Search the whole station Crushing Equipment

Gold Mine Wet pan mill applys in the gold mining industry and is one of the indispensable equipment in the modern gold mining industry. In addition, it can also apply for mining and processing other non-ferrous metals and precious metal ores.

Gold Mine Wet Pan Mill is a highly efficient, energy-saving and easy-to-operate equipment, especially suitable for gold extraction in small and medium-sized mines.

According to different structures, it has two types: double-roller and three-roller type. The most commonly used is double-roller type.

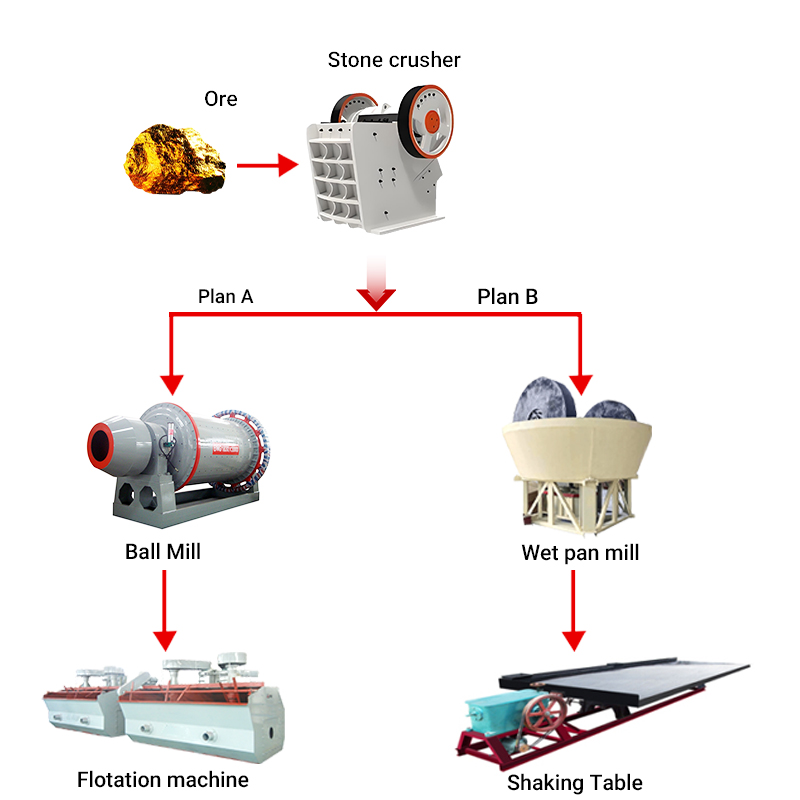

A Wet Pan Mill is a traditional and highly effective grinding and mixing machine. We also call it an edge runner mill or wheel mill. It uses two heavy, large-diameter steel wheels that rotate inside a circular steel pan. As they rotate, they crush and grind ore material into a fine slurry. Its simple design and powerful action make it a go-to piece of for miners all over the world. It is especially good at grinding ore after it has been through a jaw crusher.

The biggest advantage is its high recovery rate for fine gold. A wet pan mill grinds material so fine that it liberates tiny gold particles trapped inside the rock. This makes it easier to capture the gold through methods like amalgamation or flotation.

Here are the main benefits for your operation:

A wet pan mill, also known as a gold grinding machine, is a traditional and highly effective tool for grinding ore. It operates by crushing and grinding material between heavy steel rollers and the base of a circular pan, mixed with water.

Its primary advantages include:

Despite these benefits, its low capacity makes it unsuitable for large-scale industrial mining. Crucially, its historical association with highly toxic mercury amalgamation means that modern, safer recovery methods are now strongly recommended and often legally required.

We build our wet pan mills to last in the toughest mining environments. At ZONEDING, we focus on durability and efficiency. When you choose our machine, you are getting a piece of equipment designed from over 30 years of manufacturing experience.

Our key features include:

Wet Pan Mill is a kind of equipment for ore grinding, especially suitable for grinding and beneficiation of metal ores such as gold, silver, lead, zinc, molybdenum, iron, copper and antimony. The main application is fine grinding for gold recovery. However, its simple and robust design makes it useful in many industries. It is the perfect tool for any job that requires grinding and intensive mixing at the same time.

A wet pan mill can handle a wide range of hard and soft materials. It is particularly effective on gold-bearing ores. If you have any of the following materials, a wet pan mill can help you extract more value from them:

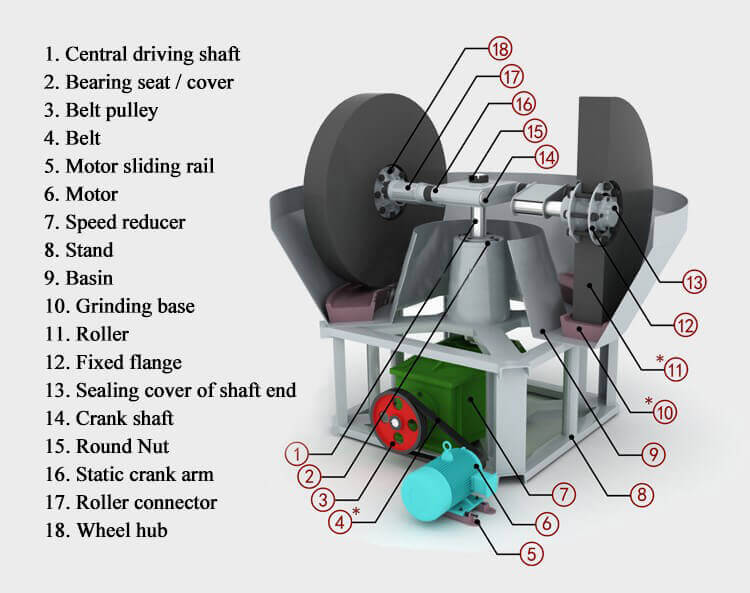

The main parts of the wet pan mill are the driving shaft, bearing seat, roller, speed reducer, motor, and so on.

It has small investment, high output, low productioncost, good efficiency, and easy installation.

The beauty of the wet pan mill is its simple and strong structure. There are no complex parts to break down. This makes it easy to maintain even in remote mining locations.The main components are:

First, the motor transmits power to the reducer, then the central transmission shaft transmits it to the horizontal shaft, and finally the roller moves counterclockwise, and the materials in the mill are ground into fine particles.

While grinding the minerals,the fine particles of the dissociated minerals float to the upper surface and are discharged from the overflow discharge port; the coarse-grained minerals settle at the bottom and continue to be ground until the fineness reaches the standard.

The process is a combination of crushing, grinding, and intense mixing. The heavy wheels provide the force. The water turns the material into a slurry.

But there is a big secret to how this machine really works. You are not just grinding; you are “activating” the material. The powerful rolling and shearing action forces water into every tiny crack in the ore. This breaks the material apart from the inside out and polishes the surface of the gold particles. This makes the gold very easy to capture with mercury or other recovery methods. It creates the perfect slurry for separation.

A new wet pan mill can cost anywhere from $3,000 to $25,000. The price depends on the size (model 1200 is common), the weight of the rollers, the quality of the materials used, and the brand.

But the machine’s price is only the start. The hidden cost that can hurt your profit is labor, especially during cleanup between batches. A mill with a poorly designed discharge gate can force your workers to manually shovel out hundreds of kilograms of sticky slurry. This downtime between batches adds up and kills your daily production. When you look at a mill, pay close attention to the discharge system. A good design will save you money every single day.

The main wear parts are the ones that are in direct contact with the ore. Because the grinding action is so intense, these parts are designed to be replaced.

The key spare parts you will need are:

We make these parts from high-manganese steel. This is not regular steel. It has a special property called “work-hardening.” This means that as the steel gets impacted by the ore, its surface becomes harder and more resistant to wear. The machine literally gets tougher with use. Paying extra for high-manganese steel is the best investment you can make for the long-term life of your mill.

The machine itself is simple, but the foundation is critical. Daily operation is straightforward. You load the material, add water, let it run, and then discharge the slurry.

However, you must get the installation right. A wet pan mill creates a powerful twisting force, also known as torsional force. It is constantly trying to twist the gearbox right off its mounting bolts. Your concrete foundation needs to be thick and heavily reinforced with rebar to handle this stress. A weak foundation will cause the machine to vibrate, which will quickly destroy the main bearings and gearbox.

Following the correct process will give you the best results. Rushing the steps, especially adding water, will lead to a poor-quality slurry.Here is the professional way to operate the mill:

A wet pan mill can typically grind ore down to 150-200 mesh (about 74 microns). This is very fine, like flour. Grinding to this size is essential because in many ores, the gold is locked inside the rock in tiny, microscopic particles. You have to grind the rock into a powder to “liberate” or expose the gold. Once the gold is exposed, it can easily stick to mercury or be captured by other separation methods. This ability to grind extremely fine is why the wet pan mill is so effective at increasing overall gold recovery rates.

We provide a complete, reliable gold recovery solution, not just a machine. With over 30 years of experience since our founding in 1990, we understand the challenges miners face. We are a direct manufacturer, which means you get a better price and direct access to our engineering expertise.

We build our gold grinding mills with the highest quality materials, like work-hardening manganese steel, to ensure they run longer and save you money on spare parts. We can customize any aspect of the mill to suit your specific ore. From initial consultation to after-sales support, we partner with you to make sure your operation is as profitable as possible.

| Model | 1600 | 1400 | 1300 | 1200 | 1100 | 1000 | 900 |

| Dia.of grinding wheel (mm) | 1600(+-)10 | 1400(+-)10 | 1300(+-)10 | 1200(+-)10 | 1100(+-)10 | 1000(+-)10 | 900(+-)10 |

| Thickness of grinding wheel(mm) | 400(+-)20 | 250(+-)20 | 250(+-)20 | 200(+-)20 | 200(+-)20 | 200(+-)20 | 160(+-)20 |

| Dia.of grinding pan (mm) | 2100(+-)30 | 2000(+-)30 | 2000(+-)30 | 1800(+-)20 | 1800(+-)20 | 1800(+-)20 | 1700(+-)20 |

| Thickness of grinding pan (mm) | 200(+-)10 | 170(+-)10 | 150(+-)10 | 90(+-)10 | 90(+-)10 | 90(+-)10 | 80(+-)10 |

| Width of grinding pan (mm) | 360 | 360 | 360 | 230-250 | 230-250 | 230-250 | 170-220 |

| Power (kw) | 25 | 18.5 | 15 | 7.5 | 5.5 | 5.5 | 3 |

| Rotary speed (r/min) | For extract gold: 10-13 other: 18-22 | ||||||

| Input size (mm) | < 25 | ||||||

| Capacity (t/day) | Gold 20 | Gold 20 | Gold 15 | Gold 10 | Gold 8 | Gold 5 | Gold 3 |

| Weight(t) | 14.5 | 8.5 | 7.5 | 5.5 | 5 | 4.5 | 3 |

Gold Mine Wet Pan Mill is an ideal choice for gold extraction in small and medium-sized mines due to its high efficiency, energy saving and easy operation. Whether you are just starting a small-scale mining operation or looking to upgrade your existing equipment, a Gold Mine Wet Pan Mill is a worthy investment that can bring long-term profitability and sustainability to your mine.

To learn more about gold wet disc mills or explore our mining equipment range, please feel free to contact us. Let us help you improve your mine efficiency and move towards a successful future!

Is a wet pan mill better than a ball mill for small-scale mining?

For small to medium-scale operations, a wet pan mill is often better. It has a lower initial cost, consumes less energy, and is simpler to operate and maintain. It also provides both grinding and excellent mixing in one machine.

How much mercury do I need to add to the pan?

The amount of mercury depends on the estimated gold content in your ore. You should start with a small amount and only add what is necessary. It is crucial to handle mercury safely and follow all environmental regulations to prevent pollution.

Can I use a wet pan mill for materials other than gold?

Absolutely. It is an excellent grinding and mixing tool for silver, copper, and other metal ores. It is also widely used in the ceramics and brick-making industries for preparing clay.

Your reliable source for high-capacity, heavy-duty ball mills engineered for mining, cement, and fine powder processing.

Zongding Machinery provides advanced ball mills and mineral processing equipment to help mining companies around the world process minerals more efficiently.

the best Ceramic Ball Mill manufacturers and their competitive prices. Our selection offers top-quality mills for various applications at affordable costs.

Efficient flotation machine for mineral processing at competitive prices. Maximum recovery and optimal grade for your mining operations.

A magnetic separator is a device that separates magnetic minerals from nonmagnetic minerals by applying a magnetic field.

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

“Optimize mineral processing with our high-efficiency Jigging Separator Machine! Ideal for gold, tin, coltan separation.

Shaking tables for gold recovery, mineral processing at great prices. Learn more about our gold shaking table, prices, and processing today.

loading…

已经是到最后一篇内容了!