Selecting Efficient Gold Tailings Dewatering Equipment

3747Discover the main types of antimony ore, like stibnite, and learn the key ore dressing methods used for extraction, including flotation and gravity separation.

View detailsSearch the whole station Crushing Equipment

The terms “mining equipment” and “ore dressing equipment” describe machinery used in mineral production. Confusion between these two categories can lead to poor planning and operational inefficiencies. A clear understanding of their roles is necessary for effective management.

The fundamental difference lies in their function: mining extraction equipment gets rock out of the ground, while ore dressing equipment separates valuable minerals from that rock. These are two distinct operational stages with different objectives, technologies, and locations.

Clarifying this division helps in understanding the production chain. This process transforms a large volume of low-value rock into a small volume of high-value product. This article outlines the journey from the mine pit to the final concentrate, detailing the purpose and machinery of each stage.

A mining operation includes both large mobile machines and a complex stationary plant. Although the process appears continuous, there is a distinct physical boundary separating these two functions.

The dividing line is the primary crusher located at the entrance of the processing plant. All activities before this point are classified as mining extraction. All activities after this point are classified as ore dressing, which begins with the preparation stage.

This handover point signifies a change in operational goals. The objective shifts from moving large quantities of material to the precise separation of minerals from waste rock, known as gangue.

The process can be understood as a sequence with a clear transition point.

Large-scale mining operations use machines like shovels and haul trucks capable of moving immense quantities of rock. These machines are designed for a specific, high-volume purpose.

Mining extraction equipment includes excavators, drill rigs, and haul trucks. Its core objective is to move the maximum volume of rock from the mine to the processing plant at the lowest possible cost per ton.

These machines provide the high-volume material movement for the operation. Their performance is measured in tonnes per hour. They are engineered to break and transport solid rock.

The design philosophy for this equipment prioritizes power and durability.

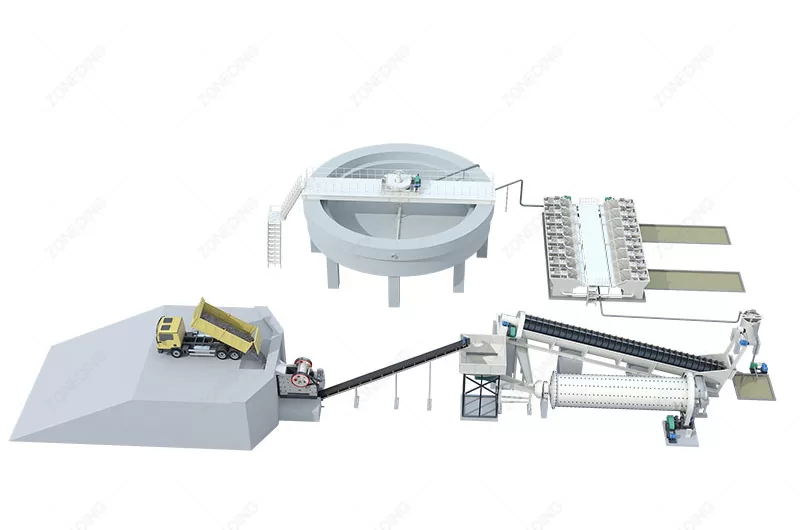

Inside the processing plant, the machinery consists of rotating drums, tanks, and extensive piping. This equipment is visibly different from the mobile machines outside and serves a much more complex function.

Ore dressing equipment’s objective is to upgrade the ore by separating valuable minerals from waste rock (gangue). This increases mineral grade, removes harmful impurities, and reduces final transport costs for the saleable product.

This equipment performs the scientific process of mineral separation, which is essential for making the mining operation economically viable. The entire process involves several interconnected stages.

The ore dressing process is a multi-step operation with several key purposes: to increase the grade of the concentrate, reduce transportation costs by eliminating waste, and remove elements that could be harmful to downstream smelting processes. This is achieved in three main stages:

The contrast between these two categories of equipment is stark. They operate in different environments, handle different materials, and are based on completely different scientific principles. This is not just a small difference; it is a fundamental divide.

Mining equipment works “dry” in the open pit, handling massive rocks. Ore dressing equipment works “wet” inside a plant, handling a fine-particle slurry. One uses mechanical force for extraction, the other uses physical and chemical principles for separation.

Understanding these core differences is essential for anyone involved in purchasing, operating, or investing in mining machinery. They are two different worlds.

The key distinctions are summarized below.

| Attribute | Mining Extraction Equipment | Ore Dressing Equipment (Mineral processing equipment) |

|---|---|---|

| Location | In the pit or underground (outdoor) | Inside a building (indoor plant) |

| Objective | Move maximum tonnes (Quantity) | Increase mineral grade & recovery (Quality) |

| Product | Run-of-mine ore (Low-value rock) | Concentrate and Tailings |

| Material Handled | Massive, solid rock boulders | Fine particle slurry (rock + water) |

| Key Principle | Brute force, logistics, impact resistance | Liberation, separation, dewatering |

| Typical Machines | Excavators, Haul Trucks, Drills | Crushers, Ball Mills, Flotation Machines, Thickeners |

This table illustrates that these are two different categories of machinery with unique operational requirements and design criteria.

The material transfer from the mine to the plant occurs at a specific, critical point. This is where operational responsibility shifts from the mine manager to the plant manager.

The handover happens when haul trucks dump the Run-of-Mine (ROM) ore into the feed hopper of the primary crusher. This crusher is the first piece of equipment in the ore dressing preparation stage and the gateway to the entire processing plant.

This step connects the two stages of the operation. The ore stockpile between the crusher and the rest of the plant acts as a buffer, linking the intermittent nature of mining with the continuous operation of the plant.

The material handover process follows a clear logistical path.

The objectives of the mining stage and the processing stage can sometimes be in conflict. A decision in the mine to increase throughput can create significant problems and costs for the plant.

Mining efficiency affects ore dressing costs because the size of the rock from the mine determines the energy consumption and wear rates in the plant. Sending larger rock to the plant forces the crushers and mills to expend more energy and consume more wear parts, increasing operational costs.

This operational conflict highlights the need for integrated management. A decision made at the mining stage to reduce its own costs can increase total production costs for the entire operation. An effective operation manages the process as a single, unified system.

This operational link can be illustrated with an example:

A mining company’s financial documents will show significant capital expenditure for equipment. Correctly classifying these assets is important for understanding the business’s operational and financial structure.

Mining extraction equipment is budgeted as a “fleet” of independent mobile units. Ore dressing equipment is budgeted as a single, interconnected “system” or circuit. The former has operational redundancy, while the latter is a highly integrated system where the failure of one component can stop the entire process.

This distinction influences capital planning, maintenance strategies, and risk assessment. They represent different types of equipment investment.

Mining extraction equipment performs the function of moving rock. Ore dressing equipment performs the function of extracting value from that rock. They are two distinct categories with different objectives, equipment, and operational principles. Understanding this fundamental difference is essential for comprehending the mining industry.

Discover the main types of antimony ore, like stibnite, and learn the key ore dressing methods used for extraction, including flotation and gravity separation.

View detailsThis guide details the dolomite processing steps: from extraction and crushing to calcination. Learn the methods that unlock its value in various industries.

View detailsTroubleshoot & resolve breakage issues in four critical ball mill parts during operation. Our guide provides solutions to keep your mill running efficiently.

View detailsMany mine operators invest heavily in advanced gold gravity concentrators, only to find that valuable fine gold is still escaping with the tailings. Maximizing the gold recovery rate is not about buying the machine with the highest...

View details