Search the whole station Crushing Equipment

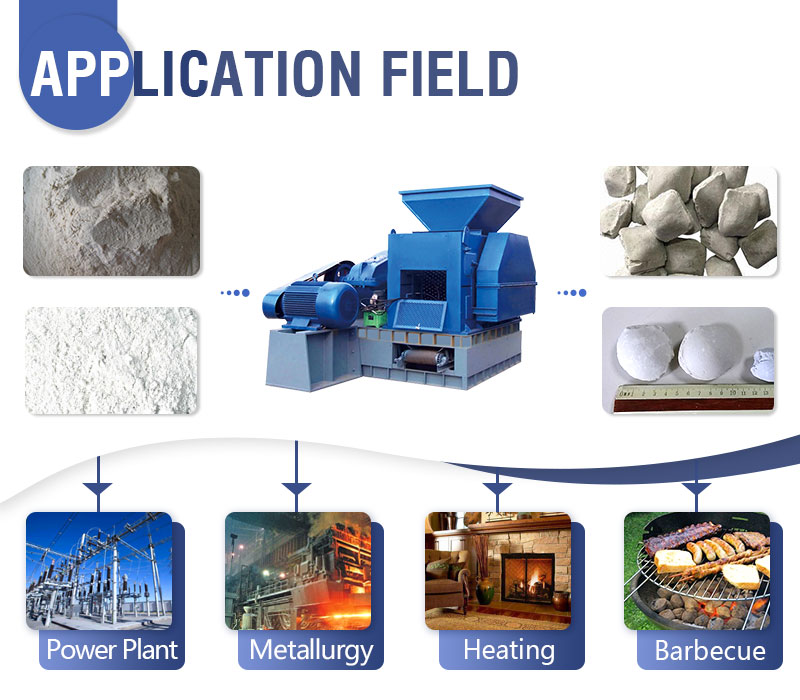

Due to the processed materials, lime briquette machine is also called quicklime briquette machine and lime briquette press machine. The finished product can be used in lime calcination, blast furnace calcination, metallurgy, and other fields. The main purpose of quicklime press is to reduce dust, control unit weight, recycle and improve its transport characteristics.

Lime briquetting machine is mainly used to press powder materials like quicklime powder, dolomite powder, copper concentrate, chromium ore, manganese ore powder, laterite-nickel ore, lead and zinc scrap, bauxite, non-ferrous metal powder, refractory materials, ceramic materials, iron powder materials in steel plant, converter sludge, ferric oxide powder, iron sheet, aluminum skimmings, activated alumina, etc.

Lime is a general term for calcium-containing inorganic materials. It is a fundamental chemical product derived from limestone. When limestone (calcium carbonate, CaCO₃) is heated in a kiln, it releases carbon dioxide. The remaining material is calcium oxide (CaO), also known as quicklime or lump lime. This is a highly reactive and caustic material. When you add water to quicklime, it undergoes a chemical reaction to become calcium hydroxide (Ca(OH)₂), also known as hydrated lime or slaked lime. Both quicklime and hydrated lime are essential materials in countless industrial processes.

Lime briquettes are used wherever lump lime is needed. The key benefit is that they are made from recovered dust and fines, which would otherwise be wasted. This makes them a cost-effective and sustainable alternative. By using a lime briquetting machine, you create a product with consistent size, density, and chemical properties, making it ideal for precise industrial applications.

Here are some primary uses:

Lime powder is notoriously difficult to handle. Understanding its properties is key to seeing why a lime briquetting machine is so necessary. The powder is very fine, lightweight, and fluffy. This means it has a low bulk density and traps a lot of air.

The key features are:

These characteristics make handling and transporting lime fines inefficient, unsafe, and costly.

We briquette lime powder to solve all the problems caused by its features. The primary goal of the lime briquetting process is to dramatically increase the material’s density and turn it into a manageable form. This unlocks significant value and improves safety across your entire operation.

The main benefits are:

Our machines can process both quicklime and hydrated lime, but the method is completely different. It is critical to understand your specific raw material, as this determines the entire setup of your briquetting plant. This is where we apply our deep process knowledge to design the right solution for you.

Lime briquette machine is suitable for lime powder, silicon powder, chromium powder, refractory briquetting and other powdery substance which has no or low water content.

Lime briquette machine produced by Zoneding Machinery is mainly used for making the lime powder in coal or power plant into briquettes. The produced lime briquettes can be directly sent into the furnace for combustion or smelting, so as to improve the added value and realize resource recycling at the same time. It can be used to suppress, lime powder, quicklime, refractory materials, non-ferrous metal powder, coal powder, iron powder, coking coal, aluminum, iron, tin oxide, carbon powder, coal powder, slag, gypsum, tailings, sludge, kaolin, clay, activated carbon, coke breeze and other powdery materials. It is widely used in refractory material, power plants, metallurgical, chemical, energy, transportation, heating, and other industries.

Applications of Lime Briquetting Machine

A lime briquetting machine works by applying immense pressure to powder, but the real secret is in the chemistry. The machine uses two large, counter-rotating rollers with pockets, or molds, machined into their surfaces. However, for quicklime, our machine becomes more than a press; it becomes a low-pressure chemical reactor.

Here’s the process:

Lime briquette machine or double roller press is driven by gear and driven shaft. The hydraulic device is mounted on the back of the driven shaft assembly and driven by electromagnetic speed regulating motor. After the belt pulley and worm reducer run, the screw feeding device presses the material into the feeding port. When the screw feeder and press have the same pressure, the feeding pressure remains constant, thus stabilizing the packing quality. If there is too much feeding, the feeder will overload. If there is too little feed, the feeder will not form a ball. Therefore, the skilled operation technology has become the key conditions of pressure ball.

The cost of a lime briquetting machine typically ranges from $5,000 to over $100,000. The final price depends heavily on the model’s capacity (tons per hour) and the specific features required for your material. However, it is crucial to understand that the press itself is only one part of the total plant cost.

You must also budget for the essential support equipment. The single biggest and most important associated cost is the dust collection system. Lime dust is aggressive and regulated. A cheap, undersized baghouse will fail quickly and create a hazardous environment. You must invest in a high-quality, properly sized dust collector. This system alone can represent 25-40% of the cost of the press. Other costs include mixers, conveyors, dryers (if needed), and control systems. We help you plan for the total project cost, not just the machine price, to ensure your success.

Our lime briquetting machines are built to withstand the harsh, corrosive environment of lime processing. We focus on robust engineering and features that ensure long-term reliability. A standard machine will quickly fail in this application.

Key structural components include:

1.The selection of binder: the choice of binder has wide source and low price. A good effect is an important issue, which is directly related with the hardness and density of the balls as well as the product quality and production cost.

2.The uniform degree of materials: the grain size and hardness of the material will affect the pressing effect and work efficiency of lime briquetting machine, so the uniformity of material will have a direct impact on the quality of the product. Before entering the lime briquetting machine, the particle size of materials must be inspected. When reaching the appropriate size, they can be put into the machine.

3.Moisture content and drying process: if the material is too wet or too dry to be placed directly into the equipment without any treatment, problems such as adhesion or ball breakage may occur. Therefore, the material should be kept at a certain humidity, not too dry or too wet.

Selecting the right model is about matching the machine to your specific production needs and material properties. Simply choosing the biggest machine is not the best strategy. For lime, control is more important than raw power.

Here are the key factors we help you consider:

The most common shapes are pillow and oval, but we can customize them. The best shape and size depend on how the final briquettes will be used. The goal is to create a briquette that is easy to handle and performs well in its final application.

We work with you to design the roller pockets to produce the exact shape and size that will bring the most value in your specific market.

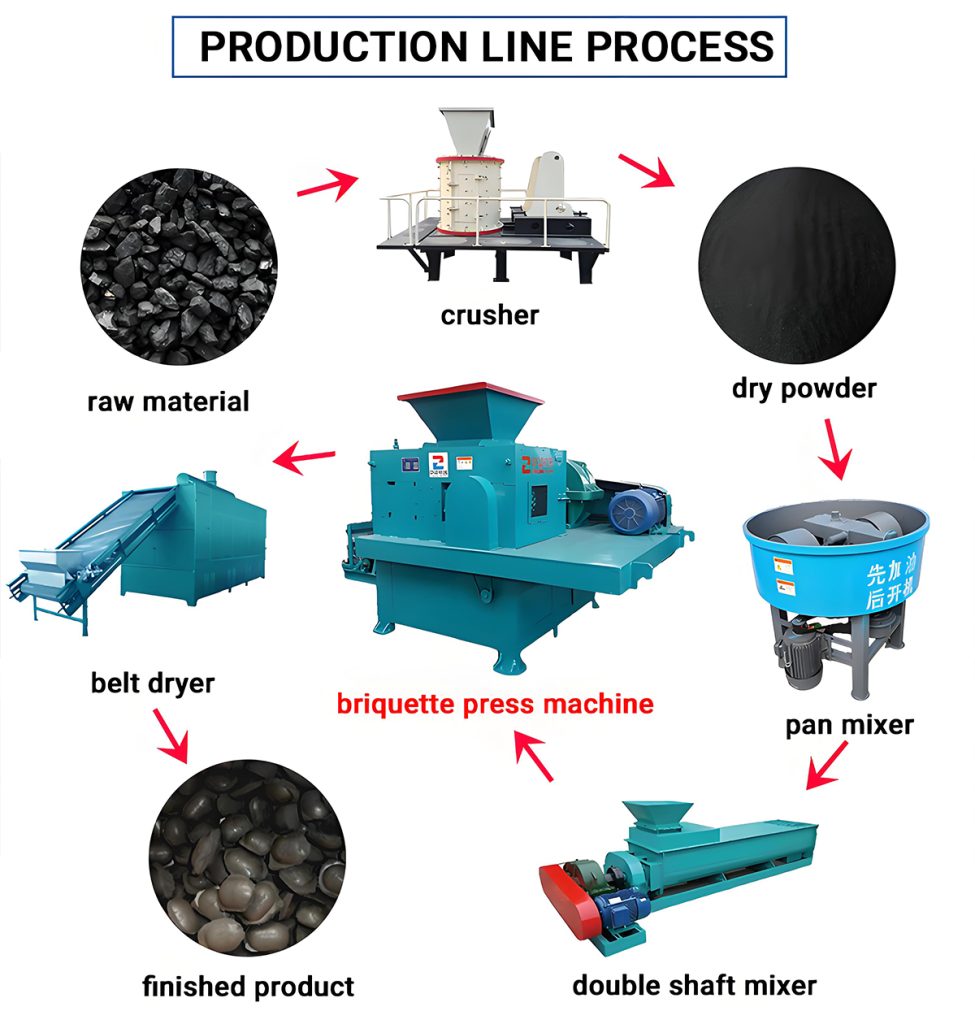

A complete production line is a fully integrated system designed for efficiency and dust control. The lime briquetting machine is the centerpiece, but the supporting equipment is just as critical for a successful operation. A typical line includes:

The main wear parts are the roller shells. The rollers are in constant contact with the abrasive lime powder and are subjected to extremely high pressure. Their lifespan is the single biggest factor in your machine’s maintenance cost. This is why we invest so heavily in the quality of our rollers. They are cast from specialized high-chromium alloy steel (like Cr13 or Cr26) and undergo a rigorous heat treatment process to achieve a very high surface hardness. While they are a consumable part, using superior materials means they last much longer, reducing your downtime and overall cost per ton produced.

Maintenance is a constant battle against the corrosive lime dust. You must have a proactive maintenance strategy focused on cleanliness and proper lubrication. Lime dust is not just messy; it is your equipment’s relentless enemy. When it combines with grease or humidity, it forms a gritty, concrete-like abrasive paste that destroys bearings and seals.

Your maintenance plan should include:

Our advantage is in the details that deliver long-term reliability and lower operating costs. We design our lime briquetting machines specifically for the severe duty of lime processing. We focus on features that solve the biggest pain points for our customers.

We view your purchase as the beginning of a long-term partnership. As a B2B manufacturer focused on providing complete solutions, our support extends far beyond the sale. We are committed to ensuring your plant operates successfully and profitably for years to come.

Our after-sales support includes:

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

What binder is used for lime briquettes?

For quicklime (CaO), the best “binder” is actually a small amount of water. It triggers a chemical reaction that self-binds the briquettes. For hydrated lime (Ca(OH)₂), you must use a binder like molasses, starch, or bentonite.

How do you make strong lime briquettes?

Strength comes from proper material conditioning, removing trapped air, and applying the right pressure. For quicklime, precise water control is key. For all lime, a powerful forced feeder and the ability to control roller speed are critical for making dense, strong briquettes.

Can I process wet lime sludge?

Yes, but not directly. Wet sludge (often 40-50% moisture) must first be processed through an industrial dryer to reduce the moisture content to an optimal level (around 15%) before it can be mixed with a binder and briquetted.

Applied Materials:nMagnesium powder, iron powder, manganese powder, bauxite, graphite powder, clay, limestone, ilmenite concentrate powder, titanium powder, manganese powder, silicon manganese alloy, etc. Dry powd…

Applied Materials:Coal ash, pulverized coal, coke powder, iron power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon, coke breeze etc. Pulverized coal briq…

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc. Gypsum briquette machine is mainly …

Materials:nMineral powder, metal powder, coal powder, coke powder, iron, ore, iron oxide, slag, refractory and other materials.n A mineral powder briquetting machine is a type of roller press designed for…

Applied Materials:nIron oxide, sludge iron power, coking coal, refractory material, etc. in the coal industry, power plants, metallurgy industry, chemical industry, energy, transportation, heating, and other industries. …

Applied Materials:nAll kinds of metal powder, such as iron powder, copper powder, aluminum powder, tungsten powder, nickel powder, lead powder, and other materials, such as gypsum, coal powder, ore powder, oxide skin, steel slag, and alumin…

Applied Materials:nAluminum powder, aluminum ash, copper powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze. The aluminite powder briquettin…

Iron Powder Briquetting Machine Applied Materials:nFine iron powder, iron oxide scale, steel slag/sludge, mill scale, manganese ore fines, charcoal powder, coal fines, coke fines, carbon black, etc. Whatsapp+8618637198006 Email:z…

Applied Materials:nvarious fines and powder of coal, coke, charcoal, carbon black, iron ore, mineral powder, metal dust, cast iron dust, mill scale, manganese ore, fluorite, gypsum, ferrosilicon, nickel alloy, blast furnace ash, etc. …

Applied Materials:nCoal powder, iron powder, coke coal, aluminum powder, iron scrap, iron oxide sheet, charcoal powder, carbon powder, slag, sludge,etc. Charcoal briquette machine or charcoal briquetting mac…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy