big problem in the field of aluminum production. Aluminum briquette machine has a wide range of applications, which can not only put aluminum materials into full use, but also save a great deal of resource consumption as well as economic cost for you. Thus, our aluminum briquetting machine is your best choice for processing aluminum wastes.

Structures of Aluminite Powder Briquetting Machine

The process is a carefully controlled production line. Each step builds on the last to ensure a high-quality final product.

Be aware that the press is only one part of the total investment. The price of the Aluminum Powder Briquetting Machine itself depends on its capacity and, most importantly, the quality of its wear parts. But you must also budget for the essential downstream equipment. The dryer and kiln system required to properly cure the briquettes can often cost two or three times more than the briquetting machine. A trustworthy aluminum briquetting machine manufacturer like ZONEDING will be transparent about these total costs and help you plan your entire project budget, not just sell you a single machine.

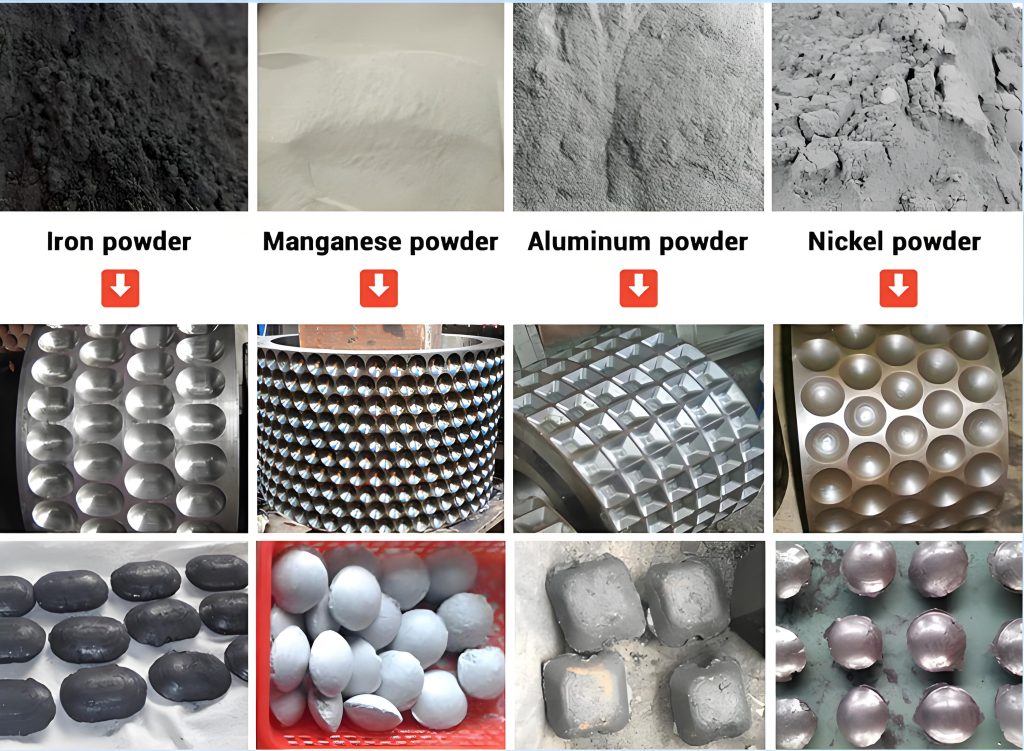

You can choose the shape and size that works best for your furnace. The rollers on the machine can be custom-machined with pockets to produce a variety of shapes. The most common shapes are:

The size typically ranges from 25mm to 60mm. The right choice depends on your furnace type and how you handle the material. We can help you select the optimal shape and size for your specific operation.

Focus on the machine’s ability to withstand extreme abrasion. For aluminum powder, the quality of the wear parts is everything.

Your maintenance schedule is a plan to manage wear and tear. Given the abrasive nature of aluminum powder, proactive maintenance is key to profitability.

Because we build machines for the real world of abrasive materials. For over 30 years, ZONEDING has engineered equipment that lasts. We know that an Aluminum Powder Briquetting Machine is not just a press; it is a fortress designed to withstand a constant abrasive attack. Our competitive advantage lies in the parts you can’t always see. We use massive, single-piece cast steel main frames that will not flex or crack under pressure.

Cheaper welded frames will eventually fail, but our cast frames provide the ultimate rigidity for decades of reliable service. We pair this with forged, high-chromium alloy rollers that offer the best possible resistance to wear, lowering your total cost of ownership. We don’t just sell you a machine; and we provide a robust, long-term solution for turning your aluminum waste into profit.

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

Briquettes have a uniform size, which allows hot gases in the furnace to flow evenly around them. This leads to much faster and more complete melting. Loose powder compacts and blocks gas flow, and a large portion of it is simply blown away before it even has a chance to melt.

Briquettes are dense and solid. They don’t create dust during transport or when being loaded into the furnace. This means almost 100% of the material you process makes it into the final melt. Their high density also means you can store more tons of material in a smaller area, reducing storage costs.

Our machines can handle a wide variety of aluminum fines. This includes dust from baghouse collectors, dross and slag from smelting operations, fine chips from machining, and other powder byproducts. The key is proper preparation and mixing before briquetting.

The immense pressure from the rollers is what forces the individual aluminum particles together, squeezing out air and creating a dense, interlocking structure. This initial “green strength” is essential for the briquette to hold its shape as it moves to the dryer for final curing.

The pillow shape is the most common because it is strong and flows well on conveyors. However, the best shape depends on your specific furnace and charging system. We can discuss your operation and recommend the ideal shape and size to maximize your efficiency.

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd…

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq…

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly …

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for…

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. …

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin…

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach…

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z…

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. …

Applied Materials:nCoal powder, iron powder, coke coal, aluminum powder, iron scrap, iron oxide sheet, charcoal powder, carbon powder, slag, sludge,etc. Charcoal briquette machine or charcoal briquetting mac…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy