What is a Ball Mill and How Does It Work?

4030Get an understanding of what a ball mill is, its fundamental components, and the detailed mechanism behind its efficient grinding process for various materials.

View detailsSearch the whole station Crushing Equipment

The lithium rush has many treating lithium ore like any other base metal. This common assumption is a fast path to financial disaster and operational failure.

The type of lithium ore, whether spodumene or lepidolite, dictates the entire processing flowsheet and equipment selection. This is due to fundamental differences in mineralogy, liberation characteristics, and associated impurities, which make a one-size-fits-all approach impossible for a successful Lithium Ore Processing Plant.

For over fifty years, I have seen that those who survive commodity cycles are the ones who respect the unique personality of their ore. Lithium is sensitive and demands a custom-tailored approach. This guide provides the ground truth on selecting the right lithium ore processing equipment.

Before you even think about a single machine, you must conduct a detailed process mineralogy study. This is the single most important step. It’s like a doctor performing a full diagnosis before prescribing medicine. A simple chemical assay tells you how much lithium is in your rock. A mineralogy study tells you how it exists, which is far more important.

This study answers critical questions that dictate your entire flowsheet:

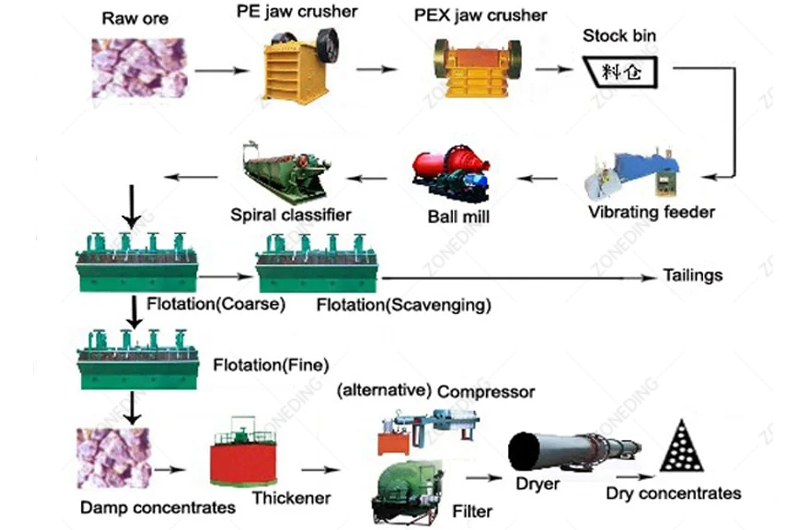

Spodumene is the most common hard-rock source of lithium. However, it presents a key challenge: its specific gravity (~3.2 g/cm³) is very close to that of quartz and feldspar (~2.6 g/cm³), its main companion minerals. This makes simple gravity separation ineffective. A typical high-performance spodumene processing flowsheet involves several key stages.

The goal is to reject as much waste as possible, as early as possible.

Lepidolite is a lithium-bearing mica. Its physical properties are completely different from spodumene, so the lepidolite processing flowsheet is also different.

The primary challenge with lepidolite is its flaky, plate-like shape. This makes it prone to creating slimes during grinding.

The goal of the crushing and grinding circuit is to reduce the ore size just enough to liberate the valuable lithium minerals from the waste rock. The motto is “liberate, don’t obliterate.” Over-grinding creates slimes, which leads to poor recovery and high reagent costs.

Your equipment choice depends on the ore’s hardness and the target liberation size determined by your mineralogy study.

| Equipment Type | Stage | Purpose | Why We Use It |

|---|---|---|---|

| Jaw Crusher | Primary Crushing | Breaks very large Run-of-Mine ore into a manageable size (-150mm). | Handles the largest, toughest rocks directly from the mine. A must-have first step. |

| Cone Crusher | Secondary/Tertiary Crushing | Reduces the ore size further (-15mm) in preparation for grinding or DMS. | Efficiently handles hard, abrasive ores. Settings can be adjusted for precise size control. |

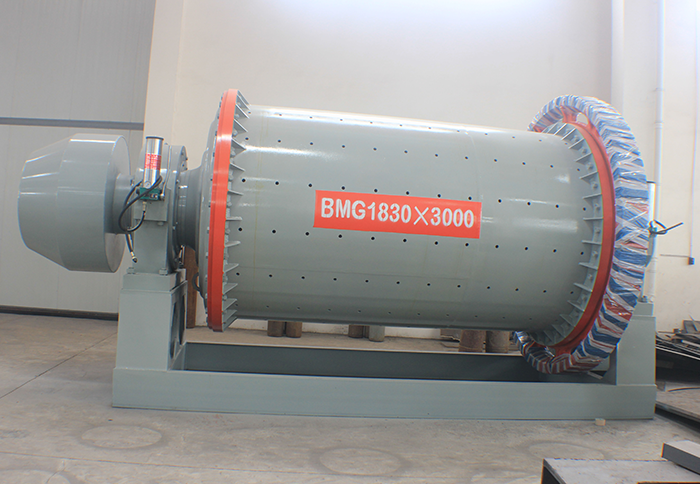

| Ball Mill | Grinding | Grinds the crushed ore with water to a fine powder (e.g., -150 microns) for flotation. | A robust and reliable machine for fine grinding. Used in closed circuit with cyclones to prevent over-grinding. |

For friable (brittle) ores like spodumene, consider a two-stage grinding circuit. A rod mill followed by a ball mill can minimize the generation of fines. High-Pressure Grinding Rolls (HPGRs) are also an excellent, though higher-CAPEX, option for this reason.

Flotation is the heart of most lithium ore processing equipment setups. The choice here isn’t just about the machine itself, but also about getting the total volume right.

Your beneficiation test will tell you the required residence time—how long the ore slurry needs to be in the flotation cells for the separation to occur. You calculate the required total volume like this:

Total Volume (m³) = [Plant Throughput (m³/hour)] x [Required Residence Time (hours)]

This total volume is then divided among a series of flotation cells. This series is split into “Rougher,” “Cleaner,” and “Scavenger” banks, each performing a different role to maximize both recovery and final concentrate grade. The physical machine type (e.g., self-aspirating or forced-air) is then selected based on the specific aeration and agitation needs of your ore and reagent scheme.

These are specialized tools used to solve specific problems.

If mineralogy is the diagnosis, then the beneficiation test is the detailed treatment plan. A full-scale lab test on a representative ore sample (a few hundred kilograms) provides the hard data needed to finalize your equipment list.

The test report will give you:

When evaluating equipment proposals, the cheapest option is rarely the best. You must consider the total cost of ownership.

The path to a successful lithium processing plant is paved with data. It begins with a deep understanding of your ore’s specific characteristics and ends with equipment selected to execute a process validated by thorough testing. There are no shortcuts.

At ZONEDING, we specialize in turning geological data into profitable operations. With over two decades of experience, we don’t just sell machines; we provide complete, customized solutions for lithium ore processing plants. We can guide you through the entire process, from initial beneficiation testing to the final equipment commissioning.

If you are planning a lithium project, don’t leave your success to chance. Contact our team of engineers today to discuss your ore and let us help you design a plant that is robust, efficient, and profitable.

Get an understanding of what a ball mill is, its fundamental components, and the detailed mechanism behind its efficient grinding process for various materials.

View detailsIn the gold mining industry, carbonaceous gold ore is known as the "Silent Thief." High gold grades may appear in geological reports, yet recovery rates can plummet below 30% due to the dreaded preg-robbing effect. The natural organic carbon in t...

View detailsDiscover what iron ore is, how it's mined, and why it's the critical backbone of the global economy. Learn how it's transformed into steel for everything.

View detailsSelecting the correct manganese beneficiation method is the most critical decision in plant design. The choice between Gravity Separation and Magnetic Separation is determined strictly by the ore's mineralogy, specifically density and magnetic pr...

View details