Search the whole station Crushing Equipment

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and aluminum ash, etc.

The metal powder briquette machine can form various metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder and so on, without adding any adhesive. The metal powder pressing machine directly processes raw materials into pressing blocks through cold forming process, without heating, adding additives and so on. In response to customer requests, Zoneding Machinery has developed a new generation of metal powder briquette machine that can press materials into various shapes, such as squares and ovals.

A Metal Powder Briquetting Machine, also known as a metal fines briquetter, is a type of high-pressure press. Its main job is to take loose, low-density metal scrap like dust, chips, filings, and turnings and compress them under immense force. This process forms the material into solid, dense blocks or “briquettes.” These briquettes are much easier and cheaper to store, transport, and melt in a furnace. For many ductile metals, the machine achieves this without any binders, a process we call binderless briquetting. The immense pressure causes the metal particles to bond together at a molecular level, a phenomenon known as cold welding.

Using a scrap metal briquetting press offers significant financial and operational benefits. You can transform a waste stream into a revenue stream. Here’s how you will benefit:

Our machines can handle a wide variety of ferrous and non-ferrous metal powders and chips. The key is understanding the properties of your material.Commonly Processed Materials:

Before investing in a machine, you must confirm your material will form strong briquettes. A simple first step is the “hand squeeze test.” Take a handful of your metal powder and squeeze it as hard as you can. If it holds some shape, that’s a good sign. However, this is just a rough indicator.

For a definitive answer, you need a professional analysis. At ZONEDING, we encourage potential clients to send us a sample of their material. We will test it in our lab on our roller press machines to determine:

This testing process removes the guesswork and ensures you get a machine that is perfectly configured for your needs.

The success of the briquetting process depends heavily on the characteristics of your raw material. Three key features are critical:

The machine’s true job is not just compaction; for many metals, it’s “cold welding.” A feeder, often a screw feeder, forces the metal powder into the gap between two counter-rotating rollers. These rollers have pockets or molds on their surface.

As the rollers turn, they pull the powder into the “nip zone,” where the pressure increases dramatically. The immense pressure, which can exceed hundreds of megapascals, does two things:

The metal powder press machine can also be used to press other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, iron powder and aluminum ash, which can also produce a variety of powder materials. Using forced pressurization, precision machining, and prepressing spiral steel billets can also be widely used in metallurgical material, chemical, coal, refractory, and other industries. Metal powder briquetting machine can press oxidize iron, dust, ash, blast furnace slag, manganese ore powder, silicon manganese alloy powder, iron smelting slag, ore concentrate and various ore powder materials in nonferrous metal industry into balls. So it is also called nonferrous metals briquetting machine.

Metal power briquetting machine can be used to suppress coal powder, coke coal, , iron scrap, iron oxide sheet, carbon powder, tailings, sludge, kaolin, activated carbon, coke as well as other powder materials and waste residue.

Metal powder briquette machine consists of three parts: Feeding part; Transmission part; Molding part.

1.Feeding part:The main purpose is to ensure the uniform feeding of materials into the roller. The screw feeding device is driven by an electromagnetic speed regulating motor and rotated by belt pulley and worm reducer to force the pressed material into the feed port. Due to the characteristics of constant moment of electromagnetic speed regulating motor, when the material quantity of screw feeder is equal to the material quantity required by the host machine, the constant feeding pressure can be maintained to stabilize the pellet quality.

2.Transmission part:The main drive system is motor – triangle belt – reducer – gear – roller. The main engine is powered by electromagnetic speed regulating motor, which is transmitted to the drive shaft through belt pulley, cylindrical gear reducer and coupling. Drive shaft and passive shaft ensure synchronous operation through gear.

3.Molding part:Mainly refers to the main part, the core part is the roll.

In the whole process, metal powder briquette machine can be free to choose according to the customer’s actual situation.

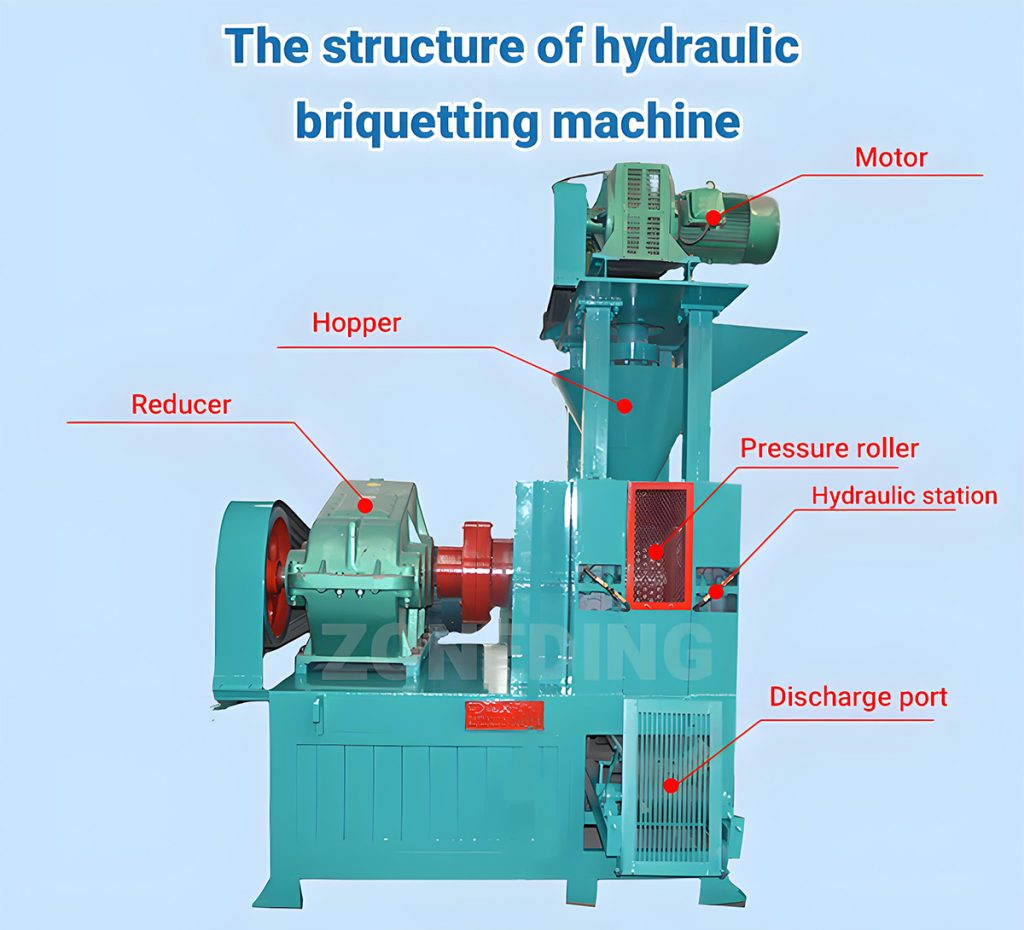

Structures of Metal Powder Briquetting Machine

1.The operator must carefully understand the contents of this manual in order to understand the performance of the machine and electrical control system, and cannot start work before relevant training.

2.In operation, the operator should first confirm the correctness of the machine work plan before continuous production.

After the machine stops, the operator should turn off the power switch, clean the mold cavity and other parts, so as to avoid curing the raw materials caused by the poor performance of the machine.

A successful operation is more than just the briquetting press. Customers often focus on the machine’s price, but the upstream preparation and downstream handling are just as important. A complete production line is a system.

Choosing the right machine is vital for long-term success. You need to consider more than just capacity.

The price of a metal briquette machine can range widely, from around $20,000 for a small-capacity machine to over $500,000 for a large, high-pressure hydraulic system for specialized alloys. The final cost depends on several factors:

The shape and size of the briquettes are determined by the pockets on the machine’s rollers. We can customize these to meet your exact specifications. Common shapes include:

The size typically ranges from 20mm to 100mm, depending on the application and the customer’s needs.

With over 30 years of experience, we at ZONEDING don’t just sell machines; we provide complete briquetting solutions. We understand the deep science behind the process. and We know that for many metals, success hinges on achieving “cold welding,” not just brute force. and We design our machines to combat “springback” with either robust mechanical designs or precise hydraulic control.

Our commitment to quality is absolute. We use high-strength forged steel for our segmented rollers, ensuring maximum durability and minimal downtime for our customers. We also provide full system design, including the crucial preparation and screening equipment that many suppliers ignore. and We build machines that work reliably for decades in the toughest industrial environments. When you choose ZONEDING, you are choosing a partner dedicated to turning your waste into wealth.

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

An ordinary press, like one for charcoal, uses low pressure and relies entirely on binders. A metal powder briquetting machine (a type of mineral press) uses extremely high pressure. It’s built with much stronger frames and uses rollers made of hardened, wear-resistant alloy steel to withstand the abrasive nature of metals and minerals.

High pressure transforms the material physically and financially. Physically, it increases the density, making the powder easy to handle and melt. Financially, this transformation turns a low-value (or negative-value) waste product into a premium, furnace-ready raw material that commands a high price.

Three main factors: 1) Material Properties (ductility, particle size), 2) Machine Pressure (enough force to achieve cold welding), and 3) Roller Design (the shape of the pockets and the “dwell time” under pressure). Our engineers balance these factors to produce strong, perfectly formed briquettes.

Our partnership doesn’t end with the sale. We offer comprehensive support including on-site installation and commissioning, training for your operators on how to run and maintain the equipment, and a reliable supply of spare parts like roller segments to keep your operation running smoothly.

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd…

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq…

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly …

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for…

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. …

Applied Materials:nLime powder briquetting machine is mainly used in coal, mining, metallurgy, refractory material, chemical industry, building materials, etc. Due to the processed materials, lime briquette mach…

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin…

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z…

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. …

Applied Materials:nCoal powder, iron powder, coke coal, aluminum powder, iron scrap, iron oxide sheet, charcoal powder, carbon powder, slag, sludge,etc. Charcoal briquette machine or charcoal briquetting mac…

loading…

已经是到最后一篇内容了!