The 3 Best Gold Gravity Separators

3559Want to maximize gold recovery? These 3 machines are essential. Learn about the shaking table, spiral concentrator, and jig for efficient gravity separation.

View detailsSearch the whole station Crushing Equipment

Fly ash is often seen as a simple waste product. This misunderstanding presents a financial risk, as using it without understanding its properties can lead to project failure.

This guide provides the technical knowledge to properly evaluate and process fly ash. Understanding its properties, applications, and quality control is essential for transforming this industrial byproduct into a consistent, high-value engineered material for commercial use.

For years, I have engineered systems that handle industrial minerals. I have seen firsthand how a deep understanding of a material’s properties can turn a liability into a profitable asset. Fly ash is a prime example. It is not simply a filler; it is a complex pozzolanic material with specific performance characteristics. The success of any Fly Ash Utilization project depends on a technical, data-driven approach rather than on assumptions. This guide outlines the critical technical and business considerations for anyone looking to use or process fly ash.

Using fly ash to replace cement saves money, but the total value is often underestimated. Focusing only on direct replacement cost misses significant indirect and long-term savings.

The primary economic benefit is the direct cost saving from replacing a portion of more expensive Portland cement. Secondary benefits include lower water and superplasticizer demand, reduced energy for mixing and pumping, and improved long-term durability, which reduces lifecycle maintenance costs.

A comprehensive financial analysis of using Fly Ash as a Concrete Admixture must extend beyond the simple price-per-ton comparison with cement. While direct replacement is the most visible saving, the “ball-bearing” effect of its spherical particles improves concrete rheology. This reduces friction, leading to lower energy consumption during pumping and easier placement, which saves labor time. The reduced water requirement can also lower the necessary dosage of expensive superplasticizers. Over the long term, the enhanced durability of fly ash concrete leads to a longer service life and reduced repair costs, a critical factor in the lifecycle cost analysis of large infrastructure projects. Quantifying these benefits provides a more accurate picture of the material’s total economic value.

| Benefit Category | Description | How to Quantify |

|---|---|---|

| Direct Savings | Replacing 15-35% of Portland cement with lower-cost fly ash. | (Price of Cement/ton – Price of Fly Ash/ton) x Tons Replaced. |

| Indirect Savings | Improved workability reduces water, superplasticizer, and energy needs. | Calculate cost savings from reduced water usage, lower admixture dosage, and lower pumping energy (kWh). |

| Long-Term Value | Increased durability reduces maintenance and repair costs over the structure’s life. | Lifecycle Cost Analysis (LCCA) comparing maintenance schedules of standard vs. fly ash concrete. |

Adding a byproduct to a concrete mix can seem counterintuitive. Without proper understanding, it can negatively affect early strength development and consistency.

Fly ash improves workability due to its spherical particles. It can slightly reduce early-age strength but significantly increases long-term strength and durability by consuming free lime in a pozzolanic reaction, creating a denser, less permeable microstructure.

The impact of fly ash on concrete is a direct result of its unique physical and chemical Fly Ash Properties. Physically, the spherical shape of the particles acts as a lubricant in the mix, improving flow and reducing the Water Requirement Ratio for a given slump. Chemically, the pozzolanic reaction is the key mechanism. Portland cement hydration releases calcium hydroxide (free lime), a relatively weak and soluble compound. Fly ash reacts with this free lime to form additional calcium silicate hydrate (C-S-H), the same compound that gives cement its strength. This secondary reaction is slower, which explains the lower early strength, but it continues for months, ultimately creating a denser matrix with higher ultimate strength and significantly lower permeability to water and chemical attack. This makes it essential for applications like Mass Concrete.

| Concrete Property | Effect of Fly Ash | Technical Mechanism |

|---|---|---|

| Workability | Improved | Spherical particles act as microscopic ball bearings, reducing inter-particle friction. |

| Strength | Lower early strength, higher ultimate strength. | The pozzolanic reaction is slower than cement hydration but produces additional strength-giving compounds over time. |

| Durability | Significantly Increased | The pozzolanic reaction consumes vulnerable free lime and creates a denser, less permeable pore structure, resisting sulfate and chloride ingress. |

The ready-mix concrete industry is the largest market for fly ash. However, relying on a single market exposes a business to fluctuations in construction demand.

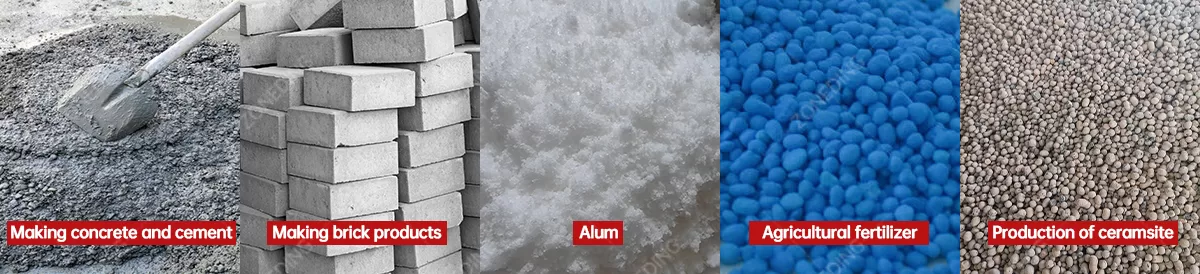

Beyond concrete, mature commercial Fly Ash Uses include soil stabilization in Road Construction, manufacturing of lightweight AAC Blocks and bricks, production of flowable fill (CLSM), and as a raw material for advanced Geopolymer cements.

Diversifying the applications for fly ash is key to maximizing its value. For civil engineering projects, Class C fly ash, with its self-cementing properties, is mixed with native soils to improve their strength and stiffness, creating a stable base for pavements. In manufacturing, fly ash serves as both a lightweight aggregate and a silica-alumina source for autoclaved aerated concrete (AAC) blocks, contributing to their excellent insulation properties. It is also used in producing traditional fired bricks, where it can reduce firing temperatures and improve product quality. A growing application is in geopolymers, a class of inorganic polymers that can be used as an alternative to Portland cement, offering high strength and excellent chemical resistance.

| Application | Role of Fly Ash | Key Benefit |

|---|---|---|

| Soil Stabilization | A binder (especially Class C) to strengthen weak or unstable soils. | Reduces the need for expensive quarried aggregate and improves the load-bearing capacity of roadbeds. |

| AAC Blocks & Bricks | A primary raw material providing silica and alumina. | Creates a lightweight product with high thermal insulation and reduces the overall energy required for manufacturing. |

| Geopolymers | The primary aluminosilicate source that reacts with an alkaline activator. | Creates a high-performance binder with a much lower carbon footprint than traditional cement. |

The source of fly ash, the power plant, is focused on producing electricity, not consistent ash. This quality variation is a major risk for end-users.

Controlling quality requires a systematic approach. This involves rigorous testing for critical parameters like Fly Ash Fineness and Loss on Ignition / LOI, followed by blending different batches in a large Fly Ash Silo and Conveyingsystem to create a homogenized, consistent final product.

Achieving a consistent product from a variable raw material is a classic process engineering challenge. The first step is measurement. A processing facility must have a lab to regularly test incoming ash for key metrics defined by standards like ASTM C618. The two most critical parameters are fineness and Loss on Ignition (LOI). Fineness affects the rate of the pozzolanic reaction, while LOI (a measure of unburnt carbon) can negatively impact air entrainment in concrete. Once the properties are known, the primary control strategy is blending. By storing ash from different deliveries or time periods in a large silo and using a controlled discharge system, the variations are averaged out, resulting in a product with predictable and consistent properties that meets the required Fly Ash Standard.

| Parameter to Control | Why It Is Critical | Control Method |

|---|---|---|

| Fineness | Affects reactivity, water demand, and workability. | Regular testing using a Blaine air permeability apparatus or laser diffraction. Controlled by grinding or classification if necessary. |

| Loss on Ignition (LOI) | High unburnt carbon adsorbs air-entraining admixtures, affecting freeze-thaw durability. | Regular testing in a muffle furnace. Controlled by source selection or processing with an Air Classifier. |

| Chemical Composition | Determines if the ash is Class F or Class C, affecting its properties. | X-ray fluorescence (XRF) analysis to confirm the content of SiO₂, Al₂O₃, Fe₂O₃, and CaO. |

Not all fly ash is suitable for direct use. Using raw, off-spec ash directly in high-performance applications will lead to product failure and financial liability.

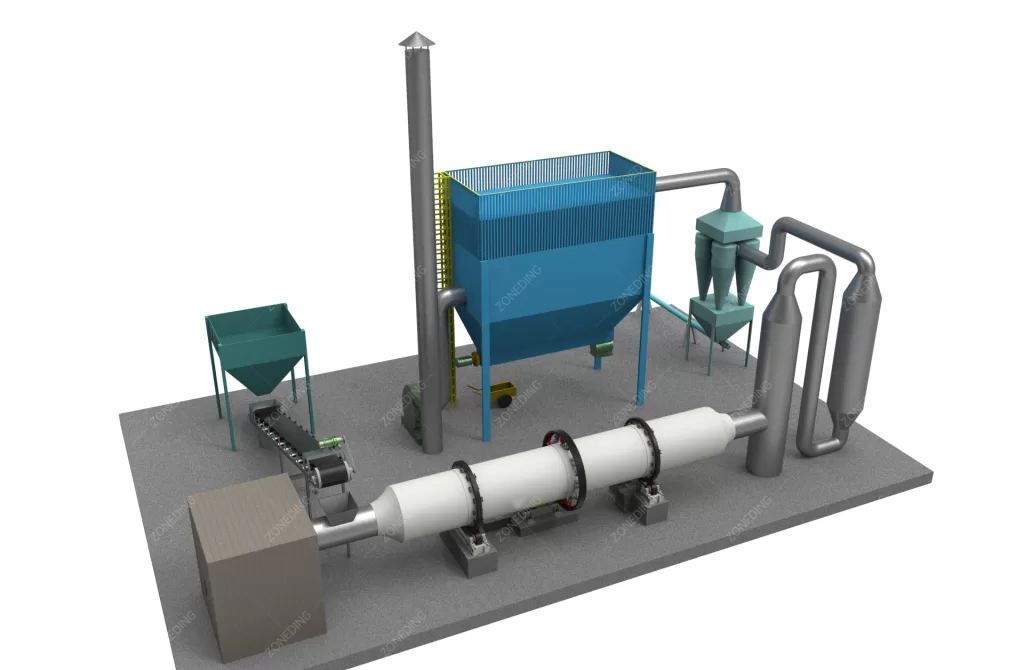

Fly Ash Pre-treatment is necessary when the raw material fails to meet quality standards. Grinding is required for coarse ash, classification is needed for high carbon content, and drying is required for high moisture content.

The decision to invest in pre-treatment equipment is based on a simple economic calculation: does the value added to the ash exceed the capital and operating cost of the equipment? If a power plant’s combustion process is inefficient, the resulting ash may be too coarse (low fineness) to react effectively in concrete. In this case, a Fly Ash Grinding Mill is used to increase its specific surface area and reactivity. If the ash has a high LOI due to unburnt carbon, an Air Classifier can separate the lighter carbon particles from the denser aluminosilicate spheres. If the ash has been exposed to weather and has a high moisture content, it will not flow properly in silos and conveyors. A Fly Ash Dryer is required to reduce the moisture to less than 1% before further processing or sale.

| Problem with Raw Ash | Required Pre-treatment Process | Resulting Improvement |

|---|---|---|

| Too Coarse (Low Fineness) | Grinding in a ball mill or vertical roller mill. | Increases surface area and Activity Index, meeting fineness specifications. |

| High Carbon (High LOI) | Separation using a static or dynamic air classifier. | Reduces LOI to acceptable levels, preventing issues with air entrainment. |

| High Moisture Content | Drying in a rotary dryer. | Improves flowability, prevents blockages in silos, and allows for pneumatic conveying. |

I want to start a business processing fly ash. However, investing in equipment without a comprehensive plan is a significant financial risk.

A successful project requires a systematic evaluation. This includes a source assessment (quality, quantity), market analysis (demand, pricing), a detailed process design based on the raw ash properties, and a complete financial feasibility study.

Launching a Fly Ash Utilization project is a multi-stage process that begins long before any equipment is purchased. The first step is a technical and logistical assessment of the raw ash source: How many tons are available annually? What is its typical quality and variability? Is there a long-term supply contract available? The second step is a thorough market analysis: Who are the potential customers (concrete plants, construction companies)? What are their quality requirements? What price will the market support? Only after answering these questions can the process engineering begin. A process flowsheet is designed to transform the available raw ash into the product the market demands. Finally, all of this data is used to create a detailed financial model to calculate the capital investment, operating costs, and projected return on investment.

| Evaluation Stage | Key Questions to Answer | Necessary Actions |

|---|---|---|

| Source Assessment | What is the annual volume? What is the average quality and consistency? | Obtain historical test data from the power plant. Conduct independent lab testing. |

| Market Analysis | Who will buy the product? What are the quality specifications and target price? | Survey local concrete producers and construction firms. Analyze competing material prices. |

| Process Engineering | What pre-treatment is required? What equipment is needed? | Develop a Process Flow Diagram (PFD). Obtain equipment quotes from suppliers like ZONEDING. |

| Economic Feasibility | What is the required CAPEX and OPEX? What is the project’s ROI and payback period? | Create a detailed financial model incorporating all costs and revenue projections. |

Fly ash is an engineered material with significant economic value. Its successful use requires technical evaluation, process control, and a clear understanding of market demands to ensure profitability.

Want to maximize gold recovery? These 3 machines are essential. Learn about the shaking table, spiral concentrator, and jig for efficient gravity separation.

View detailsTungsten is a strategic metal characterized by its extreme density and brittleness, often described in mineral processing as "heavy as iron but fragile as glass." The successful extraction of this metal depends entirely on correctly identifying t...

View detailsDiscover critical factors in steel ball configuration impacting your gold ball mill's performance. Improve grind size, throughput, and energy efficiency today.

View detailsGet a complete list of essential equipment required for a successful gold ore beneficiation plant. Understand the machinery needed for efficient gold recovery.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy