Search the whole station Crushing Equipment

Hydrocyclone is a device that classifies materials according to grain size and uses centrifugal force to increase the precipitation rate of particles.

A hydrocyclone, also known as a cyclone separator, is a static device that uses centrifugal force to separate particles from a liquid stream based on their size, density, and shape. Hydrocyclones do not have moving parts.

Hydrocyclones are simple. Hydrocyclones are reliable. Hydrocyclones are cost-effective. That is why hydrocyclones are widely used for solid-liquid separation, mineral processing, and wastewater treatment.

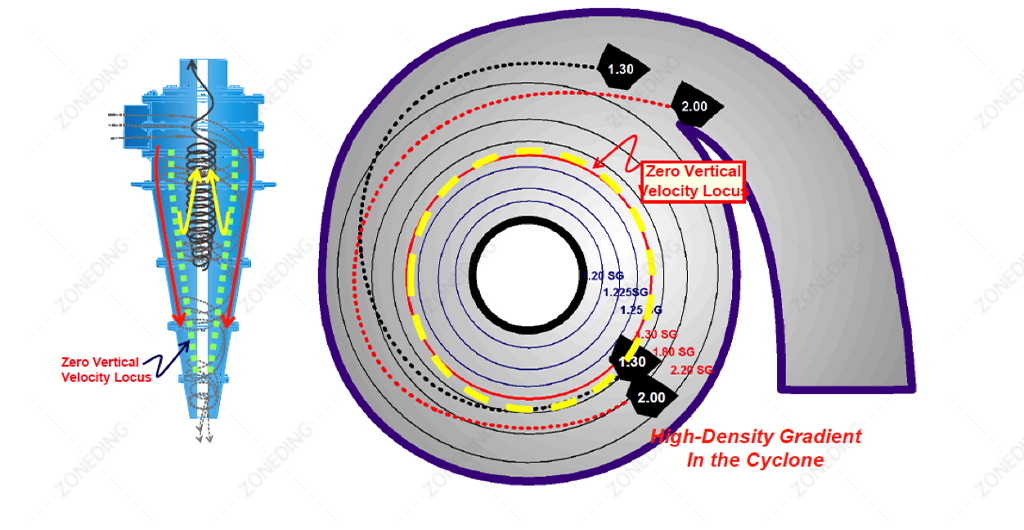

A hydrocyclone is a static separation device with no moving parts that utilizes fluid pressure to classify or separate particles within a liquid slurry. The process begins when slurry is pumped tangentially at high velocity into the cylindrical upper section, creating a powerful primary vortex.

The immense centrifugal force generated by this vortex throws heavier, denser, or coarser particles toward the inner wall. These solids spiral down the conical section and discharge through a narrow opening at the bottom, known as the apex, forming a concentrated stream called the underflow. Meanwhile, a low-pressure core in the center of the cyclone causes most of the liquid and the lighter, finer particles to reverse direction, forming an inner vortex. This secondary vortex travels upward and exits through a central pipe at the top, the vortex finder, as a more dilute stream known as the overflow. This elegant and efficient design makes the hydrocyclone an indispensable tool for separation and classification in industries such as mining, oil and gas, and wastewater treatment due to its simplicity, low cost, and high throughput.

Hydrocyclones come in various designs, including liquid-liquid hydrocyclones, solid-liquid hydrocyclones, and multi-hydrocyclone systems. The right type depends on the application.

Consider these types when selecting a hydrocyclone:

At ZONEDING, our engineers analyze your specific slurry and process goals to select the perfect Hydrocyclonnes.

The hydrocyclone work principle involves injecting a slurry tangentially into a cone-shaped vessel. The resulting centrifugal force separates particles, with heavier particles moving to the wall and exiting through the apex (underflow), while lighter particles exit through the vortex finder (overflow).

Here is a breakdown of how a hydro cyclone works:

Hydrocyclones are used for various applications, including mineral processing, wastewater treatment, oil and gas production, and chemical processing. The hydrocyclone application depends on the type of materials being separated.

Here are some key hydrocyclone applications:

Key features of a hydrocyclone include its simple design, high capacity, low operating costs, and ability to handle abrasive materials. These features make hydrocyclones a popular choice for separation tasks.

Some notable hydrocyclone features:

The key advantages of using sand cyclones include efficient sand removal, compact design, low maintenance, and continuous operation. A sand cyclone is effective at removing sand and grit from liquids.

Here are some benefits of using sand cyclone:

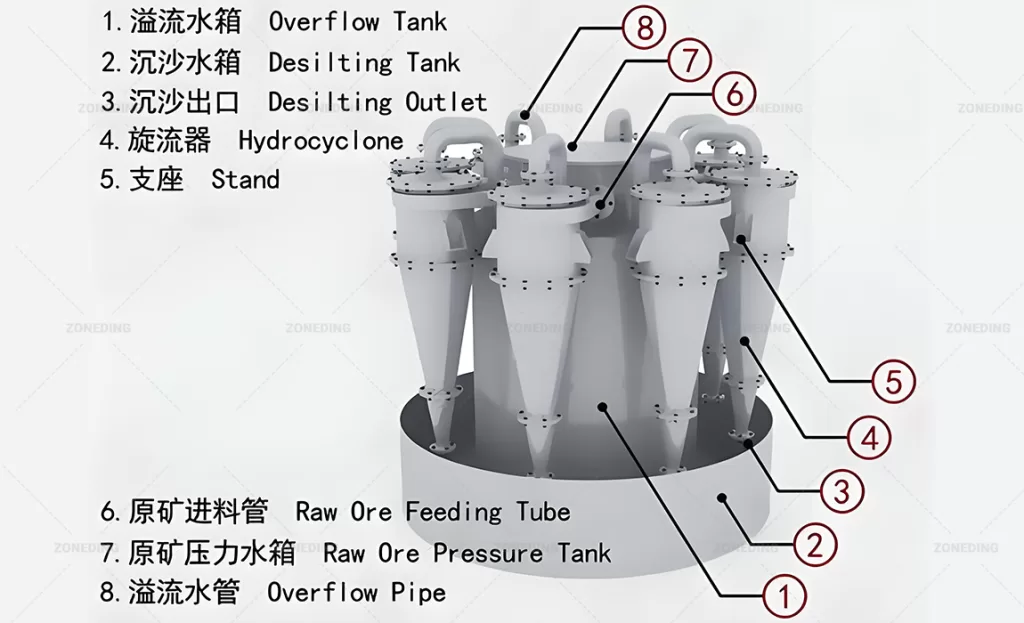

The key components of a hydrocyclone sand separator include the feed inlet, vortex finder, cyclone body, apex (underflow orifice), and overflow outlet. These components work together to achieve efficient separation.

The hydrocyclone structure consists of:

The efficiency of hydrocyclone is determined by its ability to accurately separate particles based on size and density. Factors like feed pressure, solids concentration, and hydrocyclone design influence efficiency.

The hydrocyclone efficiency depends on:

| Model | Diameter(mm) | Height(mm) | Feeding pressure(Mpa) | Separation size(μm) | Weight(kg) |

| JAX-75 | 75 | 472.5 | 0.1-0.5 | 20-60 | 4 |

| JAX-100 | 100 | 499 | 0.05-0.4 | 20-60 | 8 |

| JAX-125 | 125 | 590 | 0.05-0.4 | 25-65 | 10 |

| JAX-150 | 150 | 786 | 0.05-0.4 | 30-75 | 22 |

| JAX-200 | 200 | 1114 | 0.05-0.4 | 40-100 | 36 |

| JAX-250 | 250 | 1380 | 0.05-0.4 | 40-100 | 63 |

| JAX-300 | 300 | 1490 | 0.03-0.4 | 50-150 | 88 |

| JAX-350 | 350 | 1674 | 0.03-0.4 | 50-150 | 135 |

| JAX-500 | 500 | 2280 | 0.03-0.4 | 74-200 | 416 |

| JAX-660 | 660 | 2720 | 0.03-0.4 | 74-200 | 950 |

The hydrocyclone price varies depending on the size, material, and design. A simple cyclonic separation system can cost a few thousand dollars, while larger, more complex systems can cost tens of thousands.

Factors influencing hydrocyclone price:

Choose a water cyclone separator from ZONEDING for reliable performance, durable construction, and customized solutions. We offer a range of hydrocyclones designed for various applications.

ZONEDING’s water cyclone separator offers:

Factors affecting cyclone separation performance include feed flow rate, feed solids concentration, particle size distribution, and operating pressure. Optimizing these factors is crucial for maximizing efficiency.

Key factors influencing performance:

Choosing the right hydrocyclone filter involves considering the specific application, flow rate, particle size, and desired separation efficiency. Matching the filter to the requirements ensures optimal performance.

Consider these factors when choosing a hydrocyclone filter:

Common issues encountered with cyclone water include plugging, roping (unstable underflow), excessive wear, and reduced separation efficiency. Regular monitoring and maintenance can prevent these issues.

Potential problems with cyclone water systems:

Maintenance requirements for hydrocyclones include regular inspection for wear and plugging, cleaning of the feed inlet and apex, and replacement of worn liners. Proper maintenance extends the life of the hydrocyclone and ensures optimal performance.

Essential maintenance tasks:

Your reliable source for high-capacity, heavy-duty ball mills engineered for mining, cement, and fine powder processing.

Zongding Machinery provides advanced ball mills and mineral processing equipment to help mining companies around the world process minerals more efficiently.

the best Ceramic Ball Mill manufacturers and their competitive prices. Our selection offers top-quality mills for various applications at affordable costs.

Efficient flotation machine for mineral processing at competitive prices. Maximum recovery and optimal grade for your mining operations.

A magnetic separator is a device that separates magnetic minerals from nonmagnetic minerals by applying a magnetic field.

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

“Optimize mineral processing with our high-efficiency Jigging Separator Machine! Ideal for gold, tin, coltan separation.

Gold Mine Wet pan mill applys in the gold mining industry and is one of the indispensable equipment in the modern gold mining industry. In addition, it can also apply for mining and processing other non-ferrous metals and precious metal ore…

Shaking tables for gold recovery, mineral processing at great prices. Learn more about our gold shaking table, prices, and processing today.

High efficiency concentrator is suitable to dewater concentrate and tailings in concentrator plant. Concentrate Thickener definition: Thickener (also known as thickener or agitator) is suitable for concentra…

loading…

已经是到最后一篇内容了!