Search the whole station Crushing Equipment

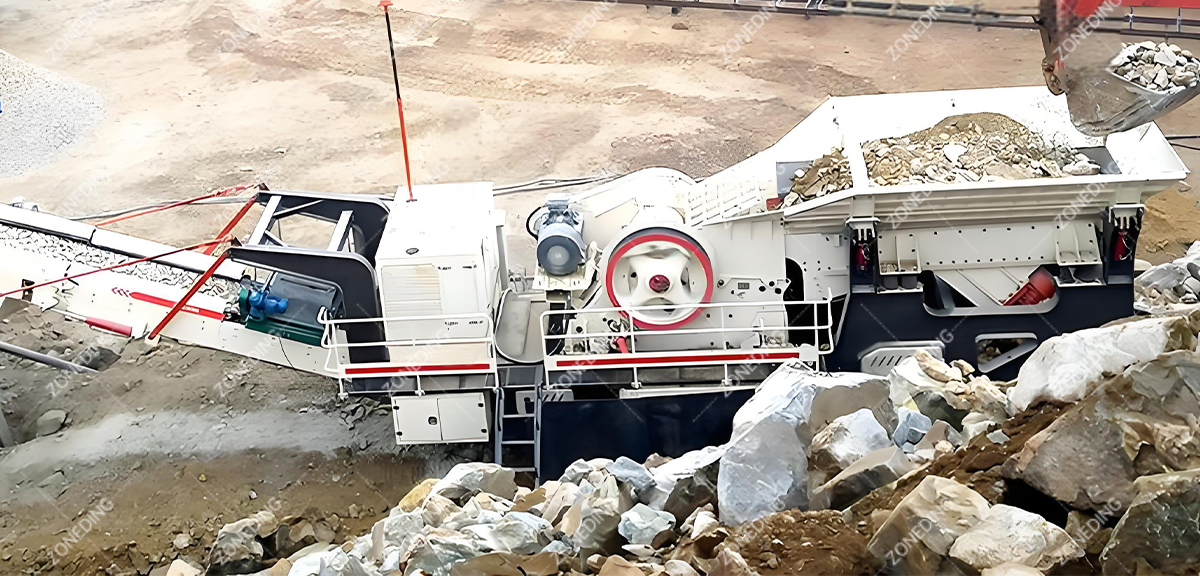

A crawler jaw crusher is a jaw crusher (a machine that uses two jaw plates to crush materials by squeezing) mounted on a self-propelled crawler chassis, integrated with feeding, conveying, and power systems. In mobile crushing operations, it typically plays the role of a “frontrunner” or “vanguard,” undertaking primary crushing (coarse crushing) tasks, specializing in processing large raw stones blasted from mountains or large concrete blocks from demolition sites.

You can think of a crawler jaw crusher as a giant “vise grip” with its own “tank tracks.” Its core component is the jaw crusher, which crushes material entering the crushing cavity through the periodic movement of the movable jaw plate towards and away from the fixed jaw plate, subjecting the material to strong squeezing, splitting, and bending fractures. Due to its powerful crushing force and simple structure, it is highly suitable as primary crushing equipment, breaking down large raw materials into sizes acceptable for subsequent mobile cone crushers or mobile impact crushers.

The biggest advantage of “crawlers” lies in their excellent site adaptability and mobility. A crawler jaw crusher can be driven directly to rugged excavation faces or operating points without needing a paved road, offering flexible relocation. This is crucial for mines, quarries, and construction waste disposal projects that require rapid deployment.

How large a stone a crawler jaw crusher can “eat” primarily depends on the “feed opening size” of its jaw crusher host (usually expressed as width x length, e.g., 1000mm x 700mm). When selecting, ensure the maximum feed edge length does not exceed 80-85% of the feed opening width, otherwise, blockages or “bridging” can easily occur. Core keywords: crawler jaw crusher feed size, jaw crusher model selection

Different models of crawler jaw crushers have significantly varying host feed opening sizes, ranging from a few hundred millimeters to over a meter. For example, a Zoneding crawler jaw crusher model ZDE1070 might have a host feed opening of 1000mm x 700mm, meaning it can theoretically process stones close to 700mm wide (usually entering on the narrower side). However, in actual production, to ensure smooth feeding and avoid blockages, the maximum material size you feed should preferably be controlled within 80%-85% of the feed opening width (the shorter side). Also, consider the bucket size of your excavator or loader to ensure large materials can be smoothly fed into the feeder.

Crawler jaw crushers can typically crush large materials down to a range of tens of millimeters to two hundred millimeters. Its discharge size can be adjusted by changing the “Closed Side Setting” (CSS) at the bottom of the jaw plates. This discharge size directly determines the feed requirements and workload of secondary crushing equipment (such as cone crushers or impact crushers).

Detailed Explanation:

Adjusting the discharge opening is the primary way to control the output particle size of a crawler jaw crusher. A smaller discharge opening results in finer output, but production capacity will decrease accordingly, and jaw plate wear may accelerate. Common adjustment methods include hydraulic adjustment and shim adjustment, with hydraulic adjustment being more convenient and quicker.

For example, if you are subsequently using a mobile cone crusher that requires a maximum feed size of no more than 150mm, then your crawler jaw crusher’s discharge opening must be set to produce material smaller than 150mm. If the jaw crusher’s output is too coarse, it will place excessive pressure on the secondary equipment, potentially damaging it; if the output is too fine, it may mean the jaw crusher is undertaking too much of the crushing task, reducing the efficiency and economy of the entire production line.

| Adjusting Discharge Opening (CSS) | Output Particle Size | Jaw Crusher Throughput | Jaw Plate Wear | Impact on Subsequent Equipment |

|---|---|---|---|---|

| Increase | Coarser | Higher | Relatively Slower | Subsequent equipment feed size is larger, load may increase |

| Decrease | Finer | Lower | Relatively Faster | Subsequent equipment feed size is smaller, load decreases, but may increase jaw crusher burden |

Jaw crushers themselves are designed for crushing hard, highly abrasive materials, so crawler jaw crushers perform excellently in processing “hard rocks” like granite, basalt, iron ore, and river pebbles. The key is to select appropriate jaw plate materials and tooth profiles, and to perform correct operation and maintenance.

Crawler jaw crushers use the principle of compressive crushing, generating immense crushing force. For hard rock, their advantages include:

Jaw plates are the main wear parts of a crawler jaw crusher. Their wear resistance depends on material hardness, abrasiveness, jaw plate material, tooth profile design, and proper operation. The service life of a set of jaw plates can range from tens to hundreds of hours. Replacing jaw plates takes some time (usually a few hours), but modern crawler jaw crusher designs have simplified the replacement process as much as possible.

The actual output (tons/hour) of a crawler jaw crusher varies widely; small machines might produce tens of tons, while large ones can reach hundreds or even thousands of tons. However, the “actual output” is often much lower than the “theoretical maximum output” stated by the manufacturer. It is affected by multiple factors such as material characteristics (hardness, moisture, feed particle size distribution), discharge opening setting, feed uniformity, and equipment maintenance condition.

The output provided by manufacturers is usually the maximum value under ideal conditions (e.g., easily crushable material, optimal gradation, continuous and uniform feeding). You need to focus on what can be achieved under your actual working conditions.

To efficiently integrate a crawler jaw crusher into a production line, the key is “matching” and “synergy.” As the primary crusher, its output and discharge particle size must match the capacity of subsequent secondary crushing equipment (like a mobile cone crusher) and screening equipment. At the same time, ensure smooth material transfer and consider the overall line’s automation control and interlock protection.

A typical crawler-type mobile crushing and screening production line usually includes:

Purchasing a crawler jaw crusher involves much more than just looking at the price. You must pay attention to: host performance (feed opening, discharge opening range, eccentric shaft design, flywheel inertia), drive system (engine/motor brand and power, direct drive or belt drive), hydraulic system reliability , frame structural strength , jaw plate material and design, feeder performance (are grizzly bar gaps adjustable?), crawler chassis quality , automation control level, and after-sales service and spare parts supply.

| Key Consideration Point | Specific Content to Focus On | Practical Significance for You |

|---|---|---|

| Crusher Host Performance | Feed opening size, discharge opening adjustment range and method, eccentric shaft stroke and speed, flywheel design, crushing chamber type (deep cavity? optimized cavity?) | Directly determines processing capacity, product particle size, crushing efficiency, and adaptability to different materials |

| Drive System | Engine/motor brand, power, fuel/electricity consumption rate, direct drive or V-belt drive | Affects power, fuel/electricity costs, transmission efficiency, and maintenance complexity |

| Hydraulic System | Brand of oil pump/motor/valves, oil tank volume, cooling capacity, filtration system, sensitivity and reliability of hydraulic adjustment for discharge opening and overload protection | The stability and response speed of the system directly affect adjustment convenience, overload protection effectiveness, and failure rate |

| Frame & Structure | Material and welding process of main frame and crawler chassis (stress relieved?), reinforcement design for key parts, overall machine weight and center of gravity stability | Determines the equipment’s sturdiness, durability, fatigue resistance, and long-term operational reliability, avoiding major failures like early cracking |

| Jaw Plates & Toggle Plate | Jaw plate material (high manganese steel grade?), tooth profile design, fixing method, toggle plate material and design | Affects wear life, crushing efficiency, ease of replacement, and protection of the main unit |

| Feeding & Conveying | Vibrating feeder size, grizzly bars (optional), main conveyor belt width and drive method, presence of pre-screening function | Affects feeding smoothness, pre-processing capability, overall machine throughput, and operational convenience |

| Crawler Travel System | Track brand, travel motor power, gradeability, travel speed, track tensioning method, chassis ground clearance | Determines the equipment’s mobility, site adaptability, relocation efficiency, and maintenance costs of the track components |

| Automation & Control | PLC control system, remote control operation, fault diagnosis, oil temperature/pressure/load monitoring and alarms | Improves operational convenience, safety, monitors equipment status, and aids maintenance decisions |

| Environmental Performance | Noise reduction measures, dust suppression system (sprays, etc.), engine emission standards | Meets environmental requirements, improves the working environment |

| After-sales & Spare Parts | Manufacturer’s technical support capability, service network coverage, timeliness and price of spare parts supply | Ensures quick resolution of equipment failures, reducing downtime losses |

| Model | WT96 | WT106 | WT120 | |

| Dimensions of Transmission Devices | Length | 14200mm | 14900mm | 15200mm |

| Width | 2900mm | 3000mm | 3200mm | |

| Height | 3470mm | 3600mm | 3700mm | |

| Weight | 38t | 50t | 65t | |

| Feeder | Hopper Volume | 5m³ | 5m³ | 6m³ |

| Loading Height | 3900mm | 4100mm | 4300mm | |

| FeederModel | GZDT3895 | GZDT1145 | GZDT1245 | |

| Unearthed Belt Conveyors | Dimensions(Width×Length) | 800×9000mm | 1000×10000mm | 1200×12000mm |

| Dumping Height | 3100mm | 3200mm | 3400mm | |

| Crusher | Model | CJ96 | CJ106 | CJ120 |

| Inlet Dimensions | 930×580mm | 1060×700mm | 1200×870mm | |

| Max.Feeding Size | 480mm | 560mm | 700mm | |

| Main Belt Conveyor | Dimensions(Width×Length) | 800×9000mm | 1000×10000mm | 1200×12000mm |

| Dumping Height | 3100mm | 3200mm | 3400mm | |

| Iron Remover | Model | RCYQ-8 | RCYQ-10 | RCYQ-10 |

| Diesel Engine | Power | 96kw | 106kw | 132kw |

| Manufacturer | Carter Perkins | Carter Perkins | Carter Perkins | |

| The Main Machine | Power | 112.9kw | 141.4kw | 196.2kw |

| Ways of Controlling | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | |

Q1. What exactly is a mobile crushing station used for? How is it better than a stationary production line?

A1: The biggest advantage of a mobile crushing station is its flexibility and convenience. It doesn’t require foundation work and can be quickly relocated or moved closer to the working face. For you, this means significant savings in civil engineering costs and time, enabling faster production startup. It also reduces the internal material transport distance on site, lowering transportation costs and dust. It’s particularly suitable for projects with tight schedules, scattered sites, or those requiring phased progression.

Q2. Crawler-type vs. tire-type mobile crushing station, which is more suitable for me?

A2: It mainly depends on your mobility needs and site conditions. Crawler-type is like a tank, suitable for moving within mines or rugged construction sites, offering flexible relocation but troublesome for long-distance transport; tire-type is like a trailer, suitable for projects with better road conditions that require frequent long-distance transfers across regions. Simply put, choose crawler for on-site flexibility, choose tire for long-distance transfers.

Q3. Mobile crushing stations have several main machine types (jaw crusher/impact crusher/cone crusher). How should I choose?

A3: Choose based on your material and output requirements. Mobile jaw crushers are suitable for primary crushing, handling large, hard materials; mobile impact crushers are suitable for processing medium-soft materials (like limestone, construction waste) and produce good particle shapes; mobile cone crushers are suitable for medium-fine crushing of hard rocks (like granite, river pebbles). Not sure? Tell us your raw materials and finished product needs, and we’ll help you configure the setup.

Q4. What capacity mobile crushing station do I need? How can I estimate reliably?

A4: The capacity stated by manufacturers is usually the “maximum capacity” under ideal conditions; actual output will be lower. You need to consider: What material needs processing (hardness)? What’s the feed size? How much soil/clay content? How fine does the output need to be? Provide this information to the supplier, and let them use their experience to help you choose a model with sufficient margin. Don’t just rely on paper figures.

Q5: Is maintaining a mobile crushing station troublesome? Is the fuel/power consumption high?

A5: Routine maintenance (lubrication, tightening, cleaning) isn’t complex, but hydraulic and electrical systems require some professional knowledge. Mobile stations have compact structures, so maintenance in some areas might be less convenient than stationary plants. Fuel/power consumption is a major operating cost, highly related to equipment power, load, and power system (diesel/electric/hybrid). Choosing a diesel-electric hybrid might save more money in the long run.

Q6: What if one mobile crushing station isn’t enough? Can they be combined into a production line?

A6:Absolutely! Mobile crushing stations are very suitable for combined use, forming a complete mobile crushing and screening production line. For example, use a mobile jaw crusher for primary coarse crushing, followed by a mobile impact crusher or mobile cone crusher for medium-fine crushing, and then add a mobile screening plant for sizing. This combination can meet complex production needs with extreme flexibility.

Q7: When selecting a mobile crushing station, what key points should I focus on besides price?

A7: Price is important, but definitely not the only criterion! Pay more attention to: 1. Quality of core components (main crusher, engine/motor, hydraulic system); 2. Match between actual output and working conditions; 3. Durability of structural parts (chassis, frame); 4. Cost-effectiveness and supply of wear parts; 5. Ease and safety of operation and maintenance; 6. Manufacturer’s after-sales service and technical support capabilities.