How to Get Gold Concentrates: 8 Key Machines

3657Get gold concentrates with the right equipment. Discover the 8 essential machines for placer & hard rock gold mining, and learn the secret to fine gold recovery.

View detailsSearch the whole station Crushing Equipment

Using a crusher producing road aggregate is the foundation of modern infrastructure. As a manufacturer of aggregate production equipment since 2001, we at Zoneding have seen that a strong road starts with high-quality crushed stone for roads. But producing aggregate that meets strict specifications is a science. It is not as simple as just making big rocks into small rocks. Your success depends on the right equipment and the right process.

This guide is our expert advice for contractors and quarry operators. We will walk you through everything you need to know. We will cover the critical details of aggregate shape and aggregate gradation. We will explain the right crusher selection for your project. By the end, you will understand how to design a road aggregate crushing line that delivers a perfect product at the lowest possible production cost.

Road construction demands aggregate with a specific shape and a precise mix of sizes. These two factors, aggregate shape and aggregate gradation, determine the strength and longevity of the road.

Good aggregate shape means the particles should be cubical, like small dice. Cubical particles interlock with each other when compacted. This creates a strong, stable structure that can resist the heavy loads of traffic. The worst shapes are flaky (thin and flat) or elongated (long and thin). These particles break easily under pressure, creating weak points in the road.

Good aggregate gradation means you have a well-defined mix of different particle sizes. Think of filling a large jar. If you only use large rocks, there will be big empty spaces, or “voids,” between them. To make it strong, you must add smaller rocks to fill the big voids, then sand to fill the tiny voids. A well-graded aggregate mix works the same way. It minimizes voids, creating a dense, strong layer that resists water penetration and frost damage. The base layer of a road requires a different gradation than the top surface layer.

Your crusher selection depends on your rock type and whether you are producing for the road base or the top surface layer. A Jaw Crusher starts the process, but an Impact Crusher or Cone Crusher creates the final, high-quality product.

The Jaw Crusher is almost always the primary crusher. Its job is to take large quarry rocks and break them down into a manageable size. It is powerful and reliable, but it does not produce a highly cubical shape.

For the next stage, you have two main choices. The Impact Crusher works by throwing rocks against impact plates at high speed. This shatters the rock along its natural fracture lines, creating a superior cubical shape. This makes it ideal for producing top-surface aggregate for asphalt and concrete. However, it has higher wear costs on very hard, abrasive rock.

The Cone Crusher uses compression to crush rock between a rotating cone and a stationary bowl. It is extremely efficient at crushing hard, abrasive materials like granite and basalt. It produces a very good cubical shape and high volumes of material, making it a workhorse for both base and surface aggregate production.

| Crusher Type | Application Stage | Crushing Action | Best For (Rock Type) | Final Product Shape |

|---|---|---|---|---|

| Jaw Crusher | Primary | Squeezing/Compression | All rock types | Coarse, less uniform |

| Impact Crusher | Secondary/Tertiary | High-Speed Impact | Soft to medium-hard | Excellent, highly cubical |

| Cone Crusher | Secondary/Tertiary | Squeezing/Compression | Medium-hard to very hard | Very good, cubical |

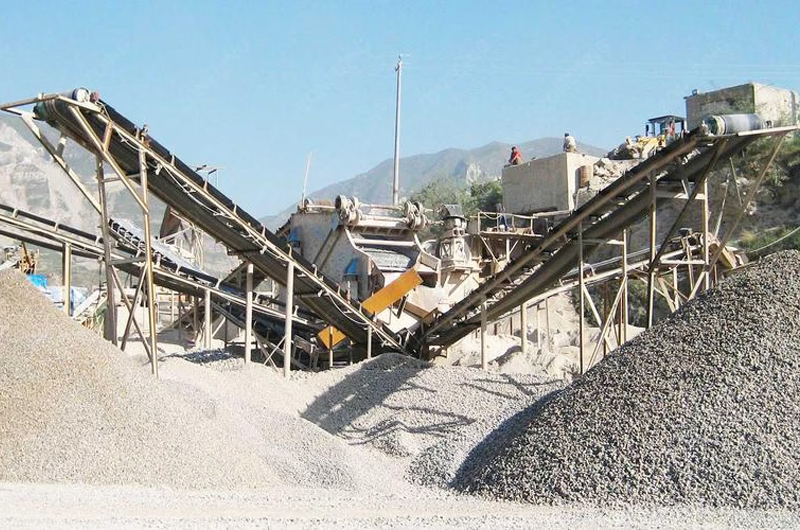

A complete road aggregate crushing line is a multi-stage system designed to crush, screen, and sort rock into precise final products. It is much more than just a single crusher.

A typical stone crushing plant for road aggregate includes the following equipment working together:

For large highway projects, using a mobile crushing plant on-site offers huge advantages in cost, logistics, and quality control compared to buying finished aggregate from a distant quarry.

A Mobile Stone Crusher is a complete crushing and screening system mounted on wheels or tracks. You can bring the entire production line directly to the job site. The benefits are significant:

Crusher fines, the fine dust and tiny chips produced during crushing, are not waste. They are a valuable resource that can be used to build a strong road sub-base, significantly lowering your overall production cost.

Every crushing operation produces a certain amount of fine material, often called crusher fines or stone dust. Instead of paying to haul this material away, you can use it as an engineered fill. This material is excellent for creating the sub-base layer of the road. This is the layer that sits directly on top of the native soil foundation. When properly graded and compacted, crusher fines create a dense, stable, and relatively impermeable layer. This provides excellent support for the more expensive base and surface aggregate layers that will be placed on top. By using 100% of your crushed material, you turn a “waste” product into a cost-saving asset.

The most cost-effective crushing plan depends entirely on the hardness and abrasiveness of your source rock. Choosing the wrong crusher for your rock type will lead to high wear costs and poor performance

Here are our expert recommendations for two common scenarios:

For Soft to Medium-Hard Rock (e.g., Limestone Crushing):

For Hard, Abrasive Rock (e.g., Granite Crushing, Basalt):

Question 1: What is the most important factor for getting a good cubical aggregate shape?

The type of secondary and tertiary crusher is the most important factor. An Impact Crusher or a VSI (Sand Making Machine) will produce the most cubical shape. A properly configured Cone Crusher also produces a very good product.

Question 2: Can I use just one crusher to produce road aggregate?

Rarely. To meet the strict specifications for both size and shape, a multi-stage process with primary and secondary (and often tertiary) crushing is necessary. A single crusher cannot provide the required level of control.

Question 3: How much does a complete road aggregate crushing line cost?

The cost varies widely based on the capacity (tons per hour), the rock type, and the number of final products. A small line might cost a few hundred thousand dollars, while a large, high-capacity plant can cost several million. The best way to find out is to get a custom quote.

Successfully producing road aggregate is a game of precision. Your success hinges on understanding the strict requirements for aggregate shape and aggregate gradation. The key is to make the right crusher selection for your specific rock type and to design a complete, multi-stage road aggregate crushing line. By using a closed-circuit system and leveraging all your products, including crusher fines, you can maximize efficiency and minimize your production cost. Whether you choose a stationary plant or a flexible mobile crushing plant, the right process will empower you to produce high-quality crushed stone for roads that will stand the test of time.

Since 2001, Zoneding has been a trusted global manufacturer of high-performance stone crushing plants. Our equipment is engineered for durability and efficiency, helping clients in over 120 countries produce top-quality aggregate for roads, railways, and buildings. Our team of experienced engineers is dedicated to designing custom solutions that deliver maximum value and performance.

Are you ready to build your own road aggregate production line? Contact our engineers today. We will analyze your rock type, output requirements, and project goals to design a custom crushing and screening solution that meets your needs and budget. Let us be your partner in building the future.

Get gold concentrates with the right equipment. Discover the 8 essential machines for placer & hard rock gold mining, and learn the secret to fine gold recovery.

View detailsDiscover what iron ore is, how it's mined, and why it's the critical backbone of the global economy. Learn how it's transformed into steel for everything.

View detailsFrom raw ore to pure copper. This guide details the essential steps: crushing, grinding, flotation, and smelting. Learn about the required methods & equipment.

View detailsIn the gold mining industry, carbonaceous gold ore is known as the "Silent Thief." High gold grades may appear in geological reports, yet recovery rates can plummet below 30% due to the dreaded preg-robbing effect. The natural organic carbon in t...

View details