Search the whole station Crushing Equipment

Our Ceramic ball mill are available in different styles and numerous model sizes in each style to adapt to various grinding requirements.

Ceramic ball mill, as a grinding tool for modern refinement industry, stands out in many industries with its unique material and efficient grinding performance. The machine adopts high-quality ceramic material to make grinding media, which ensures stable grinding effect in high-speed operation and avoids metal contamination at the same time, which is the first choice of equipment for pursuing high purity grinding effect.

A ceramic ball mill is a type of grinder, or grinding mill, that consists of a cylindrical shell lined with ceramic materials like high-purity alumina. This shell is partially filled with ceramic grinding media, typically alumina balls. The primary purpose of this all-ceramic environment is to prevent iron and other metal contamination during the milling process. This makes it the ideal choice for processing light-colored or chemically sensitive materials where even trace amounts of metal could ruin the final product’s color, chemical properties, or performance.

Ceramic ball mills are vital in any industry that demands fine powders with high purity. Their applications are diverse and critical for modern manufacturing. For example, in the electronics industry, they are used to grind ceramic powders for Multilayer Ceramic Capacitors (MLCCs). Achieving a very specific and narrow particle size distribution is crucial for the performance of these components. This requires a combination of fine ceramic grinding media, a high solids loading in the slurry, and precise control over milling time, which our machines provide. Other key applications include:

Ceramic ball mill is used primarily for one reason: product purity. The entire grinding process happens in a ceramic-on-ceramic environment, eliminating the risk of metallic contamination that is common with standard steel mills. This is critical for materials like high-quality porcelain, dental ceramics, or white pigments. Beyond purity, these mills offer excellent grinding efficiency for producing super-fine powders, often down to the micron or even sub-micron level. They are also versatile, capable of both wet and dry grinding, allowing you to choose the best method for your specific material.

Whether it is glaze preparation in the ceramic industry, powder mixing in the chemical industry, or drug grinding in the pharmaceutical industry, the ceramic ball mill can meet your grinding needs with its excellent performance. It is widely used in various scenarios that require high purity and high precision grinding, and is a powerful assistant to improve product quality and productivity.

A wide range of materials can be processed in a ceramic grinding ball mill, especially those that are abrasive or require high purity. The key is that the material should be suitable for size reduction through impact and attrition. You can confidently grind materials such as:

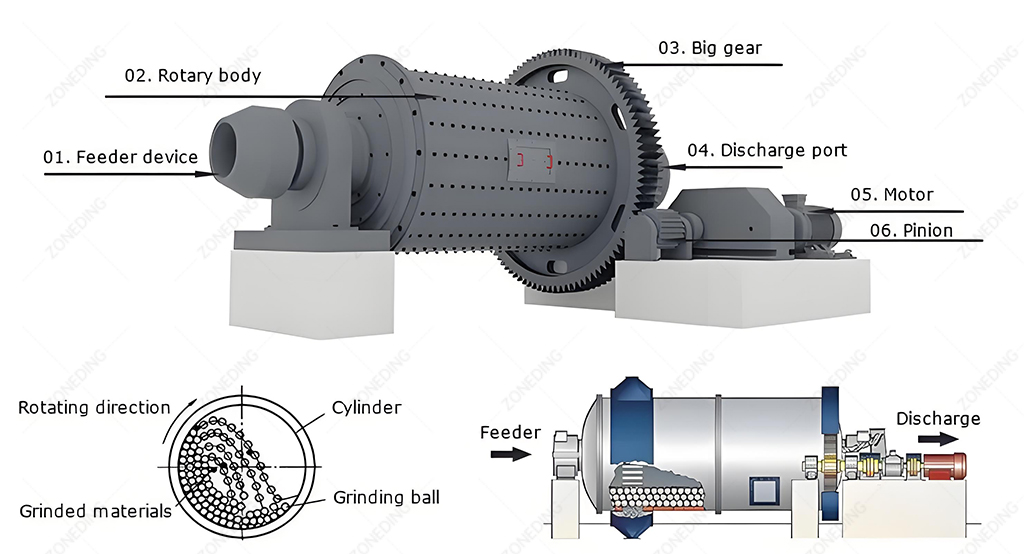

The working principle of a ball mill grinding machine is straightforward yet effective.

First, you load the material to be ground into the ceramic-lined drum along with the ceramic grinding balls. The drum is then sealed and rotated on its horizontal axis by a motor. As the drum rotates, it lifts the balls. At a certain height, the balls begin to cascade down, striking the material and each other. This motion creates two primary grinding actions: impact (from falling balls) and attrition (from balls rubbing against each other and the liner). The speed of rotation is critical; it must be fast enough to lift the balls but not so fast that they are pinned to the shell by centrifugal force. This continuous tumbling action gradually grinds the material down to the desired fineness.

A ceramic ball mill is built for durability and performance, with several key components. Understanding its structure helps you appreciate its function. The main parts include:

Ceramic ball mills are generally categorized by their method of operation. The two main types are:

Choosing the right size ball grinding mill depends entirely on your project’s needs. There is no one-size-fits-all answer. To make the right choice, you need to consider a few key factors:

While all are grinding mills, they use different media and are suited for different tasks. Here is a simple comparison:

| Feature | Standard Ball Mill | Rod Mill | Ceramic Ball Mill |

|---|---|---|---|

| Grinding Media | Steel Balls | Steel Rods | Ceramic Balls |

| Grinding Action | Point contact (impact) | Line contact (attrition) | Point contact (impact) |

| Product Size | Fine to very fine | Coarse, uniform size | Very fine, contamination-free |

| Lining | Steel or Rubber | Steel | Ceramic (Alumina) |

| Key Application | Ore grinding, cement | Coarse grinding, avoiding over-grinding | High-purity materials, glazes |

Determining the price of a ceramic ball mill is a crucial step for budgeting your project, and the final cost is directly tied to your specific application needs. A small-scale lab ball mill for research and development will have a significantly different price point than a large-capacity industrial ball mill designed for continuous production.

Several key factors influence the final quotation.

Because every project is unique, we provide tailored quotations instead of a fixed price list. This ensures you receive a competitive and accurate price for a machine built to your exact specifications.

Selecting the right grinding media is critical for efficient milling. You need to consider the material, size, and quantity of the balls.

You can operate a ceramic ball mill either wet or dry, and each method has its own advantages.

Wet Grinding:

Dry Grinding:

Even the most reliable machines can face issues. Here are some common problems with a ball mill grinder and how to address them:

Proper maintenance is key to the long-term performance and reliability of your ball mill machine. Regular checks ensure it runs efficiently and safely. Key tasks include:

A ball mill is an energy-intensive machine, so understanding its power consumption is important for managing operational costs. The main factors influencing energy use are:

Using a Variable Frequency Drive (VFD) can help optimize the motor speed and reduce energy consumption during startup and operation.

Ball milling technology continues to evolve to meet demands for higher efficiency and better products. Some of the latest advancements include:

At ZONEDING, we have been manufacturing high-quality industrial machinery since 1990. Our ceramic ball mills are designed for performance, reliability, and long life. We understand that every customer’s needs are different. That is why we offer extensive customization options, allowing you to get a mill that is perfectly tailored to your specific material and production goals. We use only the highest quality wear-resistant alumina for our liners and offer a range of grinding media options. As a direct manufacturer, we cut out the middleman, offering you a superior machine at a competitive price. Our full-service support includes everything from initial consultation and design to installation, training, and after-sales maintenance.

If you are interested in this, please contact us as soon as possible! We will provide you with more than 2 solutions for you to choose from.

| Model | Feeding capacity (t/time) | Shell rotation speed (r/min) | Reference motor (kw) | Liner material |

| 600×700 | 0.05 | 50 | 2.2 | Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |

Your reliable source for high-capacity, heavy-duty ball mills engineered for mining, cement, and fine powder processing.

Zongding Machinery provides advanced ball mills and mineral processing equipment to help mining companies around the world process minerals more efficiently.

Efficient flotation machine for mineral processing at competitive prices. Maximum recovery and optimal grade for your mining operations.

A magnetic separator is a device that separates magnetic minerals from nonmagnetic minerals by applying a magnetic field.

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

“Optimize mineral processing with our high-efficiency Jigging Separator Machine! Ideal for gold, tin, coltan separation.

Gold Mine Wet pan mill applys in the gold mining industry and is one of the indispensable equipment in the modern gold mining industry. In addition, it can also apply for mining and processing other non-ferrous metals and precious metal ore…

Shaking tables for gold recovery, mineral processing at great prices. Learn more about our gold shaking table, prices, and processing today.

loading…

已经是到最后一篇内容了!