What is a Ball Mill Used For?

Are you trying to understand the role of grinding in mineral processing? Do you need to achieve very fine particle sizes for mineral liberation or industrial applications? A Ball Mill is likely the key piece of equipment you are looking for. It is fundamental in many industries, especially mining.

This article will explain:

- The basic function of a Ball Mill and how it grinds materials.

- The main industries where Ball Mills are essential.

- Key reasons why a Ball Mill is chosen for grinding tasks.

- Different types of Ball Mills and their uses.

- What the major components of a Ball Mill are.

- How to make your Ball Mill operate more efficiently.

- Where a Ball Mill fits within a complete processing plant flowsheet.

- Common questions about Ball Mill operation.

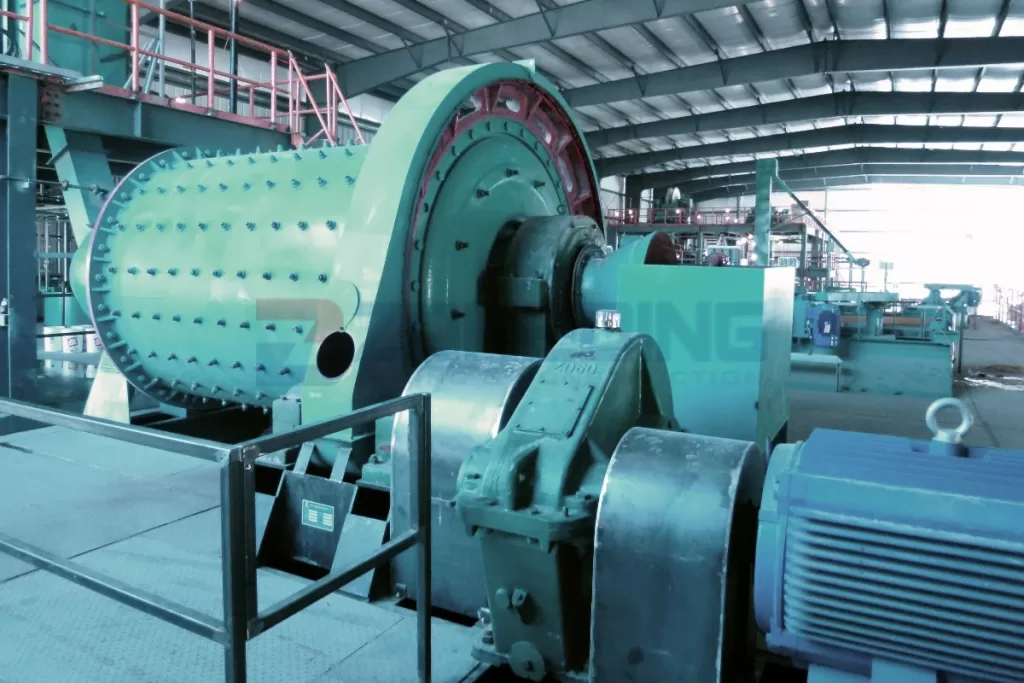

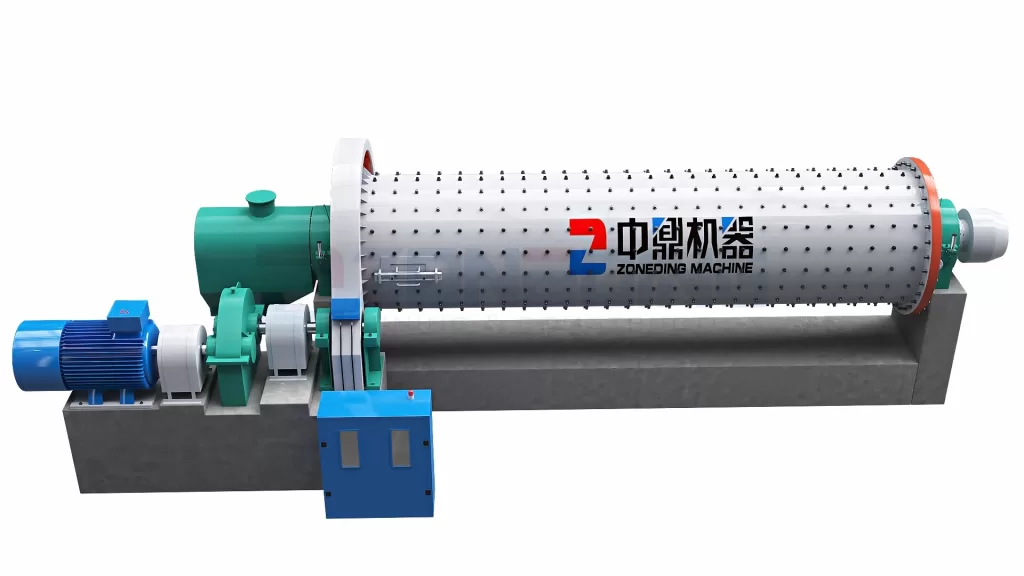

A Ball Mill is a type of grinding machine used to grind materials into extremely fine powder. It achieves this by rotating a cylinder partially filled with grinding media (like steel balls or ceramic balls) and the material to be ground. The material is ground by impact and abrasion as the media cascade inside the rotating cylinder.

Understanding the functions and applications of a Ball Mill is vital if you work in mineral processing, cement production, or many other industrial fields requiring fine particle sizes. This technology is proven and versatile.

How Exactly Does a Ball Mill Achieve Fine Grinding?

You know it uses balls to grind, but what mechanical actions are happening inside the rotating cylinder to break down hard materials?

A Ball Mill grinds material through a combination of impact and attrition. As the cylinder rotates, the grinding media (balls) are lifted up by the liners inside the shell. They then fall back down or cascade, impacting the larger particles of material below. Finer grinding happens through attrition, which is the rubbing and abrasion between the balls themselves, the shell liners, and the material particles.

The main body of a Ball Mill is a hollow cylindrical shell. It rotates on its axis. This shell is mounted on a frame and driven by a motor and gearbox system. Inside the shell are grinding media. These are typically steel balls, but ceramic balls or flint pebbles can also be used depending on the application and material being ground. The material you want to grind is fed into the mill, usually through an inlet at one end. As the shell rotates, the internal liners lift the grinding media and the material. At a certain point in the rotation, determined by the mill speed and liner design, the media and material fall or cascade downwards. This falling action provides the primary grinding force through impact. Larger particles are broken into smaller ones by being caught between the falling balls or between a ball and the shell liner. As the media slide and roll over each other during the cascade and at lower levels in the mill, they also grind the material by abrasion and attrition. This process reduces the particles to progressively finer sizes. The size distribution of the grinding media is important; larger balls are needed for initial breaking of coarser feed, while smaller balls are more effective for fine grinding by attrition. The amount of grinding media (called the charge) typically fills 30-45% of the mill volume. The shell is usually lined with replaceable wear-resistant plates made of manganese steel, high-chrome steel, or rubber to protect the shell and aid in lifting the media. My company designs and manufactures robust Ball Mills optimized for this efficient grinding process.

What Specific Industries Rely on Ball Mills for Grinding?

Is the Ball Mill only used in mining, or does it have broader applications across different industrial sectors?

Ball Mills are indispensable in many industries requiring fine grinding. These include Mining and Mineral Processing, Cement Production, Thermal Power Plants (for coal), Chemical Manufacturing, Ceramic and Pigment Production, and material recycling.

The ability to reduce a wide variety of materials to very fine particle sizes makes the Ball Mill a versatile machine used globally. Here are some of its key industrial applications:

Mining and Mineral Processing

This is a major application area. After ore has been crushed using primary and secondary Crushing Equipment, it needs further size reduction to liberate the valuable minerals from the waste rock (gangue). Ball Mills are widely used for this task, grinding ores like gold, copper, iron, lead, zinc, and platinum group metals down to the fine sizes required for subsequent mineral separation processes such as flotation, leaching, or magnetic separation. Efficient grinding in a Ball Mill is critical because the degree of mineral liberation directly impacts the recovery rate in downstream processes. The fineness required can range from tens to hundreds of microns, depending on the ore type and the liberation characteristics of the valuable mineral. My company provides robust Ball Mill solutions for various mining applications.

Cement Production

In the cement industry, Ball Mills are used to grind clinker (produced by burning limestone and clay) along with gypsum and other additives to create finished cement powder. This is often a dry grinding process. The fineness of the final cement product, measured by Blaine fineness or sieve residue, significantly impacts its hydration properties and strength development. Large Ball Mills are a standard component of cement grinding circuits.

Thermal Power Plants

Coal-fired power plants require coal to be ground into a fine powder (pulverized coal) before it is blown into the boiler for combustion. This increases the surface area of the coal particles, allowing for rapid and efficient burning. Ball Mills are one type of pulverizer used for this application, reducing coal to micron-sized particles.

Chemical Manufacturing

Various chemical processes require raw materials or intermediate products to be in a fine powder form to increase reactivity or improve product quality. Ball Mills are used for grinding a wide range of chemicals, pigments, fillers, and other materials in both wet and dry grinding applications.

Ceramic and Pigment Production

The production of ceramics, glazes, paints, inks, and dyes requires materials to be ground to very fine particle sizes and often intimately mixed. Ball Mills, sometimes using ceramic or alumina media to avoid contamination, are used for grinding minerals like kaolin, feldspar, quartz, and various pigments to achieve the desired fineness and consistency.

These examples show that while mineral processing is a primary use, the Ball Mill’s ability to finely grind diverse materials makes it valuable across a broad spectrum of manufacturing and processing industries.

Why Choose a Ball Mill for Your Grinding Needs?

With various types of grinding mills available, what makes the Ball Mill a preferred choice for many applications? What are its key advantages?

Key advantages of using a Ball Mill include its ability to produce very fine product sizes, suitability for both wet and dry grinding, high throughput capacity, robust and simple design leading to reliable operation, and relative tolerance to variations in feed material hardness.

Choosing the right grinding equipment is critical for process efficiency and product quality. Ball Mills offer several compelling benefits that make them a popular choice:

Excellent for Fine Grinding

Perhaps the most significant advantage is the Ball Mill’s capability to achieve very fine particle sizes, often down to tens of microns or even less in some cases. This level of fineness is often necessary for effective mineral liberation in complex ores or for meeting strict product specifications in industries like cement or pigments. Other grinding equipment may be more efficient for coarser sizes, but Ball Mills excel when a high degree of fineness is required.

Versatility (Wet and Dry Grinding)

Ball Mills can be designed and operated for both wet grinding (where the material is mixed with water to form a slurry) and dry grinding (where the material is processed in a dry state). Wet grinding is common in mineral processing as it aids material transport and subsequent separation steps like flotation or Spiral Classifier operation. Dry grinding is typical in cement production or when the final product needs to be dry powder. This adaptability makes the Ball Mill suitable for a wider range of applications than mills limited to one method.

High Capacity and Scalability

Large industrial Ball Mills can have diameters exceeding 5 meters and lengths over 10 meters, capable of processing thousands of tonnes of material per day. The technology scales up effectively to meet the demands of large-scale mining and industrial operations.

Robust and Reliable Design

The basic design of a Ball Mill (a rotating cylinder) is mechanically simple and robust. With proper maintenance, these machines are known for their reliability and long service life, operating continuously for extended periods in demanding environments. Wear parts, like liners and media, are designed for replacement, making maintenance straightforward compared to the internal complexity of some other mill types.

Tolerance to Feed Variation

While performance is optimized with consistent feed, Ball Mills are generally more tolerant of variations in feed hardness or particle size distribution compared to some mills (like high-pressure grinding rolls) that require a more tightly controlled feed.

My company focuses on manufacturing Ball Mills that embody these advantages, providing reliable and efficient grinding solutions tailored to our clients’ specific needs.

What are the Different Types of Ball Mills Available?

Are all Ball Mills just one basic design, or are there variations that suit different purposes or material types?

Ball Mills come in various types based on their discharge mechanism (overflow mills, grate mills), mode of operation (batch mills, continuous mills), and the way they are driven. The selection depends on the desired product fineness, capacity, and the physical properties of the material being ground.

While the core principle remains the same, variations in design allow Ball Mills to be optimized for specific tasks:

By Mode of Operation

- Batch Mills: These are typically smaller mills used for grinding specific quantities of material for a defined period. The material and grinding media are loaded, the mill runs for a set time, and then the mill is stopped and the contents are discharged. Used in laboratories, smaller production runs, or for very high-value materials.

- Continuous Mills: Material is continuously fed into one end of the mill and discharges from the other while the mill is running. These are the most common type in large industrial plants requiring high throughput, such as mining and cement operations.

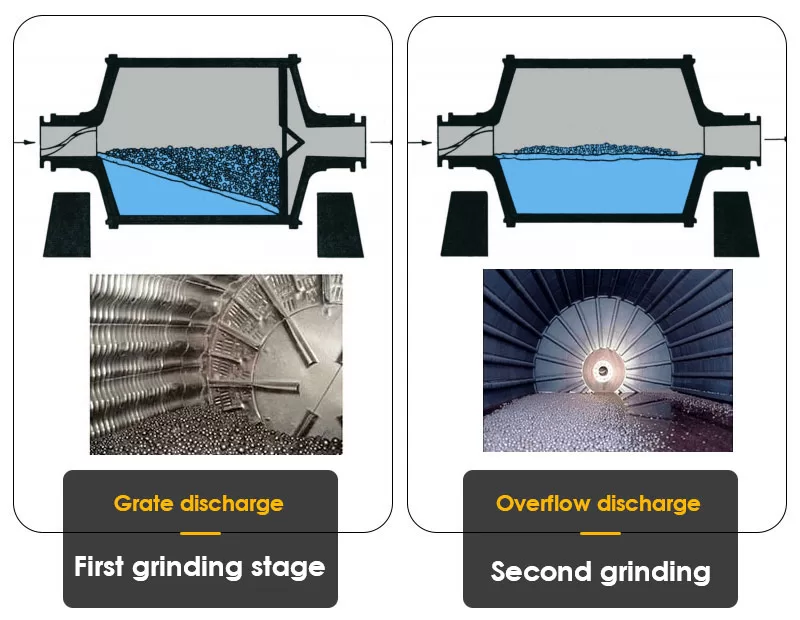

By Discharge Mechanism (for Continuous Mills)

- Overflow Mills: These have a simple discharge opening at the end of the mill. The pulp level inside the mill is higher than the discharge opening. Ground material, carried by the water (in wet grinding), overflows through the opening. This type provides longer retention time for material inside the mill, making it suitable for achieving finer product sizes.

- Grate Mills: These mills have a diaphragm or grate at the discharge end. This grate has openings that allow material finer than a certain size to pass through and exit the mill. Coarser material is retained inside for further grinding. Grate mills allow for faster material flow and are often used when grinding slightly coarser products or for primary grinding stages. They can offer higher capacity for a given mill volume compared to overflow mills.

By Drive System

- Girth Gear Drive: A large gear (girth gear) is attached around the circumference of the mill shell and driven by a pinion connected to a motor and gearbox. This is a very common drive system for larger mills.

- Trunnion Drive: Smaller mills might have the drive connected directly to the trunnion (the hollow shaft supporting the mill) via a gearbox.

- Gearless Drive: Very large, modern mills may use large ring motors mounted directly around the mill shell, eliminating the need for gearboxes and girth gears. This system offers high efficiency and reliability but has higher capital cost.

Selecting the appropriate type of Ball Mill depends on a detailed analysis of the required grinding duty, the nature of the material, desired capacity, and budget. My company offers expertise in selecting and providing the right Ball Mill type for your application.

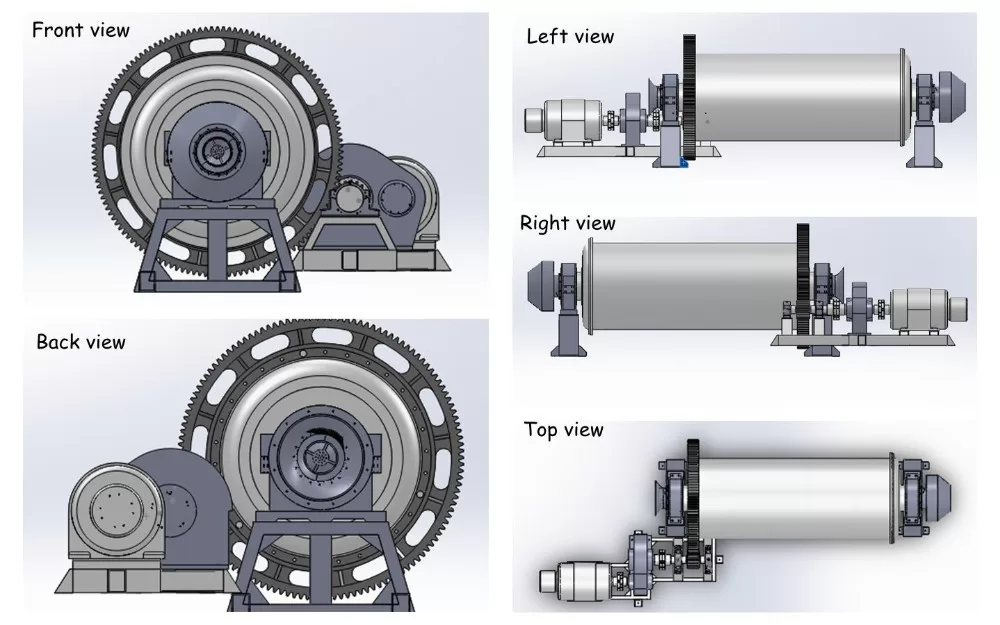

What Are the Main Parts of a Ball Mill?

To understand how a Ball Mill works and how to maintain it, you need to know its basic components and what each part does.

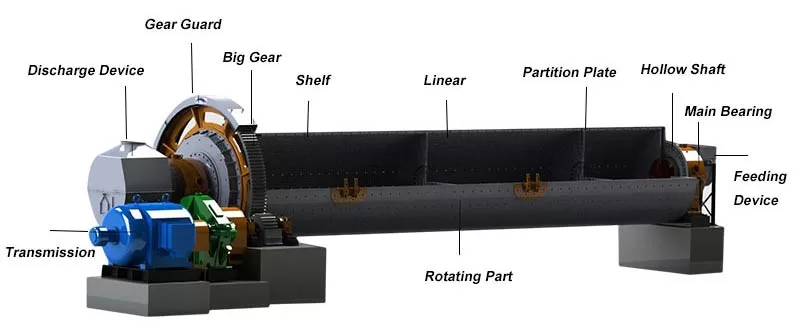

The main parts of a Ball Mill include the cylindrical Shell (the rotating body), internal Liners (wear-resistant plates inside the shell), Grinding Media (the balls), the Heads or Ends (which support the shell and allow material flow), the Drive System (motor, gearbox, gears), and the Support Bearings (which the mill rotates on).

Each component plays a specific role in the grinding process and overall mill operation:

The Shell

This is the main rotating cylinder. It is typically constructed from heavy-duty steel plate, sometimes welded in sections for large mills. Its diameter and length define the mill’s size and capacity. The shell holds the grinding media and the material being ground.

Liners

These are replaceable wear plates bolted to the inside surface of the shell. They protect the expensive steel shell from abrasion and impact by the grinding media and material. Liners also play a crucial role in lifting the grinding media as the mill rotates, influencing the cascading and tumbling action. They come in various profiles (smooth, wave, step, lifter bar) made from different materials like manganese steel, high-chrome steel, or rubber, chosen based on the ore type, grinding action, and wear resistance required.

Grinding Media (The Balls)

These are the actual grinding elements. They are usually spherical and made of high-carbon or high-chrome steel for hardness and wear resistance. Their size is selected based on the feed particle size and desired product size – larger balls break down coarser material, smaller balls are efficient for fine grinding. The total weight of media in the mill is called the media charge.

Heads or Ends

These are the structural components at each end of the cylindrical shell. They provide support for the mill shell and contain the openings (trunnions) through which material is fed into and discharged from the mill. They are typically cast or fabricated steel. In grate discharge mills, the discharge head incorporates the grate system.

Drive System

This system provides the power to rotate the heavy mill shell, media, and material. It typically consists of an electric motor, a speed reduction gearbox, a small pinion gear, and a large girth gear bolted around the mill shell circumference.

Support Bearings

The entire rotating weight of the mill (shell, liners, media, material) is supported on large bearings, usually located at the ends of the trunnions. These can be large sliding shoe bearings (hydrodynamic bearings) or roller bearings for smaller mills. They require robust design and effective lubrication.

Understanding these parts is essential for operating, maintaining, and troubleshooting a Ball Mill. My company uses high-quality materials and precision manufacturing for all these critical components to ensure long-term performance.

How Can You Optimize Ball Mill Performance?

Just owning a Ball Mill is not enough; you need to run it efficiently to get the desired product size at maximum throughput with minimum cost. What factors can you adjust or monitor to optimize performance?

Optimizing Ball Mill performance involves controlling feed characteristics (size, rate, consistency), optimizing the grinding media charge and size distribution, selecting appropriate liners, controlling pulp density (for wet grinding), operating at the correct speed, and implementing consistent preventative maintenance.

Achieving maximum grinding efficiency is a balance of several interconnected factors. Adjusting one factor can influence others.

Control Feed Characteristics

The feed material entering the Ball Mill should be within the recommended size range (typically established by upstream Vibrating Screens) and fed at a consistent rate. Feeding oversized material reduces efficiency and increases liner/media wear. Fluctuating feed rates lead to unstable operation. The objective is often to maintain a “choke feed” – keeping the mill continuously fed with material – to utilize the mill volume fully.

Optimize Grinding Media

The total amount of media charge and the ratio of different ball sizes within the mill are critical. The correct media charge ensures sufficient grinding action without overloading the mill. The size distribution of the balls should match the feed size and the target product size; larger balls break large particles by impact, smaller balls grind fine particles by attrition. As media wear, their size decreases, and new media must be added regularly (media makeup) to maintain the optimal size distribution and charge level.

Select Appropriate Liners

Liner design impacts how effectively the media are lifted and dropped (cascade vs. tumble). The correct liner profile influences grinding efficiency, power draw, and liner wear life. Different liner patterns are suited for different grinding actions and materials.

Control Pulp Density (Wet Grinding)

In wet grinding, the ratio of solids to water in the slurry (pulp density) significantly affects grinding efficiency. There is an optimal pulp density for each material and mill. If the pulp is too thick, it cushions the media and coats the balls, reducing grinding action. If it’s too thin, throughput may be reduced. Pulp density is typically controlled by adjusting the water addition rate to the mill feed.

Operate at Correct Speed

The speed of rotation (usually measured in revolutions per minute) is critical. It is often expressed as a percentage of the “critical speed” (the speed at which centrifugal force would hold the media against the shell). Operating too slow (e.g., below 60-70% of critical speed) causes the media to tumble too gently, resulting in poor grinding. Operating too fast (near critical speed) causes the media to centrifuge, reducing impact action. Optimal speed is usually between 70-80% of critical speed, but depends on the specific mill and application.

Implement Preventative Maintenance

Regular inspection and timely replacement of worn liners and media, proper lubrication of bearings and gears, and checking the drive system prevent unexpected breakdowns and ensure consistent performance. An inefficient mill uses more energy and produces less product.

Optimizing these factors requires monitoring mill performance (power draw, throughput, product size distribution) and making adjustments. My company’s engineers can provide technical guidance on optimizing your ZONEDING Ball Mill for peak performance.

Where Does a Ball Mill Fit in a Mineral Processing Plant?

A Ball Mill is rarely the first or last machine an ore sees. How is it integrated into a typical mineral processing flowsheet?

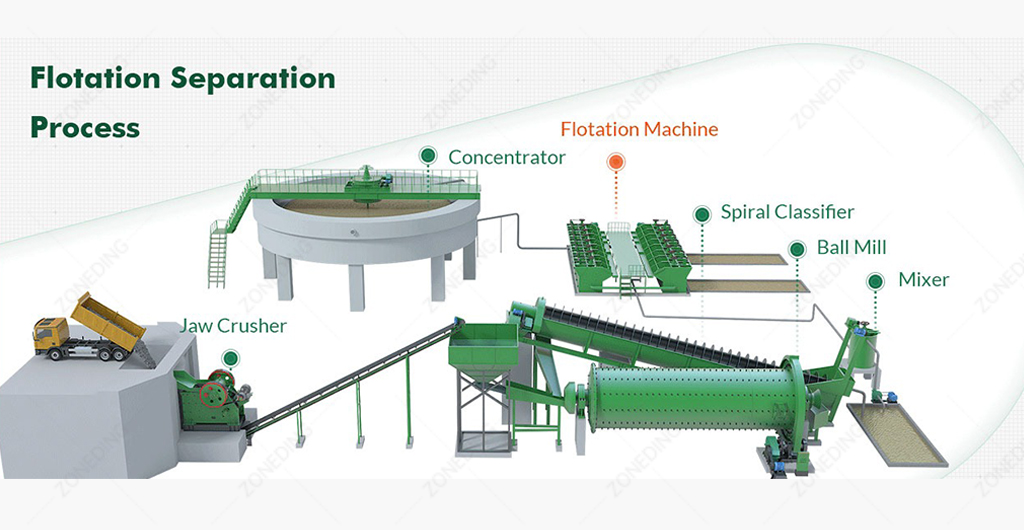

A Ball Mill is usually positioned after the Crushing and initial Screening stages in a mineral processing plant. It is the primary machine responsible for the fine grinding circuit, often operating in a closed loop with a Classifier (like a Spiral Classifier or hydrocyclone) before material moves to separation processes such as flotation, magnetic separation, or leaching.

Understanding the context of the Ball Mill within the entire plant is important for designing an efficient process.

Typical Grinding Circuit Placement

The overall goal of size reduction in mineral processing is to reduce the ore size progressively until the valuable minerals are liberated from the gangue. This process typically starts with Crushing Equipment (like Jaw Crushers and Cone Crushers) which handle large run-of-mine ore, reducing it to sizes typically less than 25-30 mm. After crushing, Vibrating Screens classify the material, sending correctly sized material to the grinding circuit and returning oversized material for further crushing. The Ball Mill receives this relatively finer feed (compared to the crusher feed).

Closed Circuit Grinding

Most industrial grinding circuits involving Ball Mills operate in a “closed circuit.” The material is fed into the mill, ground, and discharged as a slurry (in wet grinding). This discharge is then sent to a Classifier. The classifier (e.g., a Spiral Classifier or hydrocyclone) separates the slurry based on particle size. Particles that are already fine enough (the “fines” or “overflow”) are sent to the next stage of processing (e.g., flotation cells or a Shaking Table). Particles that are still too coarse (the “coarse” or “underflow”) are returned to the Ball Mill feed for further grinding. This closed loop ensures that material is only ground to the target size, preventing overgrinding (which wastes energy and can make recovery difficult) and increasing the overall throughput of the circuit compared to simple open-circuit grinding.

Downstream Processes

The finely ground slurry from the classifier overflow (the product of the grinding circuit) is then ready for the liberation of valuable minerals using various separation techniques like flotation, magnetic separation, or leaching, depending on the type of mineral being processed. The Ball Mill grinding circuit is thus a critical link between initial crushing and final mineral recovery.

My company specializes in designing and providing not just individual Ball Mills but also complete grinding circuits and integrated mineral processing plants tailored to your specific ore and production goals.

Common Questions about Ball Mills

Question 1: What is the difference between a Ball Mill and a Rod Mill?

Both are tumbling mills. A Ball Mill uses balls as grinding media. A Rod Mill uses steel rods as media. Rod mills are better for grinding coarser feed and produce a more uniform product size with less fines compared to ball mills, which are used for finer grinding.

Question 2: What are Ball Mill grinding media typically made of?

Grinding media (balls) are most commonly made of high-carbon or high-chrome cast or forged steel for their hardness and wear resistance. In some applications, like white mineral grinding where iron contamination must be avoided, ceramic balls or flint pebbles might be used.

Question 3: How often do Ball Mill liners need to be replaced?

Liner wear rate depends heavily on the abrasiveness of the material being ground, the mill’s operating conditions, and the liner material quality. Liners are replaced when they are worn down and no longer provide adequate lifting action or are close to wearing through to the shell. This can range from several months to a year or more in continuous operation.

Question 4: What is the “critical speed” of a Ball Mill?

The critical speed is the theoretical rotational speed at which the centrifugal force on the grinding media equals the force of gravity, causing the media to stick to the inside wall of the mill shell instead of cascading. Ball Mills are typically operated at speeds significantly below the critical speed (usually 70-80%) to ensure proper cascading and impact.

Question 5: Can Ball Mills operate dry?

Yes, Ball Mills can operate using either wet or dry grinding processes. Wet grinding is common in mineral processing to create a slurry for downstream separation. Dry grinding is typical in industries like cement production or when the final product needs to be a dry powder.

Conclusion

The Ball Mill is a core machine in size reduction, essential for achieving the fine particle sizes required in mineral processing, cement production, and many other industries. Its robust design and versatility make it a reliable choice for critical grinding tasks.

If you need efficient and reliable Ball Mills or complete grinding circuit solutions, my company, ZONEDING MACHINE, is ready to help. We offer high-quality equipment and expert support for your grinding needs.

Zoneding Machine

Zoneding Machine