Search the whole station Crushing Equipment

Charcoal briquette machine or charcoal briquetting machine is a kind of making machine mainly for charcoal briquettes, which is carbonized from biomass like wood chips, shavings, corn stalks, coconut shells, rice husks, bamboo and any other waste ligno-material.

For the outstanding performance as fuel, like high density, small volume and good combustibility, charcoal is extensively used in industry and household. Therefore, charcoal briquette machine is also one of the favorite choices among investors with single machine operation or large-scale briquetting line.

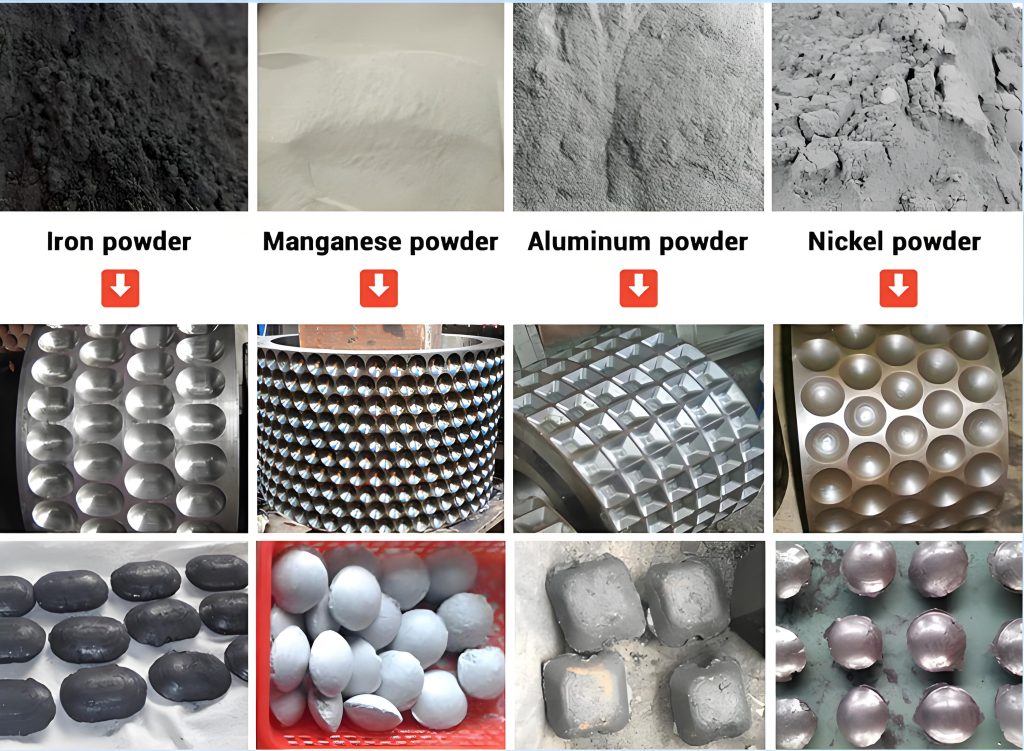

Besides, charcoal briquette machine is also applicable for press other kinds of powder into balls like coal, DRI, lime, aluminum, etc.

Charcoal briquette machine can produce charcoal briquettes with shapes of square, ball, round, oval, column, bar, bread, pillow and other special shapes. This kind of briquette machine is widely used in various fields especially in barbeque, home heating, power plant, energy, industrial and civil boiler. It can also be used for dust reduction, controlling unit weight, recycling, and improved transportation in industries such as carbon powder coal.

Here are the details of charcoal briquette machine applications:

● In barbeque, charcoal briquette machine is used to produce specially designed shape of charcoal briquette to attract customers and improve the profits;

● In industrial and civil boiler, charcoal briquette machine produces normal shaped charcoal briquette as fuel;

● In thermal power plant, charcoal briquette machine can be used to press coal powder into briquettes to improve the burning efficiency.

Applications of Charcoal Briquetting Machine

You can make high-value charcoal from almost any type of organic waste. This is one of the best things about this business. You are taking a low-cost or even free material and turning it into a valuable product. The key is that the material must first be turned into charcoal through a process called carbonization.

Here are some of the best raw materials for a biomass briquette machine:

Making briquettes is about creating a better, more profitable fuel. Your first job is to be an expert in your raw material. The biggest mistake new businesses make is using poor-quality charcoal. If the wood is not fully carbonized, it still contains oils and tars. When your customer lights this briquette, it will produce thick, smelly white smoke. This “white smoke of death” will ruin their food and destroy your brand’s reputation instantly. You must source or make fully carbonized charcoal with low volatile matter.

When you use a good raw material with a charcoal maker machine, you gain several key advantages:

People often confuse two very different types of machines. It is critical to understand the difference so you buy the right tool for your specific business. Trying to use the wrong machine for your raw material will lead to complete failure.

You must know which business you are in. Are you pressing charcoal powder, or are you making charcoal from raw wood? They require completely different machines and processes.

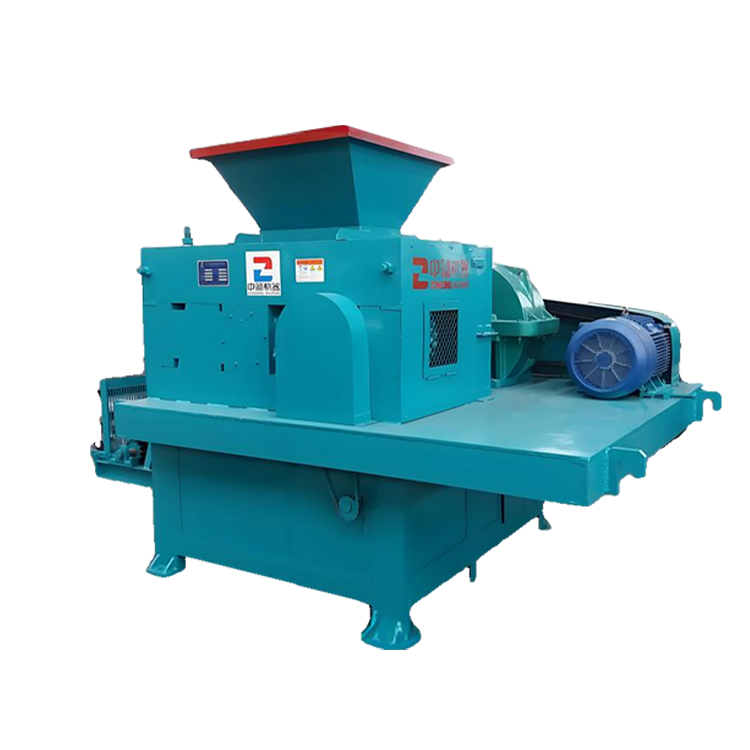

A roller briquette press is a strong and relatively simple machine. Its design is focused on applying immense pressure consistently. While there are many variations, the core components are almost always the same. Understanding these parts helps you understand how it works and what to look for when buying one.

The main parts include:

As the indispensable equipment for making charcoal, charcoal briquetting machine mainly works based on high-pressure from two rollers that rotate at a reverse direction.

The feeding device sends carbonized biomass materials into the charcoal briquetting machine feeding port. The main motor drives the V-shaped belt and rotate the rollers rolling. These two rollers are made of Mn steel with grooves of specific shape. When rotating, the materials are shaped by the grooves at the top of the charcoal briquette machine and then released and discharged at the bottom.

If needed, a screw pre-pressing device can be equipped as a feeding assistance. This device is to improve the briquette making efficiency and ensure a stable performance of the charcoal briquetting machine.

In order to ensure the good quality and mechanical strength of the final product, special attention should be paid to keep the particle size into the machine below 3mm, preferably 1-2mm of the material size, and the moisture within the range of 30-40%. Material over 2 mm, the moisture content should be no more than 10%.

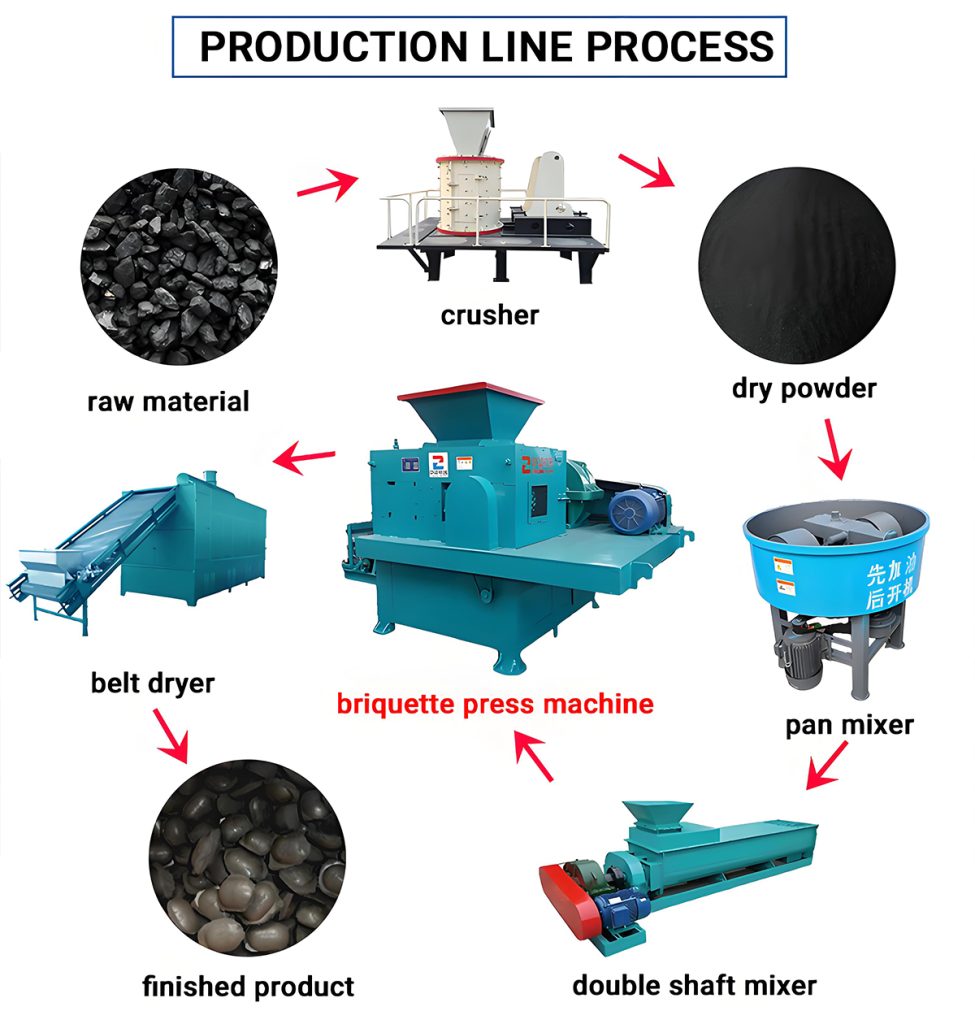

Making good briquettes is a multi-step process. The briquette press is just one part. If you miss a step or do it poorly, your final product will be weak and crumble. Here is the full process from start to finish.

A charcoal briquette machine can cost anywhere from $5,000 to over $50,000. The price depends heavily on its size, capacity, and build quality. A small machine for a startup might be at the lower end. A large, industrial machine for high-volume production will be at the higher end.

Here are the main factors that affect the charcoal briquette machine price:

Remember to budget for the other essential machines, like the crusher, mixer, and especially the drying system.

Choosing the right machine means thinking about your entire business, not just the press. You need to match the machine to your raw material, production goals, and budget. Rushing this decision is a recipe for failure.

Here are the key questions to ask yourself:

A well-designed machine is straightforward to use, but proper training is essential. Installation involves placing the machine on a solid, level concrete foundation and connecting the electricity. At ZONEDING, we provide detailed drawings and instructions to make this simple. We can also send an engineer to your site to help with installation and training.

Operating the machine is about controlling the feed rate and monitoring the output. Your main job is to ensure the mix has the perfect moisture content. Too dry, and the briquettes will be weak. Too wet, and they will stick to the machine. Maintenance is also simple. It involves daily lubrication of bearings, checking belt tension, and regularly inspecting the rollers for wear. A good supplier will provide a clear maintenance schedule.

At ZONEDING, we have been building heavy-duty machinery since 1990. We do not just sell you a machine; we provide a complete solution. We understand the entire process, from crushing the raw material to packaging the final product. We have helped customers in over 120 countries start and grow their charcoal briquette businesses.

When you work with us, you get more than just a briquette press. You get a partner.

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

What are the Essential Wear Parts (Molds, Screws) and How Long Do They Last?

The main wear parts on a roller press are the roller shells themselves. Their lifespan depends entirely on the material they are made from and the abrasiveness of your charcoal. Standard steel rollers might need replacement after 6-8 months of continuous use. High-quality rollers made from 9Cr2Mo or other chrome alloys can last for 1-2 years or even longer.

Can This Machine Produce Different Shapes like Hexagonal or Square?

Yes, absolutely. The shape of the briquette is determined by the molds on the rollers. We can manufacture rollers with a huge variety of shapes and sizes, including pillow, oval, square, cube, and hexagonal. You can even order multiple sets of rollers and change them out to produce different products on the same machine.

How Can ZONEDING Help Design Your Complete Charcoal Production Line?

We provide a complete, end-to-end service. It starts with a consultation where we analyze your raw materials, your production goals, and your site. Then, our engineers will design a custom plant layout for you. This includes selecting the right size crusher, the best mixer, the perfect charcoal briquette machine, and the most efficient drying system. We provide all the drawings, and we can guide you through the entire installation and startup process.

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd…

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq…

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly …

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for…

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. …

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin…

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach…

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin…

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z…

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. …

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy