Symons Cone Crusher

Applied Material:nPebble, gravel, granite, diabase, basalt, quartz, limestone, iron ore, sandstone, coal gangue, etc.- Feed Size:35-228mm

- Capacity:18-635TPH

What is Symons Cone Crusher?

Symons Cone Crusher Workshop

Symons Cone Crusher Selection

Application of Symons Cone Crusher

The Symons cone crusher offers several structural advantages that contribute to its superior performance and functionality.

Advantages of Symons Cone Crusher

Symons Cone Crusher Working Principle

Symons Cone Crusher Customer Site

General Specification

| Type | Model | Diameter of large end of crushing cone(mm) | Adjusting Range of Discharge Opening(mm) | Feed opening size of the open edge when recommending the min. Discharge opening (mm) | Max.feeding size(mm) | Processing capacity (t/h) | Main motor power (kw) | Machine weight (kg) |

| PSG 900 | 0910 | 914 (3′) | 9-22 | 102 | 85 | 45-91 | 6P 75 | 9980 |

| 0917 | 13-38 | 175 | 150 | 59-163 | ||||

| 0904 | 3-13 | 41 | 35 | 27-90 | ||||

| 0906 | 3-16 | 76 | 65 | 27-100 | ||||

| PSG 1300 | 1313 | 1295 (4¼′) | 13-31 | 137 | 115 | 109-181 | 6P 160 | 22460 |

| 1321 | 16-38 | 210 | 178 | 132-253 | ||||

| 1324 | 19-51 | 241 | 205 | 172-349 | ||||

| 1306 | 3-16 | 64 | 54 | 36-163 | ||||

| 1308 | 6-16 | 89 | 76 | 82-163 | ||||

| 1310 | 8-25 | 105 | 89 | 109-227 | ||||

| PSG 1600 | 1620 | 1676 (5½′) | 16-38 | 209 | 178 | 181-327 | 6P 250 | 43270 |

| 1624 | 22-51 | 241 | 205 | 258-417 | ||||

| 1626 | 25-64 | 269 | 228 | 299-635 | ||||

| 1607 | 5-13 | 70 | 60 | 90-209 | ||||

| 1608 | 6-19 | 89 | 76 | 136-281 | ||||

| 1613 | 10-25 | 133 | 113 | 190-336 |

Related Products

Jaw Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

Impact Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

Sand Making Machine

Sand Making MachineFine CrushingGet Price And SupportSand making machine is suitable for soft or medium hard and very hard ore materials with hardness not higher than 320 Pa. Also, we usually call it VSI sand making machine. It has the characteri…

Cone Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message Working Principle: ,

Spring Cone Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message Ore dressing line: Spring cone crusher is suitable for crushing iron ore, copper ore, and other metal ores in the ore dressi…

Hydraulic Cone Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

Hammer Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

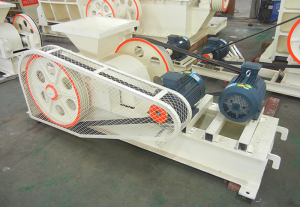

Roll Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

Toothed Roll Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

Compound Crusher

Get Price And Support Whatsapp +8618637198006 Email: zd-machine@kssb.cn Get Price Leave a message ,

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine