Gold Cyanidation: From Process Types to Plant Construction

3700Your ultimate guide to gold cyanidation. Explore CIL/CIP types, detailed processes, and the complete steps for successful plant construction and optimization.

View detailsSearch the whole station Crushing Equipment

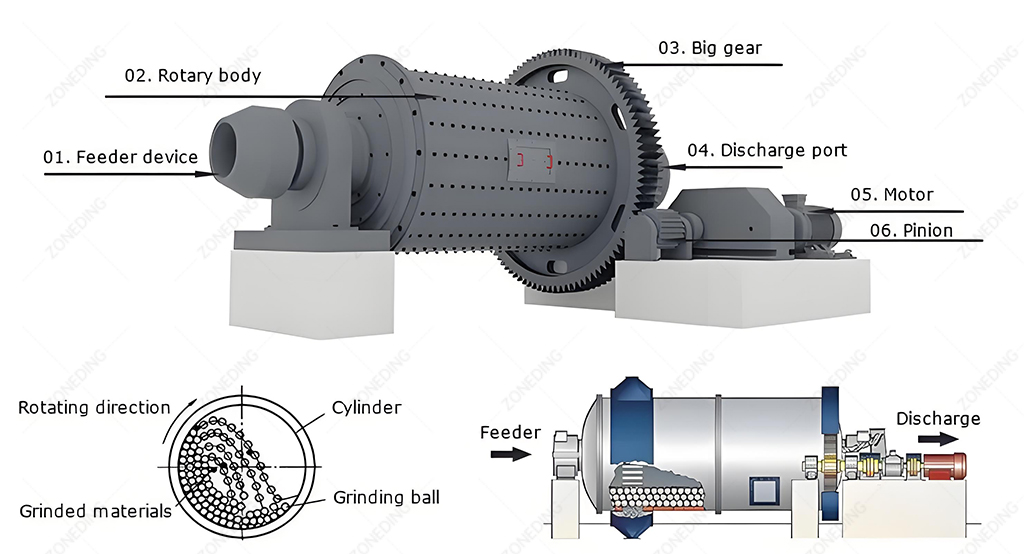

The Ball Mill is the heart of mineral processing. Its continuous, stable operation is crucial for the entire production line’s efficiency. Even with modern design and manufacturing, wear and unexpected damage to key components are unavoidable. Properly addressing these failures involves more than just replacing parts. It requires understanding their root causes. It also demands prediction, prevention, and optimization. This maximizes equipment uptime and minimizes production costs.

This guide offers practical strategies for four common Ball Mill Part Breakage scenarios. These insights will help you solve real-world production challenges.

Liner plates directly contact ore and grinding media in the Ball Mill. Wear is inevitable. However, abnormal wear or Ball Mill Liner Breakage signals deeper issues. Handling these incidents properly is essential. It prevents further damage and maintains Crushing Efficiency.

The condition of the liners reveals much about the mill’s operation. Ignoring these signs can lead to costly repairs. It also causes significant downtime. Proper diagnosis and preventive action are key for Ball Mill Maintenance.

Liner wear patterns offer clues to mill operation. Localized pitting or grooving, instead of uniform wear, suggests an imbalanced ball charge. The mill load might be too low. This leads to direct ball impact instead of proper layered grinding. Ball Mill Liner Breakage near bolt holes often indicates insufficient bolt preload or uneven installation. Many facilities focus only on when to replace liners. Purchasing decisions frequently overlook wear cause analysis, focusing solely on hardness rather than toughness. The outcome is brittle liners highly susceptible to impact breakage.

Liners do more than protect the shell. They regulate grinding efficiency. Their material and shape (lifting bars, corrugated, smooth) directly influence ball trajectories. They also affect impact and grinding actions. Abnormal wear silently points to an unsuitable grinding environment.

Preventive maintenance, like regular inspection and optimizing ball charge, costs less. It is cheaper than emergency replacement and shell repair. Selecting liners with a long life and uniform wear significantly lowers the grinding cost per ton of ore. This is a key aspect of improving Mill Liner Life.

Grinding media, primarily steel balls, are crucial for effective grinding in the Ball Mill. Abnormal wear or Ball Mill Steel Ball Breakage significantly impacts grinding efficiency. It increases operating costs. Addressing these issues correctly is vital for maintaining consistent production. It also ensures the overall Equipment Reliability.

It is not enough to just add more steel balls. Understanding the underlying causes of their degradation is key. This knowledge allows for proactive measures. It optimizes the Grinding Media Consumption and performance.

Over 90% of severe grinding media issues stem not from the balls’ inherent quality, but from operational factors. Abnormal wear, like flattening or spalling, often suggests incorrect ball size, unsuitable material for the ore, or improper pulp conditions. Breakage points to poor quality balls (with internal defects) or severe impact conditions. These severe impact conditions could be caused by tramp material or very low pulp levels.

Many operations simply add new balls without analyzing wear patterns. They might use cheap, low-quality media. This seems cost-effective upfront. But it leads to higher overall Grinding Media Consumption. It also causes inefficient grinding and potential mill damage. Grinding media acts as the “cutting tool” of the mill. Its condition directly reflects the effectiveness of the grinding process.

High-quality grinding media, though initially more expensive, often results in lower per-ton grinding costs. This is due to longer lifespan and better efficiency. Poor quality media leads to higher consumption, frequent additions, and potential damage to liners. These strategies are essential for effective Ball Mill Maintenance and reducing Downtime Reduction.

Bearings support the rotation of the Ball Mill. They are critical components. Their failure can lead to severe operational issues, including prolonged shutdowns or even main shaft damage. Addressing Ball Mill Main Bearing Failure swiftly and effectively is paramount. It ensures the longevity and Equipment Reliability of the mill.

A bearing failure is rarely an isolated event. It often points to systemic issues. These issues can be lubrication problems, improper installation, or shaft misalignment. Proactive monitoring and precise maintenance are crucial.

Ball Mill Main Bearing Failure or damage is often preventable. Lubrication issues are common. But over 80% of failures relate to overload, improper installation (especially of taper sleeves), shaft misalignment, or oil seal failure allowing contaminants. An abnormal rise in bearing temperature is the clearest early warning sign of impending failure. Many operators overlook daily monitoring of bearing temperature, vibration, and noise. Incorrect installation during bearing replacement is a frequent cause of new bearing failures. For example, using force instead of proper tools.

Bearings are like the “joints” of the ball mill. Their health directly reflects the machine’s “blood circulation” (lubrication) and “skeletal structure” (alignment). Any “joint dislocation” or “blood shortage” leads to severe consequences.

Bearings are precision components and expensive. More importantly, bearing failure can damage shaft journals or bearing housings. This multiplies repair costs. Investing in predictive maintenance, like oil analysis, monitoring equipment, and professional training, is highly cost-effective. These are essential parts of Preventive Maintenance and minimizing Downtime Reduction.

The large girth gear and small pinion are critical to the Ball Mill‘s drive system. Their failure is often catastrophic. It can lead to complete operational halts. Addressing Ball Mill Gear Breakage requires quick action and thorough investigation. This is crucial for maintaining Equipment Reliability.

Such failures are seldom sudden. They usually result from accumulated issues. These issues include poor installation, lubrication problems, or foundation instability. Understanding these root causes is vital for effective Ball Mill Troubleshooting.

Over 90% of gear breakages or abnormal wear are not due to inherent gear quality. They are caused by installation accuracy, poor lubrication, foundation settlement, or prolonged overload. Early wear signs, such as pitting, spalling, or scuffing on gear surfaces, are clear indicators. These occur long before actual tooth breakage. Many facilities neglect daily lubrication, foundation settlement monitoring, and regular checks of gear mesh conditions.

Gears are like human “joints.” They need precise alignment and continuous lubrication for smooth operation. Any “joint dislocation” or “lack of blood” leads to severe consequences.

Replacing a set of girth gears and pinions is extremely costly. It often involves weeks of downtime. The investment in regular lubrication and alignment checks is minimal compared to avoiding catastrophic failure. These are crucial steps for Preventive Maintenance and ensuring high Equipment Reliability.

My 50 years of experience tell me Ball Mill Troubleshooting is not just reactive “firefighting.” It is a comprehensive management art. It involves equipment knowledge, mineralogy, operational procedures, maintenance management, and data analysis. Treat each part failure as an opportunity to learn and optimize. Dig deep into the root causes. Adopt systemic preventive measures. This will truly enhance the Ball Mill‘s operating efficiency and lifespan. It will bring sustained value to your mining operation.

To maximize your investment, prioritize dynamic assessment of liner wear. Ensure optimal grinding media composition. Implement robust bearing lubrication and monitoring. Conduct precise gear alignment and regular foundation checks. Embrace data-driven monitoring for continuous optimization. These steps ensure peak performance and profitability for your Mining Equipment.

ZONEDING has been a leader in mineral processing since 2004. We provide a full range of Crushing Equipment and Beneficiation Equipment and solutions. We serve clients worldwide. ZONEDING specializes in customized crushing solutions. Our machines are recognized for reliability, efficiency, and top performance. We offer full-process support. This covers design, manufacturing, installation, and after-sales service. ZONEDING assists in achieving superior production value. This ensures a successful investment.

Contact us today. Our experts can assist in designing or optimizing any Crushing Production Line. Maximize your mineral value with ZONEDING’s proven technology and experience.

Your ultimate guide to gold cyanidation. Explore CIL/CIP types, detailed processes, and the complete steps for successful plant construction and optimization.

View detailsGain critical insights into hydraulic cone crushers. Understand principle and key features to make informed decisions for aggregate or mining applications.

View detailsWhat's the difference? Extraction equipment handles raw mining. Ore dressing (beneficiation) equipment refines the ore. Discover their unique functions.

View detailsOur complete guide walks you through the process of iron removal from kaolin clay. Boost whiteness and quality for industrial applications like ceramics.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy