Search the whole station Crushing Equipment

A Hammer Crusher, also known as a Hammer Mill Crusher, is a machine that crushes material through the impact of rapidly moving hammers. Material is fed into the crushing chamber from the top. The rotor, which has hammers attached, spins at a very high speed. These hammers strike the material, breaking it apart. The material is also thrown against the inner walls and breaker plates of the crusher, which causes further reduction. The final product size is controlled by grate bars at the bottom of the machine.

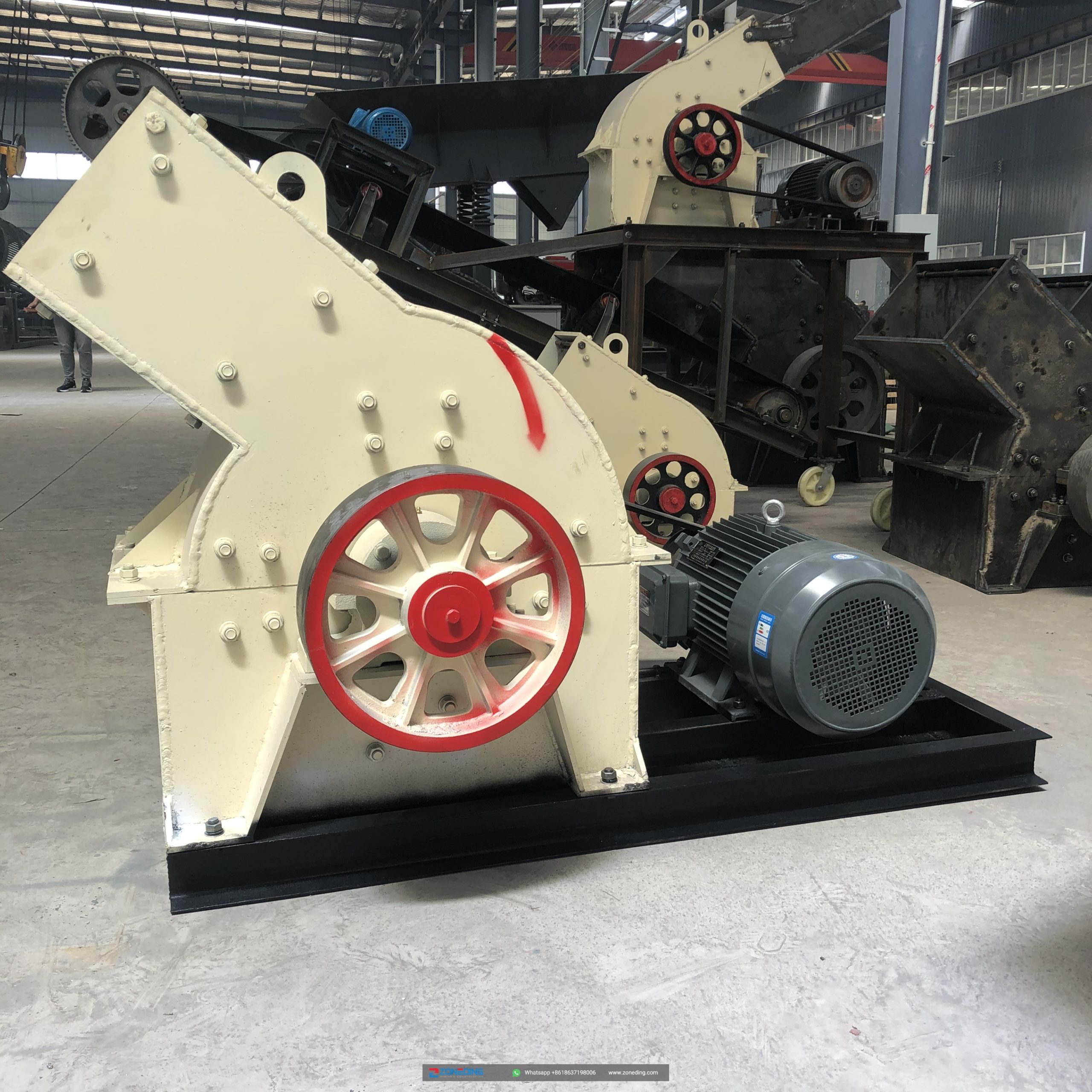

Hammer crusher is a device for crushing materials in the form of impact. It can crush materials with a maximum particle size of 600-1800 mm to 25 mm or smaller.

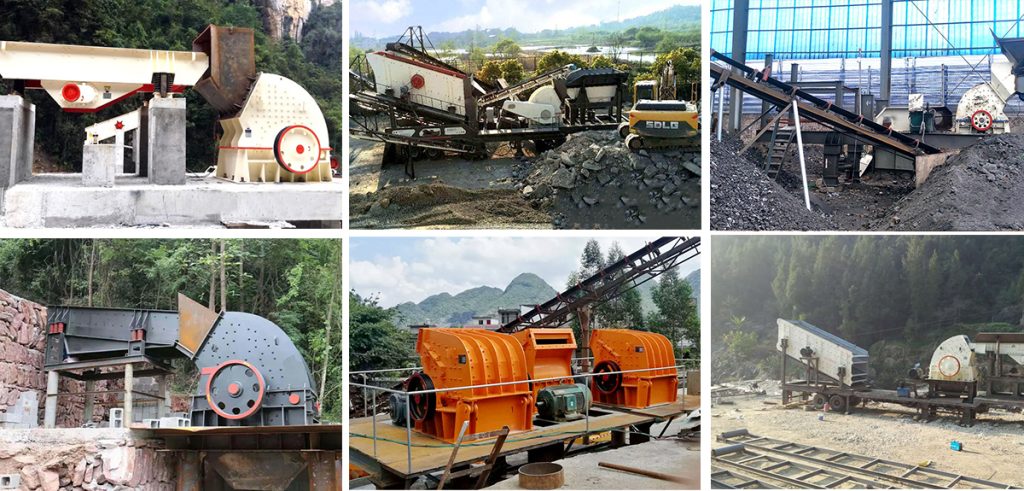

The Industrial Hammer Mill applied in many industries because of its high reduction ratio and simple design. One of the most common applications is crushing limestone in a cement plant. The Limestone Crusher must efficiently reduce the rock to a size suitable for the next stage of cement production. The hammers face high wear, so regular inspection is essential.

Other key applications include:

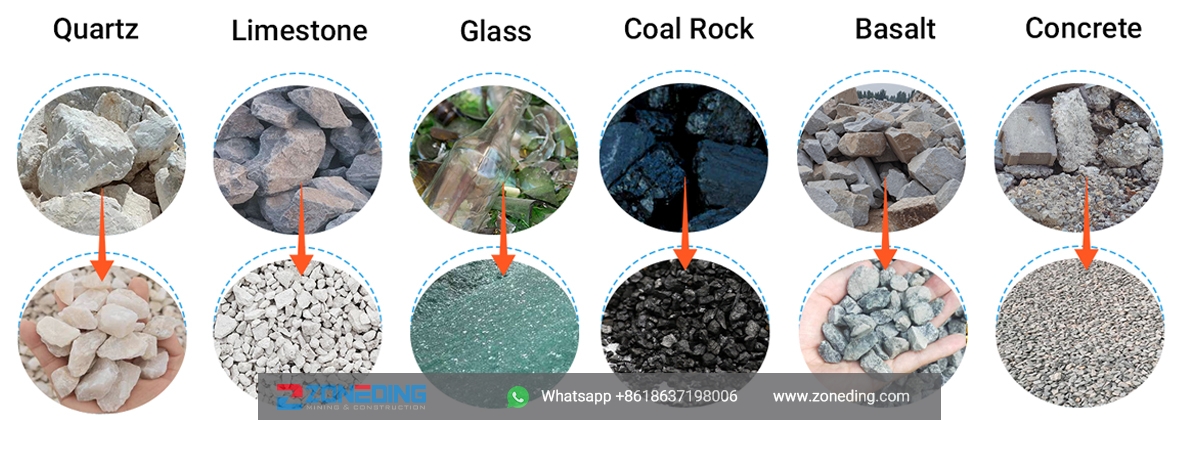

A hammer crusher is suitable for materials that are soft to medium-hard and not very abrasive. If the material is too hard or abrasive, the wear on the hammers and liners will be very high, leading to frequent and costly maintenance.

Ideal materials include:

The hammer crusher is a popular choice for many reasons. Its biggest advantages are its simple design and high performance.

Zoneding mainly provides 3 types of hammer crushers: hammer crushers, heavy type hammer crushers, mobile hammer crusher, etc. Here are details of these 3 types of hammer crushers.

Hammer crushers come in several designs to suit different needs. The main types you will find are:

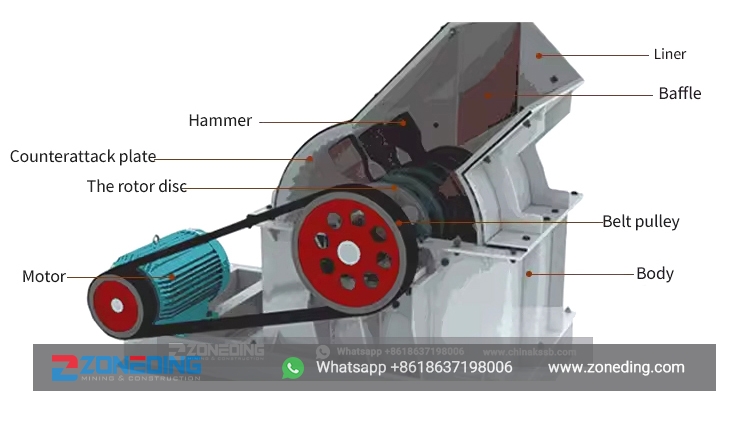

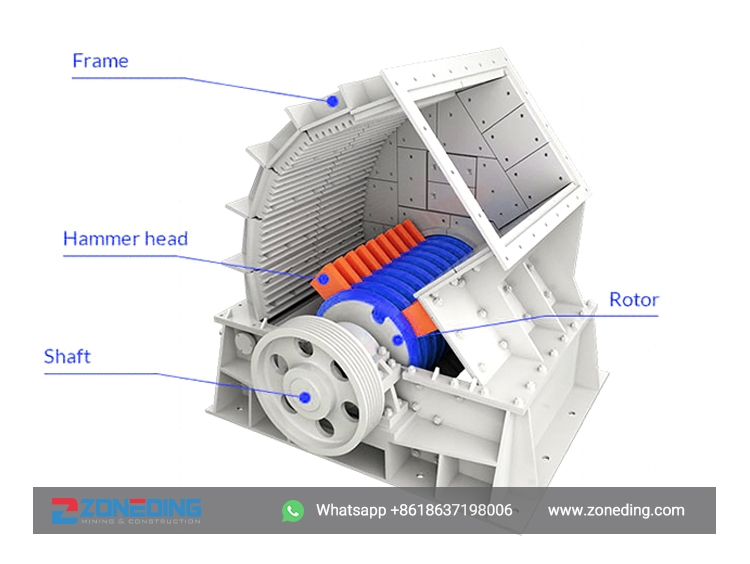

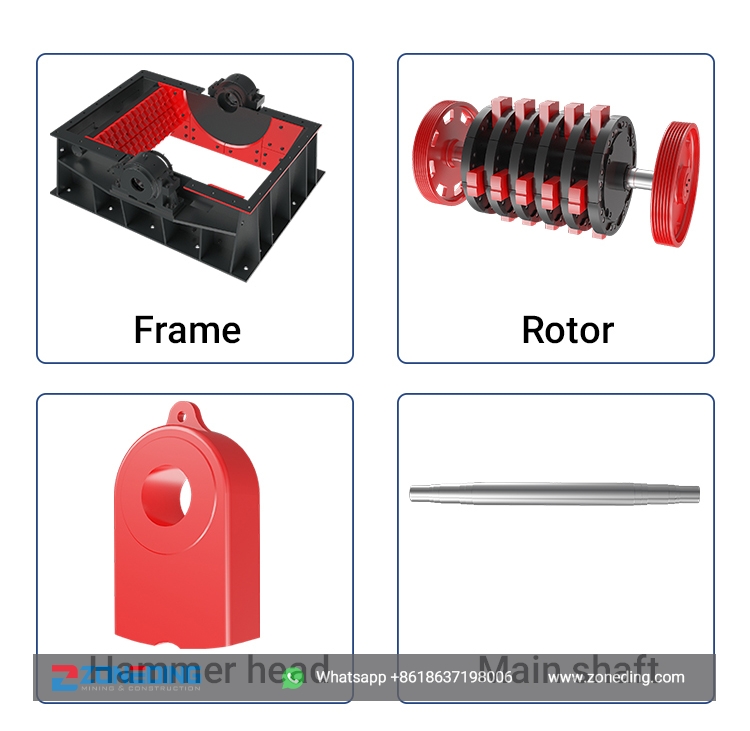

A hammer mill crusher is mainly composed of the frame, rotor, hammer head, main shaft, and other components.

The working principle of a hammer crusher is straightforward and relies on impact energy.

The working principle of the hammer mill is to crush materials by the impact force of the high-speed rotating hammer head.

When working, the motor drives the rotor to rotate at a high speed, and the materials are evenly sent into the crushing cavity. The high-speed rotating hammer heads impact and crush the minerals. The crushed materials rush to the impact plate and grate bar at high speed. At the same time, the materials impact each other and are crushed many times.

Choosing the right crusher depends on your material and goals. Here is a simple comparison:

| Feature | Hammer Crusher | Jaw Crusher | Cone Crusher |

|---|---|---|---|

| Principle | Impact | Compression | Compression |

| Best For | Medium-hard, non-abrasive | Hard, abrasive rock | Very hard, abrasive rock |

| Stage | Primary or Secondary | Primary | Secondary or Tertiary |

| Output Shape | More cubical, more fines | Angular, less uniform | Very cubical, uniform |

| Wear Parts | Hammers, Liners | Jaw Plates | Mantle, Concave |

A Hammer Crusher uses impact to shatter materials, while Jaw and Cone Crushers use compression to squeeze them. This makes the hammer mill better for softer rock like limestone.

Determining the price of a hammer crusher depends entirely on the specific configuration required to meet your production goals. As a versatile machine used for primary and secondary crushing of medium-hard materials, the final cost is built around your unique application. The most significant factor influencing the price is the model size and its crushing capacity, measured in tons per hour. A compact unit for recycling or small-scale operations will have a different price point than a heavy-duty industrial hammer mill designed for high-volume quarrying or cement production.

Further customization that affects the final quotation includes the required feed opening size and the desired output particle size. The power source is another key variable, whether you need a robust electric motor for a stationary plant or a diesel engine for a mobile hammer crusher configuration. Additionally, the material specifications for critical wear parts, such as high-manganese or high-chrome steel for the hammers and liners, play a crucial role in both the initial investment and the machine’s long-term operational cost.

To get the most out of your Hammer Mill Crusher, you need to focus on a few key areas.

First, pay close attention to the feed. A hammer crusher is sensitive to oversized material. You should use a screen before the crusher to remove any rock that is too large. Also, use a feeder to ensure the material enters the crusher at a steady, even rate. This prevents overload and ensures the hammers wear evenly.

Second, balance the rotor speed and grate spacing. A faster rotor produces finer particles but also increases wear. A smaller grate spacing also creates a finer product but can lower your total output. You must experiment to find the perfect balance for your material. Finally, make sure your discharge system, like a conveyor belt, is large enough to remove crushed material quickly to prevent blockages.

Proper maintenance is the key to a long and productive life for your hammer crusher. Hammer replacement is a major operating cost. A critical but often overlooked tip is that hammer material is not one-size-fits-all. The best material depends on what you are crushing. Manganese steel is great for impact, but a high-chromium alloy might be better for abrasive rock. At ZONEDING, we help you analyze wear patterns to select the best hammers.

Regular maintenance should include:

When you choose a ZONEDING Hammer Crusher, you are choosing over 30 years of manufacturing experience. Since 1990, we have perfected our designs to be both powerful and reliable. Our machines feature high-quality, wear-resistant components. We understand that every operation is different, so we offer customization to match the right hammer material and machine configuration to your specific needs.

Because we are a factory-direct manufacturer, we eliminate the middleman. This means you get a high-quality Stone Crusher Machine at a more competitive price. We provide full support, from designing your layout to installation and training. Our crushers are built to work hard and last long, ensuring you get the best return on your investment.

What is the main wear part of a hammer crusher?

The hammers are the main wear part. They experience constant high-impact and abrasive wear. Liners and grate bars are also common wear parts that need regular inspection and replacement.

Can a hammer crusher handle wet and sticky materials?

It can, but it is not ideal. Wet and sticky materials can build up inside the crushing chamber and clog the grate bars, which significantly reduces efficiency. A double-rotor design can sometimes help with this issue.

How do you change the output size of a hammer crusher?

You can change the output size in two main ways. The primary method is to change the grate bars to a set with different-sized openings. You can also adjust the rotor speed; a higher speed generally produces a finer product.

Is a hammer crusher very loud?

Yes, because it is an impact crusher, it generates a significant amount of noise during operation. It is important to use proper hearing protection and consider noise-dampening enclosures if it is located near residential areas.

What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Reliable Jaw Crushers for efficient primary crushing in mining, quarrying & aggregate production. Heavy-duty design, high throughput.

Cone Crusher For Sale: Highly efficient, stable and durable, ideal for all ore crushing needs. It can improve production efficiency and reduce operating costs.

High-efficiency VSI sand making machines for producing premium artificial sand from rock & gravel. Excellent particle shape, low wear cost.

PF Series Impact Crusher for secondary crushing of limestone, rock, and efficient recycling of concrete & asphalt. High throughput, excellent shape. Get Specs!

Looking for a high-performance Vibrating Feeder? Explore our durable industrial feeding machines for mining & aggregate plants.

Sand Washing Machines (Wheel & Spiral types) to remove impurities & improve sand quality for construction & industry. High cleanliness, reliable performance. Get Your Quote!

The YK series circular vibrating screens are high-performance and suitable for heavy-duty quarrying and aggregate screening operations. Multi-layer screen options are available for precise grading.

Smooth Roll Crushers for finer sizing or Toothed Roll Crushers for better grip on materials like coal & shale. Reliable, low maintenance crushers for various industries.

Looking for a high-efficiency fine crusher? Explore our industrial fine crushing machines for sale. Factory-direct pricing and large capacity.

Compound Crushers (Vertical Shaft) for efficient fine crushing of medium-hard materials like limestone & clinker. Simple structure, high ratio, ideal for sand making & aggregate. Get Quote!

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy