Search the whole station Crushing Equipment

The coal briquetting machine also known as coal dust briquetting machine, can press fly ash or particle coal slime, raw coal and lignite into spherical, oval, flat shape, referred to as briquettes. The finished coal briquetting can be used in power generation, furnace calcination, daily life and other fields.

A coal briquetting machine is a type of roller press that compresses coal fines (small particles) into a uniform shape and size, making them easier to handle, transport, and burn.

There are several compelling reasons to invest in a coal briquetting machine:

Key features of a coal briquetting machine include:

Coal briquetting machines are used in a variety of industries, including:

The coal briquetting machine is mainly used for pressing materials with low moisture content, such as various coal briquettes, mineral powder and refractory materials. Pulverized coal briquetting machine and charred coal briquetting machine are suitable for refractory industry, power plant, metallurgy, chemical industry, energy, transportation, heating and other industries.

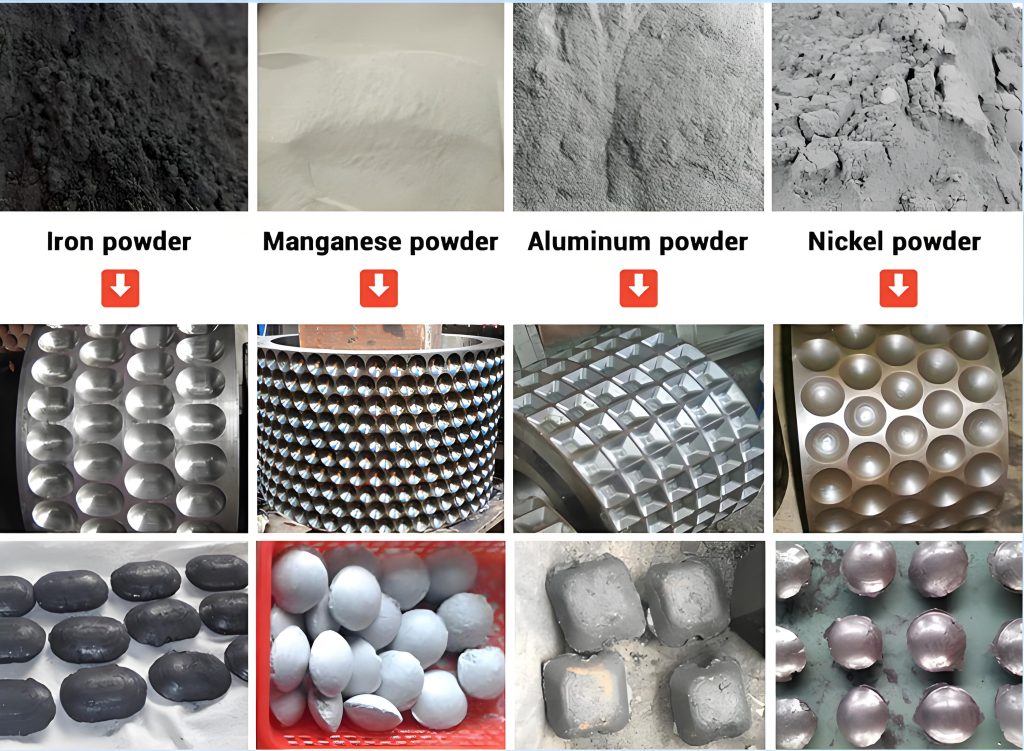

Coal briquetting machine can be used to press all kinds of powdery materials like coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, gypsum, tailings, sludge, kaolin, clay, activated carbon, coke and waste residue in refractory, power plant, metallurgy, chemistry, energy, transportation, heating and other industries.

Applications of Coal Briquette Machine

Coal briquetting machines can produce briquettes in various shapes and sizes, depending on the rollers used. Common shapes include:

The size of the briquettes can range from a few centimeters to larger blocks, depending on the application.

Here’s a step-by-step breakdown of how a coal briquetting machine works:

This coal briquetting machine can save energy and protect the environment.The final products are convenient to be transported, thus improve the utilization of the waste materials and have excellent economic and social benefits. In addition, the power consumption of this ball press machine is low.

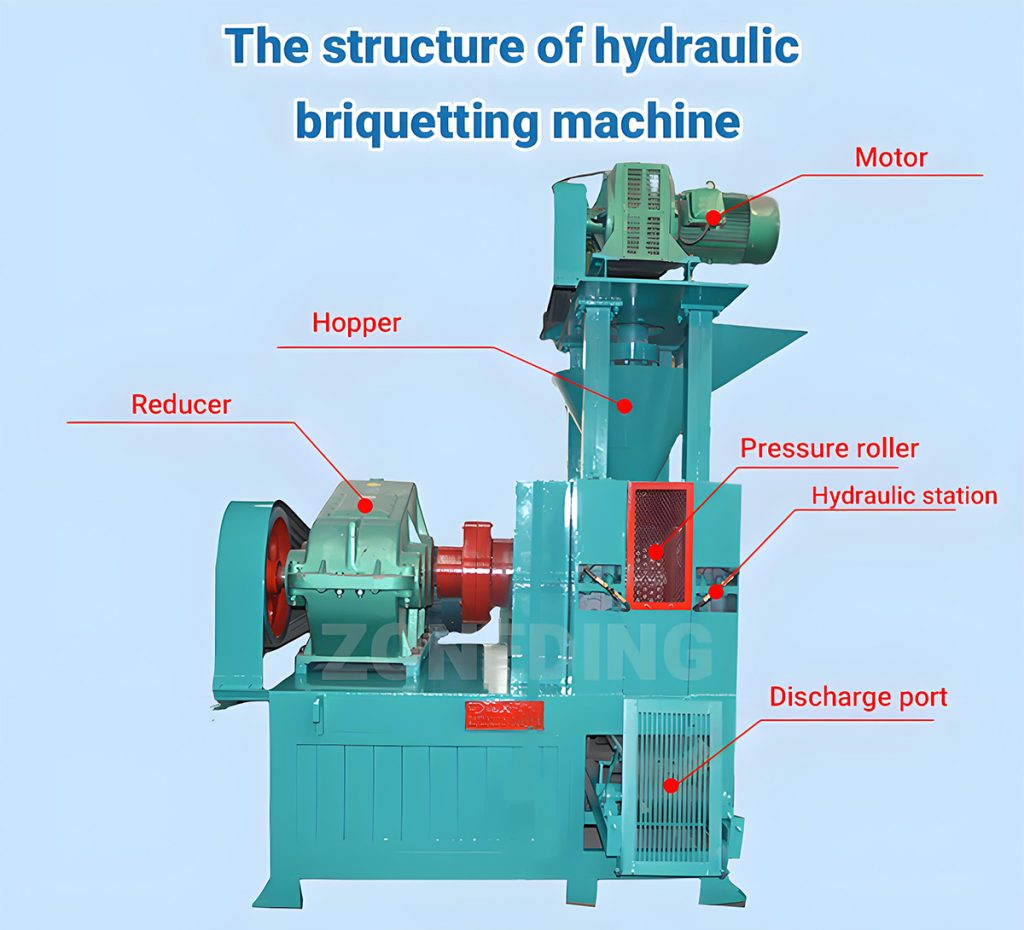

The performance of the coal briquetting machine is mainly determined by the roller skin of the main engine. This type of coal briquette machine is cast with 65 manganese, and with special heat treatment, its hardness can reach over 58°. The roller skin adopts composite assembly, so that it can be changed when abraded. This briquette machine has a shock absorber which can better protect the equipment from the impact of hard materials. The briquette machine is designed with ball bowl adjustable device to make sure the ball bowls of the two rollers are always in the adjustable range.

A typical coal briquetting machine consists of the following main components:

The key wear parts of a coal briquetting machine that need regular replacement are:

Choosing the right coal briquetting machine involves considering these factors:

A complete coal briquetting production line typically includes:

The price of a coal briquetting machine is influenced by:

Proper maintenance is essential for keeping your coal briquetting machine running smoothly. Here are some tips:

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

Can I use a coal briquetting machine for other materials?

Yes, coal briquetting machines can be used for other materials like charcoal, lime, and mineral powders. You may need to adjust the binder and pressure settings.

How do I choose the right binder for coal briquetting?

The best binder depends on the type of coal and the desired properties of the briquettes. Common binders include clay, starch, molasses, and lime.

How much does a coal briquetting machine cost?

The cost of a coal briquetting machine can range from $10,000 to $100,000 or more, depending on the capacity, features, and brand.

The drying cost

Selling a machine without providing a starting point for the binder recipe is malpractice.

Producing wet, “green” briquettes is the easy part. Drying them is where your profits are made or lost. Natural air drying is cheap but requires huge amounts of space and time, and it’s weather-dependent. It can also lead to briquettes re-absorbing moisture at night. Industrial drying solutions (mesh belt dryers, chain plate dryers) are a massive capital and operational expense. They consume a lot of energy (often from burning some of your own product). You must calculate the cost of drying per ton and include it in your business plan. I’ve seen countless operations that produced beautiful green briquettes but failed because they had no viable, cost-effective way to dry them to a commercially acceptable state.

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd…

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq…

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly …

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for…

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. …

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin…

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach…

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin…

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z…

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. …

loading…

已经是到最后一篇内容了!