Search the whole station Crushing Equipment

High efficiency concentrator is suitable to dewater concentrate and tailings in concentrator plant.

Concentrate Thickener definition:

Thickener (also known as thickener or agitator) is suitable for concentrate and tailings dehydration treatment during the beneficiation process to increase the slurry concentration from 20-30% to 40-70%.

It is of great significance to improve the utilization rate of backwater, the concentration of bottom flow and protect the environment.

In fact, the high efficiency concentrator is not a kind of simple sedimentation equipment, but a new type of dehydration equipment combined with the characteristics of mud layer filtration.

It is divided into central transmission type, peripheral transmission type, sludge, intermittent type, vertical flow and continuous thickener.

A thickener is a device used to separate solids from liquids in a slurry, increasing the solids concentration.

It is a crucial step in mineral processing, wastewater treatment, and other industries. A concentrate thickener specifically increases the solids concentration of mineral concentrates before further processing, like filtration or tailings disposal.

The goal is efficient sludge thickening.

There are several types of gravity thickeners used in mineral processing:

Each type offers unique advantages depending on the application and material characteristics.

Thickeners and clarifiers are used in a wide range of applications:

High-efficiency thickeners are particularly suitable for mineral concentrates that require high underflow density and clear overflow, maximizing water recovery. This is applicable in different mining lvl.

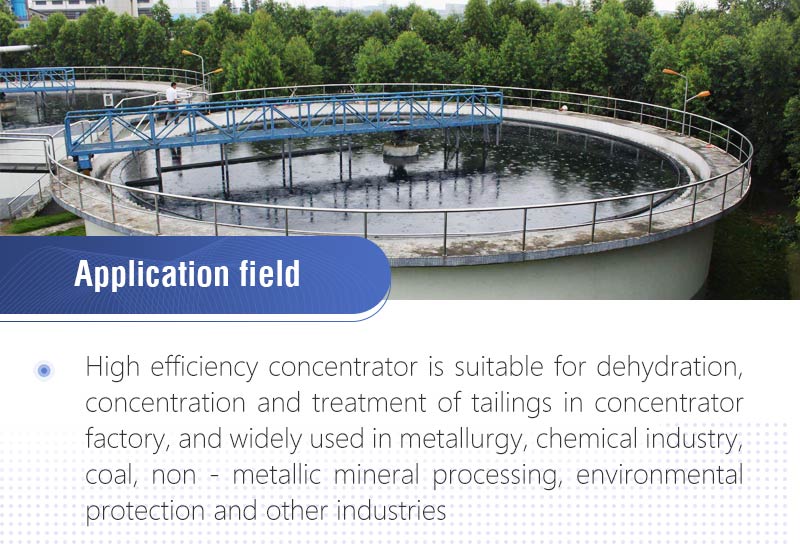

High efficiency concentrator is suitable for dehydration, concentration and treatment of tailings in concentrator factory, and widely used in metallurgy, chemical industry, coal, non-metallic mineral processing, environmental protection and other industries.

A High-Efficiency Concentrator is very versatile and can be used for almost all types of mineral concentrates.

Common Applications Include:

They are used primarily to:

In short, if you need to dewater a slurry efficiently, a high-efficiency concentrator is a suitable choice.

Concentrate thickeners offer several advantages:

ZONEDING thickeners are designed to minimize water and flocculant consumption, saving you money and resources.

An efficient thickener typically consists of:

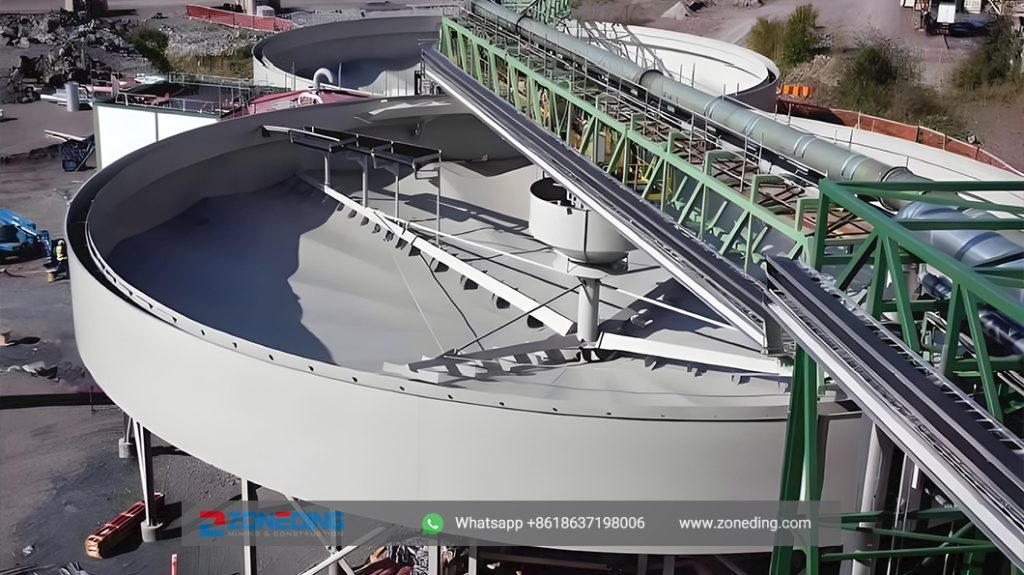

The structure of our slurry thickener contributes to efficient sludge thickening. The high efficiency concentrator generally consists of the thickener pool, transmission device, lifting device, feeding device, unloading device and signal safety device. The main feature of this machine is to add a certain amount of flocculant to the pulp to be concentrated, so that the ore particles in the pulp will form flocculation groups and accelerate its settlement rate, so as to improve the concentration efficiency.

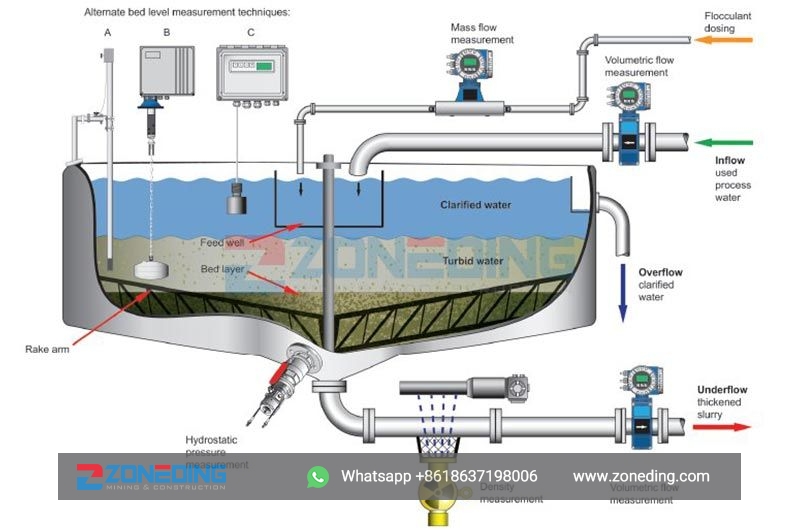

Gravity thickening equipment works based on the principle of gravity settling. The slurry enters the thickener through the feedwell, where flocculants are added to promote the aggregation of fine particles. The aggregated particles settle to the bottom of the tank, forming a concentrated slurry. The clarified water rises to the top and is discharged over the overflow weir. The rake mechanism moves the settled solids to the center discharge point, from where it is pumped out as underflow. This is the core of thickening.

The working principle of a high-efficiency concentrator involves two main aspects: increasing the size of solid particles and expanding the settlement area.

Increasing the size of solid particles in slurry and the settlement area of high-efficiency concentrator can improve the processing capacity of high-efficiency concentrator. The particle size of settling particles can be increased by adding flocculant to high-efficiency concentrator to make fine particles agglomerate. The inclined plate in the high-efficiency concentrator can increase the settlement area, shorten the settlement distance of particles and improve the concentration efficiency. The test and industrial production shows that under the same processing capacity, the diameter of the high-efficiency thickener is only two-thirds to half of the diameter of the ordinary thickener, and the area is about one-ninth to one-fourth of the ordinary thickener, while the processing capacity per unit area can be increased several times to dozens of times.

Concentrate thickeners are efficient due to several design features:

ZONEDING thickeners incorporate these features, making them highly efficient in solids recovery and water conservation.

| Model | GW-3 | GW-5 | GW-8 | GW-10 | GW-12 | GW-20 | GW-30 | GW-40 | GW-50 |

| Filter area(m2) | 3 | 5 | 8 | 10 | 12 | 20 | 30 | 40 | - |

| Cylinder size(mm) | φ1068×1060 | φ1600×1060 | φ2000×1500 | φ2000×1750 | φ2000×2000 | φ2500×2650 | φ3350×3000 | φ3350×4000 | φ3350×5000 |

| cylinder speed(r/min) | 0.156-1.56 | 0.156-1.56 | 0.1-0.6 | 0.1-0.6 | 0.1-0.6 | 0.14-0.54 | 0.12-0.56 | 0.12-0.56 | 0.12-0.56 |

| Vacuum pressure(KPa) | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 |

| Swept volume(m3/min.m2) | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 |

| Blast pressure(Kpa) | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 |

| Blast volume(m3/min.m2) | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 |

| Capacity(t/h) | 0.8-1.5 | 1.6-2.4 | 2.8-3.6 | 3-4 | 3-5 | 3-8 | 4.5-12 | 6-16 | 7.5-20 |

| Cylinder motor(kw) | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 3 | 4 | 4 | 5.5 |

| Stirring motor(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 3 | 4 |

| Weight(kg) | 2635 | 2850 | 5455 | 6317 | 6365 | 10600 | 17200 | 19500 | 21500 |

ZONEDING thickening machines are known for:

ZONEDING machines help in efficient slurry thickening and provide clear thickener meaning.

Density in the thickening process can be measured using various methods:

Accurate density measurement is crucial for controlling the thickening process and optimizing underflow density.

This sludge thickener minimizes water and flocculant costs through:

ZONEDING thickeners use advanced control systems to minimize flocculant use, reducing your operating costs.

Choosing a suitable high-efficiency thickener involves considering:

Consulting with a thickener manufacturer like ZONEDING can help you select the best thickener for your needs.

The price of thickeners varies based on:

Obtaining quotes from multiple manufacturers is essential for comparing prices and features.

Installing a mining thickener involves:

The commissioning process includes:

Professional installation and commissioning are crucial for ensuring the thickener operates efficiently and reliably. The commissioning process should consider flocculant consumption

Maintaining your thickener involves:

Proper maintenance ensures the thickener operates efficiently and reliably for many years. Part of maintenance is to clean clarifiers and thickeners.

ZONEDING thickeners have been successfully used in numerous mining operations worldwide. For example, our high-efficiency thickeners have significantly improved water recovery and reduced tailings volume in a copper mine in Chile. Another successful case involves the use of our thickeners in a lithium mine in Australia, where they have helped to produce a high-density concentrate for efficient downstream processing. These cases demonstrate the effectiveness and reliability of ZONEDING thickeners in various applications.

Question 1: What is the difference between a thickener and a clarifier?

A thickener primarily increases the solids concentration of a slurry, while a clarifier removes suspended solids from a liquid to produce a clear effluent. They both are clarifiers and thickeners.

Question 2: What is the role of flocculant in the thickening process?

Flocculant is added to the slurry to promote the aggregation of fine particles, which enhances settling and increases the settling rate.

Question 3: How do I control the underflow density in a thickener?

Underflow density can be controlled by adjusting the underflow pump speed, rake lifting mechanism, and flocculant dosage. You can find the right underflow density control.

Question 4: What is the typical residence time in a thickener?

The typical residence time in a thickener ranges from 2 to 8 hours, depending on the slurry characteristics and throughput requirements.

Question 5: How often should I replace the rake blades in a thickener?

The frequency of rake blade replacement depends on the abrasiveness of the slurry and the operating conditions. Regular inspection helps to determine when replacement is necessary.

Question 6: Can I use a thickener for multiple types of mineral concentrates?

Yes, but the thickener may need to be adjusted to optimize performance for different slurry characteristics.

Question 7: What is the energy consumption of a high-efficiency thickener?

The energy consumption depends on the size and design of the thickener. High-efficiency thickeners typically consume less energy per ton of solids processed compared to conventional designs.

Question 8: What are the advantages of using an automated control system in a thickener?

An automated control system provides precise control of process parameters, improves efficiency, reduces operator workload, and minimizes process variability.

Contact ZONEDING today to learn more about our high efficiency thickeners and how they can optimize your mineral processing operations.

Your reliable source for high-capacity, heavy-duty ball mills engineered for mining, cement, and fine powder processing.

Zongding Machinery provides advanced ball mills and mineral processing equipment to help mining companies around the world process minerals more efficiently.

the best Ceramic Ball Mill manufacturers and their competitive prices. Our selection offers top-quality mills for various applications at affordable costs.

Efficient flotation machine for mineral processing at competitive prices. Maximum recovery and optimal grade for your mining operations.

A magnetic separator is a device that separates magnetic minerals from nonmagnetic minerals by applying a magnetic field.

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

“Optimize mineral processing with our high-efficiency Jigging Separator Machine! Ideal for gold, tin, coltan separation.

Gold Mine Wet pan mill applys in the gold mining industry and is one of the indispensable equipment in the modern gold mining industry. In addition, it can also apply for mining and processing other non-ferrous metals and precious metal ore…

Shaking tables for gold recovery, mineral processing at great prices. Learn more about our gold shaking table, prices, and processing today.

Designed to improve complete classification schemes, hydrocyclone meet a wide range of needs, balancing the cost of milling circuits with the performance of the equipment.

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy