Limestone Crushing Plant Blueprint: Design a Profitable Line

3503Design a cost-effective limestone crushing plant. Our guide focuses on optimizing equipment configuration and flowcharts to boost yield and lower costs.

View detailsSearch the whole station Crushing Equipment

Your tailings pond is a costly liability. It takes up land, wastes water, and poses an environmental risk. You are paying to manage waste when you could be selling recovered products.

The solution is a modern dewatering system. By choosing the right equipment, such as a thickener, dewatering screen, or filter press based on your specific material, you can turn wet waste into dry, manageable solids and recycle over 90% of your water.

Dewatering is the process of removing water from a slurry of solids. For any mining or sand washing operation, it is a critical step. It ensures site stability, improves safety, and allows your operation to continue. But more importantly, it is your path to lower costs and higher profits. Let’s explore how to choose the right tools for this job.

Settling ponds seem simple and cheap. Just dig a hole and pump the slurry in. But this outdated method is one of the most expensive mistakes a modern operation can make.

Settling ponds are inefficient, unsafe, and occupy vast amounts of valuable land. They lose huge amounts of water to evaporation and pose a constant risk of dam failure, while trapping valuable fine sand as unrecoverable waste.

I have walked the perimeter of countless tailings ponds. They are liabilities waiting to happen. First, they require an enormous footprint. That is land you could be using for expansion or other productive means. Second, you lose a massive amount of water to evaporation, which means you have to constantly source and pay for fresh water. Third, and most critically, they are a safety and environmental risk. A dam breach can be catastrophic. Finally, all the valuable fine material that gets washed away settles at the bottom of that pond forever. You are literally burying profit. Modern Dewatering Equipment solves all of these problems on a fraction of the land.

| Feature | Settling Pond | Mechanical Dewatering System |

|---|---|---|

| Land Use | Extremely High | Very Low |

| Water Recovery | Low (High Evaporation) | High (>90%) |

| Safety | High Risk (Dam Failure) | Low Risk |

| Fine Sand Recovery | Almost None | High (Can recover valuable fines) |

| Operational Control | Poor | Precise and Immediate |

Your slurry looks like mud. But the size and nature of the solid particles within that mud determine everything. Choosing the wrong machine for your specific slurry is like using a fishing net to catch dust.

First, use a High Efficiency Concentrator (thickener) for all types. Then, for coarse sand or tailings, use a Dewatering Screen. For very fine clay or silt that is hard to dewater, you need a Filter Press for the final stage.

Every material requires a specialist. A sand and gravel operation’s primary goal is to dewater the finished sand product and recover any lost fines. A hard rock mine needs to handle massive volumes of fine-grained tailings safely. A construction site needs to deal with sticky clay-based slurry.

For a Sand Washing Plant, the main challenge is losing valuable fine sand into the wastewater. A Fine Sand Recovery Machine is the perfect solution. It is specifically designed to capture and dewater these fines, increasing your product yield.

For Mine Tailings, the goal is usually a combination of water recovery and creating a stackable, dry solid for backfill or safe storage. A system using a High Efficiency Concentrator followed by a Dewatering Screen is often the most cost-effective for high volumes.

For Construction Silt or Clay, the particles are extremely fine and hold water tightly. After initial thickening, a Filter Press is often required to squeeze out the remaining water and produce a very dry, solid cake.

You need dry material. But how dry? And at what cost? This is the core trade-off between the two main types of final dewatering equipment. One is fast and continuous; the other is slow and powerful.

A Dewatering Screen is a high-capacity, low-cost machine that produces a stackable, drip-free product. A Filter Press achieves the driest possible cake but has a higher capital and operational cost and works in batches.

A Dewatering Screen is a workhorse. It uses high-frequency vibration to force water through a polyurethane screen panel. The final product is typically around 15-20% moisture content. It is not bone-dry, but it is stackable, conveyable, and will not drip water. This is perfect for most aggregate and coarse tailings applications. Its key advantages are high throughput, continuous operation, and low operating costs.

A Filter Press, on the other hand, is a specialist for difficult jobs. It pumps slurry into a series of chambers lined with filter cloths and uses high pressure to squeeze the water out. The result is a solid “cake” with moisture content as low as 10-15%. This is the best choice when you need the driest possible solid, or when dealing with very fine particles that a screen cannot handle. However, it is a batch process, which means it has lower continuous throughput and higher maintenance costs.

| Feature | Dewatering Screen | Filter Press |

|---|---|---|

| Final Moisture | 15-20% (Stackable) | 10-15% (Solid Cake) |

| Capacity | High, Continuous | Lower, Batch Process |

| Capital Cost | Lower | Higher |

| Operating Cost | Low | High (Filter cloths, maintenance) |

| Best For | Sand, Coarse Tailings | Fine Silt, Clay, Difficult Sludge |

That cloudy water flowing out of your sand washer is not just wastewater. It is full of money. Every fine particle of sand that washes away is a saleable product you are losing.

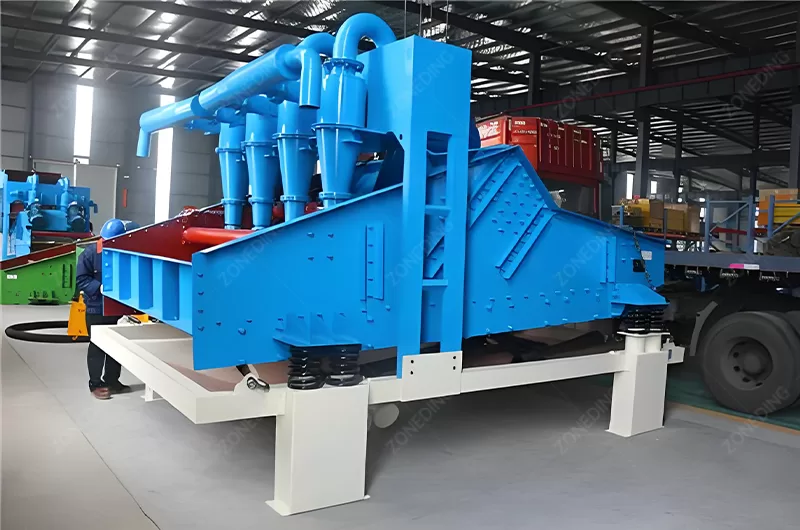

You recover valuable fines using a Fine Sand Recovery Machine. This single unit combines a hydrocyclone with a dewatering screen. It can recover over 90% of the lost fines, increasing your total sand output by 10-15%.

This is the definition of turning waste into treasure. The process is simple and brilliant. Your slurry (water mixed with fine sand) is pumped into a Hydrocyclone. The centrifugal force inside the cyclone separates the heavier sand particles from the water. The sand exits the bottom of the cyclone (the underflow) as a thick slurry and drops directly onto a dewatering screen. The screen vibrates the water out, producing a dry, saleable fine sand product. The wastewater exits the top of the cyclone (the overflow) and can be recycled back to your wash plant. A Fine Sand Recovery Machine is one of the best investments a sand producer can make. It often pays for itself in just a few months by increasing your product yield and reducing the amount of sludge you need to manage.

You understand the components. But how do they fit together? A proper solution is a complete, integrated system, not just one machine.

A complete system typically includes a slurry pump, a High Efficiency Concentrator (thickener) for initial water removal, and a final dewatering unit (screen or filter press). The investment depends on capacity and final dryness requirements.

Here is how a typical system for Tailings Dewatering works:

You have successfully separated your slurry. You have a pile of dry material and a tank of water. What can you do with them? This is where the real value is realized.

The dewatered solids can be sold, used as mine backfill, or for making bricks. The recovered water is typically over 90% clean and can be immediately reused in your plant, creating a closed-loop system that saves money and meets environmental regulations.

The goal of Tailings Dry Stacking is to create value from both outputs.

The Solids:

You have seen the options, but every slurry is unique. Its particle size, mineralogy, and clay content are different. A standard solution is a guess. You need a guaranteed outcome.

The only way to be certain is with a professional lab test. We analyze a sample of your slurry to determine its exact properties. Based on this data, we design a custom-fit solution with a performance guarantee, so you can invest with confidence.

This is how you move from a problem to a solution without risk. Here is our process:

Stop thinking of tailings and sludge as waste. With the right dewatering equipment, they are sources of profit and recycled water. It is time to drain your costly ponds and invest in a modern, efficient solution.

Design a cost-effective limestone crushing plant. Our guide focuses on optimizing equipment configuration and flowcharts to boost yield and lower costs.

View detailsThis expert guide details the process of gold gravity beneficiation, helping you optimize equipment settings and techniques for maximum recovery.

View detailsTroubleshoot & resolve breakage issues in four critical ball mill parts during operation. Our guide provides solutions to keep your mill running efficiently.

View detailsBoost quartz purity and recovery. This step-by-step guide explains how to implement and optimize the gravity-magnetic combined process for maximum efficiency.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy